Ensc 494 Project Report Design of a Micro-Machined Bistable Switch

advertisement

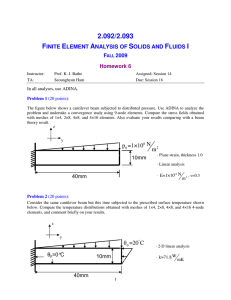

Ensc 494 Project Report Design of a Micro-Machined Bistable Switch Maria Trinh Ian Foulds Steven Liao Sam Hu Supervisors: Dr. Ash Parameswaran Robert Johnstone September 7, 2001 Table of Contents LIST OF FIGURES ....................................................................................................... III LIST OF TABLES ......................................................................................................... III 1. INTRODUCTION......................................................................................................... 1 1.1 DEFINITION OF A BISTABLE SWITCH.......................................................................... 1 1.2 THE NEED FOR A BISTABLE SWITCH .......................................................................... 1 1.3 DESCRIPTION OF MUMPS TECHNOLOGY .................................................................. 1 2. DESIGN EVOLUTION ................................................................................................ 2 2.1 PROPOSED SOLUTIONS ............................................................................................... 2 2.1.1 Pull-Crown Design............................................................................................. 2 2.1.2 Push-Crown Design ........................................................................................... 3 2.1.3 Ladder Design, the Best Solution.................................................................... 5 3. IMPLEMENTATION OF THE LADDER DESIGN ................................................ 8 3.1 LIST OF COMPONENTS ................................................................................................ 8 3.2 DESCRIPTION OF DIMENSIONS .................................................................................... 9 3.3 CONSTRAINTS AND CALCULATIONS ......................................................................... 10 3.3.1 Cantilever Beams ............................................................................................. 10 3.3.2 Box Spring ........................................................................................................ 12 3.4 DESCRIPTION OF DIFFERENT DESIGN VARIATIONS ................................................... 13 3.5 DESIGN ISSUES ......................................................................................................... 15 4. FUTURE RESEARCH ............................................................................................... 15 5. CONCLUSION............................................................................................................ 16 ii List of Figures FIGURE 1: BISTABLE SWITCH STATE DIAGRAM ................................................................... 1 FIGURE 2: PULL-CROWN DESIGN, FIRST STABLE STATE...................................................... 2 FIGURE 3: PULL-CROWN DESIGN, SECOND STABLE STATE.................................................. 3 FIGURE 4: PUSH-CROWN DESIGN, FIRST STABLE STATE ..................................................... 4 FIGURE 5: PUSH-CROWN DESIGN, TRANSITION STATE ........................................................ 4 FIGURE 6: PUSH-CROWN DESIGN, SECOND STABLE STATE ................................................. 5 FIGURE 7: LADDER DESIGN, FIRST STABLE STATE .............................................................. 6 FIGURE 8: LADDER DESIGN, SECOND STABLE STATE .......................................................... 6 FIGURE 9: LADDER DESIGN TRAJECTORY FOR STATE CHANGE............................................ 7 FIGURE 10: IMPLEMENTATION OF OUR BISTABLE SWITCH IN CADENCE SOFTWARE ............ 8 FIGURE 11: DIMENSIONS OF THE BISTABLE SWITCH ............................................................ 9 FIGURE 12: DYNAMIC MODEL OF CANTILEVER BEAM ....................................................... 10 FIGURE 13: DISPLACEMENT (W) VERSUS LENGTH (L) ........................................................ 11 FIGURE 14: SLOPE (θ) VERSUS LENGTH (L)........................................................................ 11 FIGURE 15: A.) BISTABLE SWITCH DESIGN ACTUATED BY EXTERNAL PROBE HOOKED ONTO A RING B.) BISTABLE SWITCH DESIGN ACTUATED BY STEPPER MOTORS..................... 14 List of Tables TABLE 1: LIST OF DIMENSIONS (MEASURED IN MICRONS, ΜM) .......................................... 10 TABLE 2: CONSTANTS USED TO CALCULATE THE LENGTH OF THE CANTILEVER BEAMS...... 11 TABLE 3: VARIATIONS OF THE BISTABLE SWITCH DESIGN (ALL MEASURED IN ΜM) .......... 13 iii Abstract The efficiency of many Micro-Electro Mechanical Systems (MEMS) devices can be increased with the implementation of a bistable switch. A bistable switch has two stable states that can both be reached through a single actuation or pulse of energy. Such a switch can be used to change the direction of gears, flip or rotate mirrors, engage or disengage motors, etc. Its applications are universal. Presently the substitute for a bistable switch is a monostable switch, which has only one stable state and an unstable state that requires constant energy to sustain. An effective bistable switch would allow for a dramatic decrease in the energy used in MEMS devices and as a result, increase in their efficiency. In this report, you will find the detailed design of a MEMS bistable switch, including how the solution originated, how the bistable switch was implemented, and a discussion on its underlying issues. iv 1. Introduction 1.1 Definition of a Bistable Switch A bistable switch has two stable states that can both be reached through a single actuation. Figure 1 is a state diagram illustrating the operation of a bistable switch. The switch starts out in one of the stable states and when power is applied to the actuators the switch switches to the other stable state. Power no longer needs to be applied to maintain the new state of the switch. Re-applying power to the actuators again will return the switch to its original state and the process can begin again. Actuation State 1 State 2 Actuation Figure 1: Bistable Switch State Diagram 1.2 The Need for a BiStable Switch In many Micro-Electro Mechanical Systems (MEMS) applications, such as the optical routers in a fiber-optics communication network, switches with two stable states are often required. The present solution is to use a monostable switch, which rests at one stable state when no power is applied and a second unstable state that requires a constant input of power to be maintained due to its instability. The use of such a switch has the disadvantages of high power consumption and increased heat dissipation. A more convenient and economically beneficial design would be a switch that has two stable states, which can change from state to state via a single actuation. Hence the motivation for designing a bistable switch as a micro-machined device. 1.3 Description of MUMPs Technology The technology used to design and implement this bistable switch is termed “Multi-User MEMS Processes (MUMPs),” which is defined by Cronos Integrated Microsystems as “a commercial program that provides the international industrial, governmental and academic communities with cost-effective, proof-of-concept surface micromachining fabrication. MUMPs is designed for general-purpose micromachining by outside users who would like to fabricate MEMS devices.”1 MUMPS technology is a powerful design tool, but it limits the user to only two layers of polysilicon on top of a silicon substrate, which inhibits the creation of highly sophisticated structures. In addition, since the two 1 Koester D. A., Mahadevan R., Shishkoff A., Markus K. W.. MUMPs Design Handbook 4.0. Cronos Integrated Microsystems. 3021 Cornwallis Road Research Triangle Park NC 27709. May 1999 1 layers of polysilicon are so incredibly thin (2 microns thick), most structures cannot be physically pushed without causing any folding, bending or buckling, so any movement of the structures should be achieved by pulling them. MUMPs technology also comes with a set of design rules pertaining to the actual dimensions and spacing of the structures allowable for successful fabrication. The design of our bistable switch was created with all these constraints in mind. 2. Design Evolution 2.1 Proposed Solutions In order to find the best solution for a MEMS bistable switch, we first investigated a variety of bistable switches that are found in simple existing mechanical systems. The following are descriptions of the 3 possible bistable switch designs we investigated. 2.1.1 Pull-Crown Design This design, which we entitled “the pull-crown design”, originated from the internal structure of a certain mechanical pen. Within the mechanical pen resided a crown-shaped piece that was free to move up and down the pen and swivel side to side. When the user pushed down on the end of the pen, the crown-shaped piece would be forced downward and would be lodged in a position that held the pen tip in its extended position. When the user pushed the end of the pen again, the crown-shaped piece would swivel and be free to slide up the pen again, thus allowing the pen tip to retract. Figure 2 and Figure 3 show how we attempted to modify the pen’s design into two stable states under the MUMPs constraints. Top bar Crownshaped piece spring Two locking mechanisms Figure 2: Pull-Crown Design, First Stable State 2 Figure 3: Pull-Crown Design, Second Stable State The idea behind this design is that the crown-shaped piece at the middle pinned down, but is free to rotate left and right depending on the state of the two locking mechanisms at the bottom. When the top bar is pulled upward, the crown-shaped piece rotates to a different state because of the two locking mechanisms and the two springs attached to them. The top bar then returns downward to a relaxed state and locks the crown in that state. As a result, a single pull of the top bar will alternate the state of the crown-shaped piece, resulting in two stable states. The major drawback with the latch design is the difficulty of designing the proper locking and unlocking mechanisms that would allow this design to work. 2.1.2 Push-Crown Design The push-crown design is also derived from the internal structure of the same mechanical pen described in 2.1.1, but in this design, the crown-shaped piece moves up and down (using a “push”) while everything around it stays still. Figure 4, Figure 5 and Figure 6 illustrate the operation of the push-crown design. 3 Top bar Figure 4: Push-Crown Design, First Stable State Top bar Figure 5: Push-Crown Design, Transition State 4 Top bar Figure 6: Push-Crown Design, Second Stable State In this design, no adjustable locking mechanism is required and the crown-shaped piece, while allowed to pivot, is not directly anchored to the substrate. The crown-shaped piece is attached to two springs at the middle (underneath a suspended single layer) and at the bottom. Whenever the top bar is pulled downward, the bar will push against the crown piece and move the crown piece along one of the two sides of the channel formed by the objects colored in purple (Figure 4). Due to its geometry, the crown-shape will be pushed towards to the other side of the channel from the first stable state and moved into the transition state (Figure 5). When the top bar is retracted, the spring at the top will pull the crown-shape upward until it is locked into the second stable state (Figure 6). In reverse order, another single actuation will move the crown piece from the second stable state back to the first stable state. The crown-shaped design was proven to work on a wooden model, but after consulting the details of the MUMPs technology, we found that there are serious fabrication difficulties related to this design. First of all, a compressive force between the top bar and the crown-shaped piece is necessary for this design to work, but has a high risk of bending or warping the crown piece due to the thickness of the structure in relation to its other dimensions. Secondly, the attachment of the spring at the middle of the crownshaped requires a suspended silicon layer above the spring. In MUMPs technology, a suspended layer will conform in shape to the structures below it, which would result in a kinked spring that would not be functional. 2.1.3 Ladder Design, the Best Solution The first two designs derived from the mechanical pen were not suitable to be implement as desired with the MUMPs technology. The design we chose to implement instead was 5 based not on a mechanical pen but on the locking mechanism of an extension ladder. Figure 7 and Figure 8 show the two stable states of the Ladder Design. Rail Guide Step Hook Actuator Rod Cantilever Beams Pull Figure 7: Ladder Design, First Stable State Figure 8: Ladder Design, Second Stable State In Figure 7, we can see that the ladder design is composed of two cantilever beams on the left (acting like springs), a hook in the middle, and a “step” attached to the actuator rod that is freely to move up and down, vertically. The top cantilever beam is anchored at the top and pivots from that anchor, whereas the bottom cantilever beam is anchored at the 6 bottom and pivots around that anchor. Not shown in Figure 7 or Figure 8 is a box spring attached to the top of the actuator rod, acting to return the step to its original state after each downward pull. To aid in visualization of the switch’s movement, Figure 9 illustrates the movement of the switch from state 1 to state 2 and back to state 1 again. a.) d.) b.) e.) c.) f.) Figure 9: Ladder Design Trajectory for State Change a.) All the components rest at their relaxed state in the first stable state. All the cantilevers are relaxed, and so is the unseen box spring above the actuator rod. b.) With the introduction of a pulling force, the actuator rod is pulled downward until the “step” slips into the “hook.” c.) When the pulling force is removed, the actuator rod is wishes to be restored upward by the unseen box spring but is unable to move due to the interlocking of the hook and step. This locked state is in the second stable state. d.) A second downward pull moves the step past the hook. e.) When the applied force is removed, the actuator rod will be forced upward again by the box spring, pulling the step to bypass the hook f.) Just before returning to the first stable state, the two cantilevers operate separately to manipulate the hook and return it to its original position. The design of the ladder switch is simple, which increases the chance that it can be reliably fabricated and operated. This design does not require any complex locking mechanisms, nor does it have the problem of pushing two thin sheets of silicon against one another, thus satisfying the MUMPs constraints. 7 3. Implementation of the Ladder Design 3.1 List of Components Figure 10 was generated from a Cadence2 layout and shows the actual implementation of our bistable switch in MUMPs. Rail Guide Step Hook Actuator Rod Direction of Pull Cantilever Beams Rail Guide Figure 10: Implementation of Our Bistable Switch in Cadence Software As shown in Figure 10, the main components of our bistable switch are the cantilever beams, hook, pushing rod, and actuator rod. Moreover, although not shown in the picture, the actuator rod is attached to a box spring at the top that acts to restore the actuator rod to its original state. At the bottom of the actuator rod, two linear stepper motors are used to insert the pulling force. 2 Software package used to design our bistable switch 8 All the components that come into contact with each other are designed with a double layer of polysilicon to ensure a larger contact area. These components include: the step, the hook, the ends of the cantilever beams and the rail guides. All the other components are single layers of polysilicon. 3.2 Description of Dimensions The physical size of our entire design was constrained by the required size of the rotational joint in the middle of the hook. We would have liked to make the dimensions smaller but the limitations of the MUMPs technology dictated the size of our switch. Part of our future work on our switch will be to find a way around these limitations so that the switch can be made even smaller. Figure 11 provides the labeling for the dimensions listed in Table 1. A B C D K F E H G I J M L Figure 11: Dimensions of the Bistable Switch 9 Table 1: List of Dimensions (measured in microns, µm) A 12.00 B 36.00 C 50.00 D 82.00 E 120.00 F 2.00 H 49.00 I 30.00 J 80.00 K 86.00 L 120.00 M 2.00 G 75.00 We produced different permutations of this design wherein we varied the lengths of L and E to account for different pulling forces. The dimension of L and E vary from 85 to 170 microns. The unseen box spring has a length of 250 microns. 3.3 Constraints and Calculations 3.3.1 Cantilever Beams The lengths and widths of the two cantilever beams and the box spring were calculated to best accommodate the pulling forces that would be exerted on them. These dimensions determined the spring constant of both the cantilever and box springs. To calculate the desired dimensions of the beams, we approximated the dynamics of a single beam as end load cantilever beam, as shown in Figure 12. Figure 12: Dynamic Model of Cantilever Beam We used the equations listed on the www.efunda.com web site3. Given a specific beam loading case and the dimensions of the beam, the web site provided an online calculator to determine the maximum displacements, slopes, moments, stresses, and shear forces for this beam problem. We mainly used the equations shown in Equation 1 through Equation 4, which allowed us to the approximate the beam’s maximum deflection angle (slope) and maximum displacement before breaking. The values used in Equation 1 through Equation 4 are shown in Table 2. 3 The exact web address that present the formulas is: http://www.efunda.com/formulae/solid_mechanics/beams/casestudy_display.cfm?case=cantilever_endload 10 Displacement Calculations: Figure 13: Displacement (w) versus length (L) Equation 1 Equation 2 Slope Calculations: Figure 14: Slope (θ θ) versus length (L) Equation 3 Equation 4 Table 2: Constants used to calculate the length of the cantilever beams. Length of beam, L Load on end of beam, P Young’s Modulus, E Moment of Inertia, I Varied; we estimated lengths from 85 to 170 µm 30E-6 N 160 GPa 1.6E-23 m 11 To find our spring lengths we fixed our width at 2 microns and the force at half our expected output from the stepper motors (30 µN) and iterated through lengths until we found an appropriate deflection angle of 30°. 3.3.2 Box Spring Similarly, in order to determine the dimensions of the box spring, we used the formulas presented on the web site www.sfu.ca/adm. These formulas are as follows: w ⋅ h3 12 Equation 5 96 ⋅ E ⋅ I N ⋅ L3 Equation 6 I= K= where: I = moment of inertia w = width of individual beam h = height of individual beam (thickness) L = length of individual beam K = spring constant E = Young’s Modulus = 160 x 109 Pa N = number of beams. Rearranging Equation 6, we can then solve for the length of the individual beam inside the box spring given the value of the spring constant K, which generates the formula shown in Equation 7. 96 ⋅ E ⋅ I L3 = N ⋅K Equation 7 12 3.4 Description of Different Design Variations To ensure that calculation errors and uncertainties were taken into account, we created several permutations of our original design by selecting different lengths for the cantilever beams and different sizes for the box spring. Table 3 lists the 9 different permutations of our design. Table 3: Variations of the Bistable Switch Design (all measured in µm) Top Cantilever Length Bottom Cantilever Length 85 100 120 100 120 150 120 150 170 85 100 120 100 120 150 120 150 170 # of Beams in the Box Spring 10 10 10 20 20 20 30 30 30 Each permutation in our design submission has two numbers beside it: the first number indicated the number of beams in the box spring; the second number indicates the length of the cantilever beams. We also permutated the cantilever and box spring dimensions with two different types of actuators. Some designs include a stepper motor to actuate the switch. Others include a ring to be pulled manually by hooking with an external probe. These two design variations are shown in Figure 15. 13 a.) b.) Box springs Stepper motor ring Figure 15: a.) Bistable Switch design actuated by external probe hooked onto a ring b.) Bistable Switch design actuated by stepper motors 14 3.5 Design Issues Since we have approximated the force exerted by the stepper motors, the actual dimensions of the cantilevers and box springs may not be optimal, which is why we included different variations and permutations. We are inexperienced with the mechanical properties of polysilicon. Only after careful testing will we know if our calculations are correct and which dimensions work best. We have designed all components that come in contact with each other with double layers of polysilicon for larger contact areas, but we are inexperienced with the frictional forces that occur between structures of such microscopic dimensions. Therefore, we are unsure as to whether structures will stick or become lodged against one another due to these frictional forces. We designed the corners of the cantilevers to be rounded to guard against such an event. We are also unfamiliar with potential stresses and strains that could occur in various parts of the device, and with the potential problems that could arise due to the fabrication process. But again, only after careful testing of the fabricated switches will we know the effectiveness of our design. 4. Future Research One of the main disadvantages about our current design is its size. Due to the technology constraints our design requires a stroke length in excess of 160 microns. The main constraint leading to this size factor is the design of the hub on which the hook pivots. Our next major goal in terms of research is to shrink the size of the hook so that the entire device can be minimized. Because the hook doesn’t need to turn in a complete circle, we are currently considering the replacement of the hub with a torsional spring. Other improvements we are considering include designing a single input actuator that can provide a larger stroke length and look into other implementation technologies to see if one would be a better fit for our design. 15 5. Conclusion Successful development of a MEMS bistable switch would greatly improve the efficiency and reduce the cost of many MEMS devices. Based on simple mechanical bistable switches like the mechanisms found in ballpoint pens and extension ladders, we proposed several possible solutions for the MEMS bistable switch. After analyzing our designs with respect to the MUMPs technology we decided that our ladder design best fit the MUMPs technology. For each component in the ladder design, a series of calculations were performed to select the optimal dimensions that would best approximate the ideal performance of the switch. To ensure that calculation errors and uncertainties were taken into account, we created several permutations of our original design using different dimensions for certain components like the cantilever beams and box spring. We also created some permutations that would be actuated by stepper motors, and others by manual force. Our design uncertainties stem from our inexperience with fabrication issues and with the material properties of polysilicon. But based on the simplicity of the mechanism behind this design, we feel confident that this bistable switch will work to at least some degree. The success of our switch now lies only in the future testing and refining of the device. 16