Tool s for bu i ld i ng safer wor k places i n B.C.

WorkSafeMagazine.com

July / August 2011

This issue: ASBESTOS EXPOSED | PARTICLE PERILS | ORCHARD INNOVATIONS

2

July / August 2011 WorkSafe Magazine

14

Features

10

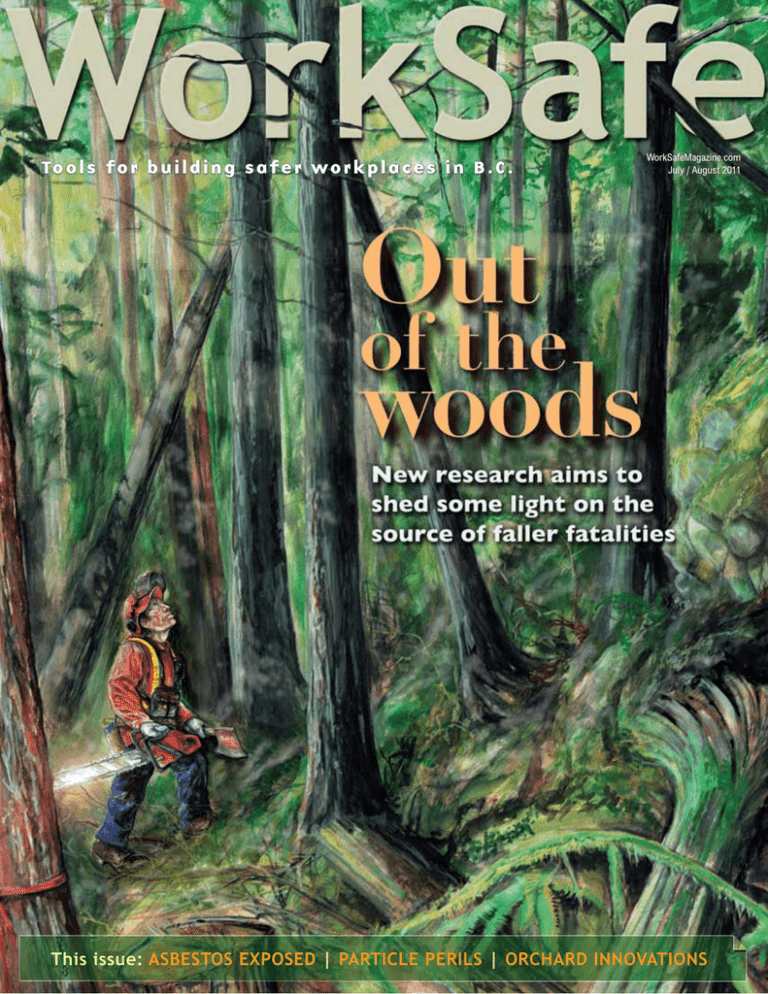

ON THE COVER

Out of the woods

As the forest industry moves toward slashing its

historically high death and injury rate, a new study asks

whether fallers can use training with 3-D images to spot

hazards.

By Helena Bryan

14

WORK SCIENCE

No small matter

The brave new world of nanotechnology poses an

unexpected threat for workers exposed to its raw

materials.

By Gail Johnson

20

Contents

C

ontents

on

July / August 2011 Volume 11, Number 4

Centre pullout:

SAFETY SOLUTIONS

Operating room

What’s wrong with this photo?

Orchard workers, engineers, safety specialists, and

industry associations have teamed up to elevate safety

standards for mobile work platforms.

By Jennifer Tsui

22

TOOL BOX

High time

With the range of safety programs and equipment

available to today’s steep slope roofers, there’s no need

to take dangerous shortcuts.

By Robin Brunet

24

10

NUTS AND BOLTS

At the ready

Recent events in Japan offer a potent reminder that time

taken to review emergency planning procedures with

employees is time well spent.

By Lynn Welburn

Departments

4

From the editor

5

In your own words

17

WorkSafeBC update

28

Penalties

Cover illustration by Graham Coulthard

WorkSafe Magazine July / August 2011

3

FROM THE EDITOR

S

teve Venus is a third-generation

forestry worker. When he started as a faller 15 years ago,

risk-taking was part of the job. As he puts it, working in the

woods meant putting your life on the line.

EDITOR-IN-CHIEF

DONNA FREEMAN

MANAGING EDITOR

DANA TYE RALLY

ASSOCIATE EDITOR

LAINE DALBY

GRAPHIC DESIGN

Things have changed. Thanks in part to the efforts of

WorkSafeBC, the BC Forest Safety Council, and others,

enforced safety standards and training are the new norm. Yet,

fallers still have the highest injury rate of any occupational

group in the province.

To combat this troubling trend, cutting-edge safety research

that’s been put to the test in war zones is now being considered

for B.C.’s forests.

It’s fascinating stuff, and the subject of our feature story on

page 10. “Visually degraded environments,” such as war zones

and heavily forested landscapes, make the ideal setting for

disaster. A soldier can have the best gear, but nothing can

protect him from what he can’t see coming. Similarly, even the

most safety-conscious faller is defenceless against massive

branches that can come crashing down if he doesn’t know

they’re there.

If these kinds of hazards seem obvious, consider that the forest

canopy itself is a visually degraded environment: dark and

shadowy, it can be shrouded in mist and fog.

Research to train workers to avoid those deadly branches —

along with other hard-to-spot hazards — is now underway,

through the combined efforts of WorkSafeBC, Western Forest

Products, and Kwantlen Polytechnic University.

The potential ramifications of this research are huge: besides

saving fallers’ lives, this unique system of hazard recognition

could be applied to many other industries. In fact, it’s already

being used to protect mine workers.

PHOTOGRAPHY

PHOTO SAFETY ADVISOR

GRAHAM COULTHARD

KHALID HAWE

ANDREW LIM

WORKSAFE MAGAZINE is published by the WorkSafeBC (Workers’ Compensation Board of B.C.)

Communications department to educate workers and employers about injury and disease prevention,

promote positive safety culture, and provide links to WorkSafeBC resources for safer workplaces.

DISCLAIMER WorkSafeBC strives for accuracy; however, the information contained within

WORKSAFE MAGAZINE does not take the place of professional occupational health and safety

advice. WorkSafeBC does not warrant the accuracy of any of the information contained in this

publication. WORKSAFE MAGAZINE and WorkSafeBC disclaim responsibility for any reader’s use of

the published information and materials contained in this publication. WorkSafeBC does not warrant

or make any representations concerning the accuracy, likely results, or reliability of the contents of

the advertisements, claims made therein, or the products advertised in WORKSAFE MAGAZINE.

WorkSafeBC does not warrant that any products advertised meet any required certification under

any law or regulation, nor that any advertiser meets the certification requirements of any bodies

governing the advertised activity.

WORKSAFE MAGAZINE is published six times a year by WorkSafeBC. The yearly issues

include January/February, March/April, May/June, July/August, September/October, and

November/December. The magazine can be viewed online at WorkSafeMagazine.com.

CONTACT THE MAGAZINE Email: Dana.TyeRally@worksafebc.com. Telephone: Editorial

604 232-7194. Subscriptions 604 231-8690. Mailing address: WORKSAFE MAGAZINE, PO Box 5350

Station Terminal, Vancouver, B.C. V6B 5L5. Courier: WorkSafeBC Communications, 6951

Westminster Highway, Richmond, B.C. V7C 1C6.

SUBSCRIPTIONS To start or stop a free subscription to WORKSAFE MAGAZINE, or to update mailing

information, follow the “Subscribe” link on our website at WorkSafeMagazine.com. You can also

email worksafemagazine@worksafebc.com, or call 604 231-8690.

EDITORIAL INQUIRIES/FEEDBACK If you’d like to comment on an article or make a suggestion,

please email Dana.TyeRally@worksafebc.com.

ADVERTISING For information about advertising your product or

service in WORKSAFE MAGAZINE, please contact OnTrack Media by

phoning 604 639-7761 or emailing worksafebc@ontrackco.com.

COPYRIGHT The contents of this magazine are protected by

copyright and may be used for non-commercial purposes only. All

other rights are reserved and commercial use is prohibited. To make

any use of this material, you must first obtain written authorization

from WorkSafeBC. Please email the details of your request to

Dana.TyeRally@worksafebc.com. WorkSafeBC™ is a registered

trademark of the Workers’ Compensation Board of B.C.

Diana Stirling

OnTrack Media

There’s no guarantee these techniques will work in the woods.

But as Venus can attest, workplace innovation can be a risk

worth taking — especially if it’s one that keeps workers alive

and unharmed.

Donna Freeman

Editor-in-Chief

Scan the MS tag with your

smartphone to view:

4

WorkSafe Magazine.com

July / August 2011 WorkSafe Magazine

IN YOUR OWN WORDS

Nursery scenario

plants a seed

about the use

of proper PPE

F

or those lucky enough to work in the great outdoors

— surrounded by oxygen-emitting

plants — it might be easier to forget about the need

for stringent work practices. But outdoor or greenhouse

nursery workers face potential exposure to dangerous

chemicals, along with other, less obvious hazards. The

May/June photo contest, featuring a worker spraying pesticides

on a row of bedding plants, elicited responses from about 130

eagle-eyed workers and employers worldwide. WorkSafeBC senior

occupational hygienist Geoff Clark selected this month’s winner;

WorkSafeBC occupational safety officer Anna Billingsley cited

key hazards:

The worker is applying pesticides within the proximity of other

workers.

•

A half-mask has been left on the gator. (Does the pesticide

require respiratory PPE?)

•

If a half-mask is needed, the worker is not clean-shaven

•

The half-mask is improperly stored

•

The worker’s legs are tangled up with the hose line

•

The pesticide containers have been left out (in the mixing area)

•

The worker is stretching to reach the plants (an ergonomic issue)

•

Food containers are present. (Has the worker been consuming

food while working with pesticides?)

He is incorrectly using his personal protective equipment (PPE):

•

No gloves

•

No signage for “Pesticide in Use” has been posted

•

No rubber boots

•

No labels are present on the pesticide containers

•

No goggles

•

No protective barrier/tape is in place

•

The mask on his head is dirty

•

He shouldn’t be wearing a cloth cap or porous clothes

Now it’s your turn. See our centre-spread, pullout poster for a

closer look at spa safety.

Nursery worker needs to protect himself from

harmful vapours

Editor, WorkSafe Magazine (Re: May/June issue, “What’s wrong with this photo?”)

Aniko has

w on

a medic sa

fety kit

for her lett

er !

Personal protective equipment

•

No ventilator, spray suit, gloves, or eye protection

•

A hepa filter, as seen on the gator seat, is needed for particulate matter; the filter

is not in use

WorkSafe Magazine July / August 2011

5

•

No gloves (have they been left on the bottle on the gator?)

•

No boots/anti-slip footwear or boot covers

Poor housekeeping, ergonomics, and

PPE pose big hazards

•

The worker is using a dust mask (dirty) on his hat —

inappropriate as protection against chemical vapours

Editor, WorkSafe Magazine (Re: May/June issue, “What’s wrong

with this photo?”

Signage

•

Improper eye protection

•

No signage: type of application, re-entry date, toxicity (or is it

water?)

•

The worker has poor posture and is twisting and leaning

outward

•

The spray notification flag has been left on the gator

•

No safety gloves

•

The coiled hose is a tripping hazard: there is also the

potential for a kink in the line; the hose is coiled in an

unsafe manner all the way back to the vehicle

•

Improper footwear

•

Improper clothing for spraying liquids, vapours

•

The box in the path is a tripping hazard

•

No respirator

•

An improper respirator for vapours, liquids, and solvents

Other hazards

•

The hose around the worker’s legs poses a tripping hazard

•

Others are working in the nearby area — they could possibly

be exposed to pesticides/chemical vapours

•

The area should be closed to other workers while they’re

applying hazardous pesticides

•

Or, spraying should be performed at the end of the day or on

a weekend, when no one is working

•

Over-stretching implies a risk of strain, or a possible fall

•

Gloves have been left behind

•

The garden rows should be wider to allow easier access

•

•

A chemical spill is present (containers by the gator have

fallen over)

The respirator has been left behind. Also, the respirator is

being exposed; it should be in an airtight container when it’s

not in use

•

There is an unmarked sprayer/contents on the gator

•

There is a key in the ignition; it should be locked out

•

There is a coffee cup on the gator (no eating while spraying

chemicals)

•

The chemical container is open and there’s no label; it’s also

a tripping hazard

•

No clear walkway is provided between the gator and the

rows (there is an empty tray on the ground); this poses a

tripping hazard

•

No label on the container: it’s in the path to the vehicle and

it’s a tripping hazard

•

The plant box in the path to the vehicle is a tripping hazard

•

The worker is wearing baggy clothing with hoody ties; this

poses a risk of being caught in the equipment

•

There appears to be a rag being used for a lid on a chemical

container; it has no label

•

The keys have been left in the ignition

•

Unknown chemical: no label, warnings, etc., or WHMIS

•

A hose is coming out of the top of the tank, not through the

side valve/regulator

•

Exposed worker, enclosed space

•

No wheel chalk to prevent accidental movement of the

vehicle

Aniko Varga

Virology technician, Sidney Laboratory

Canadian Food Inspection Agency

Sidney, B.C.

Chris Young

Facilities manager and occupational health and safety

representative

School District #47

Powell River, B.C.

6

July / August 2011 WorkSafe Magazine

Ionela Garrett,

15, displays last

month’s “What’s

wrong with this

photo?” contest

with her dad, Don,

on the Rambo

Bridge in Hope, B.C.

Hope teen has a

‘thing for safety’

Like most 15-year-old girls, Ionela Garrett likes to flip

through glossy magazines. But the object of her fascination

is unusual: if safety or first aid is the subject matter, she can’t

wait to dive right in.

Photo by Barry Stewart

So, when the May/June issue of WorkSafe Magazine arrived

at her father’s office last month, the Hope teen was the first

to pull out the centre-spread poster for the “What’s wrong

with this photo?” contest on nursery safety and begin

drafting her submission.

Her father, Don Garrett, transcribed his daughter’s list on his

computer, and sent it in by email. He was surprised — and

pleased — to learn that Ionela’s submission had placed third

among about 130 contest entries.

“I don’t know if she’s ever been in a greenhouse,” says Don,

owner of D.R. Garrett Construction Ltd. “But she is very

observant. And safety has always been kind of a thing for

her.”

The Garretts adopted Ionela from a Romanian orphanage at age

three. Although she faces physical and mental challenges, her

father describes her as a happy, athletic, and outgoing special

needs student at Hope Secondary. “She’s a survivor,” he says.

Ionela was a keen participant in the RCMP DARE program, and

she regularly reads safety literature and watches WorkSafeBC

and first aid videos on Youtube. Ultimately, she would like to

pursue her interest in first aid.

Other workers

•

Equipment

•

The hose is kinked, knotted, and laying underneath the

spraying man’s feet, creating a tripping hazard and poor

posture

•

The wand might be too short, creating poor posture

•

One of two jugs of the product is tipped over by the gator

and has no lid

•

The jugs and plant container are on the roadway, too close

to the gator

Ionela’s submission to the May/June contest is as follows:

The man spraying

Due to the unknown product being sprayed, the other

workers possibly require PPE.

•

Not wearing gloves

•

Not wearing goggles

•

The solution in the tank on the gator is not marked

•

Not wearing a respirator or mask

•

•

Not wearing safety footwear

The torn filter cloth on the pathway in front of the other

worker (walking) is a tripping hazard

•

Not wearing hearing protection

•

•

If he’s spraying toxins, he’s not wearing personal protective

clothing (PPE)

The sharp steel protruding from the building column behind

the kneeling worker creates a hazardous situation, especially

if it’s at eye height

•

Poor housekeeping: the Tim Horton’s cup has been left on

the gator seat

•

The respirator is hanging off the edge of the gator seat

•

Dust masks are to be fastened to the worker’s head, not his hat

WorkSafe Magazine July / August 2011

7

Confined Space Rescue Solutions.

TRAINING

Open-enrollment Coursess

On-site Training

Roco training is designed to meet the needs of our clients. In fact, we believe our

courses will exceed your expectations. Our classes include Confined Space, High

Angle, Industrial Rope Rescue, Fall Protection, Tower Work & Rescue, Structural

Collapse and Trench Rescue. Roco’s Rope Rescue courses are approved by the

Technical High Angle Rope Rescue Program (THARRP).

SERVICES

Confined Space Stand-by Rescue Services

Rope Access & Industrial Rope Rescue

CALL:

800-647-7626

RocoRescue.com

Our teams are uniquely qualified to bring added safety and professional rescue to

your next construction or maintenance project. For short-term jobs, or long-term

projects, we provide quality services that you can depend on.

Nursery worker needs a proper

respirator and rubber boots

Editor, WorkSafe Magazine (Re: May/June issue, “What’s wrong

with this photo?”)

Fraud costs

everyone

•

Improper respirator (it’s not being worn anyway)

•

The proper respirator hanging here should be in a sealed

storage bag, away from contamination

•

Other people should not be present during spraying

•

Signage is required at all entry points: i.e., “Do not enter,

spraying in progress”

WorkSafeBC doesn’t take fraud lightly and neither should you.

Improper handling of hazardous material: spill containment

cleanup lid

call WorkSafeBC’s Field Investigations Department toll-free at

•

•

Respirator, eye, and face protection required

•

Disposable coveralls are required for pesticide spraying

•

Overreaching and poor posture can cause an MSI

•

CSA-approved footwear is required (rubber boots)

•

A coiled hose creates a tripping hazard

•

Proper gloves are required; all exposed skin needs to be

covered

•

Ergonomics — the wand should be extended to prevent

overreaching

•

Ergonomics — the walkways are too far apart and force

overreaching for all activities

•

Clear labeling is required on all containers (WHMIS)

•

Ensure this is not a combustion engine pump creating exhaust

gases inside

•

Ensure the E-brake is on

•

The vehicle is overloaded

Everyone has a stake in fighting

workers’ compensation fraud because

we all end up paying the costs.

If you suspect an individual or company of committing fraud,

1 877 523-3315 to make a confidential report, or email

fraudinfo@worksafebc.com.

For more information, including examples of workers’

compensation fraud, visit our website at

www.worksafebc.com/contact_us/fraud/default.asp.

Tell us what you think!

We’re continuing to collect your valuable feedback on our

reader survey at WorkSafeMagazine.com.

Respond now and you’ll be entered in a draw to win one

of six WorkSafeBC watches or first aid kits. You’ll also

provide information we need to tailor the magazine to

meet your needs with regard to workplace wellness and

injury prevention.

Thanks for your input. Read on!

Arden Bolton

Manager of Utilities, on behalf of the utility crew

Thompson Nicola Regional District

Kamloops, B.C.

View more responses to

“What’s wrong with this photo?”

on our website,

WorkSafeMagazine.com.

WorkSafe Magazine July / August 2011

9

on the cover

Photo by Kevin Bennett

By Helena Bryan

Out of the woods

As the forest industry moves toward slashing its historically high

death and injury rate, a new study asks whether fallers can use

training with 3-D images to spot hazards.

10

July / August 2011 WorkSafe Magazine

10

A Vancouver Island faller labours deep in the woods. Fallers are the subject of

innovative new research and training initiatives to reduce the forestry death

and injury toll.

“When it comes to making sure workers — particularly fallers — get home to

their families at the end of the day, good isn’t good enough.”

—Tom Bailey, WorkSafeBC forestry manager for Industry and Labour Services

I

t’s an industry rife with risks. So

workplace safety researchers are

taking a few risks of their own,

applying leading-edge thinking in B.C.’s

forests in the hopes of preventing further

deaths and injuries in the woods.

in 2005, still have the highest overall

injury rate and the highest serious injury

rate of all occupational groups in B.C.

And new hurdles such as an aging

workforce and the continued

fragmentation of the industry (see

for fallers.

The research in question draws from the

established field of science known as

human factors, an area of study

developed to optimize human

performance in the workplace; in this

case, to lessen the likelihood of human

error in hazardous jobs such as falling.

Coming to a screen near you, page 13)

are only adding to the risks fallers face.

rely on certain visual cues to identify

potential sources of danger.

An analysis in 2009 of injuries and

fatalities among fallers showed that even

certified fallers were dying or getting hurt

on the job. “While none of the fallers in

the analysis had gone through the new

faller training program — they’d been

certified as competent due to experience,”

Bailey says. “What this said was that

there are times and circumstances where

people just don’t see the risks.”

As WorkSafeBC human factors specialist

Jenny Colman explains, this technique

will train fallers to optimize the human

visual system to detect hazards. These

hazards might include intertwined tree

limbs, blown-down trees, rootwads, and

many others. Each of these situations

contain a myriad of hazards that are

often hard to spot, and cannot even be

seen until the tree is in motion. “Falling

is a dynamic process involving multiple,

simultaneous hazards that fallers are

challenged to detect,” Colman says. “This

technique will train fallers to spot hidden

hazards, beyond those determined by

previous or more formal risk

assessments.” (For more information on

human factors, please see

www2.worksafebc.com/Topics/

AccidentInvestigations/HumanFactors.

asp. For information about an upcoming

human factors conference, see the back

of this month’s pullout poster.)

While the industry has successfully

renewed its commitment to combating

faller fatalities through its forestry

certification and training programs, a

group of psychologists and forestry safety

experts have teamed with forestry giant

Western Forest Products to improve the

way fallers assess day-to-day hazards —

and thereby vastly improve their chances

of survival.

“Think of the industry as a rocket,” says

Tom Bailey, WorkSafeBC forestry

manager for Industry and Labour

Services. “There was the booster stage,

when the industry recognized it had a

problem and assessed the risks. Then it

took flight with the new training

program, safety standard, and quality

control. Now, it’s in the third, more

targeted stage: to do all it can to improve

safety in the field.”

For now, the target is fallers, who, despite

an increased focus on faller safety begun

Competent fallers hurt

by what they can’t see

John Bulcock also saw that analysis. As

corporate manager of health and safety

for Vancouver-based Western Forest

Products (WFP), Bulcock and his team of

health and safety advisors provide

support to company and contractor

falling supervisors. These supervisors, in

turn, are responsible for the well-being of

40 full-time fallers and up to 200 on

contract during peak times. Through his

efforts, the company is partnering with

Kwantlen Polytechnic University to test

whether human factors training first

devised to help U.S. military personnel

identify enemy targets — and currently

used to protect miners — has applications

The training in question takes into

account the effect of “visually degraded

environments” found in places like war

zones or mines, or in this case, forests,

and teaches workers and supervisors to

Bulcock says he could see the potential

for this research after noticing the

number of fallers who had been seriously

injured or killed by being struck by

something from above.

WorkSafe Magazine July / August 2011

11

“It’s not that they’re not looking up,”

Bulcock observes, “or that they don’t

have the technique to remove the

hazards safely when they see them. In

fact, fallers are highly trained to focus on

safety. And no faller would fall a tree if

they knew something was in the canopy

that could come down and strike them.

will recreate hazards in a variety of

degraded visual conditions. And then

she’ll test how well fallers who’ve been

given this training can then go on to

spot hazards in the field. If all goes well,

the group will design and deliver a

training module and then track its

success over several years.

“Then we realized how difficult it is to

see clearly in the forest canopy. Even on

a bright, sunny day, you look up and it’s

dark or full of shadows. Add fog or snow

and it gets even harder.” What’s more, he

points out, as workers age, their vision

begins to diminish.

Falling safety has come

a long way

Hazard recognition

study set to go ahead

An internet search led Bulcock toward a

whole body of research on the benefits

of hazard recognition training through

the use of 3-D images in the U.S. mining

industry. “The training is about teaching

people to look at things differently,” he

says. “And the research showed that

people who had the training didn’t get

hurt at the rate that people without it

did.”

It was enough to convince Bulcock. And

with funding from WorkSafeBC and help

from Colman, a field study involving

WFP fallers has been given the green

light. Under the supervision of Kevin

Hamilton, chair of Kwantlen’s

Department of Psychology, researcher

Niloufar Saffari will conduct the

research this spring and summer, with

preliminary findings expected soon.

As part of her research, Saffari will visit

WFP cutting sites to do a task analysis

and identify the visual hazards and

degraded conditions typical of that

environment. She’ll develop a series of

3-D images for use in the training; these

12

July / August 2011 WorkSafe Magazine

Meanwhile, longtime foresters are buoyed

by a glimpse into the future. Falling is

still a hazardous profession, but a strong

push for safer training and certification —

along with the promising new degraded

imagery research — is forging a new path

in the industry.

Third-generation logger Steve Venus

recalls the arguments that ensued when

he told his Dad at age 18 he wanted to

follow in his footsteps. “It was the only

contentious time between us,” Venus

says. “It took awhile for him to accept

what I wanted to do.

“Logging has been good to my family for

more than 70 years. But back then, a

culture of risk-taking permeated the

industry,” Venus says. “And the prevailing

attitude was that if you worked in the

woods, you were going to get hurt.”

Fifteen years later, Venus is now a

qualified supervisor trainer and the

owner of a successful Vancouver Island

falling contracting company. He says he

wouldn’t hesitate to recommend falling as

a long-term job. “My friend’s son wants to

be a faller just like I did,” he says. “Today,

I can tell him it’s a good occupation —

that with the proper training and the

right attitude, he can expect to have a

long, fulfilling — and safe — career.”

New safety standards

revolutionize the

industry

Today, Venus represents a new breed of

company in an industry that has undergone

a major overhaul since 2005. That was

when 43 forestry workers lost their lives in

one of the deadliest years ever. Reaction to

the terrible toll created a groundswell of

support for change — change that might put

an end to the grim statistics that have

plagued the industry for decades.

Fast forward six years and enter a whole

new world. In the past two years, forest

industry fatalities — largely associated with

logging truck accidents, transportation of

workers in boats, crummies, and aircraft, as

well as roll-overs of skidders and other

heavy logging vehicles — have dropped

from an average of 22 per year to an

average of 5.5. Furthermore, the BC Forest

Safety Council provides an infrastructure

for comprehensive safety programs.

Thousands of fallers — the group heaviest

hit by serious injuries — have been newly

certified to the highest safety standards

and are now under the supervision of

specially qualified faller-supervisors.

“Falling is therefore no longer the

dominant job category where fatalities

occur in B.C.’s forests,” Bailey says.

Then there’s the 80 percent of forestry

companies in the province now certified

through the SAFE Companies certification

program, meaning their safety programs

and policies have to meet certain standards,

while translating into safe practices in the

field.

Most importantly, that culture of

risk-taking Venus refers to has been

replaced at every level — in the boardrooms,

the mills, and out in the woods — by a

safety-first approach.

As a result, Bailey says, a more favourable economic forecast for

2011 and beyond means forestry workers can expect to be busier,

and safer, than a decade ago. “But this is no time for complacency,”

he insists, quoting bestselling author Jim Collins, who coined the

phrase, “the enemy of great is good.”

“Yes, the industry is getting to be good,” Bailey says. “But when it

comes to making sure workers — particularly fallers — get home to

their families at the end of the day, good isn’t good enough. We need

to do everything we can to get to great.”

Venus says communication is key to building a better safety culture.

“If the licencees and logging contractors don’t talk with the falling

supervisors, we’re all putting people at risk,” he says. Supervising

requires teamwork between the falling supervisor, the fallers, the

loggers, and the road crews. You can’t assume people know what’s

going on; you have to take the time to talk about it.”

Coming to a screen near you

There’s nothing as powerful as a good

story to get a point across. That’s the

theory behind a new faller safety video

released this spring. It depicts a day in the life of a faller in

today’s fragmented industry.

third-generation logger on Vancouver Island. “When I first

started falling, we never had to work around heavy

equipment. Now, we’re constantly working around

roadbuilding, rigging, or logging crews. If I don’t talk to the

licensee or the logging contractors, I put my guys at risk.”

“In the old days, the engineers, fallers, and logging truck

drivers all belonged to one big company and they talked to

each other,” says Tom Bailey, WorkSafeBC forestry manager

for Industry and Labour Services. “Today, 88 percent of

registered forestry companies have four or fewer employers.

And each segment operates independently of the others —

raising questions about who holds the responsibility for

safety.”

Dave Lachance, WorkSafeBC forestry industry specialist,

says the point of the video is to show the importance of

personal responsibility. “People need to get beyond the idea

that ‘this is my job and that’s all I need to do,’” Lachance

says. “The video shows how planning and supervision can

prevent a serious injury or save a life.”

At the same time, different phases of the logging process

tend to overlap, so clear communication between each group

becomes even more important, says Steve Venus, a

The video is now available on WorkSafeBC.com and on

YouTube, as well as in the WorkSafeBC Store in hard copy.

It is also being translated into seven languages: simplified

Chinese, traditional Chinese, Spanish, French, Punjabi,

Vietnamese, and Korean.

WorkSafe Magazine July / August 2011

13

WORK SCIENCE

No small matter

The brave new world of nanotechnology

poses an unexpected threat for workers

exposed to its raw materials.

N

anotechnology is the science of the invisibly small.

Applying a combination of chemistry, physics, and

biology, scientists can manipulate individual atoms and

assemble them into specific structures, devices, or systems. The

work occurs on a scale between one and 100 nanometers. We’re

talking tiny: A nanometer is a billionth of a metre; the width of a

single human hair is roughly 100,000 nanometers.

Naturally produced and man-made nanoparticles have always

existed. Nowadays, nanotechnology offers many fascinating

applications, one of which is the use of engineered nanoparticles,

designed for specific purposes. Engineered nanoparticles are

already used as additives in some food and medicines. They’ve

been used to make tennis balls, sunscreen, and clothes. The

science of nanotechnology could lead to faster computers and

new treatments for disease.

It’s a pursuit that’s as thrilling as it is lucrative. But there’s a flip

side to all this super science: nanotechnology presents potent

14

July / August 2011 WorkSafe Magazine

By Gail Johnson

challenges for worker health and safety.

WorkSafeBC senior occupational hygienist Geoff Clark says that

by handling these minute particles on a daily basis, workers risk

hazardous exposure — and potentially adverse health effects.

“Regardless of how they enter the body — nanoparticles — which

can be various forms of metals, carbon compounds, or other

chemicals, can pass into the bloodstream and affect organs

throughout the body,” Clark says.

Workers often unaware of the risks

But not all nanotechnologists work with nanoparticles, and it’s

important to know the difference. Clint Landrock works in a

sterile environment and wears a clean-room suit. The chief

technology officer at Surrey’s NanoTech Security Corporation

handles such sophisticated tools as a scanning electron

microscope and focused ion beam. He has several patents to his

name, and recently took part in the development of an

Simon Fraser University researchers

Byron Gates and James Zhou examine

nanoscale-sized fibres via scanning electron

microscopy.

anti-counterfeit measure for banknotes using nano-structured

optics.

Landrock views the field of nanotechnology in terms of its

potential, rather than its limitations: “To be at the forefront of

this industry is very cool,” he says. “Nanotechnology is going to

become increasingly accessible to people.”

And although he wears a protective suit, Landrock is more

conscious of his own body contaminating the materials. “Many

lay people think nanotechnology is scary because of possible

exposure to nanoparticles,” he says. “Creating nano-sized

structures in a macro-sized device is different from making

nanoparticles, and therefore doesn’t carry the same health risks.

Those working with nanotechnology should understand the

difference.”

Yet, as Clark points out, those who work with nanoparticles

should consider more serious precautions: workers can actually

breathe in nanoparticles or ingest them accidentally — say, by not

washing their hands before eating. While the skin-penetration

properties of nanoparticles are still under discussion, some

studies suggest certain types of nanoparticles can enter the body

through sweat glands and hair follicles. One animal study has

even shown them travelling along the olfactory nerve from the

nose straight to the brain.

Clark says some nanoparticles might cause even worse health

effects than those associated with their “parent” materials. “Take

silver versus nanosilver, for example. Exposure to silver can cause

a variety of toxic effects, and WorkSafeBC has an occupational

exposure limit for silver and silver compounds. But some types of

nanosilver may be even more toxic. And the existing exposure

limit might not be applicable.”

Nanoparticles pose possible safety hazards too, Clark explains. As

particles decrease in size, so does their surface area, and certain

types of nanoparticles can become more combustible. “If these

materials are allowed to accumulate in an uncontrolled fashion in

the workplace, they can cause a fire or explosion.”

Simon Fraser University (SFU) chemistry professor Byron Gates

says best practices on the job are crucial to protecting workers.

“Regardless of how they enter the

body — nanoparticles — which can

be various forms of metals, carbon

compounds, or other chemicals,

can pass into the bloodstream and

affect organs throughout the body.”

—WorkSafeBC senior occupational

hygienist Geoff Clark

Gates is the lead researcher for two current studies that look at

ways to minimize exposure to nanoparticles, funded in part by

WorkSafeBC’s Research Secretariat.

Effects of nanoparticle exposure under

scrutiny

The first study, which received a $30,000 WorkSafeBC Research

at Work development grant, focuses on the safe handling and

monitoring of nanoscale materials in the workplace. It will

examine strategies that aim to establish best practices for

handling nanoparticles and simple methods for assessing their

stability. The second phase, awarded a $50,000 WorkSafeBC

Innovation at Work grant, looks at how to reduce nanoparticle

contamination in the workplace, and will include protocols for

cleaning up nanoparticle spills.

Research Secretariat director Ed McCloskey says WorkSafeBC

and its industry partners consider nanoparticle safety research a

top priority. “Because of their unique properties, nanoparticles

are becoming widely used in industrial and commercial

applications. Research is being conducted worldwide to

understand their potential health effects, and to ensure workers

are not exposed to harmful amounts.”

At the same time, Gates says nanotechnology need not be a

dangerous science. “There are many ways employers and workers

can prevent exposure to nanoparticles, providing workers use

appropriate personal protection when they work with nanoscale

particles, along with cautious handling practices.”

WorkSafe Magazine July / August 2011

15

Worker training is just the start, Gates says.

Worker exposure can be minimized if each step of the

manufacturing operation is enclosed. Anti-exposure measures

are already established in places like NanoTech, UBC’s (the

University of B.C.) Microsystems and Nanotechnology Group,

and Gates’ own lab at SFU.

Other safety strategies include separate changing areas for

employees, just like those provided at other industrial sites, such

as lead-product-manufacturing facilities. Proper ventilation can

reduce exposure and recapture nanomaterials.

Exposure reduction saves money

Employers have a financial incentive for decreasing worker

exposure as well: those ultrafine particles might travel home

with workers — and they’re too expensive to leave the workplace.

“Health and safety measures not only protect workers, but can

reduce product loss,” Clark says. “Some facilities have workers

bag and package carbon nanotubes by hand, using a scoop. Lots

of dust is produced, material is lost, and workers are

unnecessarily exposed. An automated packaging process would

prevent exposure and probably pay for itself through the

recovery of lost product.”

While safety measures are being developed, the challenge with

nanoparticles lies in their widespread use. “The extent of this

industry is unknown, as new materials and products are being

developed almost daily,” Gates says.

Meanwhile, WorkSafeBC occupational hygiene officer Mark Teo,

who has completed his doctorate in analytical chemistry at UBC

and previously worked in the field of nanotechnology, is

currently a member of the Canadian Standards Association

nanotechnology occupational health and safety technical

committee. The goal of this committee is to come to a consensus

on a Canadian standard and guideline to protect workers

handling engineered nanomaterials.

Clark says the enthusiasm toward nanoparticles must be

tempered with caution.

“Nanotechnology promises to be an exciting and ongoing

industry,” he says. “We just have to make sure — as we move

forward — that we’re building worker health and safety into the

process.”

Achieve Excellence with Small COR

Enroll today and earn up to a 15% rebate on your WorkSafeBC premiums.

The Small Certificate of Recognition program demonstrates a standard of excellence for small construction employers.*

Employers who go beyond the regulatory requirements of the Workers Compensation Act and the OH&S Regulation by implementing health

and safety management systems as well as injury management/RTW systems, are rewarded through our monetary incentive program.

Bring your company safety to a level of excellence. Call us at 1.877.860.3675 today!

*

companies with 19 or fewer permanent employees

Raising awareness, reducing injuries

16

July / August 2011 WorkSafe Magazine

www.bccsa.ca

WorkSafeBC UPDATE

Get your

safety

game on

“As young people transition from

spending their days in school to taking

on summer jobs, safety can be the last

thing on their minds. And that can be

a fatal oversight.”

—Trudi Rondou, WorkSafeBC young and new

worker manager for Industry and Labour Services

By Alexandra Skinner-Reynolds

W

hat do arcade games and workplace safety

have in common? At first glance, not much.

Until now, that is. WorkSafeBC’s 2011 Raise

your Hand (RYH) campaign — designed to draw

attention to safety for young workers — has launched a

retro-style video game to encourage young workers to

stay safe on the job.

The game launched in April on RaiseYourHand.com, andd is

reminiscent of 1980s arcade games, complete with synthesized

music, pixilated graphics, and the computerized voice of

Paralympian Josh Dueck. (The highlight of last year’s RYH

campaign featured Dueck beating the Guinness World Record for

the most high-fives in 24 hours.)

The game is designed as one way to engage young workers and

their employers into keeping workplace safety uppermost in their

minds over the summer, when so many young workers join the

workforce — some for the first time. The RYH campaign features

WorkSafeBC’s own street team, which goes out to workplaces,

schools, and events this time of year to spread the workplace

safety message and educate young people about the role of

WorkSafeBC.

“As young people transition from spending their days in school to

taking on summer jobs, safety can be the last thing on their

minds. And that can be a fatal oversight,” says Trudi Rondou,

WorkSafeBC young and new worker manager for Industry and

Labour Services. “Because whether they’re bussing tables in a

downtown restaurant, or planting trees in the backwoods,

workers under 25 are at high risk of getting injured on the job”

Every day in B.C., 28 workers under the age of 25 are injured.

That’s why, every summer, just as more young workers are

entering the workforce, WorkSafeBC launches the Raise your

Hand campaign to reach out to these workers.

“Our main goal is to build awareness among young workers,

rather than lecture them,” Rondou says. “Just like the rest of us,

young people will engage in a topic if they are interested and

won’t bother if they aren’t. This game draws attention to safety in

a way that’s interactive and fun.”

Each level of the game reinforces one of three basic rights for

young workers: The right to know how to do a job safely, the

right to speak up about unsafe work practices, and the right to

refuse unsafe work.

The game kicks off with a card-matching challenge, where gamers

must quickly match pairs of safety equipment. In the second level,

young people are encouraged to speak up by blasting workplace

hazards, like vats of hot oil, sharp knives, and electrical wires —

before the hazards zap them. The third level, modelled after the

popular carnival game “whack-a-mole,” asks gamers to refuse

unsafe work by whacking dangerous work practices (like

standing on top of a ladder or not using a blade guard), and

avoiding whacking safe ones (like staff meetings and answering

phones).

To check out the game, go to www.RaiseYourHand.com

WorkSafe Magazine July / August 2011

17

New asbestos

website spreads

cautionary tales

By Rob McMahon

A

hidden killer remains on the loose. And WorkSafeBC

has another tool in its arsenal that aims to stop it in its tracks.

A new website — entirely devoted to preventing the spread of

asbestos-related diseases due to exposure — launched at the end

of June this year.

Modelled on a similar website created by the United Kingdom’s

Health and Safety Executive, the site (HiddenKiller.ca) is part of

WorkSafeBC’s ongoing campaign against a mineral that’s hard

to detect, yet contained in a wide array of household

construction materials. Asbestos is currently B.C.’s number-one

occupational disease killer.

We believe we can eradicate

asbestos disease by limiting

people’s exposure to it. But first,

people need to know what it is,

and what it can do to them.

The site provides resources to help employers, workers, and

others — particularly those in the construction industry — safely

identify, handle, and deal with asbestos or exposure to asbestos.

It features a quiz, video, real-life stories, and downloadable

pamphlets highlighting safe work practices. Visitors will

ultimately learn how to submit information on asbestos

—Al Johnson, director of construction for

the Lower Mainland

.QRZOHGJH

VKDULQJWKH

&RQWDFW&DWK\&RRN([HFXWLYH'LUHFWRU

3)(FFRRN#EFPVDFD

7KH%&06$LVWKHUHVRXUFHIRURFFXSDWLRQDOKHDOWKDQGVDIHW\LQIRUPDWLRQIRU/RFDO*RYHUQPHQWV3DUWLFLSDWHLQWKH&HUWLÀFDWHRI

5HFRJQLWLRQ&25SURJUDPLPSURYH\RXURYHUDOOVDIHW\SHUIRUPDQFHDQGUHFHLYHDUHEDWHRQ:RUN6DIH%&SUHPLXPVXSWR

6DIHW\&RPPLWWHH0HPEHU5HVSRQVLELOLWLHV

:RUNVLWH6DIHW\,QVSHFWLRQV,QFLGHQW$FFLGHQW

,QYHVWLJDWLRQV+D]DUG,GHQWLÀFDWLRQ

5LVN$VVHVVPHQWV&RQÀQHG6SDFH(QWU\WKHRU\

SUDFWLFDO([FDYDWLRQ6DIHW\3RRO6DIH%&6DIHW\

0DQDJHPHQW6\VWHPV,QWHUQDO$XGLWRUIRU/RFDO*RY·W

&25$XGLWV+D]DUG$ZDUHQHVV5HFRJQLWLRQIRU

0XQLFLSDO,QVSHFWRUVFRPLQJVRRQ

0XQLFLSDO6XSHUYLVRUV+6&HUWLÀFDWH3URJUDP

FRQIHUHQFH

WUDLQLQJ

75$,1,1*23325781,7,(6

%&081,&,3$/2&&83$7,21$/

+($/7+6$)(7<&21)(5(1&(

DFRQIHUHQFHIRUPXQLFLSDOLWLHVVFKRROERDUGVDQG

SXEOLFVHFWRURUJDQL]DWLRQV

1RYHPEHUWR

6KHUDWRQ9DQFRXYHU:DOO&HQWUH+RWHO

5HJLVWUDWLRQIURPDVORZDV

SURJUDPGHWDLOVDYDLODEOHDWZZZEFPVDFD

ZZZEFPVDFD

18

July / August 2011 WorkSafe Magazine

Find out more about how to prevent

asbestos exposure at HiddenKiller.ca.

exposure, via WorkSafeBC’s upcoming occupational

disease exposure registry.

homes built before 1990 contain asbestos, which can be released

during demolition and renovation projects.

Despite widespread public education about the

dangers of asbestos, exposures continue to occur,

particularly in the residential construction industry,

where some owners and employers might choose to

cut corners in the demolition and renovation of older

homes — key sources of asbestos.

To catch these violations, WorkSafeBC has embarked on a

zero-tolerance campaign toward improper asbestos management.

In 2011, seven new officers joined on-the-ground compliance

teams dedicated to finding and shutting down dangerous

worksites.

“We believe we can eradicate asbestos disease by preventing

people’s exposure to it,” says Al Johnson, director of construction

for the Lower Mainland. “But first, people need to know what

asbestos is, and what it can do to them.”

Formerly celebrated as a “miracle mineral,” asbestos was used in

the 1950s in everything from linoleum tiles to hair dryers.

Asbestos was deemed cheap, tough, and flame-resistant. However,

once its fibres were released and inhaled, they led to devastating

side effects. Now we know that exposures to asbestos can

eventually result in chronic diseases, such as asbestosis, or a

deadly lung cancer like mesothelioma.

The late Paul Douglas — who blogged about his experiences with

mesothelioma — contracted the asbestos-related disease during

his 20-year career as a construction boilermaker in B.C. Initially

given only three to six months to live, Paul advocated

passionately against the dangers of asbestos for the past decade,

before passing away in 2010, days from his 56th birthday.

“Unfortunately, there are contractors who don’t tell their

employees and clients about the risks of asbestos,” Johnson says.

“But our compliance teams are taking a strong enforcement

approach, both in the Lower Mainland and around B.C. They’ll

catch offenders after hours, on weekends — people think they’re

off the hook, and are surprised when we show up. Our teams will

shut down job sites, hand out fines; even initiate legal action. If

people don’t follow the procedures, there will be penalties.”

As part of its ongoing asbestos campaign, WorkSafeBC will

expand its outreach speakers program to include insurance

adjustors, engineers, architects, real estate agents, developers,

and others, in the effort to help them identify potential sources of

asbestos on worksites. From May to August — the peak season for

demolition activity — WorkSafeBC will offer an information desk

to guide homeowners about asbestos removal and disposal

requirements, survey records, and clearance letters. Finally,

concerned individuals can report suspicious construction-related

activities through an anonymous tip line, available at

1 888 621-7233 or toll-free at 1 866 922-4357.

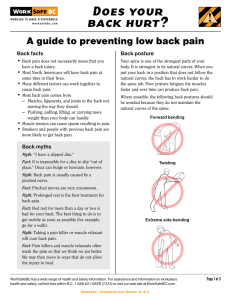

“Asbestos-related diseases don’t arise right

away. There’s a long latency period, so it’s

very different than when someone is cut or

burned,” says WorkSafeBC senior

occupational hygienist Geoff Clark. “People

don’t face the consequences for 20, 30, or

40 years.”

Health Canada strictly regulates the sale of

pure asbestos and high-risk consumer

products that contain the mineral under the

Hazardous Products Act. However, it

remains a problem. That’s because most

WorkSafe Magazine July / August 2011

19

Orchard workers, engineers, safety specialists, and

industry associations team up to elevate safety

standards for mobile work platforms.

I

magine trying to put your barbecue

together without installation

instructions, or operating a forklift

without a manual or training. It’s not only

unsafe, but downright dangerous. But if

you depend on that equipment for your

livelihood, you’re going to make it work —

manual or no manual.

That’s essentially what fruit growers in the

central interior of B.C. have been doing for

years. This group has long been using

rather dated, mobile elevating work

platforms (MEWPs) to harvest fruit and

prune their trees. Several hundred of

20

July / August 2011 WorkSafe Magazine

these platforms are in use throughout the

Kelowna area — all in various states of

functioning. If the equipment breaks

down, growers often fix it themselves.

“These farmers or growers are often

skilled, yet creative, manual workers. They

will take any piece of equipment and make

changes or repairs on it,” says Don Dahr,

WorkSafeBC manager of agriculture for

Industry and Labour Services. “Most

MEWP manufacturers are unknown, and

information on their equipment is

nonexistent. It’s unlikely, and perhaps,

unrealistic, for them to consult with an

By Jennifer Tsui

engineer. Their main focus is on getting

these platforms to operate.”

Understandably, the do-it-yourself

modifications on these machines pose

serious safety concerns for the operator.

The safest solution, of course, would be to

contact the manufacturer to have it fixed

properly. But that’s the problem with the

mobile platforms, Dahr says: “These

machines were built 40 or 50 years ago.

So no one knows who the manufacturers

are, let alone where the manuals are to

operate them — or even if any manuals

were there in the first place.”

Photo by WorkSafeBC occupational safety officer Patricia Fair

Operating room

Orchard supervisor David Thiessen demonstrates the use of a mobile

elevating work platform at Alfred Witzke Orchard in Oyama, B.C.

Farmers and engineers

provide a team solution

The farmers depend on these platforms to

do their jobs and earn their living. But to

continue using them without knowing the

correct operating instructions or how to

work with them safely was a recipe for

disaster.

That’s why the BC Fruit Growers’

Association and the Farm and Ranch

Safety and Health Association (FARSHA)

teamed up with WorkSafeBC’s Kelowna

regional office and Industry and Labour

Services to develop a safe solution for

farmers.

Since the lack of any engineering or

operation manual was the main problem,

the answer seemed simple: why not just

create them? Then, the Prairie

Agricultural Machinery Institute (PAMI)

and the University of B.C.–Okanagan

entered the picture. PAMI, an applied

research and development engineering

organization, developed a generic manual

— similar to what the manufacturer would

Serving Western Canada

have created — containing all the

information operators need to know on

how to run and maintain the machine

safely.

A group of local UBC–Okanagan

engineering students and their professor

also pitched into the project, creating a

computer modelling system to determine

the maximum slope these platforms could

move on without tipping, whether or not

the equipment could be used to traverse a

slope, and how high the arm could go

before flipping the entire unit over.

To complement the manual, FARSHA

developed a training program they will be

delivering to employers once the manual is

finalized, says Bruce Johnson, FARSHA

executive director. The first program

module will focus on educating owners

about the manual and engineering

standard. The second will go over the

responsibilities of the worker, the

supervisor, and the employer relating to

the use of these platforms.

“This is a win-win

any way you look at

it: B.C. fruit growers

will be in compliance

and the operators of

this machine will have

the training and

resources to use the

equipment safely.”

—Don Dahr, WorkSafeBC

manager of agriculture for

Industry and Labour

Services

Continued on page 32

Head Office: Surrey, British Columbia

Phone: 604-594-7490

Visit: www.envirovac.com

Automated Vacuum Loaders and Baggers Save You Time and Money

Safety is Enviro-Vac’s First Priority

with strict attention to schedule and

client satisfaction.

Enviro-Vac™ is one of the largest

full service abatement contracting

companies in Canada. The company

has been in operation since 1976

and has offices in Victoria,

Vancouver and Edmonton.

Toxic Substance Control Act,

U of C Berkeley Certified. WCB COR,

CSO, HMA, SSPC Certified & more.

$5 mil CGL Environmental Insurance.

Bonded.

* ASBESTOS * LEAD * MOULD * PCB

* MERCURY * BIO-HAZARDS * SILICA

* HEAVY METALS DUST * INDUSTRIAL

VACUUMING / PLANT CLEAN UP

* DECONTAMINATION TRAILORS

* WASTE MANAGEMENT

* SHRINK-WRAP CONTAINMENTS

ASBESTOS ABATEMENT / HAZARDOUS MATERIALS SPECIALISTS

WorkSafe Magazine July / August 2011

21

TOOL BOX

High time

Photo by Heath Moffat Photography

By Robin Brunet

With the range of

safety programs and

equipment available

to today’s steep

slope roofers, there’s

no need to take

dangerous shortcuts.

F

ormer steep slope roofer Jay

Beddows had only been a corporate

safety officer at Parker Johnston

Industries Ltd. for one year when he got to

witness first-hand the consequences of

ignoring safety protocols.

His co-worker was roped off, but decided

to release the slack on his fall protection

device in order to move from one part of

the roof to another.

“He was cutting a piece of wood, and he

slipped and fell over the edge,” Beddows

recalls. “He dropped 13 feet and landed

feet-first on concrete. He was never the

same again.”

In 2010, steep slope roofers accounted for

35 percent of all WorkSafeBC penalties.

As well, this subsector of the construction

industry represented more than

22

July / August 2011 WorkSafe Magazine

40 percent of all WorkSafeBC construction

claims and more than 80 percent of all

claim costs. With each claim averaging

almost $64,000, workplace injuries have

cost this particular trade $14.4 million

over the past five years — not to mention

an immeasurable loss of life.

Nonetheless, steep slope roofers have an

abundance of safety training programs to

choose from in B.C., so there’s really no

excuse for the terrible toll on workers’

health and safety, says Shirley Caldwell,

education and training manager for the

Roofing Contractors Association of British

Columbia (RCABC). “We overhauled our

programs in 2009 and now provide

everything workers and contractors need

to know about avoiding hazards and

injury,” she says.

Nate Nelson, crew foreman for Parker Johnston Industries, conducts a tear-off of old

asphalt shingles on a sloped roof in Saanich, B.C.

“Many roofing companies are small operations

whose contractors demand fast work and feel they

don’t have time for operating fall arrest lines.”

Unfortunately, a lack of education and

training — particularly in the residential

steep slope roofing sector — has prompted

many contractors to take safety shortcuts.

Mike McKenna, executive director of the

B.C. Construction Safety Alliance

(BCCSA), says pressures to meet demand

lead to hasty errors in judgement. “Many

roofing companies are small operations

whose contractors demand fast work and

feel they don’t have time for operating fall

arrest lines.”

Beddows also cites the following six

activities workers must avoid while

working on a sloped roof:

How to stay safe on high

•

Beddows draws on his years of experience

as a roofer and safety officer to offer the

following advice to workers:

•

•

•

•

•

—Mike McKenna, executive director of the

B.C. Construction Safety Alliance

Do not perform work before a proper

fall hazard assessment has been

conducted, regardless of the height.

•

Attend any safety orientations to

become familiar with the rules and

hazards of the jobsite.

Do not perform work before a proper

electrical hazard assessment has been

conducted.

•

Wear appropriate personal protective

equipment as required for each

hazard, and stop work if such

equipment is not available.

Do not perform work without fall

protection when working above 3 m

(10 ft.) or when faced with an

exceptional hazard.

•

Inform your employer if you’re not

trained or qualified to perform specific

work procedures.

Do not perform work without footwear

that provides adequate traction on

sloped surfaces.

•

Do not perform work with fall

protection equipment that is damaged,

worn, or unable to provide a proper fit.

•

Do not perform work using fall

protection equipment that you have

not been trained to use.

Stop work and inform your employer if

you cannot perform the work in

accordance with established safety

rules and guidelines.

Exercise your right to refuse unsafe

work.

Get in gear!

The main components (and associated

components) of steep slope roofing safety

equipment are as follows:

•

CSA or ANSI standard fall restraint

devices

•

CSA or ANSI standard fall arrest

systems

•

Anchors that can support anywhere

from 3.5 kN (800 lbs.) to 22 kN

(5,000 lbs.), in accordance with the

Occupational Health and Safety

Regulation

•

Lanyards, lifelines, and other

connecting equipment

The OHS Regulation states that workers

using fall restraint must wear a full body

harness or a safety belt. When using fall

arrest, a worker must wear a full body

harness or other harness deemed

acceptable by WorkSafeBC. The

Regulation also requires safety gear to be

Continued on page 27

WorkSafe Magazine July / August 2011

23

NUTS AND BOLTS

At the ready

By Lynn Welburn

Recent events in Japan offer a potent reminder that time taken

to review emergency planning procedures with employees —

including new staff or those with disabilities — is time well spent.

L

ike so many others, Mike Chislett

watched in horror at the

devastation that unfolded March 11,

following an unprecedented earthquake

and tsunami in Japan.

As the resort concierge at Parksville,

B.C.’s Tigh-Na-Mara Seaside Spa Resort

and Conference Centre, Chislett was

prompted to take a hard look at the

resort’s own emergency preparedness

plans. And when he realized more current

information might be available, he

contacted WorkSafeBC right away to look

for more resources.

His quick thinking earned kudos from his

employer. “We’re pleased with Mike’s

initiative,” says Paul Drummond,

Tigh-Na-Mara’s general manager. “He’s

enthusiastic and energetic. We take pride

in caring about our employees and our

guests, and Mike exemplifies that.”

Drummond says the resort has been

24

July / August 2011 WorkSafe Magazine

improving its emergency readiness plan

ever since.

Employees welcome

emergency planning

process

One improvement the resort made to its

earthquake preparedness plan was to

move its evacuation areas away from

parking lots surrounded by large trees

toward more open areas — safer locales if

the earth began to tremble.

As a resort, Drummond says,

Tigh-Na-Mara must not only consider its

nearly 300 employees but also, in high

season, up to 800 guests staying in rooms

spread across the resort’s nine hectares.

As such, the resort already had many good

practices in place, such as radio

communication between night employees

to ensure that — whatever the hazard —

people are able to stay in contact.

“It was mostly details we took into

account,” says Therese Lowe, co-chair of

Tigh-Na-Mara’s health and safety

committee. “We reviewed our basic policy

for fire evacuation and earthquakes, made

sure our employees understood it, checked

government links to make sure we were

up to date, and linked up with the City of

Parksville’s emergency evacuation

procedures.”

When they decided to upgrade the

procedures, the resort found its employees

receptive.

“It was so close to the Japan disaster that

there was no negativity,” Lowe says.

“Everyone was glad to get more

information, and to have localized

information. We even gave our employees

preparedness tips they could use at home.”

Although the changes were relatively

minor, just going through the process

heightened awareness among existing

staff — and reinforced the need to review

Cecilia Hemsworth, front office manager for

Tigh-Na-Mara resort in Parksville, B.C., and

resort concierge Mike Chislett assess potential

emergency concerns near the resort’s oceanfront.

Photo by Lance Sullivan photography

these emergency procedures

regularly, particularly among

newer employees. To ensure

these procedures work, for

instance, the resort considers

the orientation of its newly

hired staff a priority. On the

first day of employment, new

staff must review fire-exit

locations, emergency

procedures, locations of first

aid stations, and emergency

phone numbers.

A few weeks later, this same

group of new employees has a

resort-wide orientation session

to refresh these lessons, along

with monthly department

meetings to tackle safety

topics.

In some ways, Drummond says, the resort

is better prepared than many businesses

because it already has food and water on

site, generators, guest rooms with

emergency lights for power outages, and

teams of employees trained in what to do

and whom to contact for any problem —

from a windstorm power-cut to a

full-blown disaster.

Include all employees in

the plan

As Tigh-Na-Mara learned through its own

planning exercises, it’s important for small

business to consider all employees in

preparing for an emergency. In addition to

the fact that new employees are often

overlooked, increasing evidence shows

some employers fail to consider staff with

disabilities — especially disabilities that

aren’t readily apparent.

Karen Martin, emergency preparedness

project coordinator for the BC Coalition of

People with Disabilities (BCCPD),

conducted a study on emergency

preparedness for people with disabilities

through the support of WorkSafeBC’s

Research Secretariat.

“We found that general workplace

emergency plans do not address the needs

of people with disabilities and put people

at risk,” she says, noting that many

disabilities are not always as evident as,

say, wheelchairs. “Some degree of visual

impairment can make it hard for people to

read posted emergency procedures, or for

employees who are deaf or hard of hearing

and don’t hear alarms in time.

“In B.C., there is a growing number of

people with disabilities in the workplace,”

Martin says, noting that 55 percent of all

employable people with disabilities in B.C.

are employed here — some 130,000 people.

And with the population aging and people

working longer, more employees have

hidden disabilities — some degree of vision,

hearing, or mobility impairment.

“We need to start thinking in terms of a

workplace that is safe for everybody,”

Martin says. “After Japan, we’re being

asked to do a lot of presentations. People

An emergency can

happen at any time

and people need to be

ready to protect

themselves, as well as

their facility and their

inventory.

—Terri Holizki, WorkSafeBC

small business manager for

Industry and Labour Services

are concerned, as they should be.”

The BCCPD trains businesses, government

departments and community

organizations to create emergency plans

that include people with disabilities and

seniors. Free booklets, checklists, and

more are available at www.bccpd.bc.ca/

projects/emergency.htm. Businesses or

organizations interested in applying to

take Strategic Inclusive Training for

Emergencies (SITE) can contact

www.bccpd.bc.ca/site.htm to set up

training for their group.

Readiness is a legal

requirement

Regardless of whether emergency

planning is at the top of everyone’s list, all

employers need to be thinking about it,

says Terri Holizki, WorkSafeBC small

business manager for Industry and Labour

UBSafe

A c o m p l e t e p r o v i d e r f o r y ou r

w o r kp l a c e s a f e g u a rd i n g n e e d s !

Penalties, Claim costs and Downtime can be disruptive and costly

forr your businesss contaactt us forr a free consultation

UBSafe | safety@ubsafe.ca | ww w. ubs a f e .c a | 604.205.9080

WorkSafe Magazine July / August 2011

25

Services. “Employers are required to have an emergency plan in

place.”

And while earthquakes might be on everyone’s minds at the

moment, Holizki points out that emergency planning also deals

with less dramatic events. “The kinds of scenarios employers

need to plan for are the same for small or large businesses: fire,

chemical spills, and power outages.” Under the Occupational

Health and Safety Regulation, Part 4, employers must do as

follows:

•

Conduct a risk assessment

•

Develop and implement written procedures and assign a

worker to coordinate their implementation

•

Designate and mark emergency exit routes

•

At least once a year, hold emergency drills

ones, they also face barriers to emergency planning, Holizki

says. They might think that an emergency just won’t happen to

them, or be hindered by a lack of resources.

“When smaller businesses have conducted drills, we’ve found

some didn’t want to leave their businesses behind. This is their

livelihood that’s kept them and their families going for years, and

they find it hard to just leave,” she says. “But an emergency can

happen at any time and people need to be ready to protect

themselves, as well as their facility and their inventory.”

Holizki’s small business team members worked together to make

preparedness easier for small businesses. The result is Act Now,

an online printable guide (www.worksafebc.com/publications/

health_and_safety/by_topic/assets/pdf/emergency_response_

guide.pdf) that includes a sample, step-by-step emergency

response plan.

Although smaller businesses might face the same risks as larger

PLAN FOR YESTERDAY

IH

™

Prepare for tomorrow. Total Safety’s Industrial Hygiene Safety

Services help create and maintain a safe, healthy workplace.

Know Safety.

S E R V I C E S

-

S T R AT E G I E S

-

E Q U I P M E N T

- T R A I N I N G

Contact the best minds in Industrial Hygiene.

604.980.3577 | PacificEnvironmentalBC/EHS.com

26

July / August 2011 WorkSafe Magazine

High time

Continued from page 23

regularly inspected and properly maintained, and to be removed

from service if it’s damaged, or after it has been used to arrest a

worker’s fall.

A number of safety and construction equipment suppliers — such

as Acklands-Grainger, Jelco, and Hazmasters — provide the latest

in fall protection gear. Derek Malone, outside sales manager for

Hazmasters, says the latest equipment enables workers to

operate with a minimum of hindrance. “Plus, the gear is

ergonomically designed and comfortable to wear, which was not

always the case in the past.”

As for design innovations, Malone says that descent and ascent

systems are becoming more prevalent on jobsites where steep

slope metal roofing prevents the installation of toe boards or

footholds. “And rather than causing the descent to speed up, the

latest descenders stop a worker’s descent if he suddenly panics

and squeezes the control handle extra-hard,” Malone says. “This

feature still enables workers to control their speed of descent

and location to park. And if the worker slips or lets go for any

reason, the descender automatically stops.”

A new look at safety

WorkSafeBC is working with members of the construction

industry to host a future Metro-Vancouver-area roofing

symposium for workers and contractors. “The purpose is to raise

awareness about proper safety procedures, equipment, and

supervision,” says WorkSafeBC construction industry specialist

Kathy Tull.

Johnston, he’s redoubled his efforts to make his workplace

accident-free after witnessing the trauma of a serious injury.

“Today, our penalties for non-compliance start with being

suspended a week without pay and end with unconditional

termination. Plus, we have a safety fund that is paid out to crews

that remain accident-free for a certain length of time,” Beddows

says. “These initiatives may seem drastic, but they’ve nipped

non-compliance in the bud.

“We’re constantly looking for ways to mitigate risk. And that’s

how you create a culture of safety in what is an extremely

hazardous environment.”

In the meantime, it’s up to roofing employers to set higher safety

standards for their employees, Beddows says. At Parker

Employers’ Advisers

Helping Employers Manage Workers’ Compensation

The Employers’ Advisers Office provides independent advice, assistance and representation on all

matters related to compliance with the Workers Compensation Act and WorkSafeBC’s regulations

and policies. To further assist employers, we provide educational seminars.

Please visit ourwebsite for more information about upcoming seminar

dates: www.labour.gov.bc.ca/eao All services BSFprovided without cost to

employers. Contact us UollGree: 1800925-2233

WorkSafe Magazine July / August 2011

27

Penalties

Administrative penalties are monetary

fines imposed on employers for health

and safety violations of the Workers

Compensation Act and/or the

Occupational Health and Safety

Regulation. The penalties listed in this

section show the date the penalty was

imposed and the location where the

violation occurred (not necessarily the

business location). The registered

business name is given, as well as any

“doing business as” (DBA) name.

The penalty amount is based on the

nature of the violation, the employer’s

compliance history, and the employer’s

assessable payroll. Once a penalty is

imposed, the employer has 90 days to

appeal to the Review Division of