Pulsed laser deposition vs. matrix assisted pulsed laser evaporation for growth

advertisement

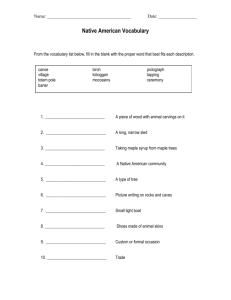

Appl. Phys. A 81, 591–599 (2005) Applied Physics A DOI: 10.1007/s00339-004-2994-2 Materials Science & Processing a.l. mercado c.e. allmond j.g. hoekstra j.m. fitz-geraldu Pulsed laser deposition vs. matrix assisted pulsed laser evaporation for growth of biodegradable polymer thin films University of Virginia, Dept. of Materials Science and Engineering, 116 Engineer’s Way, Charlottesville, VA 22904-4745, USA Received: 20 April 2004/Accepted: 20 July 2004 Published online: 30 September 2004 • © Springer-Verlag 2004 Thin films of poly (lactide-co-glycolide) (PLGA), a biodegradable polymer, were deposited on Si wafers by both conventional pulsed laser deposition (PLD) and matrix assisted pulsed laser evaporation (MAPLE) using chloroform (CHCl3 ) as a matrix solvent. This research represents an initial study to investigate the deposition characteristics of each technique at comparable conditions to gain insight into the transport and degradation mechanisms of each approach. The deposited materials were characterized by scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FTIR), proton nuclear magnetic resonance (1 H NMR), and gel permeation chromatography (GPC) with refractive index (RI) detection. While FTIR and NMR results do not show a measurable departure from the native, in sharp contrast GPC results show a significant change (up to 95%) in molecular weight for both deposition methods. This result makes it clear that it is possible to overlook substantial degradation when incomplete chemical analysis is conducted. Optical transmission measurements of the starting MAPLE targets yielded laser penetration depths on the order of 0.362 cm and 0.209 cm for pure CHCl3 and 1 wt. % PLGA in CHCl3 , respectively. Straightforward application of the Beer–Lambert law for laser energy deposition predicts a negligible temperature rise of less than 1 K at the target surface, which is in clear contradiction with ablation rates of 1.85 µm/pulse experimentally measured for polymer loaded samples. With an ablation process of this magnitude, the material ejection is likely due to contributions of nonlinear or non-homogeneous laser light absorption rather than evaporation. Severe non-uniformity of the final surface morphologies of the MAPLE films, similar to solvent wicking artifacts found in spin casting supports the spallation scenario in MAPLE. ABSTRACT PACS 81.15.Fg; 1 79.20.Ds; 78.66.Qn; 42.70Jk Introduction To intelligently design active and passive organic thin film materials for application in next generation medicine and electronics requires control over both chemical and structural film properties. In many situations, it will be necessary u Fax: +1-434-982-5660, E-mail: jmf8h@virginia.edu to deposit films discretely with uniformity containing single or multilayer structures of organic or polymeric materials, homogeneous composite materials, or materials with graded compositions, which is the case with the electronic materials industry. Thin films of polymeric, inorganic and organic materials play an important role in batteries, high performance dielectrics, optical data storage, optical communications and displays based on organic electroluminescent materials [1–7]. Polymer and organic coatings are essential for the fabrication of chemical and biochemical sensors [8, 9], and in biomedical applications ranging from passive films for prosthetic devices to coatings for targeted drug delivery systems [10–13]. Thin films of specific organic materials have been processed via several non-vacuum routes ranging from conventional methods such as spin casting, electrochemical deposition, dip coating, solvent evaporation, aerosol coating, to plasma and thermal evaporation [14–19]. For example, recent applications of conjugated polymers to optical and optoelectronic devices require the formation of thin polymer films of high quality (retained functionality, thickness, morphology, etc.) [20]. Although spin casting has been widely used, this technique is limited to soluble polymers possessing excellent processibility. Moreover, the volume dilution of the optically active main chains in the derivative forms modified for solubility results in reduced linear and non-linear optical responses as compared with their parent polymers [21, 22]. Along with the rapidly developing field of plasma polymerization [23], several other vacuum methods have been applied to thin polymer film preparation: electron beam irradiation [24, 25], ultraviolet (UV) light vapor irradiation [26, 27], thermally assisted vacuum evaporation [28], and by polymer sputtering [29]. However these can only be used in special cases where polymers with a low molecular weight evaporate as polymer units and condense on the substrate without a reaction. When heated to the evaporation temperature most polymers are fragmented, these gaseous fragments “condense” on the substrate without creating a proper polymer network. While the use of high energies and temperatures in plasma processing and UV curing of fragile polymers is generally prohibitive [30–32], two laser based methods have also emerged onto the polymer deposition field, namely pulsed laser deposition (PLD) and matrix assisted pulsed laser evaporation (MAPLE). 592 Applied Physics A – Materials Science & Processing Pulsed laser deposition is largely an inorganic thin film deposition technique used for the deposition of complex, multi-component materials in thin film form (ceramics, superconductors, metals, etc.) [33–38]. PLD utilizes the output of a pulsed UV laser focused onto a solid target which rapidly heats, vaporizes and creates nearly atomic (partially ionized) vapor that is deposited upon a heated substrate, which is typically comprised of a ceramic, metal or glass. Via an alternative mechanism, PLD has also been performed with a large degree of success in the infrared region (IR-PLD), with the use of free electron lasers in both on/off resonance modes of vibrational excitation for the growth of materials such as polyethylene glycol and polystyrene in thin film form from solid targets [39, 40]. Matrix assisted pulsed laser evaporation was developed at the Naval Research Laboratory in the late 90’s for the deposition of functional organic materials for chemical sensor applications, specifically directed at the detection of nerve and mustard gases [41]. In MAPLE the “target” consists of a polymer dissolved in an optically absorbing solvent with a high vapor pressure. The purpose of the volatile solvent in the target is to aid desorption by absorbing a majority of the laser energy and vaporizing when the laser energy is converted to thermal energy by photochemical processes entraining the organic molecules of interest to the substrate [42, 43]. Thus, highly absorbing solvents that are sufficiently volatile and do not form a film once evaporated by the laser are ideal. The present research was performed to gain insight into the deposition and degradation characteristics of thin films of PLGA grown by both conventional PLD and MAPLE techniques. 2 Experimental procedure The deposition system for both MAPLE and conventional PLD is shown in Fig. 1. A uniform solution of 1 wt. % poly(DL-lactide-co-glycolide) (PLGA, 75% lactic acid (LA), 25% glycolic acid (GA), m w = 100,000, Birmingham Polymer, Inc.) in chloroform (CHCl3 ) was used in all MAPLE experiments. As a matrix material, CHCl3 has a relatively high melting temperature (210 K) making it desirable for these experimental operations in comparison to other volatiles such as acetone, and methanol. The solution was poured into a Cu container and inserted onto a cold stage maintained at ∼ 120 K after being flash frozen in liquid nitrogen (LN2 ). Depositions were conducted with an excimer laser (λ = 248 nm, τ = 25 ns FWHM, 5 Hz) in Ar at 100 mTorr, laser energy densities were varied from 0.1 to 1 J/cm2 . For the conventional PLD experiments, solid targets of PLGA were fabricated by conventional casting methods. For both methods, the chamber was pumped down to a base pressure of 10−6 Torr, and backfilled to 100 mTorr with Ar. During MAPLE processing, since the volatiles must be pumped out of the system during deposition, a continuous flow of Ar was maintained. Thin films were deposited onto single crystal Si(100) (10 cm diameter wafers and 1 cm2 samples) along with single crystal NaCl substrates (for FTIR). Energy regimes of 0.1 J/cm2 to 1.0 J/cm2 and 0.2 J/cm2 to 1.0 J/cm2 were investigated for MAPLE and PLD respectively. 3 Results 3.1 Scanning electron microscopy SEM was performed to characterize the thickness and morphological characteristics of the deposited materials. SEM images of MAPLE and PLD deposited films as a function of fluence are shown in Figs. 2 and 3 respectively. Films deposited via MAPLE, regardless of laser energy, had varied amounts of surface features and matrix trace patterns on the surface. At fluences > 0.2 J/cm2 , the particulate population (25 – 500 nm) becomes more pronounced and apparent matrix effects are minimized with film thickness ranging from 20 – 100 nm overall. At low energies, the MAPLE deposited films have a low roughness, but radial, wicking type patterns on the film surface, similar to spin cast films, may indicate a significant presence of chloroform on the substrate during deposition suggesting the mechanism of material transport may not be a straightforward evaporation process. In contrast, PLD deposited films showed a significantly larger range of features in comparison to the MAPLE deposited films. At energies > 0.2 J/cm2 significant film roughness was observed with thicknesses ranging from 50 nm (0.2 J/cm2 ) to 2.2 µm (1 J/cm2 ). At 0.2 J/cm2 , the asdeposited films did not present surface features, thereby requiring intentional mechanical indentation with a stylus to provide a film reference, as shown in Fig. 3a. 3.2 FIGURE 1 Experimental setup for the deposition of PLGA thin films by both conventional PLD and MAPLE Fourier transform infrared spectroscopy In general, distinct functional groups in polymers preferentially absorb tunable IR light allowing for FTIR analysis. These molecular vibrations are equivalent to the stretching or bending of chemical bonds in the polymer, in our case PLGA. The optically absorbing functional groups, or chromophores, in PLGA and the particular molecular vibrations of these chromophores observed in the FTIR spectra are shown in Table 1 [44]. The peak at 3509.9 cm−1 corresponds to the vibrational excitation of the OH end group in the PLGA native. The peaks at 3010 and 2955 cm−1 coincide with MERCADO et al. Pulsed laser deposition vs. matrix assisted pulsed laser evaporation for growth of biodegradable polymer thin films 593 FIGURE 2 Scanning electron microscope images of MAPLE deposited thin films of PLGA. The SEM micrographs show trends of particulate formation, showing morphology effects in terms of matrix patterns, particle roughness and droplet formation as a function of laser fluence (a–g) while (h, i) illustrating the thickness regime for the films which ranged from 20–100 nm FIGURE 3 Scanning electron microscope images of PLD deposited thin films of PLGA. The images show increased surface roughness and undulations at energy densities above 0.2 J/cm2 Functional Group OH End group C–H Stretch of CH3 C–H Stretch of CH2 C=O Stretch C–O Stretch C–H Bends TABLE 1 Corresponding Peak 3509.9 cm−1 3010 cm−1 and 2955 cm−1 2885 cm−1 1762.6 cm−1 1186–1089.6 cm−1 1450–850 cm−1 Functional groups for FTIR analysis the C–H stretches of the CH3 groups. The peak at 2885 cm−1 was indicative of the C–H stretch of CH2 while the peak at 1762.6 cm−1 corresponded to the carbonyl (C=O), vibrational excitation. Peaks at 1450 to 800 cm−1 are deemed to be the traditional “fingerprint” region for this material. The fingerprint region is an important identifier for various polymers; Fig. 4 illustrates the complete spectra including the fingerprint region for native PLGA. Figure 5 shows FTIR spectra from both MAPLE (a) and PLD (b) deposited thin films. The re- 594 Applied Physics A – Materials Science & Processing FIGURE 4 FTIR spectra for native PLGA showing characteristic features at ∼ 3500, 3000, 1750, and 1100 cm−1 FIGURE 5 FTIR spectra for MAPLE (a), and PLD deposited (b), films of PLGA MERCADO et al. Pulsed laser deposition vs. matrix assisted pulsed laser evaporation for growth of biodegradable polymer thin films 595 sults from the FTIR spectra demonstrate that the deposited films resemble the native polymer to a finite degree. Insets show a minor peak at 760 cm−1 in both the native and PLD deposited materials while a minor peak is shown at 780 cm−1 for the MAPLE deposited materials which could be identified as C–Cl stretch [45]. 3.3 Nuclear magnetic resonance To provide further chemical analysis, NMR was performed using proton resonance. The resulting signal peaks due to the precession of all hydrogen atoms within each functional group are shown in Table 2. The multiplet at 5.2 ppm stems from resonance in the CH species in the lactic acid while the multiplet at 4.8 ppm corresponds to the resonance of the CH2 species in the glycolic acid [46]. These peaks were complex multiplets because of the different D-lactide, L-lactide, and glycolic acid monomers that comprise PLGA, and their relationships to each other in the polymer chain. The overlapping doublets at 1.55 ppm were attributed to the chiral methyl groups in the lactic acid monomer units for both D- and L- stereographic configurations. The peak at approximately 1.25 ppm is attributed to the methyl group attached to the hydroxyl end group. Standard solutions were prepared by dissolving the deposited films in deuterated chloroform, CDCl3 . The NMR spectra from the native PLGA is shown in Fig. 6. Figure 7 Functional Group Corresponding Peak Lactic acid - CH Glycolic acid - CH2 Methyl groups of the D- and L- lactic acid repeat units Methyl group attached to the hydroxyl endgroup Multiplet @ 5.2 ppm Multiplet @ 4.8 ppm Overlapping doublets @ 1.55 ppm 1.25 ppm TABLE 2 Corresponding peaks of functional groups in PLGA measured by proton resonance FIGURE 7 Nuclear magnetic resonance spectra of PLGA deposited by MAPLE (a) and PLD (b) shows the comparative NMR spectra from the MAPLE (a) and PLD (b) deposited materials. Specifically, the multiplets associated to the lactide and glycolide groups were similar for both native PLGA, MAPLE, and PLD processed films. 3.4 FIGURE 6 Nuclear magnetic resonance spectra from native PLGA showing the methyl groups at 1.25 and 1.55 ppm and the glycolic and lactic acid groups at 4.8 and 5.2 ppm Gel permeation chromatography analysis GPC analysis of native PLGA in CHCl3 (flow rate = 1 mL/min) is shown in Fig. 8a. The analysis for all material is shown in Table 3 along with the polydispersity (PD). Molecular weight estimates using a RI detector with linear polystyrene standards indicates an average molecular weight of 100 kDa for the native polymer. GPC analysis of MAPLE deposited material is shown in Fig. 8b, the molecular weight was measured to be ∼ 25 kDa, with a significant shift of the oligomer peak at higher elution volumes to 200 Da. Materials 596 Applied Physics A – Materials Science & Processing FIGURE 8 GPC elution profiles for native PLGA (a) and MAPLE (b) deposited PLGA showing intermediate (MAPLE 1) and total monomer breakdown of PLGA (MAPLE 2) Native m w : 99 kDa PD: 1.725 TABLE 3 PLD MAPLE Peak 1 m w : 8.0 kDa PD: 2.7 Peak 2 m w : 210.0 Da PD: 1.0 Peak 1 m w : 26.0 kDa PD: 2.0 Peak 2 m w : 210.0 Da PD: 1.3 Molecular weight results from GPC analysis deposited by PLD (0.38 J/cm2 ) show contrary behavior with the oligomer peak remaining at a molecular weight of ∼ 8 kDa and a monomer peak occurring at higher elution volumes at ∼ 200 Da as shown in Fig. 9a. It is also noted that below 1 kDa the accuracy of GPC analysis is in question, so it is assumed that all materials in this region are monomer. 4 Discussion Growth of PLGA thin films by both methods showed trends in both surface morphology and degradation behavior. In terms of chemistry, the FTIR and the NMR of the deposited materials are comparable to the native. A GPC GPC elution profiles for PLD deposited PLGA is shown in (a). The PLD deposited materials showed a large intermediate breakdown peak (PLD1), and a total monomer degradation peak (PLD 2). An overlay of the native, MAPLE and PLD profiles is shown in (b) FIGURE 9 overlay of native and deposited polymers is shown in Fig. 9b. Peaks at long elution volumes (time) are consistent with degradation of polymer to a lower molecular weight, which could be monomer or oligomers. It is clear that both techniques significantly reduce the molecular weight of the starting material. The data also suggest that MAPLE processed PLGA retained higher molecular weight fractions in comparison to PLD, along with a large fraction of monomer, while PLD processed films showed a broad oligomer peak with a molecular weight of 7 kDa and a smaller monomer fraction. The overall polymer degradation suggests significant absorption of UV radiation by the polymer in both MAPLE (with the sacrificial matrix) and PLD. The optical absorption of several functional groups within PLGA can be compared to that of the functional groups inside the structure of many solvents with a known absorption at 248 nm such as acetone [47]. By eliminating the low absorption bonds, the carbonyl group present in the PLGA backbone is mainly responsible for the high absorption which has also been noted by Gardner between 200 and 300 nm [48]. This absorption of high energy photons by the carbonyl group was one reason that Bubb et MERCADO et al. Pulsed laser deposition vs. matrix assisted pulsed laser evaporation for growth of biodegradable polymer thin films 597 FIGURE 10 Digital images of a frozen target (1 wt. % PLGA-CHCL3 ) taken (a) prior to ablation, (b) during ablation (two areas were ablated for comparison), and (c), (d) fractured target following ablation showing the ablation depth and remaining wall thickness. The target was maintained in LN2 bath during all measurements al. were concerned that the carbonyl bonds might break during laser ablation of PLGA in the PLD case [49]; therefore, a significant deviation in molecular weight from the starting material can be expected. The deposition characteristics and surface morphology of the PLD deposited films are in good agreement with previous research [50–54]. In the case of MAPLE deposited materials, a high ablation rate of the target combined with an irregular surface morphology was observed. Experiments were performed (0.237 J/cm2 , 5 Hz, 100 mTorr Ar) to determine the actual ablation rate of the frozen target, followed by fracture of the frozen target. By fracturing the frozen targets and immediately immersing in LN2 , cross-section measurements of the ablation trenches were obtained as shown in Fig. 10. After 6,500 pulses, the ablation trenches were on the order of 1.2 cm deep, yielding an ablation rate of ∼ 1.85 µm/pulse, suggesting that a large portion is being vaporized and evaporated [55, 56], or that solid spallation [57] of the target surface is occurring. This observation may be reflected on the deposited films shown in Fig. 2b, c where images of the surface morphology reflect significant signs of solvent evaporation from the films while on the Si substrates. This suggests that either a large amount of solvent (CHCl3 ) is transferred to the films or that solid layers of the target are landing on the substrate, melting, and then in both cases the volatile is pumped out of the system, leaving behind the wicking patterns on the film surfaces. To further understand the laser-solid interactions that may lead to either large scale evaporation or spallation, optical absorption data is required. Laboratory experiments were conducted for both pure solvent and 1 wt. % PLGA solutions due to a lack of optical absorption data for frozen CHCl3 based solutions in the literature. The initial energy distribution in the near surface regions of the target were calculated based on the Beer–Lambert (BL) law that describes the attenuation of light with depth: I(z) = I0 e−αz (1) where I0 is the intensity of the incoming light, I(z) is the intensity of the light at a depth of z , and α is the absorption coefficient, specific to the material. In general the laser penetration depth L P is commonly expressed as 1/α. Transmission data were recorded from pure CHCl3 at film thicknesses of 609 µm, 3048 µm, 5461 µm, and for a 1 wt. % PLGA so- FIGURE 11 Transmission as a function of film thickness calculated with the Beer–Lambert relationship. Three transmission measurements at varying thicknesses were recorded for each solution. The upper and lower curves were generated from targets of pure CHCl3 and CHCl3 w/1 wt. % PLGA respectively 598 Applied Physics A – Materials Science & Processing lution at 1016 µm, 3149 µm, and 4648 µm. The experimental data was correlated with respect to the BL relationship, with a fit to the data showing an experimental agreement ( R2 = 99.5%, pure CHCl3 , 99.2% PLGA in solution) from the BL relationship. From this initial data, the laser penetration depth, L P , was calculated to be 0.362 cm for pure CHCl3 and 0.209 cm for the PLGA solution, indicating a weakly absorbing at 248 nm. The transmission as a function of solution thickness, z , is shown in Fig. 11. If the heat capacity is constant, the temperature rise at the start of ablation can be expressed as αFe−αz T(z) = T0 + (2) CP β with where Γ is the Grüneisen coefficient defined as κC p β is the thermal expansion coefficient, κ is the isothermal compressibility, is the density, C p is the specific heat at constant volume. For pure CHCl3 with F = 2000 J/m2 , L P = 0.00362 m, D = 0.99, equation (6) predicts a peak stresses, σP , ranging from 276 kPa (for Γ = 1) to 820 kPa (for Γ = 3), which are clearly insufficient to cause spallation as described [61, 62]. Therefore neither temperature nor stress calculations can account for the experimentally observed ablation rate, providing a basis for further research investigations of effects that may be related to non-homogenous absorption. where T0 is the initial temperature, C P is the specific heat capacity, assumed to be independent of temperature, and F is the fluence. The heat capacity was estimated from tabulated data over a temperature range of 221 K to 324 K to be 117 J/mol-K [58–60], ( F = 0.2 J/cm2 , = 1.48 g/cm3 , m w = 119.38 g/mol, α = 2.762 cm−1 , T0 210 K, as the cold stage is maintained at 120 K). From these data set the temperature rise is calculated to be less than 1 K (at z = 0), which does not support the high ablation rate observed. It is noted that the value for the heat capacity found does not represent chloroform in the frozen/solid state, which would be lower due to the loss of rotational states. For an estimate of the change of the C p for chloroform, the heat capacity of water varies by approximately 52% from 20 ◦ C (75 J/mol-K) to −10 ◦ C (36 J/mol-K). For our case with frozen/solid chloroform, an estimate of the solid is 60 J/mol-K, which still yields a negligible temperature rise. An alternative desorption mechanism that does not require high temperature can be termed “cold laser ablation” or spallation as described by Dingus et al. [57], with further investigations performed experimentally [61] and computationally [62]. Spallation is a hydrodynamic process in which layers next to a free surface are ablated at energy densities too low for vaporization resulting in large scale material removal. This effect becomes pronounced when τL (laser pulse duration) is shorter than the time of mechanical equilibration or thermal relation of the absorbing volume, τs , usually referred to as stress confinement [63], τL≤ τs ∼ L p /Cs , where Cs is the speed of sound in the target material, which can be approximated as 3000 m/s. For this research, τs is on the order of 1200 ns for pure CHCl3 , and 696 ns for the PLGA solution, which places the system in the stress confinement regime. In calculating the stress waves propagating out of the irradiated volume, a damping factor can be accounted for [61] Films grown by PLD were uniform, showing a trend of increased roughness as a function of fluence. MAPLE deposited films did not follow the same trend, with large sections of non-uniformity and particulates present at all fluences. Chemical characterization performed with FTIR and NMR did not reveal a significant deviation from the native. Size exclusion analysis with GPC showed a clear shift to lower molecular weights for both techniques. The GPC profiles for the MAPLE deposited materials showed a poorly defined shoulder at 26 kDa, with a large, well defined peak in the monomer region. The weight distributions for the PLD deposited materials showed two clearly defined peaks at 7 kDa and in the monomer region, with the peak at 7 kDa dominating the trace. Of greater importance to the biomedical community is the fact that no substantial fraction of toxic species was observed in the degraded materials by FTIR or NMR keeping the door open for medical application areas with either technique. The geometric patterns present in the MAPLE films are solvent evaporation patterns; these patterns are consistent with solvent evaporation patterns normally associated with the spin casting process. This may be due to the ejection of large slices of the target surface, explosive evaporation, or spallation of layers onto the substrate that melt, leading to evaporation of the solvent, and thus residual polymer was deposited. A high ablation rate supports this scenario, suggesting that large volumes of the target are being ejected, rather than entrainment transport of individual molecules. Preliminary calculations for the thermal and stress confinement behavior based on the Beer-Lambert relationship do not support the current spallation or evaporation models, [55–57] further suggesting that other mechanisms may dominate the ablation process for this system, such as non-linear surface effects, which will be the focus of future research in this area. D= 1 − e−θ θ (3) where θ = τL/ τs = 0.020 for pure solution and 0.035 for the 1 wt. % PLGA solution, giving negligible damping values of D ∼ 0.99 and 0.982 respectively. The amplitude of the peak tensile stress is then given as σP = D F Γ 2 LP (4) 5 Conclusions ACKNOWLEDGEMENTS This work was supported by the University of Virginia and the Air Force Office of Scientific Research under the DURINT program. The authors are thankful to Professors Leonid Zhigilei and Cassandra Fraser for many insightful and helpful discussions. REFERENCES 1 L.H. Wang, W. Wang, W.G. Zhang, E.T. Kang, W. Huang: Chem. Mater. 12, 2212 (2000) 2 A.C. Edrington, A.M. Urbas, P. DeRege, C. Chen, T. Timothy, N. Hadjichristidis, M. Xeridou, L. Fetters, J.D. Joannopoulos, Y. Fink, E.L. Thomas: Adv. Mater. 13, 421 (2001) MERCADO et al. 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 Pulsed laser deposition vs. matrix assisted pulsed laser evaporation for growth of biodegradable polymer thin films 599 Y. Okamoto: Makromol. Chem., Macromol. Symp. 59, 82 (1992) C.X. Du, L. Ma, Y. Xu, W.L. Li: J. Appl. Polym. Sci. 66, 1405 (1997) A.L. Jenkins, O.M. Uy, G.M. Murray: Anal. Chem. 71, 373 (1999) P. Zhang, J.S. Moore: J. Polym. Sci., Part A: Polym. Chem. 38, 207 (2000) M.S. Mousa, K. Lorenz, N.S. Xu: Ultramicroscopy 79, 43 (1999) R.A. McGill, M.H. Abraham, J.W. Grate: Chemtech 24, 27 (1994) B.R. Ringeisen, J. Callahan, P. Wu, A. Pique, B. Spargo, R.A. McGill, M. Bucaro, H. Kim, D.M. Bubb, D.B. Chrisey: Langmuir 17, 3472 (2001) A. Hickey: Respiratory Drug Delivery VI., (Hilton Head, SC: Interpharm Press Inc., 1998) D.A. Edwards, J. Hanes, G. Caponetti, J.S. Hrkach, A. Ben-Jebria, M.L. Eskew, J. Mintzes, D. Deaver, N. Lotan, R. Langer: Science 276, 1868 (1997) A. Gopferich, M.J. Alonso, R. Langer: Pharm. Res. 11, 1568 (1994) J.D. Talton, J.M. Fitz-Gerald, R.K. Singh, G. Hochhaus: Respiratory Drug Delivery VII (Hilton Head, SC: Interpharm Press, Inc., 2000) pp. 67–74 X. Cui, J.F. Hetke, J.A. Wiler, D.J. Anderson, D.C. Martin: Sens. Actuators A 93, 8 (2001) K. Skrobis, D.D. Denton, A. Skrobis: Polymer Engineering and Science 30, 193 (1990) M.A. Bopp, G. Tarrach, M.A. Lieb, A.J. Meixner: J. Vac. Sci. Technol., A 15, 1423 (1997) W.L. Wu, W.E. Wallace: J. Vac. Sci. Technol., B 16, 1958 (1998) S. Sakurai, C. Furukawa, A. Okutsu, A. Miyoshi, S. Nomura: Polymer 43, 3359 (2002) T.H. Young, Y.H. Huang, L.Y. Chen: J. of Membrane Science 164, 111 (2000) See for example, T.A. Skotheim, R.L. Elsenbaumer, J.R. Reynolds (Eds.): Handbook of Conducting Polymers, 2nd edn., (Dekker, New York 1996) A.J. Heeger, S.A. Kivelso, J.R. Schrieffer, W.P. Su: Rev. Mod. Phys. 60, 781 (1998) T.M. Lee, S. Mittler-Neher, D. Neher, GI Stegeman, C. Roux, M. Leclerc: Opt. Mater. 1, 65 (1992) F.F. Shi: Surf. Coat. Technol. 82, 1 (1996) P. Favia, R. d’Agostino: Surf. Coat. Technol. 98, 1102 (1998) N. Inagaki, S. Tasaka, M. Makino: J. Appl. Polym. Sci. 64, 1031 (1997) M.J. Sowa, M.E. Littau, V. Pohray, J.L. Cecchi: J. Vac. Sci. Technol. A 18, 2122 (2000) G.H. Hishmeh, T.I. Barr, A. Skylarov, S. Hardcastle: J. Vac. Sci. Technol. A 14, 1330 (1996) K. D’Almeida, J.C. Bernede, F. Ragot, A. Godoy, F.R. Diaz, S. Lefrant: J. Appl. Poly. Sci. 82, 2042 (2001) H. Biederman: J. Vac. Sci. Technol. A 18, 1642 (2000) T.R. Gengenbach, H.J. Griesser: J. Polym. Sci. 36, 985 (1998) X. Cui, J. Hetke, J.A. Wiler, D.J. Anderson, D.C. Martin: Sens. Actuators A 93, 8 (2001) 32 A. Kiesow, A. Heilmann: Thin Solid Films 343, 338 (1999) 33 R.K. Singh, N. Biunno, J. Narayan: Appl. Phys. Lett. 53, 1013 (1988) 34 J.T. Cheung, H. Sankur: CRC Critical Reviews in Solid State and Materials Sciences 15, 63 (1988) 35 J.M. Fitz-Gerald, P.D. Rack, T.A. Trottier, M. Ollinger, S.J. Pennycook, H. Gao, R.K. Singh: J. Appl. Phys. 86, 1759 (1999) 36 J.M. Fitz-Gerald, T.A. Trottier, P.H. Holloway, R.K. Singh: Appl. Phys. Lett. 72, 1838 (1998) 37 D.B. Chrisey, J.S. Horwitz: Thin Solid Films 206, 111 (1991) 38 D. Lowndes, D.B. Geohegan, A.A. Puretzky, D.P. Norton, C.M. Rouleau: Science 273, 898 (1996) 39 D.M. Bubb, M.R. Papantonakis, B. Toftmann, J.S. Horwitz, R.A. McGill, D.B. Chrisey, R.F. Haglund Jr.: J. Appl. Phys. 91, 9809 (2002) 40 D.M. Bubb, M.R. Papantonakis, J.S. Horwitz, R.F. Haglund Jr., B. Toftmann, R.A. McGill, D.B. Chrisey: Chem. Phys. Lett. 352, 135 (2002) 41 R.A. McGill, D.B. Chrisey: Patent, Navy case No. 78, 117 (1999) 42 L. Zhigilei, E. Leveugle, B.J. Garrison, Y.G. Yingling, M. Zeifman: Chem. Rev. 103, 321 (2003) 43 K. Dreisewerd: Chem. Rev. 103, 395 (2003) 44 Y.P. Li, X.Y. Zhang, Z.H. Gu, Z.H. Zhou, W.F. Yuan, J.J. Zhou, J.H. Zhu, X.J. Gao: J. Controlled Release 71, 203 (2001) 45 D.M. Bubb, P.K. Wu, J.S. Horwitz, J.H. Callahan, M. Galicia, A. Vertes, R.A. McGill, E.J. Houser, B.R. Ringeisen, D.B. Chrisey: J. Appl. Phys. 91, 2055 (2002) 46 J.S. Hrkach, M.T. Peracchia, A. Domb, N. Lotan, R. Langer: Biomaterials 18, 27 (1997) 47 S.L. Murov: Handbook of Photochemistry (Marcel Dekker, Inc., 1973) 48 W. Schnabel: Polymer Degradation: Principles and Practical Applications (Hanser, 1982) 49 D.M. Bubb, B. Toftmann, R.F. Haglund Jr., J.S. Horwitz, M.R. Papantonakis, R.A. McGill, P.K. Wu, D.B. Chrisey: Appl. Phys. A 74, 123 (2002) 50 R. Srinivasan, B. Braren: Chem. Rev. 89, 1303 (1989) 51 R. Srinivasan, B. Braren, R.W. Dreyfus: J. Appl. Phys. 61, 372 (1986) 52 G.M. Davis, M.C. Gower: J. Appl. Phys. 61, 2090 (1987) 53 G.B. Blanchet, S.I. Shah: Appl. Phys. Lett. 62, 1026 (1993) 54 P.E. Dyer, D.M. Karnakis: Appl. Phys. Lett. 64, 1344 (1993) 55 L.V. Zhigilei, B.J. Garrison: J. Appl. Phys. 88, 1281 (2000) 56 T.E. Itina, L.V. Zhigilei, B.J. Garrison: Nucl. Instrum. Methods Phys. Res., Sect. B 180, 238 (2001) 57 R.S. Dingus, R.J. Scammom: SPIE Proc. 1427, 45 (1991) 58 V.Y. Kurbatov: Zh. Obshch. Kim. 18, 372 (1948) 59 W.T. Richards, J.H. Wallace Jr.: J. Am. Chem. Soc. 54, 2705 (1932) 60 J.W. Willams, F. Daniels: J. Am. Chem. Soc. 46, 903 (1924) 61 R. Cramer, R.F. Haglund Jr., F. Hillenkamp: J. Mass Spectrom. Ion Processes 169/170, 51 (1997) 62 E. Leveugle, D. Ivanov, L.V. Zhigilei: Appl. Phys. A 79, 1643 (2004) 63 L.V. Zhigilei, B.J. Garrison: Appl. Phys. A 69[Suppl.], 75 (1999)