Matrix assisted pulsed laser deposition of light emitting polymer thin films

advertisement

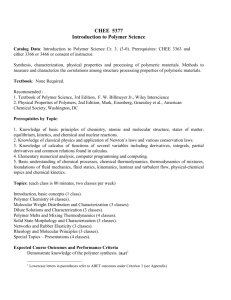

Appl. Phys. A 80, 1109–1113 (2005) Applied Physics A DOI: 10.1007/s00339-003-2392-1 Materials Science & Processing j.m. fitz-gerald1,u g. jennings1 r. johnson2 c.l. fraser2 Matrix assisted pulsed laser deposition of light emitting polymer thin films 1 University 2 University of Virginia, Department of Materials Science and Engineering, Charlottesville, VA 22904, USA of Virginia, Department of Chemistry, Charlottesville, VA 22904, USA Received: 27 August 2003/Accepted: 21 October 2003 Published online: 19 December 2003 • © Springer-Verlag 2003 Matrix assisted laser processing allows for the deposition of functional and fragile materials with a minimum of breakdown and decomposition. In this communication we report on light emitting thin films of ruthenium tris(bipyridine)-centered star-shaped poly(methyl methacrylate), Ru(bpyPMMA2 )3 (PF6 )2 , grown by matrix assisted pulsed laser deposition. A pulsed excimer laser (KrF) operating at 248 nm was used for all experiments. Due to the absorption at 248 nm and the solubility characteristics of [Ru(bpyPMMA2 )3 ](PF6 )2 , dimethoxy-ethane (DME) was used as a solvent [1]. Dilute solutions (2 wt. %) of [Ru(bpyPMMA2 )3 ](PF6 )2 and DME were flash frozen in liquid nitrogen producing a solid target. Thin films ranging from 20 to 100 nm were grown on Si in an Ar atmosphere at 200 mTorr at a laser fluence of 0.04 J/cm2 . The deposited materials were characterized by proton nuclear magnetic resonance (1 H NMR) and gel permeation chromatography (GPC) equipped with refractive index (RI), and ultraviolet/visible (UV/vis) detection. ABSTRACT PACS 81.15.Fg; 1 79.20.Ds; 78.66.Qn; 42.70.Jk Introduction Next generation applications require tighter tolerances on the structural, morphological, and chemical composition of the thin films used in their fabrication. This is especially the case for the deposition of high quality thin films of organic or polymeric materials as opposed to purely inorganic materials where high temperatures and native oxides are used to overcome the hurdles in their fabrication. Depending on the particular application, it may be desirable to deposit films containing single or multilayer structures of different organic or polymeric materials, homogeneous composite materials, or materials with graded compositions [2]. In many situations, it will be necessary to deposit the films discretely, achieve conformal coverage, and provide high quality films, especially with regard to surface coverage uniformity and thickness control. Thin films of polymeric, inorganic and organic materials also play an important role in batteries, high performance dielectrics, optical data storage, optical communications, and u Fax: +1-434/982-5660, E-mail: jmf8h@virginia.edu displays based on organic electroluminescent materials [3–5]. Polymer and organic coatings are essential for the fabrication of chemical and biochemical sensors [6, 7], and in biomedical applications ranging from passivation films for prosthetic devices to coatings for targeted drug delivery systems [8–11]. Based on their varied structures, physical properties, and reactivities, metal complexes can play key roles in macromolecules [12–14]. Metal complexes may serve as templates for self-assembly, as cross-links, or as part of the polymer backbone. Metal ions may be labile or inert with donors or acceptors in the form of chromophores, magnetic, or conducting centers. These systems allow for the introduction of a variety of features into polymers. One fascinating class of inorganic polymers are site-isolated metal-centered starshaped polymers (MCSPs) as shown in Fig. 1. These materials often exhibit interesting and well defined responses to stimuli in solution and in bulk, with significant potential for next level sensing and imaging applications [15–17]. [Ru(bpyPMMA2)3 ](PF6 )2 is in the class of polymeric metal complexes whose electroluminescent and photoluminescent properties are being actively studied for potential application to the expanding field of light emitting polymers (LEP), among other applications. After excitation at ∼ 468 nm, a metal-to-ligand charge transfer band (MLCT), [Ru(bpyPMMA2)3 ](PF6 )2 emits at 610 nm, producing a characteristic orange color. Matrix assisted pulsed laser evaporation (MAPLE) was developed at the Naval Research Laboratory in the late 90 s for the deposition of functional organic materials for chemical sensor applications, specifically directed at the detection of nerve and mustard gases [18]. This process has met with moderate success in depositing specific soft materials without structural damage (i.e. with native properties retained) [19]. This process has been described in detail elsewhere [20]. 2 Experimental In this report thin films of [Ru(bpyPMMA2)3 ](PF6 )2 were deposited on Si(001) via MAPLE using an KrF excimer laser operating at the following conditions: λ: 248 nm, repetition rate: 10 Hz, fluence: 0.04 J/cm2 . The Ru polymer was prepared via metalloinitiation using atom transfer radical polymerization (ATRP) which allows for 1110 Applied Physics A – Materials Science & Processing FIGURE 1 The metal-centered star-shaped polymer, [Ru(bpyPMMA2 )3 ](PF6 )2 and the response to optical stimuli controlled polymer growth, control over molecular weight distribution, and architecture [21]. A solution of 2 wt. % [Ru(bpyPMMA2)3 ](PF6 )2 was dissolved in dimethoxyethane (DME), vortex mixed and ultrasonicated. Dimethoxyethane is a clear, colorless liquid with a melting temperature of −58 ◦ C and an absorbance of 25% cm−1 (λ = 248 nm) [22]. Prior to deposition, the solution was flash frozen in liquid nitrogen and then transferred to a vacuum chamber with a cold stage. The chamber was pumped down to a base pressure of 10−6 Torr and continuously backfilled with Ar, maintaining 200 mTorr during deposition. During deposition the beam was scanned across the stationary target with a computer controlled translating mirror for a total of 36 k pulses. As a first order test, following deposition, films were exposed to low intensity UV radiation from a hand held (generic portable UV light) UV source (λ = 266 nm) and emitted in the orange (∼ 610 nm) as shown in Fig. 2. Although the material only needs 468 nm light for excitation, the portable UV allows for large area exposure and also imaging with a digital camera. The dark square areas in Fig. 2 represent the locations of Si witness substrates. The deposited and native films were compared using conventional characterization techniques. GPC analysis of the original star polymer in CHCl3 (flow rate = 1 mL/min), with in-line UV/vis spectroscopy, indicated the presence of the [Ru(bpy)3]2+ chromophore co-eluting with the polymer, clearly demonstrating that the metal complex is associated with the native polymer. Molecular weight estimates using the RI detector with linear PMMA standards [Ru(bpyPMMA2 )3 ](PF6 )2 thin film grown on a 4 Si wafer by MAPLE emitting characteristic orange light (610 nm) under a hand held UV light source FIGURE 2 indicate a number average molecular weight, Mn , of ∼ 33 kDa for the native polymeric metal complex. GPC analysis of the deposited material reveals several key differences from the native material: a low molecular weight shoulder, a slight shift of the majority peak to lower elution volume, and a high molecular weight tailing. A GPC overlay of native and deposited polymers is provided in Fig. 3. The low molecular weight shoulder indicates partial cleavage of the PMMA chains. This raises the question of where polymer degradation may be occurring. Significant overlap of the shoulder with the main peak precludes accurate molecular weight determination of the lower molecular weight component formed in the deposition process. However, estimates using linear PMMA standards suggest an Mn of ∼ 9 – 12 kDa, approximately 1/3 of the molecular weight of the original star polymer. A 3-D in-line UV/vis spectrum of the MAPLE deposited material is shown in Fig. 4. This figure clearly shows the presence of the [Ru(bpy)3]2+ chromophore again co-eluting with the majority peak, therefore suggesting that the star remains intact in a majority of the sample. In contrast, the chromophore is clearly absent in the low molecular weight shoulder, suggesting that polymer may be degraded by destruction of the metal-ligand bond (i.e. macroligand dissociation). Moreover, if scission were occurring predominantly along the polymer backbone or at the ester functional groups FIGURE 3 GPC overlay for deposited and native [Ru(bpyPMMA2 )3 ](PF6 )2 . The overlay clearly shows a low molecular weight fraction (higher elution volume) in the MAPLE deposited material perhaps resulting from the destruction of metal–ligand bonds. Also evident is the slight shift to higher MW and overall broadening FITZ - GERALD et al. Matrix assisted pulsed laser deposition of light emitting polymer thin films 1111 FIGURE 4 A 3-D plot of the GPC UV-vis spectra of the MAPLE deposited films showing the presence of the [Ru(bpy)3 ]2+ chromophore co-eluting with the majority peak. This suggests that the star predominantly remains intact. The chromosphere is absent in the low molecular weight shoulder (larger elution volume) that is roughly 1/3 the molecular weight, implying that one mechanism of polymer degradation may involve photolysis of the metal–polymeric bpy ligand bond that serve as the attachment point of the polymer to the metal complex on the bipyridine ligands, the resulting metal-free fraction would be 1/6th (weight of one arm of the original star) or lower in molecular weight. The metal-containing fragments would retain the tris(bipyridine) chromophore and would be detected by in-line UV-vis and could range in molecular weight from a polymer-free [Ru(bpy)3]2+ analogue to nearly the size of native polymer. That is, rather than two distinct fractions, a long tail from native polymer too much lower MW fragments would be expected for either of these alternative degradation mechanisms. However, the data does not preclude a small degree of degradation by these methods. Careful analysis of the GPC overlay also indicates some high molecular weight tailing in the deposited polymer. Reasons for this may include star-star coupling as a result of laser/polymer interaction (e.g. reactive intermediates formed at polymer chain ends or other sites could lead to interchain coupling reactions). Additionally, a slight shift toward lower elution volume for the major fraction after laser deposition is also indicative of an increase in molecular weight. This increased molecular weight also has chromophores present (and can be seen in the 3-D plot), lending credence to this hypothesis. Comparison of 1 H NMR spectra shown in Fig. 5 for the native and deposited material also reveals some degradation, as evidenced by changes in peak ratios in the methyl region (1.6 – 1.2 ppm). However, the complexity of this region of the spectrum of PMMA makes it difficult to determine exactly what bonds are affected. It is conceivable for a percentage of the polymeric material to be cleaved in the polymer backbone, and recombination or termination of any reactive species present. 3 Conclusions We have succeeded in depositing thin films of a visible light emitting polymer, [Ru(bpyPMMA2 )3 ](PF6 )2 by ma- 1 H NMR spectra of native (a) and laser deposited (b) [Ru(bpyPMMA2 )3 ](PF6 )2 samples in CDCl3 FIGURE 5 trix assisted pulsed laser deposition. Under a UV light the deposited materials exhibited characteristic emission at 610 nm (orange). Though a majority of the polymer seems to remain intact during deposition, 1 H NMR and GPC with UV/vis analysis reveal some polymer degradation under the conditions investigated in this preliminary study. Data are consistent with both polymer coupling reactions and some polymeric ligand dissociation from the ruthenium center. In future studies, we will attempt to control polymer degradation processes and optimize deposition processes by changing the laser wavelength and exploring other solvent matrices that ideally, for reasons of energy and degradation effects, are highly absorbing in the visible region. 1112 Applied Physics A – Materials Science & Processing REFERENCES 1 C.L. Fraser, A.P. Smith: J. Polym. Sci, Part A: Polym. Chem. 38, 4704 (2000) 2 R.A. McGill, A. Piqué, D.B. Chrisey, J.M. Fitz-Gerald, V. Nguyen, R. Chung: Proc. Sixth Int. Conf. on Composites Eng., ICCE/6 Orlando, FL (1999) p. 563 3 L.H. Wang, W. Wang, W.G. Zhang, E.T. Kang, W. Huang: Chem. Mater. 12, 2212 (2000) 4 A.C. Edrington, A.M. Urbas, P. DeRege, C.X. Chen, T.M. Swager, N. Hadjichristidis, M. Xeridou, L.J. Fetters, J.D. Joannopoulos, Y. Fink, E.L. Thomas: Adv. Mater. 13, 421 (2001) 5 A.L. Jenkins, O.M. Uy, G.M. Murray: Anal. Chem. 71, 373 (1999) 6 R.A. McGill, M.H. Abraham, J.W. Grate: Chemtech. 24(9), 27 (1994) 7 B.R. Ringeisen, J. Callahan, P.K. Wu, A. Pique, B. Spargo, R.A. McGill, M. Bucaro, H. Kim, D.M. Bubb, D.B. Chrisey: Langmuir 17, 3472 (2001) 8 A. Hickey: Respiratory Drug Delivery VI. (Interpharm Press Inc., SC 1998) 9 D. Meisner: In Pharmaceutical Particulate Carriers, A. Rolland (Marcel Dekker, NY 1993) pp. 31–63 10 D.A. Edwards, J. Hanes, G. Caponetti: Science 276, 1868 (1997) 11 A. Gopferich, M.J. Alonso, R. Langer: Pharm. Res. 11(11), 1568 (1994) 12 I. Manners: Sci. 294, 1664 (2001) 13 P. Nguyen, P. Gómez-Elipe, I. Manners: Chem. Rev. 99, 1515 (1999) 14 Q. Wang, L. Yu: J. Am. Chem. Soc. 122, 11 806 (2000) 15 C.L. Fraser, A.P. Smith: J. Polym. Sci., Part A: Polym. Chem. 38, 4704 (2000) 16 J.J.S. Lamba, C.L. Fraser: J. Am. Chem. Soc. 119, 1801 (1997) 17 X. Wu, C.L. Fraser: Macromolecules 33, 4053 (2000) 18 R.A. McGill, D.B. Chrisey: MAPLE patent, Navy case No. 78, 117 (1999) 19 D.M. Bubb, R.A. McGill, J.S. Horwitz, J.M. Fitz-Gerald, E.J. Houser, R.M. Stroud, P.K. Wu, B.R. Ringeisen, A. Piqué, D.B. Chrisey: J. Appl. Phys. 89, 5739 (2001) 20 D. B Chrisey, A. Pique, R.A.J.S. Horwitz, B.R. Ringeisen: Chem. Rev. 103, 553 (2003) 21 R.M. Johnson, P.S. Corbin, C. Ng, C.L. Fraser: Macromolecules 33, 7404 (2000) 22 Aldrich Chem. Co., Aldrich catalog/Handbook of fine chemical, Aldrich Chem. Co., Milwaukee, WI. P. 710, # 30 (1988) pp. 743–2