ICH guideline Q11 on development and manufacture of

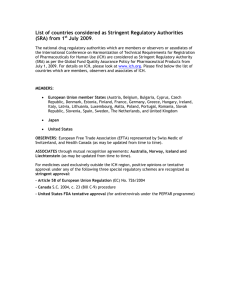

advertisement