Document 14174175

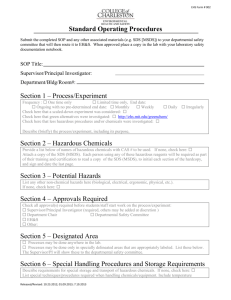

advertisement