Lesson Plan Manufacturing Processes Flexible Manufacturing

advertisement

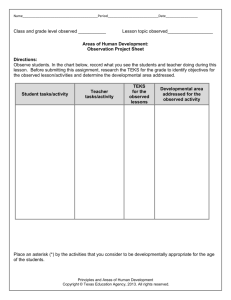

Manufacturing Processes Flexible Manufacturing Lesson Plan Performance Objective At the end of the lesson, students will be able to describe four types of manufacturing processes. Students will demonstrate how the lab could benefit from implementing one of these processes by developing a presentation that matches the criteria in the Manufacturing Processes Rubrics. Specific Objectives Define four different manufacturing processes (5S, Lean Manufacturing, Just-in-Time, and Six Sigma) Describe four different manufacturing processes Examine the flexible lab for possible implementation one of the processes Identify changes to improve the lab Draw diagrams of lab area for explanation of manufacturing process Take photos of lab for explanation of manufacturing process Create a team presentation and present to the class Terms 5S - a system to organize the workplace to be more productive. Lean Manufacturing - a system that bases production on customer needs. Just-in-Time - a manufacturing strategy where inventories are delivered to production area when needed. Six Sigma - a manufacturing process for improving quality to near perfection. Time It should take approximately four classes at 45 minutes each to teach the lesson. Preparation TEKS Correlations This lesson, as published, correlates to the following TEKS. Any changes/alterations to the activities may result in the elimination of any or all of the TEKS listed. Flexible Manufacturing 130.327 (c) o (1) The student describes the importance of teamwork, leadership, integrity, honesty, work habits, and organizational skills. The student is expected to: (G) use time-management techniques to develop work schedules. Copyright © Texas Education Agency, 2014. All rights reserved. 1 130.327 (c) o (2) The student explores the employability characteristics of a successful worker in the global economy. The student is expected to: (E) communicate effectively with others in the workplace to clarify objectives. Interdisciplinary Correlations 113.41 United States History Studies Since 1877 o (27) Science, technology, and society. The student understands the impact of science, technology, and the free enterprise system on the economic development of the United States. The student is expected to: (C) understand the impact of technological and management innovations and their applications in the workplace and the resulting productivity enhancements for business and labor such as assembly line manufacturing, time-study analysis, robotics, computer management, and just-in-time inventory management. Occupational Correlation (O*Net – www.onetonline.org/) Job Title: Industrial Production Managers O*Net Number: 11-3051.00 Reported Job Titles: Area Plant Manager, General Production Manager, Manufacturing Coordinator, Manufacturing Manager, Plant Manager, Plant Senior Manager, Product Line Manager, Production Control Manager, Production Manager, Sub Plant Manager Tasks Review processing schedules or production orders to make decisions concerning inventory requirements, staffing requirements, work procedures, or duty assignments, considering budgetary limitations and time constraints. Direct or coordinate production, processing, distribution, or marketing activities of industrial organizations. Develop or implement production tracking or quality control systems, analyzing production, quality control, maintenance, or other operational reports, to detect production problems. Review operations and confer with technical or administrative staff to resolve production or processing problems. Hire, train, evaluate, or discharge staff or resolve personnel grievances. Prepare and maintain production reports or personnel records. Set and monitor product standards, examining samples of raw products or directing testing during processing, to ensure finished products are of prescribed quality. Develop budgets or approve expenditures for supplies, materials, or human resources, ensuring that materials, labor, or equipment are used efficiently to meet production targets. Initiate or coordinate inventory or cost control programs. Copyright © Texas Education Agency, 2014. All rights reserved. 2 Coordinate or recommend procedures for facility or equipment maintenance or modification, including the replacement of machines. Soft Skills Critical Thinking Monitoring Speaking Coordination Time Management Active Listening Judgment and Decision Making Reading Comprehension Management of Personnel Resources Active Learning Accommodations for Learning Differences These lessons accommodate the needs of every learner. Modify the lessons to accommodate students with learning differences by referring to the files found on the Special Populations page of this website. Preparation Preview the Manufacturing Processes slide presentation and print the handouts. References Webster’s new compact office dictionary (2003). New York, NY: Houghton Mifflin Harcourt Publishing Co. Instructional Aids Manufacturing Processes slide presentation Manufacturing Processes Grade Sheets Introduction The purpose of this lesson is to help students understand four different types of manufacturing processes and how manufactures use time-management techniques to develop work schedules. Say o Manufacturers use different processes to improve product production. Ask o Can anyone name the processes? Say o The processes are Just-in-Time, Lean Manufacturing, 5S, and Six Sigma. Copyright © Texas Education Agency, 2014. All rights reserved. 3 o The slide presentation explains the four processes. o During the presentation think about how these could be used in the lab. Show o Manufacturing Processes slide presentation Outline MI OUTLINE NOTES TO TEACHER I. Manufacturing Processes A. Just-in-Time B. Six Sigma C. Lean Manufacturing D. 5S Show Manufacturing Processes slide presentation and discuss the different types of processes. II. Just-in-Time (JIT) A. Inventories B. Inspection After presentation, have students talk about the processes and explain the assignment. III. Six Sigma 6σ A. Define B. Measure C. Analyze D. Improve E. Control F. Management G. Projects IV. Lean Manufacturing A. Products B. Goals C. Ideas V. 5S A. B. C. D. E. The students will be divided into teams of two to examine the lab for ways to improve their experience in the course. They will work together to produce a presentation and give it in class. They will be graded by using the Manufacturing Processes Rubric. Sort Straighten Shine Standardize Sustain Copyright © Texas Education Agency, 2014. All rights reserved. 4 VI. Assignment A. Examine lab B. Prepare presentation C. Make presentation D. Assess presentation Multiple Intelligences Guide Existentialist Interpersonal Intrapersonal Kinesthetic/ Bodily Logical/ Mathematical Musical/Rhythmic Naturalist Verbal/Linguistic Visual/Spatial Application Guided Practice The teacher will discuss the different processes with the students. Independent Practice The students will work in their team to examine the lab for areas that, with change, would benefit from implementing one of the four manufacturing processes. They will develop a presentation about their findings and the team will present it to the class. Summary Review The students will be able to describe the four types of manufacturing processes described in the presentation. Evaluation Informal Assessment The students will be evaluated by teacher observation as they work on the presentation. Formal Assessment The students’ presentation will be graded with the Manufacturing Processes Rubric. Enrichment Extension The students will be given time to research other information on the manufacturing processes discussed. Copyright © Texas Education Agency, 2014. All rights reserved. 5 Name _________________________________________ Name _________________________________________ Date _____________ Period ______ Manufacturing Processes Grade Sheet Task Statement Students will develop a team presentation and present to the class on the changes that could be made to improve the flexible lab and make it more like a manufacturing production area. Task Assignment Students will work as a team of two to examine the lab for changes that could be made (based on what they have learned about four manufacturing processes), prepare a slide presentation with photos and diagrams, and present to the class. Grading 1. Written notes for presentation (up 15 points) Points Received ______________ 2. Slides in presentation (2 points per slide up 10 points) ______________ 3. Photos of lab for explanation of manufacturing process (5 points per photo, up to 25 points) ______________ 4. Student drawn diagrams of lab area for explanation of process (up to 20 points) ______________ 5. Student explanation of changes in lab (up to 25 points) ______________ 6. Presentation Design (up to 5 points) ______________ Copyright © Texas Education Agency, 2014. All rights reserved. 6 Total Points______________ Name _________________________________________ Name _________________________________________ Date _____________ Period ______ Manufacturing Processes Grade Sheet # 1 2 3 4 5 6 Description Written notes for presentation Slides in presentation Photos of lab Student drawn diagrams Text Presentation design Points per 2 points per slide 5 points Maximum 15points 10 points 25 points 20 points 25 points 5 points Total Points Received Explanation for grade Copyright © Texas Education Agency, 2014. All rights reserved. 7