HOME FOOD PRESERVATION DATE. OF

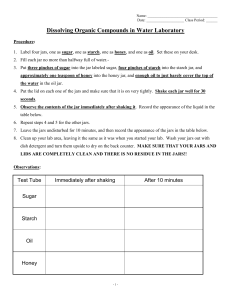

advertisement