Systems Analysis & Design Structured Analysis

advertisement

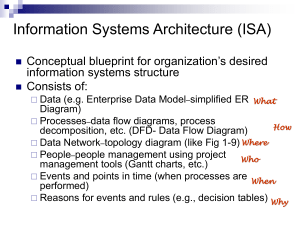

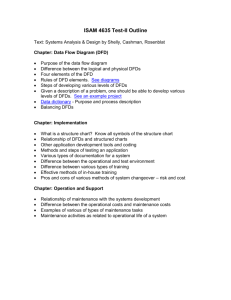

Systems Analysis & Design Structured Analysis Structured analysis is a development method for the analysis of existing manual or automated systems, leading to the development of specifications for a new or modified system. The underlying objective in structured analysis is to organise the tasks associated with requirements determination to provide an accurate and complete understanding of a current situation. The word structure in structured analysis means: 1. the method attempts to structure the requirements determination process, beginning with documentation of the existing system. 2. the process is organised in such a way that it attempts to include all relevant details that describe the current system. 3. it is easy to verify when relevant details have been omitted. 4. the identification of requirements will be similar among individual analysts and will include the best solutions and strategies for systems development opportunities. 5. the working papers produced to document the existing and proposed systems are effective communication devices. This method of analysis has become synonymous with data flow analysis which provides a tool for documenting an existing system and determining information requirements in a structured manner. Data Flow Analysis Data analysis attempts to answer four specific questions: What processes make up a system? What data are used in each process? What data are stored? What data enter and leave the system? Data drive business activities and can trigger events (e.g. new sales order data) or be processed to provide information about the activity. Data flow analysis, as the name suggests, follows the flow of data through business processes and determines how organisation objectives are accomplished. In the course of handling transactions and completing tasks, data are input, processed, stored, retrieved, used, changed and output. Data flow analysis studies the use of data in each activity and documents the findings in data flow diagrams, graphically showing the relation between processes and data. SAD4.DOC CMSCS201 1 Systems Analysis & Design Data flow diagrams are used in a number of methodologies (SSADM and I.E.) to name two) and have the advantage of being able to be used in a number of contexts within the analysis and development framework, representing models of the system during its various stages of refinement. i.e.: Current physical Current logical Required logical Required physical How the existing system works What the current system accomplishes What the new system is required to accomplish How the required system will be implemented Physical and Logical DFDs There are two types of data flow diagrams, namely physical data flow diagrams and logical data flow diagrams and it is important to distinguish clearly between the two: Physical Data Flow Diagrams An implementation-dependent view of the current system, showing what tasks are carried out and how they are performed. Physical characteristics can include: Names of people Form and document names or numbers Names of departments Master and transaction files Equipment and devices used Locations Names of procedures Logical Data Flow Diagrams An implementation-independent view of the a system, focusing on the flow of data between processes without regard for the specific devices, storage locations or people in the system. The physical characteristics listed above for physical data flow diagrams will not be specified. Data Flow Notation Although the use of data flow diagrams is common to a number of analysis and design methodologies the notation used in each instance varies slightly. The notation in use here is drawn from SSADM and is recommended for use on this course. There are generally five symbols used to construct data flow diagrams: 1. Data Flow. Data move in a specific direction from an origin to a destination in the form of a document, letter, telephone call or virtually any medium. The data flow can be thought of as a 'packet' of data. SAD4.DOC CMSCS201 2 Systems Analysis & Design sales order At the highest level DFD, one arrow may represent several data flows, which may be decomposed into individual flows at the lower levels. There are some validation rules about where data flows may or may not travel. Data stores may not be linked by data flows: flows must travel from one to another via a process. External entities may not send or receive data flows directly to or from a data store: they must communicate via a process. Data cannot be generated by a process, or be swallowed by a process; documents may be swallowed or generated, but there must be an output that is related directly to all inputs to the process. 2. Physical flow. Used to represent the flow of physical items in the system. Goods 3. External Entities. External sources or destinations of data, which may be people, programs, organisations or other entities which interact with the system but are outside its boundary. They may be external to the whole company, such as customers, Inland Revenue etc. or just external to the application area. Thus if we are modelling a Sales Office system, Accounts & Despatch areas would be shown as external entities. Each external entity communicates in some way with the system, so there is always a flow of data shown between a process in the system and an external entity. Supplier Supplier It may be desirable for the sake of clarity to duplicate an external entity on the diagram, rather than have arrows from all points converging on one entity. If that is the case, put a small line along the top of the entity. 4. Data Store. Here data are stored or referenced by a process in the system. The data store may represent computerised or non computerised devices. It may be a filing cabinet, an in-tray, a card index, a reference book or a computer file. Anywhere that data is stored and retrieved is a data-store. The notation is simple: a long, open-ended rectangle. with a box at the left end. The box is labelled with an alpha pre-fix and a number. The alpha is either D (for an automated data store) or M (for a manual/card data store). The number has no significance; it is purely a reference. The rectangle is labelled with a description of the contents of the data store. SAD4.DOC CMSCS201 3 Systems Analysis & Design D1 Stock file D1 Stock File Again, for the sake of tidiness, you wish to show the data store in more than one part of the diagram, add a bar o the left hand box. Each occurrence of the box should display the additional bar. 5. Process. A process is an activity that receives data and carries out some form of transformation or manipulation before outputting it again. The activity may be carrying out calculations , creating a new document from information that triggered the process, or amending the document . It is depicted by a box divided into three parts: the upper left position is given a number. This has no significance other than as a reference number; it does not imply priority or sequence. The longer top rectangle beside it names the location where the processing takes place; this may on an overview DFD, be a broad term, Sales Accounts etc. As the DFDs become more detailed so do these descriptions. The rest of the box describes what is happening in the process. The rule here is to keep the description as concise and meaningful as possible. Use an imperative verb with an object, but make the verb specific. 'Process...' and 'Update...' are too vague and give little clue as to what is meant. 'Calculate...', 'Add...' or 'Validate...' give a clearer picture of what is happening. 6 Sales Calculate VAT Developing Data Flow Diagrams The most comprehensive and useful approach to developing an accurate and complete description of the current system begins with the development of a physical data flow diagram. The use of physical data flow diagrams is desirable for three reasons: 1. Analysts initially find it easier to describe the interaction between physical components than to understand the policies used to manage the application. Identifying people, what they do, which documents and forms trigger which activities and what equipment is used in the processing. The movement of people, documents and information between departments and locations is also identified. 2. Physical data flow diagrams are useful for communicating with users. Users relate easily to people, locations and documents as they work with these each day. Users may consider logical DFDs abstract as they do not contain these familiar SAD4.DOC CMSCS201 4 Systems Analysis & Design components, however, with physical DFDs users can quickly identify incorrect or missing steps. 3. Physical DFDs provide a way to validate or verify the user's current view of the system with the way it is actually operating. If there are differences, they will be noted and discussed. It is not unusual to find that what a users thinks is happening differs in an important way from what actually occurs. Drawing a Context Diagram The first diagram developed is the context diagram (Level 0). It contains a single process and plays an important role in studying the current system in that it defines the system under investigation by determining the boundaries of the system. So anything that is not inside the process identified will not be part of the systems study. The manner in which other organisation or external elements function is out of our control and so are not studied in detail. An example context diagram. Supplier P ay sO od o G r rde plier S up me n t e .N voic G.R r In plie Sup Disp atch Sales System Note Customer er Custo mer Ord Returned G oods No te The Level 0 (Context Diagram) can be drawn by following three steps:Step 1 - List the documents used in the system. Step 2 - List all the sources & recipients Step 3 - Draw a box representing the system and show the flow of documents from these sources and recipients. Those areas which are known to be inside the system are hidden within the box. Exploding the Process to produce a Top-level (1) DFD In order to extend the study it is necessary to ‘explode’ the context diagram to show the processes which achieve the transformation of the entire system. Initially we must SAD4.DOC CMSCS201 5 Systems Analysis & Design identify the major functional areas within the system, transform those entities into processes and label them accordingly. E.g. Context Diagram 0 Process 0 External Entity 1 External Entity 2 System Dataflow 1 Dataflow 2 Level 1 Diagram 1.0 Process 1 2.0 Process 2 External Entity 2 Flow 2,1 External Entity 1 Dataflow 2 Dataflow 1 Flow 1,3 Flow M1,1 M1 3.0 Process 3 Datastore 1 Flow 3,D1 Level 2 Diagram 1.1 Process 1.1 1.2 Process 1.2 Flow 2,1 External Entity 1 1.3 Flow M1, 1.1 Process 1.3 Flow 1.1, 1.3 M1 Datastore 1 Flow 1,3 SAD4.DOC CMSCS201 6 Systems Analysis & Design Hence, we have the overall process of the system on the context diagram being broken down into processes 1.0, 2.0 and 3.0 on the level 1 diagram and then process 1.0 broken down into processes 1.1, 1.2 and 1.3 on the level 2 diagram. The high-level DFD is not yet complete: we have not identified how many processes each of these functional areas perform, and what data stores are used. As we are describing a physical system, we must consider the types of data moving through the system. As a rule of thumb, we can consider the following types of data store: 1. Standing data, used for the day-to-day functioning of the system and is kept updated. 2. Historical data that is required to be maintained for reference and enquiry purposes, but is no longer 'live'. 3. Temporary data stores, which will cease to exist when the need for their data is exhausted. 4. Extracted data that is retrieved from different sources for the purpose of preparing reports, statistics and so on. We can now consider the data flows which cross boundaries into processes/functional areas and determine what actions are carried out on them. Each process will probably require one data store. Our initial investigations will identify all such data stores and their access, so what ever is unclear at this point can be clarified. Validating the DFD Before moving on from this initial high-level DFD, we must ensure it is consistent. Below is a checklist of points to watch out for before moving on to a detailed investigation which will take us to lower levels. 1. Has each process a strong imperative verb and object? 2. Are data flows in related to data flows out? Data should not be swallowed up by a process, only transformed in some way. A data store is the only place data is allowed to rest. Similarly, data cannot be generated by a process. A document may be, but the data on the document comes from a data flow into that process. 3. Can the flows be reduced? If a process is too busy, it can perhaps be broken down into two or more processes: six data flows in or out of a process should be enough. 4. Do all data stores have flows both in and out? A one-way data store is of little use, unless it is a reference file. If the Current Physical DFD should identify such a data store, confirm with the User that you have correctly understood the procedures. 5. Are symbols correctly labelled and uniquely referenced? 6. Do all external entities communicate with a process? No entity should be allowed direct access to data, either to read or to update it. When these checks are complete we can verify the diagram with the user. On being satisfied that the diagram is a faithful reflection of the business area, we can proceed to decompose the diagram. SAD4.DOC CMSCS201 7 Systems Analysis & Design Decomposition of top-level DFDs The Level 1 DFD presents us with an overview of the system, a description that could come from a preliminary interview with departmental managers, perhaps. Now we must examine each process in more detail and break it down into other processes. The following steps explain how this is done. Step 1. Make each process box the system boundary. All data flows to or from that process are now flows across the lower-level system boundary. Step 2. Draw, outside the new boundary, the sources and recipients of these flows, as shown on the higher level DFD, (these can be external entities, data stores or other processes. Ensure the labelling is consistent with the higher level. Step 3. Identify and draw the processes at the lower levels that act on these data flows. Number the sub-processes with a decimal extension of the higher level number. i.e. Level 1, Process 3 will break down to processes 3.1, 3.2, 3.3 etc. Those processes that cannot be decomposed further, mark with an asterisk in the bottom right-hand corner. Step 4. Carry out consistency checks as before. Step 5. Make sure that all lower level DFDs map onto the Level 1 diagram, by checking data flows. Step 6. Review the lower levels with the User to be sure that every activity performed by the system is depicted. When the DFD has progressed as far as it is possible to go, the details must be recorded on an Elementary Process Description (EPD) using a concise and precise narrative. If more than four or five sentences are required, perhaps the process has still to be broken down to another level. Supporting documentation A data dictionary, either paper or automatic, should be maintained at every stage of DFD production. The dictionary should contain the following descriptions. External Entity Description This describes all the external entities shown on the diagram. Included will be such details as the functions of the entity and constraints on how it is to interface to the system. Input/Output Description A list of all data flows, the contents and the start and end references for each flow crossing the system boundary. It is important that this dictionary is maintained for the current system and for the required system. The details will grow with each iteration, of course the first attempts are not expected to be more than a guide. Some Additional Notes on DFD Production. SAD4.DOC CMSCS201 8 Systems Analysis & Design All activities, data flows and data stores used in this lower-level view of the system must be included within the previous data flow diagram. The lower-level diagrams must be consistent with the higher-level view. In general the following rules apply: All data flows that appeared on the previous diagram explaining the process are included in the lower level diagram. New data flows and data stores are added if they are used internally in the process to link processes introduced for the first time in the explosion at this level. Data flows and data stores that originate within the process must be shown. No entries should contradict the descriptions of the higher level data flow diagrams (if they do, one or the other is either incorrect or incomplete and a change must be made). How far should the explosion of detail be carried out? Because the nature and complexity of systems vary, it is inadvisable to fix a specific number of levels. In general, we should go as far as necessary to understand the details of the system and the way it functions. Deriving the Logical View Physical DFDs are a means to an end, not an end in themselves. They are drawn to describe an implementation of the existing system for two reasons: to ensure a correct understanding of the current implementation (users are generally better able to discuss the physical system as they know it through people, workstations and days of the week.) the implementation itself may be a problem or limiting factor; changing the implementation, rather than the system concept may provide the desired results. A logical view steps back from the actual implementation and provides a basis for examining the combination of processes, data flows, data stores, inputs and outputs without concern for the physical devices, people or control issues that characterise the implementation. A logical data flow diagram is derived from the physical version by doing the following: Show actual data needed in a process, not the documents that contain them. SAD4.DOC CMSCS201 9 Systems Analysis & Design Remove routing information; that is, show the flow between procedures, not between people, offices or locations. Remove references to physical devices. Remove references to control information Consolidate redundant data stores. Remove unnecessary processes, such as those that do not change the data or data flows. General Rules for Drawing Logical Data Flow Diagrams . Any data flow leaving a process must be based on data input to the process. . All data flows are named; the name reflects that data flowing between processes, data stores, sources and sinks. . Only data needed to perform the process should be an input to the process. . A process should know nothing about, that is, be independent of any other process in the system; it should depend only on its own input and output. . Processes are always running; they do not start or stop. Analysts should assume a process is always ready to function or perform necessary work. . Output from processes can take one of several forms: a) b) c) d) e) An input data flow with information added by the process (for example, an annotated invoice). A response or change of data form (such as a change of £’s profit to profit percentage. Change of status (from unapproved to approved status). Change of content (assembly or separation of information contained in one or more incoming data flows). Change in organisation (e.g. the physical separation or rearrangement of data). Maintain Consistency Between Processes When developing DFDs in more detail it is important to maintain consistency between levels. No new inputs or outputs to a process should be introduced at a lower level that were not identified at a higher level. However, within a process, new data flows and data stores may be identified. Follow Meaningful Levelling Conventions SAD4.DOC CMSCS201 10 Systems Analysis & Design Levelling refers to the handling of local files (those that are used within a process). The details that pertain only to a single process on a particular level should be held within the process. Data stores and data flows that are relevant only to the inside of a process are concealed until that process is exploded into greater detail. Add Control on Lower-Level Diagrams Only The logical data flow diagrams developed to this point do not include control information. No mention has been made of how to handle errors or exceptions. Although this information is necessary in the final analysis, it should not be a concern while identifying the overall data flow. The secondary diagrams (below second or third level) show error and exception handling in the process being exploded. Some physical control information is unnecessary in logical DFDs. Copy numbers or annotations for documents (e.g. Copy 1, Copy 2, Shipping copy or Accounting copy), procedural orders (e.g. Find the record; Review the record; Annotate the record), or day-of-the-week triggers (e.g. Do on Monday; Do the last day of the month) do not belong with the logical and data aspects of requirements determination. The important elements for understanding a process during logical data flow analysis are not document copy numbers but descriptions of the data needed to perform the process. Assign Meaningful Labels The descriptions assigned to data flows and processes should tell the reader what is going on. All data flows should be named to reflect their content accurately. Data Flow Naming The names assigned to data flows should reflect the data of interest to the analysts, not the documents on which they reside. For example, an invoice contains many different elements of information. Analysts are concerned with the contents of the invoice that are important for a particular process. It may be the invoice number and date of issue or the signature or authorisation associated with the invoice. It is not the sheet of paper itself. Data flowing into a process undergo change. Therefore, the outbound data flow is named differently from the inbound one. (If no change is made to the data flow, what is the purpose of the process?) Process Naming and Numbering All processes should be assigned names that tell the reader something specific about the nature of the activities in the process. The names INVENTORY CONTROL, PURCHASING and SALE are too general to be useful in a logical DFD. It is much better to use ADJUST QUANTITY ON HAND, PREPARE PURCHASE ORDER or EDIT SALES ORDER to describe the process. SAD4.DOC CMSCS201 11 Systems Analysis & Design The following guidelines can be used for process naming: Select names that indicate the action taking place. Selecting an action verb and an object to receive the action is most appropriate. Be sure the name fully describes the process. (If a process both edits and validates invoice data, it should not be labelled EDIT INVOICES). Select process names that explain the linkage between inflows and outflows of data. Avoid vague process names, such as PROCESS, REVIEW, ASSEMBLE, HANDLE or ORGANISE. Use lower-level process names that are much more specific and descriptive than those associated with high-level processes. Assign process names that are unique to the activity they describe. The process numbering system introduced earlier further identifies processes especially between levels of detail. The highest level diagram (Context) need not be numbered. All lower level diagrams should be identified by number. So if a Level 1 diagram identifies five processes (numbered 1 to 5) then lower-level explosions of these processes are assigned a decimal to indicate that they are further explanations of a higher-level process. For example, if high-level process 3 contains four processes then they are numbered 3.1, 3.2, 3.3, 3.4. Successive explosions add additional decimal digits: 3.1.1, 3.1.2., 3.1.3., etc. Evaluating Data Flow Diagrams for Correctness It is essential to evaluate all DFDs carefully to determine if they are correct. Errors, omissions and inconsistencies can occur for several reasons, including mistakes in drawing the diagrams. But the presence of what appears to be an error may in fact point out a deficiency in the system or a situation in which users are not aware of how certain processes operate. These questions are useful in evaluating data flow diagrams: Are there any unnamed components in the data flow diagram (data flows, processes, stores, inputs or outputs)? Are there any data stores that are input but never referenced? Are there any processes that do not receive input? Are there any processes that do not produce output? SAD4.DOC CMSCS201 12 Systems Analysis & Design Are there any processes that serve multiple purposes? If so, simplify by exploding them into multiple processes that can be better studied). Are there data stores that are never referenced? Is the inflow of data adequate to perform the process? Is there excessive storage of data in a data store (more than the necessary details)? Is the inflow of data into a process too much for the output that is produced? Are aliases introduced in the system description? Is each process independent of other processes and dependent only on the data it receives as input? SAD4.DOC CMSCS201 13 Systems Analysis & Design Elementary Process Description Variant: Current Physical Process ID/Common processing ref: Process name: 4.3 Update Wallchart Common processing cross-reference N/A Description The Booking Clerk receives no. of places booked for a given Course Run, and records on the wallchart the numbers of provisional/confirmed numbers. After making the update to the wallchart, the Bookings Clerk posts all the delegate details to the Bookings Folder. SAD4.DOC CMSCS201 14 Systems Analysis & Design I/O Description Variant: Project/System Required Physical Author Date Version Status Page Of ANO System From To Data Flow Name Data content Comments D 7.1 Notice of Cancellation Course Code Course Date Delegate No. Branch No. Input to process 7.2 Cancellation Notice Course Code Course Date Delegate No. Branch No. M5 Old Delegate Details 7.1 7.3 Request for Standby Course Code Course Date Branch No. No. of Places 7.3 D Offer Course Code Course Date New Delegate No. New Delegate Name 7.3 Candidate Details Branch No. Branch Address Delegate No. Delegate Name 7.1 7.2 M3 SAD4.DOC Course Code Course Date Delegate No. CMSCS201 15 Systems Analysis & Design External Entity Description Variant: Current Physical Project/System Author Date Version Status Page Of ANO System ID SAD4.DOC Name A Branch B Tutor C Course Manager Description A regional unit of ANO PLC that places requests, via nominating managers, for training for it members. An employee of ANO PLC, who delivers sessions on Scheduled Courses The owner of a Course Title, who is responsible for providing details of courses and making the decision to cancel Scheduled Courses CMSCS201 16 Systems Analysis & Design Tutorial Question Data Flow Diagrams From the following investigation notes: Produce a Level 0 Context Diagram. Produce a Level 1 DFD of the physical system Produce a Level 2 DFD of the physical Reception Process Produce a Level 2 DFD of the physical Filing Process X-Ray Management Investigation Notes Reception Patients present X-ray request forms obtained from their GP to reception. Each X-ray request form is allocated an appointment which is written on an appointment card and given to the patient. X-ray request forms are filed. A diary is maintained which contains details of all appointments. When patients arrive for X-ray, they present their appointment card. A nurse checks the validity of the appointment, passes the appointment card to a clerk and takes care of the patient. The clerk generates an X-ray file/report request for the filing section. The X-ray request form is retrieved from the file and given to the radiographer. X-ray film/report requests are placed in a temporary file for collection by the filing section. Radiographer On receipt of the X-ray request form, the radiographer takes the appropriate X-rays (called films) and places them in a temporary file for collection by the filing section. Each appointment results in a set of X-ray films. Filing Clerk The filing clerks collect the X-ray film/report requests. These request all X-ray films and reports previously generated for the patients. Patients can have many X-ray films and reports. The new X-ray films are attached and the complete set placed in a temporary file for the attention of the radiologist who makes out a report for the appointment. When a copy of the new report is received from the radiologist, all X-ray films and reports are returned to their permanent file. Radiologist The radiologist examines all X-ray films and reports a patient has and makes out a new report. The report is sent to the GP with a copy to the filing section. SAD4.DOC CMSCS201 17