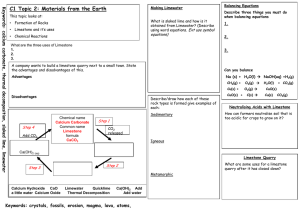

Evaluation and Verification of Limestone and Dolomite origin CO

advertisement