WHO guidelines on good manufacturing practices for blood establishments Annex 4

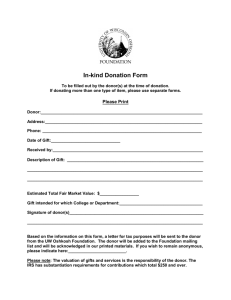

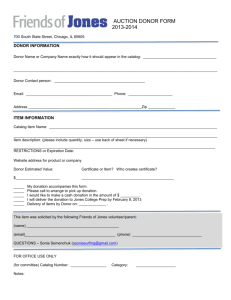

advertisement