THE RCN SAFETY REPRESENTATIVES HANDBOOK Proud to help you make a difference

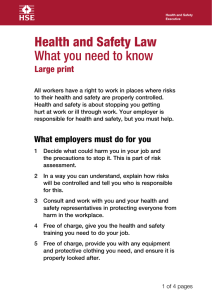

advertisement