KARTHIK KUMAR.A Mobile Number: +919003589737 Home Number: +91-422-2668531

advertisement

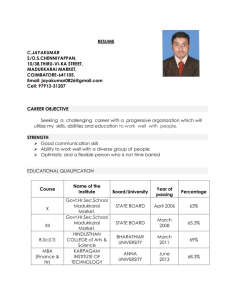

KARTHIK KUMAR.A Mobile Number: +919003589737 Home Number: +91-422-2668531 Mail Id: karthik22394@gmail.com : amritakarthik@yahoo.co.in OBJECTIVE: Seeking a challenging Research / PhD position in the field of Mechanical Engineering, involving Modeling, Analysis & simulation of Mechanical Systems & Smart Sttructures, where vast research & professional experience can be effectively utilized to develop theories, methods & to simulate real life problems. EDUCATION PROFILE Master of Technology (Engg Design) Jul 2005 to Jul 2007 From Amrita Vishwa vidyapeetham, Amrita University, Coimbatore - India B.E., Mechanical Engineering Jul 2000 to Jun 2003 From Park College of Engineering and Technology Bharathiar University, Coimbatore – India Diploma in Mechanical Engineering Jun 1997 to Jun 2000 From Sri Ramakrishna Polytechnic, Coimbatore – India. SKILLS SUMMARY: An Enthusiastic, dedicated and a resourceful engineer with 5 years experience in Product development. Self-motivated and aspiring attitude to provide innovative and cost effective solutions. Ability to upgrade quickly and deploy emerging technologies. Flexible and Adaptable team member with risk taking attitude. RESEARCH EXPERIENCE: INDIAN SPACE RESEARCH ORGANIZATION Area of Research: Vibration (Periodic & Harmonic) Design Optimization Applied Mechanics & Kinematics Dec 2006 - Jun 2007 Finite Element Method (FEA & Structural - Dynamic Analysis) The project is aimed to reduce the vibrations in the structure of Inertial Navigation Sensor Assembly. This is done to reduce the data error of other optical components mounted on the unit and to get perfect data with compact design. Implemented a new Design and methodology for vibration control of inertial sensor Assembly Unit. An Alternate Counteracting Device is designed by considering the Optimized parameters, Mass reduction, Compactness and Manufacturability Developed 3D Solid Model of the system by using Pro Engineer. Optimization of the Counter mass structure is done by using Pro-Mechanica. Then the Structure is analyzed in different modes of Frequencies. Time Harmonic Analysis is carried out to get the amplitude of vibration. It is compared with the previous stage. The Results were validated by comparing the experimental results. ACADEMIC PROJECT PROFILE NON CONVENTIONAL ENERGY RESOURCES: SOLAR WATER PUMPING SYSTEM Description: With the objective of developing a cost effective and eco-friendly system, the solar water pumping system is designed .The machine utilizes the non-conventional fuel (Solar Energy), so it helps to save conventional fuels and operates eco-friendly. Duration : Nov 2002 - Mar 2003 Course : B.E., Team Size : 4 members Guidance : Udaya semiconductors limited Role : Involved in system study and Design of equipments PNEUMATIC PUNCHING AND RIVETING SYSTEM Description: To develop a special purpose machine for the sheet metal industry, It is used to join the sheets for boiler shells & heaters. The key advantage of this machine is to overcome the difficulties in mass production and generate high power with less electricity. Duration : Nov 1999 - Mar 2000 Course : Diploma Team Size : 5 members Guidance : Coimbatore Hydraulics Limited Role : Involved in System study and Design of equipments Page 2 of 4 IT SKILLS: Operating Systems : Windows NT/ Win 2k / Win XP / Windows Vista CAD software : AutoCAD / Pro-E / ANSYS / HYPERMESH /ABACUS Packages : MS Office (Word, Excel, PowerPoint) and MS Project PROFESSIONAL EXPERIENCE: MEP CO ORDINATOR Aug 2008 – Till Date Al Wasl Al Jadeed Consultants (Architectural & Mechanical) DUBAI, UAE. Working as an MEP Coordinator, Responsible for Prelaunch Design, Drawings, Verification & approval. Preparation of customer Specification documents of all Mechanical Related Activities & coordinating with other services. Projects Handled: Student Complex Academic city Dubai – AED 900 Million Staff Complex Media City Dubai – AED 1 Billion MEP Engineer Dec 2007 – Aug 2008 AMANA Steel Buildings & Contracting (Steel Structures & Builders) DUBAI, UAE Worked as an MEP Engineer Responsible for Maintaining Site based Mechanical Activities. Responsible for Cost Estimation & Quantity Survey of Mechanical Work as approved by the clients. Mechanical Engineer – Product Design & Development ROOTS INDUSTRIES LIMITED, COIMBATORE Oct 2003 – Sep2005 Worked as a Product Development Engineer for a Specialty Horn Manufacturer for Domestic & Heavy vehicles to meet the global market requirements including the US defence vehicles. TRAINING UNDERGONE Knowledge-based Training: ISO /TS 16949, QS 9000, MS 9000 conducted by Nathan and Nathan consultancy. Failure Mode Effective Analysis (FMEA), Statistical Process Control (SPC) Techniques, 5 S House keeping, Single Minute Exchange of Dies (SMED), JIT and KANBAN. Page 3 of 4 ACHIEVEMENTS & EXTRA CURRICULAR Team Work, Project Management & Documentation, Production Planning & Scheduling, Product design & Optimized work methods. Organized a National Level Technical Symposium as a Student Coordinator. Participated & Presented papers in National Level Technical Symposiums. PERSONAL PROFILE: Fathers Name : A.Ayyalusamy B.T.Asst (Retd) Date of Birth Age : 11th April 1982 & 26 Years Gender : Male Marital Status : Single Passport Number : F8970653 Address for Communication: 58,Vinayagar koil street,Velappanaickenpudur, Saravanampatty post,Coimbatore, Tamilnadu,India - 641035 REFERENCES: Dr. K. MOHANDAS Chairman, Dept. of Mechanical Engg. Official Address Department of Mechanical Engineering Amrita School of Engineering Ettimadai, Coimbatore, India. Email: k_mohandas@amrita.edu Phone No 0422-2656422 –Extn 210 Dr.S.GOSHTEESWARAN Professor. Official Address Department of Mechanical Engineering, Amrita School of Engineering, Ettimadai, Coimbatore-641105, India. E-mail: s_gosh_eswar@ettimadai.amrita.edu Phone No: +919865492807 Page 4 of 4