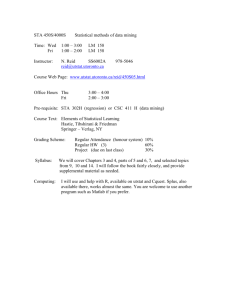

CIFE

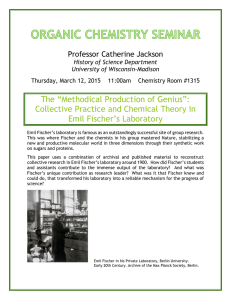

advertisement