Material Handling Conventional

advertisement

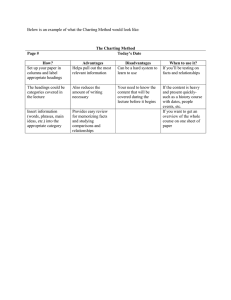

Material Handling Conventional Operations Process (Flow) Chart Flow diagram is a plan of work area, indicating the position of machines, flow of materials and their relationships Flow diagram allows one to view the total flow plan and to visualize potential storage areas, inspection stations and potential unsafe factors, etc. Flow diagram will present problems such as cross traffic, backtracking and unnecessary traveling distance Operations Process (Flow) Chart OPCs are used for: Showing sequences of all events Identifying all major operation procedures Distinguishing manufactured and purchased parts Providing information for materials used and standard times Establishing the relationships between parts, fabrication processes and assemblies OPC Symbols Operation: an object is changed in its characteristics Transportation: an object is moved from one place to another Inspection: an object is examined with a standard as to quantity and quality Delay: the immediate performance of the next planned action does not take place Storage: an object is kept under control such that its withdrawal requires authorization Advantages of Charting Provide clear representation of the task Diagrammatic format aids comprehension Can incorporate the sense of time Information presented in format suited for creating operational procedures Format can provide links for human tasks, system functions, material flows, and equipment used The Performance Principle Know what your material handling costs are and continuously work to reduce them. The process chart provides the form to calculate the unit cost of every move. Tracking this percentage can show the improvements in performance. Material Handling Hours Percentage of M.H. = Total Labor Hours Charting and Line / Cell balance Line balancing is simply a means to maximize production. By studying the OPC data, balancing determinations can be made. Balanced Line Unbalanced Line 10 9 8 7 6 5 4 3 2 1 0 20 15 10 5 0 A B C D Operation E A B C D Operation E Charting and Line / Cell balance 6 min 3 min 3 min 6 min 4 min 2 min 18-min C/T using 3 people / 8-hr shift 3 shifts / day = 3 x 8-hr x 60 min = 1,440 min/day 1,440 min/day / 9 min = 160 pieces/day Total daily labor hours = 3 shifts x 3 people x 8-hr = 72 hr Charting and Line / Cell balance 6 min 3 min 3 min 6 min 4 min 2 min 12-min C/T using 4 people / 8-hr shift 2 shifts / day = 2 x 8-hr x 60 min = 960 min/day 960 min/day / 6 min = 160 pieces/day Total daily labor hours = 2 shifts x 4 people x 8-hr = 64 hr Line Balancing Impact Line Balancing Impact: For the same production output (160 pieces /day) Labor Reduction (hrs) = (72 –64)/72 x 100 = 11% C/T Improvement = (9-6)/9 x 100 = 33% RIF = (9-8)/9 x 100 = 11% Eliminated third shift expense Total capacity doubled Weighted Unit Load Analysis Equivalency considerations: Shape – awkwardness, square, round, etc. Weight – per unit or specific weight Size – length, width, height Value – wood versus gold Fragility – risk of damage, hazardous, etc. Conditions – wet, cold, hot, etc. Equipment – fork truck, cart, crane, etc. Key Manufacturing Fundamentals Four Fundamental Customer Expectations: 1. 2. 3. 4. Product Quality Delivery as scheduled / requested Flexibility to handle change and service Low $$$ One method to achieve this is by implementing Lean Manufacturing principles Conclusion Two Major Elements of the Direct and Indirect Factory Labor Costs Equation are Effected by: 1. The way we handle materials 2. The way our facilities are laid out This will be our focus this semester