West Virginia University Laboratory Training Module 3. General Laboratory Safety

advertisement

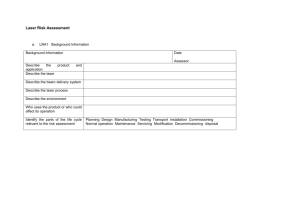

West Virginia University Laboratory Training Module 3. General Laboratory Safety Topics to be covered 1. 2. 3. 4. 5. 6. 7. 8. Contacting the Safety Department Incident Reporting Electrical Safety Laser Safety Centrifuge Safety Housekeeping Personal Protective Equipment Cryogenic Liquids 1. Contacting the Safety Department The Health Sciences Center Safety Department is located at g139 of the Health Sciences Center. If at any time you feel there is any type of safety related issue please contact the safety department 2. Incident/injury Reporting Incident reporting is the most effective way for the safety department to gage the effectiveness of its safety program. Therefore, by reporting all incidents no matter how insignificant they may seem will aid the safety department in ensuring a safe working environment for you and your coworkers. Hurt at Work You've carefully thought out all the angles. You've done it a thousand times. It comes naturally to you. You know what you're doing, its what you've been trained to do your whole life. Nothing could possibly go wrong, right ? Think Again! How do I report an Incident/Injury? Supervisors or Principal Investigators are responsible for completing Incident / Injury report forms. If the supervisor or principal investigator does not possess this form, one may be printed from WVU’s Environmental Health and Safety home page at: http://www.wvu.edu/~ehs 3. Electrical Safety All areas on the West Virginia University campus at some points utilize electricity. The goal of electrical safety is to educate you on the importance of the hazards involved with electricity and the precautions and some simple rules to follow to avoid becoming a victim of those hazards. Hazards: The hazards associated with electricity come from the direct contact that results in current flow through an inappropriate conductor, the human body, or from excessive heating by current flow through a conductor with a greater resistance than expected. In basic terms the hazards are electrocution or fire. Most electrical accidents result from unsafe equipment, unsafe environment, and unsafe work practices. Shock and Electrocution: Direct contact with electricity can cause electric shocks that can result in death by electrocution. The human body is a good conductor and when the body is exposed to electric current the muscles and nerves of the human body are electrically stimulated. The muscles will attempt to contract at the same frequency as the electric current. The muscle of the diaphragm will clamp and you will stop breathing and the heart will go into fibrillation and stop beating. Death is most likely to occur in the 100 to 300 mA current range. Effects of electric current in the human body Below 1 milliampere Not perceptible. 1mA Tingle. 5mA Slight Shock. 6-25mA women Painful Shock and Letgo range. 9-30mA men Let-go range (Individual cannot let go). 50-150mA Extreme pain, Death possible. 1000-4300mA Death Likely. 10,000mA Cardiac arrest, Death. Electrical Fires: The most common cause of laboratory fire is worn or damaged power cords. An exposed cord can burn or heat objects in contact with them to their flash point. Electrical Fire Prevention Take the time to do it right the first time When needed request electrical repairs and changes that are necessary Never try to fix electrical equipment. Keep water and electricity separated Do not stretch electrical cords across aisles or doorways. Do not use extension cords as a substitute for wiring additions or changes. Do not use electrical equipment that has worn or damaged power cords. Electrical Fire Prevention FUSES: Before removing any fuse from a circuit, be sure the switch for the circuit is open or disconnected. When removing fuses, use an approved fuse puller and break contact on the hot side of the circuit first. When replacing fuses, install the fuse first into the load side of the fuse clip, then into the line side. Lockout/Tagout Electrical power must be removed when electrical equipment is inspected, serviced, or repaired. To ensure the safety of personnel working with the equipment, power is removed and the equipment must be locked out and tagged out. Personal Protective Equipment: Employees who work directly with electricity should use the personal protective equipment required for the job which may include rubber insulating, gloves, hoods, sleeves, matting, blankets, line hose, and industrial protective helmets. 4. Laser Safety • A laser should be isolated from areas where the uninformed and curious would be attracted by its operations. Doors should be closed or locked to keep out unqualified personnel. Signs should be posted to keep out unqualified persons. Work Area Safety Practices The illumination in the area should be as bright as practicable in order to constrict the eye pupils of users. The laser should be set up so that the beam path is above or below normal eye level (below 4.5ft or above 6.5ft.). Where practical, the laser system or beam should be enclosed to prevent accidental exposure to the beam. The potential for specular reflections should be minimized by shields and by removal of all unnecessary shiny surfaces. Work Area Safety Practices continued: Windows to hallways or other outside areas should be provided with adequate shades or covers. The main beams and reflected beams should be terminated or dumped. This is required for any accessible laser for which the MPE limit could be exceeded. Electrical installation must meet electrical safety standards. The active laser shall not be left unattended unless it is part of the controlled environment. Good housekeeping should be practiced to ensure that no specular reflector is left near the beam. Warning devices should be installed for lasers with invisible beams to warn of operation. Laser Use Safety Practices Avoid looking into the primary beam at all times. Avoid looking at the pump source. Before operating the laser, warn all personnel and visitors of the potential hazard, and ensure all safety measures are satisfied. Be very cautious around lasers that operate at frequencies not visible to the human eye. Do not wear bright, reflective jewelry or other objects. Use proper eye protection when working with a Class III, or Class IV laser. Clothing such as gloves and covers for the forearms may be required to protect the skin if laser intensity and wavelength warrant such protection. 5. Centrifuge Safety Always inspect the centrifuge prior to use. This will ensure that you are not harmed and equipment is not damaged. Always follow the manufacturer’s instructions for operation and maintenance. Centrifuge Safe Operating Procedures Lids shall be closed at all times during operation. The operator shall not leave the centrifuge until full operating speed is attained and machine appears to be running safely without vibration. If vibration occurs the centrifuge should be stopped immediately and load balances checked. Swing-out buckets should be checked for clearance and support. Rooms where potentially hazardous biological, radioactive materials, toxic or other hazardous chemicals are centrifuged must be identified by the appropriate warning signs. Centrifuge Safe Operating Procedures Continued: Plastic centrifuge tubes should be discarded after one cycle of ultracentrifugation. Nitrocellulose tubes should be used only when transparent and flexible (fresh). They must never be heated because of explosive possibility. Rotors and cups should be cleaned and disinfected after each use with non-corrosive cleaning solutions (mild detergent and distilled water are recommended). Test tube brushes must not be used for cleaning the cup cavities. All traces of detergents should be removed prior to air drying. 6. Housekeeping By maintaining a neat, orderly work area, you will greatly reduce hazards in the lab. Good Housekeeping Practices Put items back where they originated from promptly when you are done using them. Stay organized! Do not let papers and materials accumulate. Maintain clean counters and floors. Lab Hygiene There is a definite relationship between housekeeping and safety! Lab Hygiene Individual Items to Look For: 1.Excessive amounts of chemicals in work areas - Hoods and bench tops. 2. Old, outdated, unused equipment and chemicals cluttering up the work area 3. Floor Storage 4. Blocked exits / equipment / controls 5. Visual assessment of hoods and other safety equipment 6. Are special hazards marked? 7. Personal Protective Equipment (PPE) Anything that is used to protect a person from exposure Latex or Nitrile gloves, goggles, CPR mouth barriers, aprons, respirators PPE Rules to Remember Always check PPE for defects or tears before using If PPE becomes torn or defective remove and get new Remove PPE before leaving a contaminated area Do not reuse disposable equipment 8. Cryogenic Liquids Because of the extremely low temperatures of cryogenic liquids and their vapors, direct skin or eye contact can result in severe damage to tissues similar to burn injuries. Handling Procedures for Cryogenic Liquids Face shield and/or safety goggles to protect eyes. Suitable dry gloves to protect hands. Gloves should be loose fitting so that quick removal is possible if liquid should splash into them. Even with gloves, contact with cold liquids should be for a very brief time. Suggested protective clothing may consist of, depending on hazard, rubber aprons, overalls without pockets or cuffs, and hightop shoes to protect against skin contact in the event of a splash or spill. Cryogenic Liquid Ventilation Cryogenic liquids should be stored and handled in well- ventilated areas to prevent excessive buildup of gas concentration. These should never be used in closed environmental chambers. Transfer of cryogenic liquids from storage vessel Attach a 1 to 3 foot length suitable hose that has a phase separator in place to the control valve located on the top of the storage vessel. All transfers must be made into an appropriate container. Any funnels used must be stainless steel. If the receptacle is glass, it should be shielded to protect the person making the transfer from possible implosive fragmentation of the flask. Transfer of Cryogenic Liquids from Storage Vessel continued: Do Not Use A Household Thermos. They are not designed for holding cryogenic liquids and will fail. Withdraw liquid slowly at first because the interior of the flask may still be at room temperature and rapid boil off will occur. Disposal of Cryogenic Liquids Evaporation in a well-ventilated area, from a well-anchored and approved container is the best method of disposal of cryogenic liquids. Oxygen (b.p. -183oC) Oxygen can be condensed out of the air by cryogenic fluids which boil at a sufficiently low temperature (e.g. nitrogen, b.p. -195oC). For this reason care must be exercised in disposing of the final residue of an open container of liquid nitrogen since it may be oxygen rich. Emergency/First Aid Procedures for Cryogenic Liquids Rapidly rewarm contact area by immersion in warm water (100-110oF), with body heat, or warm air. DO NOT USE AN OPEN FLAME FOR THIS PURPOSE. (NOTE: this procedure is the opposite of the procedure for a burn injury which is to rapidly cool the contact area). Do not rub or massage the affected area. Prevent infection by cleansing with mild soap and water. Notify supervisor and then proceed to the Emergency Room. Hey, Jeff, where’s your lab coat and what’s in the mystery beaker?