Machining a V-Block Lesson Plan Flexible Manufacturing

advertisement

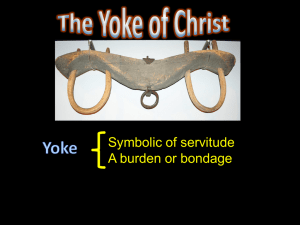

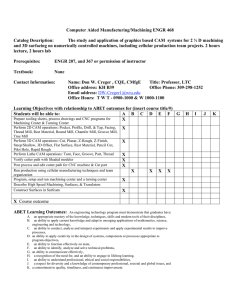

Machining a V-Block Flexible Manufacturing Lesson Plan Performance Objective Students will demonstrate a basic understanding of mill and lathe operations using different machining processes to machine a v-block and yoke; student grade will be determined by using the Project Rubric for the V-Block and Yoke Assembly. Specific Objectives Demonstrate the proper use of the mill and lathe Produce and assemble the different parts to form the v-block and the clamping yoke (yoke arm, yoke support, yoke screw) Terms Clamp- a bar used to apply pressure on the part to be machined Step Block- a support for the clamp that allows the clamp to be placed parallel with the table T-Bolt- a special bolt made to slide into the slots on a milling table Nut- a fastener to fit the t-bolt and apply pressure to the part T-Slot- a groove machined in a milling table Time This lesson should take approximately 55-65 minutes to teach and 55-65 minutes for each of 10 lab sessions. Preparation TEKS Correlations This lesson, as published, correlates to the following TEKS. Any changes/alterations to the activities may result in the elimination of any or all of the TEKS listed. TEKS Correlations Flexible Manufacturing 130.327 (c) o (6) The student applies the technical concepts and skills of the machining industry to simulated and actual work situations. The student is expected to: (A) use various work mounting procedures on all appropriate machines; (B) examine the cutting operations such as drill press, lathe, saw, grinders, and milling machines; Copyright © Texas Education Agency, 2013. All rights reserved. 1 (C) properly execute lathe procedures such as cut threads, turn tapers, drills, reams, polishes, knurls, and bores; (D) mill flat surfaces, bevels, chamfers, grooves, and key-seats; and (E) machine precision pieces. Interdisciplinary Correlations Geometry 111.41 (c) o (1) Mathematical process standards. The student uses mathematical processes to acquire and demonstrate mathematical understanding. The student is expected to: (A) apply mathematics to problems arising in everyday life, society, and the workplace; (B) use a problem-solving model that incorporates analyzing given information, formulating a plan or strategy, determining a solution, justifying the solution, and evaluating the problem-solving process and the reasonableness of the solution; and (C) select tools, including real objects, manipulatives, paper and pencil, and technology as appropriate, and techniques, including mental math, estimation, and number sense as appropriate, to solve problems. Occupational Correlation (O*Net – www.onetonline.org/) Job Title: Machinists O*Net Number: 51-4041.00 Reported Job Titles: Gear Machinist, Journeyman Machinist, Machine Operator, Machine Repair Person, Machinist, Maintenance Machinist, Maintenance Specialist, Production Machinist, Set-Up Machinist, Tool Room Machinist Tasks Calculate dimensions or tolerances, using instruments such as micrometers or vernier calipers. Machine parts to specifications, using machine tools, such as lathes, milling machines, shapers, or grinders. Set up, adjust, or operate basic or specialized machine tools used to perform precision machining operations. Align and secure holding fixtures, cutting tools, attachments, accessories, or materials onto machines. Measure, examine, or test completed units to check for defects and ensure conformance to specifications, using precision instruments, such as micrometers. Monitor the feed and speed of machines during the machining process. Maintain machine tools in proper operational condition. Study sample parts, blueprints, drawings, or engineering information to determine methods or sequences of operations needed to fabricate products. Soft Skills Operation Monitoring Critical Thinking Copyright © Texas Education Agency, 2013. All rights reserved. 2 Operation and Control Monitoring Reading Comprehension Accommodations for Learning Differences It is important that lessons accommodate the needs of every learner. These lessons may be modified to accommodate your students with learning differences by referring to the files found on the Special Populations page of this website. Preparation Review and become familiar with the terminology and proper machining techniques. Have Machining a V-Block and Project Rubric for the V-Block and Yoke Assembly handouts for each student. Have different types of clamping devices for a milling machine (mill vise, bolt to table, clamp system) and v-block examples to show students. References Machining a V-Block slide presentation Instructional Aids Machining a V-Block slide presentation Machining a V-Block handout Project Rubric for the V-Block and Yoke Assembly handout Introduction The main purposes of this lesson are to help students understand the following concepts: Explain the use of the machines used to produce the v-block Explain the different types of holders used on the mill Use information about machining and complete the v-block project Safely use the different machining equipment in the lab Show V-blocks made and used in the flexible manufacturing lab Ask Would you like to work in a machine shop to produce a working product? Show Different types of clamping devices for a milling machine (mill vise, bolt to table, clamp system) and v-block examples Copyright © Texas Education Agency, 2013. All rights reserved. 3 Outline MI OUTLINE NOTES TO TEACHER I. V-block plans and bill of materials II. Manufacturing steps for a v-block III. Machining the yoke arm IV. Machining the yoke support Show Machining a V-Block slide presentation, v-block project examples students will produce, and clamping devices for a milling machine. V. Machining the yoke screw VI. Assembling the yoke VII. Project Rubric for the V-Block and Yoke Assembly V-block Plans o Slides 2-6 V-Block Bill of Materials o Slide 7 Machining Steps for a V-Block o Slides 2-20 Machining Steps for the Yoke Arm o Slides 21-25 Machining Steps for the Yoke Support o Slides 26-29 Machining Steps for the Yoke Screw o Slides 30-35 Assembling the Yoke o Slides 36-39 Assembling the VBlock o Slide 40 After showing the presentation, pass out the Machining a V-Block plans/ instructions for the students to start machining the v-block. Grade project using the Project Rubric for the V-Block and Yoke Assembly. Copyright © Texas Education Agency, 2013. All rights reserved. 4 Multiple Intelligences Guide Existentialist Interpersonal Intrapersonal Kinesthetic/ Bodily Logical/ Mathematical Musical/Rhythmic Naturalist Verbal/Linguistic Visual/Spatial Application Guided Practice The students will set up the mill to begin manufacturing a v-block and yoke assembly. Independent Practice The students will manufacture a v-block and yoke assembly to the given specifications. Summary Review The students will be able to explain the different types of machines used to produce a v-block or other project. Evaluation Informal Assessment The teacher will observe the students as they practice machining the parts of the v-block and the yoke assembly. Formal Assessment The students will have the v-block and yoke assembly graded using the Project Rubric for the V-Block and Yoke Assembly. Enrichment Extension The students will research other projects they can machine. Copyright © Texas Education Agency, 2013. All rights reserved. 5 Copyright © Texas Education Agency, 2013. All rights reserved. 6 Copyright © Texas Education Agency, 2013. All rights reserved. 7 Copyright © Texas Education Agency, 2013. All rights reserved. 8 Copyright © Texas Education Agency, 2013. All rights reserved. 9 Copyright © Texas Education Agency, 2013. All rights reserved. 10 Name __________________________________________Date_______________ Period ____ Bill of Materials for the V-Block and Yoke Assembly Name Quantity Length Width Thickness Material Finish Block 1 1.500 1.500 1.500 Aluminum Polished Yoke Arm 2 1.500 0.500 0.375 Aluminum Polished Yoke Support 1 2.250 0.625 0.500 Aluminum Polished Yoke Screw 1 2.000 0.500 dia. Aluminum Polished Handle 1 1.750 0.250 dia. Aluminum Polished Pan Head Screw 2 0.500 #5-44 V-Block and Yoke Assembly Cut Sheet Cut the following pieces of metal • 2” X 12” X 2” piece of aluminum • ⅜” X ½” X 3 ½” piece of aluminum • ½” X ⅝” X 2 ¼” piece of aluminum • ½” diameter X 2” piece of aluminum • ¼” diameter X 1 ¾” piece of aluminum Copyright © Texas Education Agency, 2013. All rights reserved. 11 Name __________________________________________Date_______________ Period ____ Manufacturing Steps for a V-Block V-Block 1. Face all sides of the cube on the mill. 2. Mill a ⅛” (0.125”) wide slot ⅛” (0.125”) deep on one face of the cube. This slot is in the center of the face. 3. Turn the cube to the opposite face of the cube and mill a matching slot. 4. Turn the cube 90 degrees. The surface should be aligned with the side slots. Mill a groove in the face starting 0.312” from the edge. The groove should be 1.437” wide. 5. Begin milling step slots to form the “V” in the block. 6. Move in 0.062” on each side and 0.03” deep for each step. 7. Continue to cut slots, stepping in 0.062” and down 0.030” until the “V” is formed. Copyright © Texas Education Agency, 2013. All rights reserved. 12 Name __________________________________________Date_______________ Period ____ Manufacturing Steps for a V-Block (Continued) 8. Place the block to be milled into a v-block for the correct angle of 90⁰ (degrees). 9. Place the two blocks on the mill table and adjust the t-bolt, step block, and clamp. 10.Tighten the nut to apply pressure to the clamp and secure the blocks in place. 11.When finished with the first side, turn the block around and mill the other side. 12.After the machining is done, sand and polish the block. 13.Store the block until the other parts are milled. Copyright © Texas Education Agency, 2013. All rights reserved. 13 Name __________________________________________Date_______________ Period ____ Machining Steps for the Yoke Arm 1. Place a piece of ⅜” X ½” X 2” into the mill vise. 2. Square the surfaces and mill the ⅛” (0.125”) away to make the finger fit in the slot. 3. Size the finger to slide in the slot milled in the side of the v-block. 4. Drill the ¼” (0.250”) diameter counter bore ⅟₁₆” (0.062”) deep for the pan head screw head. 5. Drill the ⅛” hole for the #5-44 pan head screw. Copyright © Texas Education Agency, 2013. All rights reserved. 14 Name __________________________________________Date_______________ Period ____ Machining Steps for the Yoke Support 1. Face all surfaces of a 2 ¼” (2.250”) X ⅝” (0.625”) X ½” (0.500”) to make the yoke support. 2. Mount the blank in the mill vise and machine the slot on the end of the yoke support. 3. Machine a slot on both ends. 4. Locate the hole for the yoke arm screws, drill them with a #37 drill ¼” (0.250”) deep, and tap to a #5-44 thread pattern. 5. Locate the center hole for the yoke screw ⅝” (0.312”) X ⅞” (0.875”). 6. Drill a hole using a #4 drill and then tap to ¼ - 20 threads. 7. Sand and buff to a shiny finish, and then place in your storage container. Copyright © Texas Education Agency, 2013. All rights reserved. 15 Name __________________________________________Date_______________ Period ____ Machining Steps for the Yoke Screw 1. Take a ¼” (0.250”) rod 1 ¾” long from the storage area. 2. Place the rod in a lathe, face the end, and cut a ⅟₁₆” chamfer in the outside edge. 3. Flip the rod and repeat the step above (#2). 4. Sand and polish the rod for the handle of the screw. 5. Take a ½” (0.500”) rod 2” long from the storage area. 6. Place the rod in a set of v-blocks and drill the ¼” (0.250”) hole for the handle. 7. Place the rod in a lathe, face the end, and cut a ⅟₁₆” chamfer in the outside edge. 8. Flip the rod, face, and machine the shaft down to ¼” (0.250”) diameter for the threads. 9. Machine the ¼ - 20 threads into the screw. 10.Sand and polish the screw and the handle until shiny. 11.Place the handle in the hole in the screw and carefully drive the handle until the handle is centered in the screw. Copyright © Texas Education Agency, 2013. All rights reserved. 16 Name __________________________________________Date_______________ Period ____ Assembling the Yoke 1. Place the arm into the slot in the yoke support and tighten the pan head screw into the support. 2. Place the second arm into the slot in the yoke support and tighten the pan head screw into the support. 3. Place the screw into the threaded hole in the yoke support and tighten the screw. 4. Slide the completed yoke into the slots on the v-block. Copyright © Texas Education Agency, 2013. All rights reserved. 17 Name ___________________________________________ Date _____________________ Period _________ Project Rubric for the V-Block and Yoke Assembly Task Statement: Students will demonstrate a basic understanding of mill and lathe operations using different machining processes to machine a v-block and yoke assembly. Task Assignment: Students will work as individuals to machine a v-block and yoke assembly. Criteria Concepts/ Skills to be Assessed V-block (Possible 20 points) Yoke Arm (Possible 20 points) Yoke Support (Possible 20 points) Yoke Screw (Possible 20 points) Yoke Assembly (Possible 20 points) Novice 1 Criteria Categories (Novice to Exemplary) Developing Accomplished 2 3 Size is over 0.030 larger or smaller; 8 or more machine marks Size is 0.030 to 0.020 larger or smaller; 5 to 7 machine marks Size is 0.019 to 0.010 larger or smaller; 2 to 4 machine marks (1-5 points) Size is over 0.030 larger or smaller; 8 or more machine marks (6-10 points) Size is 0.030 to 0.020 larger or smaller; 5 to 7 machine marks (11-15 points) Size is 0.019 to 0.010 larger or smaller; 2 to 4 machine marks (1-5 points) Size is over 0.030 larger or smaller; 8 or more machine marks (6-10 points) Size is 0.030 to 0.020 larger or smaller; 5 to 7 machine marks (11-15 points) Size is 0.019 to 0.010 larger or smaller; 2 to 4 machine marks (1-5 points) Size is over 0.030 larger or smaller; 8 or more machine marks (6-10 points) Size is 0.030 to 0.020 larger or smaller; 5 to 7 machine marks (11-15 points) Size is 0.019 to 0.010 larger or smaller; 2 to 4 machine marks (1-5 points) Size is over 0.030 larger or smaller; 8 or more machine marks (6-10 points) Size is 0.030 to 0.020 larger or smaller; 5 to 7 machine marks (11-15 points) Size is 0.019 to 0.010 larger or smaller; 2 to 4 machine marks (1-5 points) (6-10 points) (11-15 points) A = 76-100 points; B = 51-75 points; C = 26-50 points; D = 5-25 points Exemplary 4 Points Earned Size is 0.009 to 0.000 larger or smaller; no machine marks (15-20 points) Size is 0.009 to 0.000 larger or smaller; no machine marks (15-20 points) Size is 0.009 to 0.000 larger or smaller; no machine marks (15-20 points) Size is 0.009 to 0.000 larger or smaller; no machine marks (15-20 points) Size is 0.009 to 0.000 larger or smaller; no machine marks (15-20 points) Total Points: ____________ Copyright © Texas Education Agency, 2013. All rights reserved. 18