Document 14065901

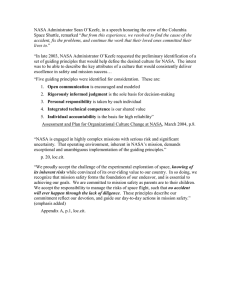

advertisement