Math for Manufacturing Lesson Plan

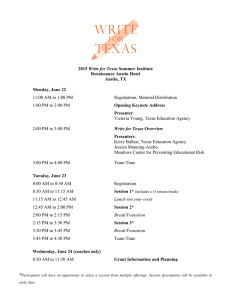

advertisement

Math for Manufacturing Practicum in Manufacturing Lesson Plan Performance Objective Upon completion of this lesson, each student will gain a better understanding regarding how to solve math problems as required in a manufacturing environment by completing the activities and quiz. Specific Objectives The student will be able to Identify specific lengths on a standard tape measure Add and subtract fraction problems Add and subtract problems with decimals Convert fractions to decimals Terms English Standard Measurement System- the system of measurement used in the United States (adopted from the English imperial measurements) based on the number 12 and inches, feet, and yards as basic standards of lengths. Whole number- a number that has no fraction or decimal; for example, 0, 1, 2, 3, 4, 5, 6, 7, 8, etc. Decimal- is defined as a system of numbers or currency where everything is based on the number 10, or on parts of 10. Simplify- used in math to combine numbers into lower or fewer numbers. Reducing- occurs when a fraction is changed into its lowest terms; for example, 3/6 can be reduced to 1/2. Prime number- a number that can only be divided by itself and the number one. Proper fraction- a fraction written where the numerator is less than the denominator. Positive number- a number with a value greater than zero. Numerator- the top number or symbol of a fraction. Mixed number- a number that contains both a whole number and a fraction. Lowest common denominator- to reduce a fraction; where the smallest number is found that can be evenly divided by all denominators in the problem. Fraction- a set of numbers that expresses part of a whole; it contains a numerator and a denominator. Difference- the result found when numbers are subtracted. Improper fraction- a fraction where the numerator is larger than the denominator. Time This lesson should take approximately 12 class periods (45 minutes each). Preparation TEKS Correlations 1 Copyright © Texas Education Agency, 2015. All rights reserved. This lesson, as published, correlates to the following TEKS. Any changes/alterations to the activities may result in the elimination of any or all of the TEKS listed. Practicum in Manufacturing 130.330 (c) o (2) The student applies concepts of critical thinking and problem solving. The student is expected to: (A) analyze elements of a problem to develop creative and innovative solutions; (B) critically analyze information to determine value to the problem-solving task; (C) compare and contrast alternatives using a variety of problem-solving and criticalthinking skills; and (D) conduct technical research to gather information necessary for decision making. English Language Arts and Reading, English I • 110.31 (b) o (24) Listening and Speaking/Listening. Students will use comprehension skills to listen attentively to others in formal and informal settings. Students will continue to apply earlier standards with greater complexity. Students are expected to: (A) listen responsively to a speaker by taking notes that summarize, synthesize, or highlight the speaker's ideas for critical reflection and by asking questions related to the content for clarification and elaboration; (B) follow and give complex oral instructions to perform specific tasks, answer questions, solve problems, and complete processes; and (C) evaluate the effectiveness of a speaker's main and supporting ideas. Discrete Mathematics for Problem Solving • 111.46 (c) o (1) Mathematical process standards. The student uses mathematical processes to acquire and demonstrate mathematical understanding. The student is expected to: (A) apply mathematics to problems arising in everyday life, society, and the workplace; (B) use a problem-solving model that incorporates analyzing given information, formulating a plan or strategy, determining a solution, justifying the solution, and evaluating the problem-solving process and the reasonableness of the solution; (C) select tools, including real objects, manipulatives, paper and pencil, and technology as appropriate, and techniques, including mental math, estimation, and number sense as appropriate, to solve problems; (D) communicate mathematical ideas, reasoning, and their implications using multiple representations, including symbols, diagrams, graphs, and language as appropriate; (E) create and use representations to organize, record, and communicate mathematical ideas; (F) analyze mathematical relationships to connect and communicate mathematical ideas; and (G) display, explain, and justify mathematical ideas and arguments using precise mathematical language in written or oral communication. 2 Copyright © Texas Education Agency, 2015. All rights reserved. Accommodations for Learning Differences It is important that lessons accommodate the needs of every learner. These lessons may be modified to accommodate your students with learning differences by referring to the files found on the Special Populations page of this website (cte.unt.edu). Preparation Review and become familiar with the terminology, website links, and the slide presentation. Have materials, slide presentation, and websites ready prior to the start of the lesson. References Webster’s new compact office dictionary (2003). New York, NY: Houghton Mifflin Harcourt Publishing Co. Instructional Aids Math for Manufacturing slide presentation and notes Warm-up Activity (Slide 3) Manufacturing Math Terms and Definitions handout for each student Manufacturing Math Terms and Definitions Answer Key Manufacturing Math Quiz for each student Manufacturing Math Quiz Answer Key Additional Manufacturing Math Activities o Drawings I, II, III, IV o Understanding a Drawing o Understanding a Drawing Answer Key o Production Cost o Machining: Punch Plans and Rubrics o Measurement Worksheet o Precision Measurement Worksheet o Manufacturing Math Introduction The main purpose of this lesson is to give students an understanding of math calculations commonly used in the manufacturing workplace. Say o Accurate math calculations are critical in a manufacturing environment. Ask o What math calculations do you use in your everyday life? Say o Math calculations help ensure the correct quantity of raw materials are purchased for the production process. 3 Copyright © Texas Education Agency, 2015. All rights reserved. Show o Photos of manufacturing processes and raw material storage locations. Outline MI OUTLINE I. NOTES TO TEACHER Introduction of lesson A. Manufacturing Math slide presentation B. Bell work activity C. Warm-up activity Begin the Manufacturing Math slide presentations. I. How to use a standard measuring ruler Warm-up Activity: Leadership Terms and Definitions handout II. Calculating fractions A. Addition B. Subtraction III. Calculating decimals A. Addition V. Subtraction A. Converting fractions to decimals VI. Manufacturing Math Quiz VII. Assign additional math activities A. Drawings I, II, III, IV B. Understanding a Drawing C. Production Cost D. Machining: Punch Plans and Rubrics E. Measurement Worksheet F. Precision Measurement Worksheet G. Manufacturing Math Have students work on the Bell Work Activity. (Slide 2) Students (in pairs) will teach each other the terms and definitions. They may do computer-based research to look up the meaning. (Slide 3) Each slide is meant to be discussed. Have some background knowledge, and challenge the students to make some contributions to the discussion. Administer quiz and grade using answer key. Explain and assign the additional math assignments. 4 Copyright © Texas Education Agency, 2015. All rights reserved. Multiple Intelligences Guide Existentialist Interpersonal Intrapersonal Kinesthetic/ Bodily Logical/ Mathematical Musical/Rhythmic Naturalist Verbal/Linguistic Visual/Spatial Application Guided Practice The teacher will present the Math for Manufacturing slide presentation and will have the students complete the assignments. Independent Practice Students will complete the math assignments and worksheets. Summary Review The standard increments on a ruler The differences in calculating like and unlike fractions Converting fractions to decimals using a calculator Evaluation Informal Assessment The teacher monitors during activities to check for understanding. Formal Assessment Daily grade on assignments Manufacturing Math Quiz Extension Students will research and write a 150-word essay on one of the most commonly used computer software programs, which is used by top manufacturing companies to track and calculate the quantities of raw materials used during the manufacturing process. 5 Copyright © Texas Education Agency, 2015. All rights reserved. Name_____________________________________Date_______________________Class____________ Math Terms and Definitions Directions Use the internet to research the definitions to the math terms below. 1. Decimal 2. Difference 3. English Standard Measurement System 4. Fraction 5. Improper fraction 6. Lowest common denominator 7. Mixed number 8. Numerator 9. Positive number 10. Prime number 11. Proper fraction 12. Reducing 13. Simplify 14. Whole number 6 Copyright © Texas Education Agency, 2015. All rights reserved. Math Terms and Definitions Answer Key 1. English Standard Measurement System- the system of measurement used in the United States (adopted from the English imperial measurements) based on the number 12 and inches, feet, and yards as basic standards of lengths. 2. Whole number- a number that has no fraction or decimal; for example, 0, 1, 2, 3, 4, 5, 6, 7, 8, etc. 3. Simplify- used in math to combine numbers into lower or fewer numbers. 4. Reducing- occurs when a fraction is changed into its lowest terms; for example, 3/6 can be reduced to 1/2. 5. Prime number- a number that can only be divided by itself and the number one. 6. Proper fraction- a fraction written where the numerator is less than the denominator. 7. Positive number- a number with a value greater than zero. 8. Numerator- the top number or symbol of a fraction. 9. Mixed number- a number that contains both a whole number and a fraction. 10. Lowest common denominator- required to reduce a fraction; where the smallest number is found that can be evenly divided by all denominators in the problem. 11. Fraction- a set of numbers that expresses part of a whole; it contains a numerator and a denominator. 12. Difference- the result found when numbers are subtracted. 13. Improper fraction- a fraction where the numerator is larger than the denominator. 14. Decimal- a numerical system where everything is based on the number 10, or on parts of 10. 7 Copyright © Texas Education Agency, 2015. All rights reserved. Name_____________________________________Date_______________________Class____________ Math Quiz Directions Name the fraction at each arrow in each diagram below. 1. ___________________ 2. __________________ Complete the calculations below. Find the least common denominator and reduce the answers where applicable. 3. 4. _1 + _3 = ____ 6 8 12 + 14 11 11 = 5. 11 – 8_ = 13 13 6. _8 - _7 = 13 18 ____ ____ ____ 8 Copyright © Texas Education Agency, 2015. All rights reserved. Complete the calculations below. 7. 6.135 + 9.044 8. 91.274 + 34.312 9. 95.24 - 48.56 10. 59.984 - 46.394 Convert the following fractions to decimals. 11. 1/16 = _____ 12. 7/8 = _____ 9 Copyright © Texas Education Agency, 2015. All rights reserved. Math Quiz Answer Key Directions Name the fraction at each arrow in the diagrams below. 1. Answer: 15/16 2. Answer: 9/16 Complete the calculations below. Find the Least common denominator and reduce the answers where applicable. 3. _1 + _3 = ____ 6 8 4. 12 + 14 11 11 = 5. 11 - _8 13 13 = 6. _8 - _7 = 13 18 ____ Answer: 13 24 Answer: 26 11 ____ Answer: _3 13 ____ Answer: _53 234 Or, 2 and _4 11 10 Copyright © Texas Education Agency, 2015. All rights reserved. Complete the calculations below. 7. 6.135 + 9.044 Answer: 15.179 8. 91.274 + 34.312 Answer: 125.595 9. 95.24 - 48.56 Answer: 46.68 10. 59.984 - 46.394 Answer: 13.590 Convert the following fractions to decimals. 11. 1/16 = ___ 12. 7/8 = ___ Answer: .0625 Answer: .875 11 Copyright © Texas Education Agency, 2015. All rights reserved. Drawing I - Punch Drawing II - Small Hammer 12 Copyright © Texas Education Agency, 2015. All rights reserved. Drawing III – Tablet Computer Stand Drawing IV – Welded Angle Shelf 13 Copyright © Texas Education Agency, 2015. All rights reserved. Name __________________________________________Date_______________ Period ____ Understanding a Drawing or Plan Directions Refer to Drawing I, II, III, and IV and answer the questions. Punch 1. What length are the punches? ______________ 2. What is the diameter of the punch? ______________ 3. What is the length of the taper on the center punch? ______________ Small Hammer 4. How many parts does the hammer have? ______________ 5. What is the size of the metal used to make the handle? ______________ 6. What size piece of metal will it take to make the hammer head? ______________ 7. What do the numbers ¼ - 20 X ¾” mean? ______________ ___________________________________________________________________ 8. What is the total length of the hammer assembled? ______________ Tablet Computer Stand 9. What is the size of the piece of sheet metal needed to make the stand? _____________ 10. How tall will the stand be when bent into shape? _____________ Welded Angle Shelf 11. How many pieces of metal are needed to produce the shelf? ______________ 12. What is the total amount of angle used to make the shelf? ______________ 13. What size piece of 3/16” plate metal will be used for the shelf bottom? ______________ 14. The cost of 3/16” plate is $0.50 per foot. What is the cost of the shelf bottom? ______________ 15. The cost of ¾” angle iron is $0.25 per foot. What is the cost for the shelf frame? ______________ 14 Copyright © Texas Education Agency, 2015. All rights reserved. Understanding a Drawing or Plan Answer Key Directions Refer to Drawing I, II, III, and IV and answer the questions. Punch 1. What length are the punches? ___5 inches____ 2. What is the diameter of the punch? ____1/2 inch____ 3. What is the length of the taper on the center punch? ___1 ½ inches___ Small Hammer 4. How many parts does the hammer have? ___3__________ 5. What is the size of the metal used to make the handle? __1/2” dia. by 3”_ 6. What size piece of metal will it take to make the hammer head? _3/4” X ¾” X 3”__ 7. What do the numbers ¼ - 20 X ¾” mean? ______________ __1/4” by 20 threads ¾” long_______________________________________________ 8. What is the total length of the hammer assembled? Tablet Computer Stand __8 ¼”________ (The threads screw in 1 ½” 9 ¾” – 1 ½”) 9. What is the size of the piece of sheet metal needed to make the stand? __6” X 17”____ 10. How tall will the stand be when bent into shape? ____5”_______ Welded Angle Shelf 11. How many pieces of metal are needed to produce the shelf? _____9________ 12. What is the total amount of angle used to make the shelf? _204” / 17’_____ 13. What size piece of 3/16” plate metal will be used for the shelf bottom?__12” X 44”____ 14. The cost of 3/16” plate is $0.50 per foot. What is the cost of the shelf bottom? ___$1.83______ 15. The cost of ¾” angle iron is $0.25 per foot. What is the cost for the shelf frame? ____$4.25_____ 15 Copyright © Texas Education Agency, 2015. All rights reserved. Name __________________________________________Date_______________ Period ____ Production Cost Production Cost The customer wants 1000 drive punches manufactured. You will have to calculate the total cost to manufacture the punches. Use the chart below to figure the cost. Show your work. 1/8 CHAMPER TAPER TO 1/4 DIA. 1 1/4 /2 DIA. TOOL STEEL ROD 5 DRIVE PUNCH Materials ½” X 12’ tool steel bar Cost $25.00 Production Cost Chart Operations Cost Machine ¼” dia. $0.50 each Time 2 minute each Cut off $0.05 each ½ minute each Heat treating $0.25 each 3 minute each Polishing $0.10 each 5 minute each The cut off operation waste ¼” of material for each cut. ______________________________________________________________________________________ 1. How many bars of ½” are needed to make 1000 punches? __________________ (Round up to a full 12’ bar) 2. How much time does it take to make one punch? __________________ 3. How much does it cost to make one punch? __________________ 4. What is the cost of the metal to make one punch? __________________ 5. How many punches can be made from a 12 foot bar? __________________ 6. What is the total cost to make all 1000 punches? __________________ 7. What process takes the longest time to perform? __________________ 8. What could be done to decrease production time? __________________ ______________________________________________________________________________ 9. The production time to complete all punches is 10 days. Office charges and electricity are added at $100 per day. What are the costs of the 1000 punches? __________________ 16 Copyright © Texas Education Agency, 2015. All rights reserved. Production Cost Answer Key Production Cost The customer wants 1000 drive punches manufactured. You will have to calculate the total cost to manufacture the punches. Use the chart below to figure the cost. Show your work. 1/8 CHAMPER TAPER TO 1/4 DIA. 1 1/4 1/2 DIA. TOOL STEEL ROD 5 DRIVE PUNCH Materials ½” X 12’ tool steel bar Cost $25.00 Production Cost Chart Operations Cost Machine ¼” dia. $0.50 each Cut off Heat treating Polishing The cut off operation waste ¼” of material for each cut. $0.05 each $0.25 each $0.10 each Time 2 minute each ½ minute each 3 minute each 5 minute each _____________________________________________________________________________ 1. How many bars of ½” are needed to make 1000 punches? _____35___________ (Round up to a full 12’ bar) 2. How much time does it take to make one punch? _____10.5 minutes_____ 3. How much does it cost to make one punch? ______$0.90________ 4. What is the cost of the metal to make one punch? ______$0.89________ 5. How many punches can be made from a 12 foot bar? ______28____________ 6. What is the total cost to make all 1000 punches? ____$1790___________ 7. What process takes the longest time to perform? __Polishing___________ 8. What could be done to decrease production time? __________________ ____Shorten the polishing time by using more people or machines________________________ 9. The production time to complete all punches is 10 days. Office charges and electricity are added at $100 per day. What are the costs of the 1000 punches? ____$2790_________ 17 Copyright © Texas Education Agency, 2015. All rights reserved. Name ___________________________________________ Date_______________ Period ____ Machining: Punch Plans and Rubrics Center Punch Measurement Section Drive Punch Points Measurement Section Total length Total length End taper End taper Taper length ¼” dia. end Finish Finish Grade Grade Points 18 Copyright © Texas Education Agency, 2015. All rights reserved. Name _________________________________________ Date_______________ Period ____ Hammer Measurement Section Points Measurement Section Handle length Head length Handle taper Head taper Handle thread Assemble Shaft length Finish Shaft threads Grade Points Shaft threads 19 Copyright © Texas Education Agency, 2015. All rights reserved. Name ______________________________________ Date________________ Period ______ Measurement Worksheet Directions Use the diagram below to complete the measurement shown at each arrow. 1. ________ 6. ________ 2. ________ 7. ________ 3. ________ 8. ________ 4. ________ 9. ________ 5. ________ 10. ________ 20 Copyright © Texas Education Agency, 2015. All rights reserved. Measurement Worksheet Answer Key Directions Use the diagram below to complete the measurement shown at each arrow. 1. __7/16______ 6. __2 and 1/4______ 2. __13/16______ 7. __2 and 1/2______ 3. __1 and 1/16______ 8. __2 and 7/8______ 4. __1 and 9/16______ 9. __3 and 3/8______ 5. __1 and 15/16______ 10. __3 and 13/16___ __ 21 Copyright © Texas Education Agency, 2015. All rights reserved. Measurement Chart Fractions / Decimals / Metric Equivalents Sheet Metal Gauge Size Chart Fraction 1/16 1/8 3/16 1/4 5/16 3/8 7/16 1/2 Decimal 0.0625 0.125 0.1875 0.250 0.3125 0.375 0.4375 0.500 Metric 1.587 3.175 4.762 6.350 7.937 9.525 11.113 12.700 Fraction 9/16 5/8 11/16 3/4 13/16 7/8 15/16 1 Decimal 0.5625 0.625 0.6875 0.750 0.8125 0.875 0.9375 1.0000 Metric 14.287 15.875 17.462 19.050 20.637 22.225 23.812 25.400 Inch 0.0478 0.0359 0.0299 0.0239 0.0179 0.0149 0.0120 Metric 1.204 0.912 0.759 0.607 0.455 0.378 0.305 Standard Steel Gauge Gauge 3 6 8 10 12 14 16 Inch 0.2391 0.1943 0.1644 0.1345 0.1046 0.0747 0.0598 Metric 6.073 4.935 4.176 3.416 2.657 1.897 1.519 Gauge 18 20 22 24 26 28 30 Cutting Speed Chart Material Type Feet per Minute Meter per Minute Mild Steel 100-125 30-38 Cast Iron (medium) 60-80 18-24 Alloy Steels 65-120 20-37 Carbon Steel 70-130 21-40 Stainless Steels 75-130 23-40 Bronzes 80-150 80-150 Aluminum 250-350 75-210 Brass 300-700 90-210 22 Copyright © Texas Education Agency, 2015. All rights reserved. Name ______________________________________ Date___________ Period ___ Precision Measurement Worksheet Convert the following fractions to equivalent decimals. 1. ½ = _____________ 6. 1/16 = _____________ 2. ¾ = _____________ 7. 3/8 = _____________ 3. 1/8 = _____________ 8. 9/16 = _____________ 4. ¼ = _____________ 9. 15/16 = _____________ 5. 7/8 = _____________ 10. 3/16 = _____________ Add the following measurements. 11. 0.250 + 0.500 = ______________ 16. 0.0625 +0.125 = ______________ 12. 0.125 + 0.250 = ______________ 17. 0.3125 + 0.0625 = ______________ 13. 0.500 + 0.250 = ______________ 18 0.4375 + 0.500 = ______________ 14. 0.75 + 0.125 = ______________ 19. 0.625 + 00.625 = ______________ 15. 0.500 + 0.375 = ______________ 20. 0.500 + 0.750 = ______________ Calculate the revolutions per minute for the following parts. (Use the chart for the cutting speeds for the material.) 21. The material is brass with a diameter of 2.25 inches. 22. The material is aluminum with a diameter of 3.5 inches. 23. The material is mild steel with a diameter of 3.5 inches. 24. The material is mild steel with a diameter of ¾ of an inch. 25. The material is carbon steel with a diameter of 3/8 of an inch. 23 Copyright © Texas Education Agency, 2015. All rights reserved. Precision Measurement Worksheet Answer Key Convert the following fractions to equivalent decimals. 1. ½ = ____0.500____ 6. 1/16 = ____0.0625____ 2. ¾ = ____0.750____ 7. 3/8 = ____0.1875____ 3. 1/8 = ____0.125____ 8. 9/16 = ____0.5625____ 4. ¼ = ____0.250____ 9. 15/16 = ____0.9375____ 5. 7/8 = ____0.875____ 10. 3/16 = ____0.1875____ Add the following measurements 11. 0.250 + 0.500 = ____0.750____ 11. 0.250 + 0.500 = ______________ 12. 0.125 + 0.250 = ____0.375____ 12. 0.125 + 0.250 = ______________ 13. 0.500 + 0.250 = ____0.750____ 13. 0.500 + 0.250 = _____________ 14. 0.75 + 0.125 = ____0.875____ 16. 0.0625 +0.125 = ____0.1875____ 15. 0.500 + 0.375 = ____0.875____ 20. 0.250 + 0.750 17. 0.3125 + 0.0625 = ____0.3750____ 18 0.4375 + 0.500 = ____0.9375____ 19. 0.625 + 00.625 = ____1.250____ = ____1.000____ Calculate the revolutions per minute for the following parts. (Use the chart for the cutting speeds for the material.) 21. The material is brass with a diameter of 2.25 inches. RPM = 300 * 4 / 2.25 RPM = 533 22. The material is aluminum with a diameter of 3.5 inches. RPM = 250 * 4 / 3.5 RPM = 285 23. The material is mild steel with a diameter of 3.5 inches. RPM = 100 * 4 / 3.5 RPM = 114 24. The material is mild steel with a diameter of ¾ of an inch. RPM = 100 * 4 / 0.75 RPM = 533 25. The material is carbon steel with a diameter of 3/8 of an inch. RPM = 70 * 4 / 0.375 RPM = 746 24 Copyright © Texas Education Agency, 2015. All rights reserved. Name___________________________________________ Period__________ Date___________________ Manufacturing Math Flexible Manufacturers are to package 3,000 sets of tools. It takes three minutes to organize and package the sets. If five people are working to package the sets how much time will it take to complete the job? The workers are paid $9.50 per hour. What is the labor cost for this job? CNC lathe machine time cost $25 dollars per hour to operate. The machine produces 400 parts in an eight hour shift. What is the machining cost per part? Number of hours worked _____________ Labor Cost _____________ Answer ________________________________________ The Flexible Manufacturers are asked to produce 1,000 4 X 6 plastic frames. The frames are made from a sheet of 1/4 thick plastic 4” wide and 14” long. The sheet material used to make these frames is 48” wide and 96” long. How many sheets of material will it take to produce the order of frames? Each sheet costs $25.00 and labor cost per frame is $.75. What is the cost of labor? What is the cost of the materials? Number of sheets needed for job? _____________ What is the material cost per frame? ___________ What is the total cost per frame? _____________ 25 Copyright © Texas Education Agency, 2015. All rights reserved. Name___________________________________________ Period__________ Date___________________ Board Footage Use the measurements on the drawing to fill in the chart. The chart will help you with the measurements for finding the board footage for the bookcase. 33 3/8” 11 A C V B Board Footage __T X W X L__ 1” X 12” X 12” 12 All material is 3/4” in thickness* except the back is 1/4” plywood. 12 C 12 C 12 C Use this space to show your work. Use the back if needed. C B 51 10 3 D 321 Part Name Quality Thickness Width Length Board Footage A Top B Side C Shelf D Foot Back *Material less than 1” in thickness is figured at 1” in the formula. 26 Copyright © Texas Education Agency, 2015. All rights reserved. Name___________________________________________ Period__________ Date___________________ Material Cost Answer the following questions in the answer blanks. The blank space below the question is a place for you to figure the answer. Smith Lumber Company filled an order of 45 sheets of oak plywood. The sheets have 32 square feet in them (4’ X 8’ sheet). The company was going to produce cabinets out of the plywood. Each cabinet needed 15 square feet of plywood. How many cabinets can be built out of the plywood ordered? Answer____________________________________ Conner Nut and Bolt Company received an order for 300 of each of the items listed in the chart. The chart shows the cost of each. Figure the cost of the order. Part Nut Lock Washer Flat Washer Bolt Cost $0.25 $0.12 $0.04 $0.75 Answer________________________________ ____ ABC Cabinet Company was contracted to build fifty wood framed mirrors. The mirror frame size is twenty four inches tall by thirty six inches long. What is the cost to make the mirror if the frame material cost 75 cents per foot and the mirror glass is a dollar per square foot? Answer____________________________________ 27 Copyright © Texas Education Agency, 2015. All rights reserved. Name___________________________________________ Period__________ Date___________________ Figure the board footage for the Shelf Coat Rack. A C B B D Shelf Coat Rack All material is 3/4” thick. 24 6 1 1/2 dowels 1/2” dia. 3” long 5 3 6 4 5 4 1/2 5 2 22 1/2 Part Quality Name A Top B Side C Back D 3 Dowels Thickness 1/2 ” dia. Width Length Board Footage 4” Answer_______________________________________ 28 Copyright © Texas Education Agency, 2015. All rights reserved. Name___________________________________________ Period__________ Date___________________ Manufacturing Math Answer Key Flexible Manufacturers are to package 3,000 sets of tools. It takes three minutes to organize and package the sets. If five people are working to package the sets how much time will it take to complete the job? The workers are paid $9.50 per hour. What is the labor cost for this job? Answer Labor Cost: 3,000 sets X 3 minutes each = 9,000 minutes for all sets $9.50 X 30 hours = $285 per person 9.000 minutes / 5 people = 1800 minutes $285 per person X 5 people = $1,425 1800 minutes / 60 minutes per hour = 30 hours Number of hours worked ___30 hours___ Labor Cost ___$1,425___ CNC lathe machine time cost $25 dollars per hour to operate. The machine produces 400 parts in an eight hour shift. What is the machining cost per part? Answer 400 parts / 8 hours = 50 parts per hour $25.00 per hour / 50 parts per hour = $0.50 per part Answer ___$0.50 per part___ The Flexible Manufacturers are asked to produce 1,000 4 X 6 plastic frames. The frames are made from a sheet of 1/4 thick plastic 4” wide and 14” long. The sheet material used to make these frames is 48” wide and 96” long. How many sheets of material will it take to produce the order of frames? Each sheet cost $25.00 and labor cost per frame is $.75. What is the cost of labor? What is the cost of the materials? 29 Copyright © Texas Education Agency, 2015. All rights reserved. Answer 4” X 14” = 56 sq inch of plastic per frame 56” X 1000 = 56,000 total sq inches plastic needed 48” X 96” = 4608 sq inches of plastic per sheet 56,000 / 4608 = 12.15 sheets of plastic 4608 / 56 = 82 frames per sheet $25.00 / 82 = 0.30 cost of plastic per frame $0.30 + $0.75 = $1.05 total cost per frame Number of sheets needed for job? __12.15____ What is the material cost per frame? __$0.30___ What is the total cost per frame? __$1.05_____ 30 Copyright © Texas Education Agency, 2015. All rights reserved. Name___________________________________________ Period__________ Date___________________ Board Footage Answer Key Use the measurements on the drawing to fill in the chart. The chart will help you with the measurements for finding the board footage for the bookcase. 33 3/8” 11 A C V Board Footage __T X W X L__ 1” X 12” X 12” 12 All material is 3/4” in thickness* except the back is 1/4” plywood. 12 C Use this space to show your work. Use the back if needed. 12 C Answer 12 C Top 1 * 11 * 33 ÷ 144 = 2.52 3 B Foot 1* 3 * 32 ÷ 144 = 0.67 Back 32 * 51 = 11.33 sq ft B 51 10 D 32 Side 1 * 10 * 51 ÷144 = 3.54 *2 = 7.08 Shelves 1 * 10 * 32 ÷ 144 = 2.22 * 4 = 8.89 C Part Quality Thickness Name Width Length Board Footage A Top 1 3/4” 11” 33” 2.52 bd ft B Side 2 3/4” 10” 51” 7.08 bd ft C Shelf 4 3/4” 10” 32” 8.89 bd ft D Foot 1 3/4” 3” 32” 0.67 bd ft Back 1 1/4” 32” 51” 11.33 sq ft *Material less than 1” in thickness is figured at 1” in the formula. 31 Copyright © Texas Education Agency, 2015. All rights reserved. Name___________________________________________ Period__________ Date___________________ Material Cost Answer Key Answer the following questions in the answer blanks. The blank space below the question is a place for you to figure the answer. Smith Lumber Company filled an order of 45 sheets of oak plywood. The sheets have 32 square feet in them (4’ X 8’ sheet). The company was going to produce cabinets out of the plywood. Each cabinet needed 15 square feet of plywood. How many cabinets can be built out of the plywood ordered? Answer Answer __96 cabinets__ 45 * 32 = 1440 sq ft total sq ft of order 1440 ÷ 15 = 96 cabinets Conner Nut and Bolt Company received an order for 300 of each of the items listed in the chart. The chart shows the cost of each. Figure the cost of the order. Part Cost Answer Nut $0.25 .25 + .12 + .04 + .75 = 1.16 per group Lock $0.12 Washer $1.16 * 300 = $346. Flat $0.04 Washer Answer ___$346___ Bolt $0.75 ABC Cabinet Company was contracted to build fifty wood framed mirrors. The mirror frame size is twenty four inches tall by thirty six inches long. What is the cost to make the mirror if the frame material cost 75 cents per foot and the mirror glass is a dollar per square foot? Answer ___$12.40___ 24” + 36” + 24” + 36” = 120” inches perimeter 120” ÷ 12” = 10’ changing inches to feet 10’ * $0.75 = $7.50 cost of wood for the frame 22” * 32” = 704 sq inches 704” ÷ 144 = 4.9 sq ft 4.9 * $1.00 = $4.90 cost per mirror $7.50 + $4.90 = $12.40 total cost for mirror 32 Copyright © Texas Education Agency, 2015. All rights reserved. Name___________________________________________ Period__________ Figure the board footage for the Shelf Coat Rack. Date___________________ Answer Key A C B B D Shelf Coat Rack All material is 3/4” thick. 24 6 1 1/2 dowels 1/2” dia. 3” long 5 3 6 4 5 4 1/2 5 2 22 1/2 Part Quality Name A 1 Top B 2 Side C 1 Back D 3 Dowels Thickness 1” Width Length 6” 24” Board Footage 1 bd ft 1” 5” 6” .42 bd ft 1” 6” 22.5” .94 bd ft 1/2 ” dia. A Top 1” X 6” X 24” ÷ 144” = 1.00 bd ft B Side 1” X 5” X 6” ÷ 144” = 0.21” 2 parts .21” X 2 = 0.42 bd ft C Back 1” X 6” X 22.5” ÷ 144” = 0.94 bd ft Total = 2.36 bd ft 4” Answer ___2.36 bf___ 33 Copyright © Texas Education Agency, 2015. All rights reserved.