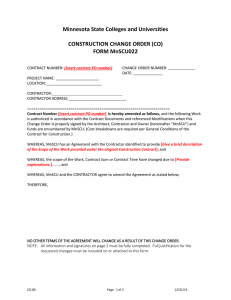

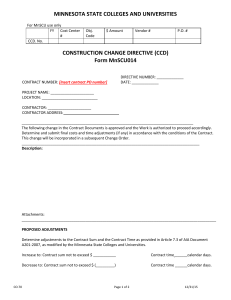

FACILITIES DESIGN STANDARDS

advertisement