The Oregon Forest Products Laboratory INFORMATION CIRCULAR 3 OREGON FOREST PRODUCTS LABORATORY

advertisement

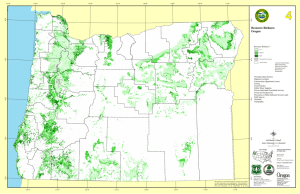

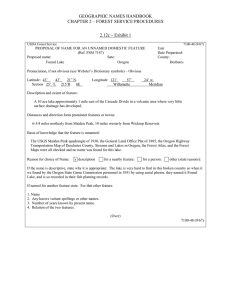

INFORMATION CIRCULAR 3 Revised JUNE 1952 The Oregon Forest Products Laboratory OREGON FOREST PRODUCTS LABORATORY State Board of Forestry and School of Forestry, Oregon State College Cooperating Corvallis OREGON FOREST PRODUCTS LABORATORY THE was established by legislative action in 1941 as a result of active interest of the lumber industry and forestry-minded citizens. It is associated with the State Board of Forestry and the School of Forestry at Oregon State College. The Dean of the School of Forestry is its Director. An Advisory Committee composed of men from representative interests determines Laboratory policy and guides the research program that is directly pointed toward the fuller utilization of Oregon's forest resources. The following men constitute the present membership of the Advisory Committee: DOUGLAS McKAY, GovernorChairman ROBERT W. COWLIN HERBERT J. Cox PAUL M. DUNN . . Pacific Northwest Forest Ezperiment Station . . Willamette Valley Lumbermen's Association School of Forestry, Oregon State College CHARLES W. Fox Oregon Plywood Interests FRANK A. GRAHAM West Coast Lumbermen's Association CARL A. RASMUSSEN Western Pine Association GEORGE SPAUR, State Forester . Secretary Information Circular 3 Revised June 1952 The Oregon Forest Products Laboratory Compiled and edited by William J. Baker Revised by R. H. Plow A Release of the Oregon Forest Products Laboratory Corvallis, Oregon Table of Contenfs Authorization for the Laboratory Functions of Advisory Committee Need for the Program Research Findings Must Be Applied to Be Beneficial Laboratory Staff and Organization Physical Facilities of the Laboratory Scope of Research Program How You Can Use the Laboratory Cooperative Agreements Forestry Research Foundation List of Publications The Oregon Forest Products Laboratory OREGON FOREST PRODUCTS LABORATORY is a tax-supported THE research agency maintained by the state at Corvallis, the State Board of Forestry and the School of Forestry, Oregon State College, cooperating. Its functions, briefly, are to obtain and to disseminate technical information in efforts to attain the fullest utilization of our total forest crop, to improve the serviceability of present products, to develop new products, to preserve and extend appropriate markets for all Oregon forest products, and to assist users in the application of technical knowledge that will enable them to obtain the inherent satisfaction and serviceability of forest products. Authorization for the Laboratory The Laboratory was created in 1941 by an Act of the State Legislature that authorized the State Board of Forestry, in cooperation with the School of Forestry at Oregon State College, to institute and carry on research in the fields of utilization, fabrication, and manufacture of forest products for the purpose of furthering the interests of forestry and forest products industries within the state. This law and subsequent amendments provide for: 1 Initiation of research to improve the utilization of unused residues resulting from the harvesting of forest crops and from the manufacture of lumber and other wood products. 2 Establishment of a Forest Products Laboratory at Oregon State College, such laboratory to be under the direction of the Dean of the School of Forestry. The Director is responsible (a) for cooperating with individuals, corporations, associations, and public agencies, and (b) for hiring personnel and purchasing materials and equipment to do or cause to be done all things necessary to the research program or other projects, objects, and purposes of the Act. 3 Creation of an Advisory Committee of eight members, six of whom are appointed by the Governor of the state. Each of the following recommends a member for appointment: Oregon plywood interests, Pacific Northwest Forest and Range Experiment Station, School of Forestry at Oregon State College, West Coast Lumbermen's Association, Western Pine Association, and the Willamette Valley Lumbermen's Association. The Governor, an ex-officio member of the Advisory Committee, is its chairman, and the State Forester is its secretary. 3 INFORMATION CIRCULAR 3 4 Financing of the program at first by direct legislative appropriations, which later were supplemented by the establishment of a privilege tax on all timber in excess of 25,000 board feet harvested by each operator in the state. After deducting costs of collection, 60 per cent of the remainder of the privilege tax of five cents per thousand feet (log scale) is allotted to research at the Oregon Forest Products Laboratory the other 40 per cent is allocated to the State Board of Forestry for forest management research This privilege tax was effective July 1, 1947 and is to terminate June 30 1953, it is intended primarily to provide funds 5 for the establishment of adequate research facilities and for the conduct of the functions specified in the Act. Granting and vesting the State Board of Forestry with author- ity to accept gifts or donations that may come from any source and are intended to further the objectives of the law. The State Board of Forestry is authorized also to enter into contracts and agreements with the United States of America or any of its agencies provided that such con tracts or agreements are necessary proper and convenient to the attainment of the objectives of the program and provided that they are not contrary to the laws of the State of Oregon In 1951 this authority to enter into contracts and agreements was extended to include any person, firm, or corporation. Authorizing the State Board of Forestry, under such terms as it may determine, to sell, transfer, license, or assign to any person, firm or corporation any patent results relating to forest products utilization which have been acquired by the state from any employee of the Laboratory or from any other source Of the net income from such a transaction, 40 per cent shall go to the General Fund for general governmental purposes, and the balance to a special ac- Figure 1. Industrial Research Building, Oregon State College. TIlE OREGON FOREST PRODUCTS LABORATORY 5 count with the State Treasurer for the use of the Labora- tory in the same manner and for the same purpose as other funds made available to it. Functions of Advisory Committee Members of the Advisory Committee receive no compensation for their services, but they are reimbursed for actual travel expenses incurred in attending Committee meetings and in the performance of other official services. By law, the functions of the Advisory Committee are: To survey the entire field of research in wood utilization for 1 the purpose of assembling definite information covering current research projects as well as past accomplishments, and rendering practical counsel in the field of economic forest utilization. 2 To explore new fields for the utilization of forest products and to encourage the establishment of new industries of this type within the state. 3 To guide and approve all research activities undertaken by the Forest Products Laboratory. 4 To suggest, as a result of contacts with wood-using industries, promising wood utilization projects to other research organizations. S To recommend the compilation and release to industry and to the general public of all research information and data. Need for the program The State of Oregon has about 26 million acres of commercial forests on land that is better suited for the growth of forest products than any other use. The wealth that this land will produce depends entirely on the completeness of utilization of the forest crop and on the utility values attained by its products through research. Although the state, its counties, and municipalities own but 4 per cent of this land, compared with the 62 per cent in federal and 34 per cent in private ownership, the state is justified in applying tax money to forest products research. Better adaptation of wood, the principal product of the forest crop, is of direct concern to consumers whose proper housing and standards of living are closely associated with the satisfactory use of wood products. Greater utility of wood is vital to workers who need the millions of dollars of wages furnished by stable employment in forests, sawmills, pulp mills, and all other industries that use 6 INFORMATION CIRCULAI 3 wood in manufacture and construction. Full utilization of products is essential if owners of forest land, public and private, are to realize the maximum value of the tree crop Local communities, counties, the state and the nation at large have a basic interest in obtaining taxes continuously from owners of productive forest land and successful forest industries Forest products research must aid in solving many difficult problems such as 1 How to create values for the residues that develop during the harvesting and the conversion of trees into articles of commerce 2 How to obtain utilitarian products from tree species that are now unused or little used 3 How to utilize more efficiently the small-sized and secondgrowth trees that will form the bulk of our future forests 4 How to increase the serviceability and economic advantages of wood by proper use, by selection of suitable material, by modification of properties by improved treating processes and by the development of better or entirely new methods of wood conversion and fabrication. Research findings must be applied to be beneficial Research merely for extension of knowledge may have potential value, but application of research results can benefit everyone (a) be- cause the use of forest products is so universal and so much a part of the daily life of every individual (b) because the conversion and processing of the forest crop constitute the largest manufacturing industry within the state and (c) because Oregon's forest products are shipped into every other state in the Union Specifically, application of fruitful research achievements will be profitable to 1 Producers of forest crops including the general public as owners of community, county state, and national forests, the farm woodland owner the commercial forest owner, and the people engaged in growing managing and protecting forest crops 2 Processors and handlers of forest products consisting of all individuals and organizations engaged in harvesting converting processing, transporting distributing and selling forest products This group provides the greatest amount of employment for labor and it is the group that can make the greatest contribution to the stability of forestry communities. THE OREGON FOREST PRODUCTS LABORATORY / 3 Consumers of forest products, comprising virtually the entire population of the nation, particularly labor, farmers, home owners, industrial organizations, and public agencies, all of whom use vast quantities of forest products. 4 Governmental units, municipal, county, state, and federal, all of whom, because of the broader tax base resulting from the creation of values where none had existed heretofore, may render greater service to the general public without increasing rates of taxation. The Oregon Forest Products Laboratory, within the limitations of its staff, will assist manufacturers, users, and others in applying technical knowledge that will enable them to utilize the forest crop more fully and to obtain greater satisfaction and serviceability from forest products. Laboratory staff and organization The Dean of the School of Forestry is cx officio the Director of the Laboratory. The internal organization is headed by a Managing Director in charge of administration and the research program. Figure 2. One of the chemical laboratories. INFORMATION CIRCULAR 3 The functions of the Laboratory are divided among three divisions: Chemical Research and Development, Physical Research and Development, and Administration. The first two units are under Division Chiefs, the third is under an Administrative Assistant, all responsible to the Managing Director. The present Laboratory staff comprises 35 men and women, professional and nonprofessional: chemists, chemical and mechanical engineers, wood technologists, industrial relations specialists, a business manager, librarian, storekeeper, clerical workers, and mechanics. When extra work demands arise, part-time workers, usually students, are employed. Physical facilities of the Laboratory The Laboratory is housed in the Industrial Research Building, located at the edge of the Oregon State College campus. This building is a modern, two-story, wood-steel-tile-concrete structure having ground-floor dimensions of 60 by 300 feet. It was provided by the State Board of Higher Education in July 1947 in response to state- Figure 3. 24" x 24" hydraulic molding press (left) and laminating press with high frequency generator (right). THE OREGON FOREST PRODUCTS LABORATORY Figure 4. Rotary digester and double-disk, 24-inch diameter mill for producing fiber from waste. wide interest in industrial research. For the present, the Forest Products Laboratory is sharing the building with the Department of Chemical Engineering of Oregon State College; the Laboratory occupies about one-half of the building. Space is allocated to chemistry and chemical utilization, wood technology, wood seasoning, wood preservation, fiberboard, plywood, timber mechanics, and four controlled temperature-humidity rooms. The building also houses a business office, six staff offices, library, wood shop, and storage space. In 1951, a one-story, laminated-arch, frame building was constructed adjacent to the Laboratory, with Laboratory funds, to provide additional space. This structure houses the stockroom, machine shop, experimental gas turbine project, wood and bark grinding equipment, and two Laboratory vehicles. The Laboratory already possesses much of the basic equipment essential for wood research and for the duplication of standard wood processing. As the research program expands to cover different fields of wood utilization and processing, essential equipment will be 10 INFORMATION CIRCULAR 3 Figure 5. Small, experimental dry kiln. purchased, or designed and assembled in the Laboratory shops, to meet the problems presented. Full use is made also of the equipment available at cooperating agencies and facilities. Whenever practicable, cooperative research projects are conducted at the industrial plants where they are initiated. THE OREGON FOREST PRODUCTS LABORATORY 11 Figure 6. Preservation (left) and vapor seasoning (right) equipment. Scope of research program The original 1941 law provided for the initiation of research to improve the utilization of residues arising from the harvesting of forest crops and from the manufacture of lumber and other forest products. It was appropriate, therefore, that first research efforts should be directed toward determining the quantities of sawmill residues available and possible uses for these materials. Since sawdust, slabs, and edgings constitute the bulk of unused wood, the costs of converting these materials into fuel and transporting the fuel by various methods to large consuming centers were studied. As the needs of the wood industries became more apparent, the scope of Laboratory activities broadened to include work on salvage logging and utilization of logging wastes and secondary species. In turn came projects on the chemical utilization of wastes, the improvement of lumber products through better seasoning and preservation methods, and basic studies on the physical and related properties of wood and component parts of wood products. 12 INFORMATION CIRCULAR 3 Approximately eighty major investigations, and twenty minor tests and studies were completed prior to 1952. These included such diversified projects as the following: Utilization and seasoning of five secondary species. Evaluation of wood-sugar molasses as a feed for cows, swine, sheep, and poultry. Utilization of wastes from the wood hydrolysis process. Vapor seasoning of major Pacific Northwest species. Properties of hardboards made from West Coast species pulped in an attrition mill. Effect of certain testing procedure variables on the strength property values of different hardboards. Economic studies of the Inland Umpqua Basin, Roseburg, and Tillamook areas in Oregon and the Grays Harbor area in Washington. Evaluation of tanoak as a face veneer and a core stock for plywood. Figure 7. Post farm for evaluation of durability of woods, preservatives, and methods of preservation. THE OREGON FOREST PRODUCTS LABORATORY 13 Determination of the strength and related properties of second-growth Port Orford cedar. Studies of the chemical components of bark from four major Pacific Coast softwood species. 1. Carbonization of sawmill waste, briquetting of the charcoal, and recovery of the volatile byproducts. Evaluation of different preservatives for wood and of different methods of their application. Development of methods and machinery for incising and peeling round timbers. Improved utilization of o. 3 Douglas-fir lumber. Strength and related properties of old-growth Douglas-fir infected by Fomes pini. Development of a dry-forming process for wood waste core material. Evaluation of charcoal and comminuted Douglas-fir cones as soil mulches. Dielectric properties of Douglas-fir and ponderosa pine woods. Study of grade recovery from defective Douglas-fir logs. Current Laboratory activities in 192 are indicated in the following outline: 1. Chemical Research and Development Division Chemistry of woods Fundamental and applied studies of the chemical composition of 14 lesser-known West Coast species. Chemistry of barks Fundamental and applied studies of the chemical na- ture and properties of the components of the bark from 12 West Coast species. Chemistry of cork Studies of the chemistry and chemical utilization of the cork from the bark of 8 West Coast species. Chemical utilization of wood residues The production of levulinic acid. Chemical engineering The development of practical techniques for the extraction of chemicals from the bark of West Coast species. The development of processes for the purification and modification of the chemicals from these barks. 14 INFORMATION CIRCULAR 3 2. Physical Research and Development Division Forest injuries by plant organisms The evaluation of present and probable damage in defective old-growth Douglas-fir infected with the fungus Fomes pini (Cooperative project) Forest measurements The development of methods for measuring, estimating and forecasting the growth and yield in defective, old growth Douglas-fir stands infected with the fungus Fomes pini (Cooperative project) Wood structure and properties a The determination of basic data on the strength and other physical properties of 10 West Coast hardwoods b A study of the effect of vapor drying and other methods of drying on the physical propertis of West Coast woods Surveys a A survey and evaluation of quantity and quality of logging wastes in the State of Oregon (Cooperative project ) b Cooperative surveys and evaluation of wood wastes and industrial potentialities in specific areas within the state. Oregon hardwoods a. The acquisition and dissemination of basic information on the supply, physical properties manufacture and outlets for Oregon hardwoods b The promotion of the use of these hardwoods as a valuable raw material in the manufacture of furniture and other products such as face veneer stock Wood preservation a The investigation of accelerated service test methods and biological tests for evaluating wood preservatives for the purpose of formulating standard treating procedures (Cooperative project ) b The determination of the natural durability of native and introduced woods, and the effectiveness of various preservatives for different species (Cooperative project.) THE OREGON FOREST PRODUCTS LABORATORY 15 Wood seasoning The development of drying schedules for a number of Oregon woods when using a known method of vapor drying, and the determination of the effect of such drying on the physical properties of the wood. (Cooperative project.) The design of kiln drying schedules for various Oregon softwoods and hardwoods, and determination of the effect of these schedules on the equilibrium moisture content and dimensional stability of the woods. Consolidated boards The study of the manufacture of a consolidated particle board from the components of barks, either before or after the extraction of chemicals from the barks. The study of the advantages of adding bark to fiber in the formation of fiberboard products. The determination of the best methods for producing fiberboard from sawmill residues of different Oregon species. Other utilization of wood residues The development of a sawdust-fired gas turbine power unit to generate electric power, and the use of the spent gases for the kiln drying of wood. The evaluation of wood and bark residues as soil mulches. The evaluation of wood-sugar molasses as a feed for livestock. Timber mechanics Testing of shear-wall panels and roof diaphragms to find stress distribution, the data to be used in formulating design criteria for earthquake resistance of wooden structures. A study of standard methods used in testing the physical properties of fiberboards to enable the hardboard industry to set up specifications for their products. 16 INFORMATION CIRCULAR 3 3. Industrial Relations Division Information a. Editing, publication, and dissemination of research and other information pertaining to the forest products industries b Consultation on wood utilization and forest products c Contacts and correspondence with individuals, firms, agencies, and associations interested in forest products and wood utilization. Investigations a Surveys of wood utilization industries b Log and lumber grading studies in connection with West Coast hardwoods. c Surveys of raw material supplies for industry d. Surveys of finished material outlets. How you can use the Laboratory Merely by writing to or calling at the Oregon Forest Products Laboratory, 17th and May streets Corvallis and subject only to the limitations of Laboratory personnel and available data a resident of Oregon may, without charge obtain advice, information and assistance on any forest products utilization problem Many final and progress reports on Laboratory research projects have been published as bulletins circulars, or trade journal articles Copies of most of these reports are available to interested persons If the data necessary to solve a given forest products utilization problem are not in the Laboratory files, but are known to be available elsewhere, reasonable attempts will be made to obtain such data in order to save the time effort, and money that might otherwise be expended in duplicate research activities Since the major objective of the program is to obtain complete utilization of the forest crop, it is the policy of the Advisory Committee and the Laboratory to cooperate fully with individuals industry and public agencies in a sincere effort to attain that objective The Laboratory welcomes suggestions for research projects that will further the maximum utilization of our forest crop All suggestions will be given careful consideration and the ones showing promise of wide application will be incorporated into the research program at the earliest time consistent with personnel and facilities available and the priorities assigned to active research projects. THE OREGON FOREST PRODUCTS LABORATORY 17 Cooperative agreements In 1951, the State Board of Forestry was authorized by law to accept gifts of money, and to enter into contracts and agreements concerning the acceptance of such funds, grants, donations, or gifts. The Laboratory is thus enabled to enter into cooperative research agreements with individuals, industries, associations, or agencies. In such agreements, the following items are considered mutually by the Laboratory and the donor: The detailed, all-inclusive estimated cost of the project to the donor. Disposition of any residual funds from the donation, over and above the actual cost of the project. The method of accounting by the Laboratory that is agreeable to the donor. The frequency of progress reports to the donor and the form of the final detailed report. A mutually agreeable arrangement for the publication of information and results by the Laboratory after the completion of the project. A mutually agreeable arrangement for the ownership and assignment of patent arising from the project, and the participation in the patent rights. The terms of cancellation of the agreement. Payment of the estimated cost is made to the Forest Products Laboratory, Donation Fund, and is contributed in advance. Forestry Research Foundation The Forestry Research Foundation, a nonprofit, perpetual, Oregon incorporation, was established in 1945 to stimulate and facilitate research in all branches of forestry and related fields by the Oregon Forest Products Laboratory, Oregon State College, and others who collaborate with the Laboratory and the College, especially for the benefit of the forestry and related industries of the Pacific Northwest. The Director of the Laboratory is vice president of the Foundation and with six industrial leaders comprise the board of trustees. Not only does the Foundation promote basic research, but it also provides and assists in providing means for developing research results for application in the forestry and related industries. To attain these objectives, the Foundation solicits donations, gifts, grants, bequests, assignments of patent rights, and similar considerations of value. List of PubIications An Inventory of Sawmill Waste in Oregon, by Glenn Voorhies. Oregon State Engineering Experiment Station Bulletin Series No 17 1942 Saving Fuel in Oregon Homes, by E. C. Willey. Oregon State Engineer. ing Experiment Station Circular Series No 7 1942 *3 Production and Transportation of Fuel from Sawmill Refuse, by G. Eugene Tower, School of Forestry, Oregon State College Leaflet No. 4. 1942 *4 Cork from Douglas Fir Bark by Leo Friedman and A I Ezell from The Timberman, Vol. 43, No. 11. September 1942. Reprint *5 Composition Cork from Douglas Fir by Leo Friedman and A I Ezell Reprint from The Timberman Vol 44 No 4 February 1943 *6 Sawdust Plaster Project by Leo Friedman Albert I Ezell and Robert D Englert. Reprint from The Timberman, Vol. 45, No. 2. December 1943. 7 Report of Investigation of Emergency Fuels for Domestic Sawdust Burners by Earl C Willey and G Eugene Tower Oregon Forest Products Laboratory Research Leaflet No. 1. October 1948). 1943. (Slightly revised *8 The Essentials of Kiln Drying Oregon Hardwood Lumber by Glenn Voorhies. Oregon Forest Products Laboratory Research Leaflet No. 2. 1944. Industrial Fuel from Controlled Pyrolysis of Sawmill Wood Waste: Part I, by H. George Rieck, Jr., Edward G. Locke, and Eugene Tower. Reprint from The Timberman, Vol. 46, No. 2. December 1944. *10 Industrial Fuel from Controlled Pyrolysis of Sawmill Wood Waste Part II by H George Rieck Jr Edward G Locke and Eugene Tower. Reprint from The Timberman, Vol. 46, No. 4. February 1945. *11 Industrial Tars from Controlled Pyrolysis of Sawmill Wood Waste Part III by Paul G Schrader Bert E Christensen and Leo Friedman Reprint from The Timberman Vol 46 No 5 March 1945 12 The Effect of Storage on Douglas Fir Hogged Wood and Sawdust by Leo Friedman Eugene Tower and R B Boals Oregon Forest Prod ucts Laboratory Research Leaflet No. 3. 1945. Recovery of Forest Waste: Part I, by J. B. Grantham. Reprint from The Timbernuin, Vol. 46, No. 8. June 1945. Recovery of Forest Waste: Part H, by J. B. Grantham. Reprint from The Timberman Vol 46 No 10 August 1945 The Production of Poles from Lodgepole Pine in Oregon, by John B. Grantham. Reprint from West Coast Lumbernuin, Vol. 72, No. 9. September 1945. 16 Testing of Plastics from Scholler Lignin by Robert D Englert and Leo Friedman Reprint from Pacific Plastics Vol 3 No 10 October 1945. *17 Industrial Alcohol from Wood Waste by Paul M Dunn Chemical Prod ucts, Vol. 9, No. 1-2, November-December 1945. 18 Yeasts from Wood Sugar Stillage by E F Knrth Reprint from Indus trial and Engineering Chemistry, Vol. 38, No. 2. February 1946. No longer available. 18 THE OREGON FOREST PRODUCTS LABORATORY 19 Wood Utilization Research in Oregon, by Paul M. Dunn. Proceedings of the American Wood Preservers' Association, Vol. 42, 1946. Feeding Yeasts from Wood Sugar Stillage, by E, F. Kurth and V. H. Cheldelin. Reprint from Industrial and Engineering Chemistry, Vol. 38, No. 6. June 1946. The Oregon Forest Products Laboratory, by Phimister B. Proctor. Wood, Vol. 2, No. 1. January 1947. Wood Waste Carbonization: Part I, by H. 0. Ervin. Reprint from Wood, Vol. 2, No. 2. February 1947. Western Relogging, by John B. Grantham. Reprint from Wood, Vol. 2, No. 3. March 1947. Wood Carbonization: Part II, by H. 0. Ervin. Reprint from Wood, Vol. 2, No. 4. April 1947. Hard Pressed Board Utilizes Wood Waste, by Hugh Wilcox. Reprint from Wood, Vol. 2, No. 5. May 1947. Salvage Logging in the Douglas-Fir Region of Oregon and Washington, by Elmer E. Matson and John B. Grantham. Oregon Forest Products Laboratory Bulletin 1, 1947. Salvage Operations in the Douglas-Fir Region: Their Present and Future, by John B. Grantham. Oregon Forest Products Laboratory Information Circular 1, 1947. The Utilization of Wood Waste by Fermentation Processes, by E. F. Kurth. Reprint from Chemurgic Digest, Vol. 6, No. 24. December 31, 1947. Byproducts from the Lignin Residue in Ethanol Manufacture, by E. F. Kurth. Reprint from Chemurgic Digest, Vol. 6, No. 24. December 31, 1947. *3Q, Die-molding Wood Products: Part I, by Mortimer D. Macdonald. Pacific Plastics, Vol. 5, No. 12. December 1947. *31. Die-molding Wood Products: Part II, by Mortimer D. Macdonald. Pacific Plastics, Vol. 6, No. 1. January 1948. Utilization of Oregon Hardwoods, by Dan D Robinson. Oregon Forest Products Laboratory Information Circular 2, 1948. Chemical Analysis of Western Woods: Part I, by E. F. Kurth. Reprint from Paper Trade Journal, Vol. 126, No. 6. February 5, 1948. *34 Carbonization of Douglas Fir Sawdust, by J. D. Ross. Proceedings of the Forest Products Research Society, Vol. 2. 1948. Paper presented at the May 19, 1948 meeting of the Pacific Northwest Section, Forest Products Research Society, Portland, Oregon. Wax from Wood-sugar Lignin Residue, by E. F. Kurth. Utilization of Douglas Fir Bark, by E. F. Kurth, Harry J. Kiefer, and James K. Hubbard. Reprint from The Timberman, Vol. 49, No. 8. June 1948. The Constituents of Sierra Juniper Wood (Juniperus occidentalis Hooker), by E. F. Kurth and Homer B. Lackey. Reprint from Journal of the American Chemical Society, Vol. 70, No. 6. June 1948. The Oregon Forest Products Laboratory, by William J. Baker. Oregon Forest Products Laboratory Information Circular 3, 1948. Forest Products Research in Oregon, by Paul M. Dunn. Reprint from Iowa State College Journal of Science, Vol. 22, No. 4. July 1948. No longer available. 20 INFORMATION CIRCULAR 3 40. Investigation of Methods of Alleviating the Pollutional Effects of Douglas- Fir Ethanol Stillage, by W. B. Bolien. Oregon Forest Products Laboratory Bulletin 2, September 1948. 41 Service Life of Treated and Untreated Fence Posts (1947 Progress Re- port on the T J Starker Post Farm) by R D Graham and W J Baker Oregon Forest Products Laboratory Report 1 October 1948 *42 The Chemical Composition of Barks by E F Kurth Chemical Reviews Vol 40 No 1 1947 Reprinted in Northeastern Wood Utilization Council Inc., Bulletin No. 25, 1949. *43 New Developments in Wood Utilization by P B Proctor Proceedings of the 39th Annual Meeting Western Forestry and Conservation Association, December 1948. 44. The Constituents of the Extractives from Douglas Fir, by H. M. Graham and E F Kurth Reprint from Industrial and Engineering Chemistry Vol 41 1949 45 The Chemical Analysis of Western Woods Part II Douglas Fir Bark Analysis, by E. F. Kurth. Reprint from Tappi, Vol. 32, No. 5. April 1949. 46 Defects Developed in Kiln Drying and Their Control by W J Baker and L D Espenas Proceedings of the Fourth Annual Northwest Wood Products Clinic April 1949 47 Chemical Composition of Ponderosa and Sugar Pine Barks by F F Kurth, J. K. Hubbard, and J. D. Humphrey. Proceedings of the Forest Products Research Society Vol 3 1949 Paper Trade Journal Vol 130 No 17 April 1950 48 Service Life of Treated and Untreated Fence Posts (1948 Progress Re port on the T J Starker Post Farm) by R D Graham Oregon Forest Products Laboratory Progress Report 2 May 1949 49 Dielectric Properties of Douglas Fir at High Frequencies by J J Witt kopf and M D Macdonald Oregon State Engineering Experiment Station Bulletin 28 July 1949 50. Douglas-Fir Bark Tannin, by J. K. Hubbard and E.. F. Knrth. Reprint from Journal of the American Leather Chemists As.cociation, Vol. 44, No. 8. August 1949. 51 Dielectric Properties of Ponderosa Pine at High Frequencies by J J Wittkopf and M D Macdonald Oregon State Engineering Experi ment Station Bulletin 29 September 1949 52 Extraction of Tannin from Douglas Fir Bark and Concentration of the Tan Liquor by E F Kurth J K Hubbard and Maurice Gekeler Reprint from Leather and Shoes November 5 and November 19 1949 53. Service Life of Treated and Untreated r'ence Posts (1949 Progress Re- port on the T J Starker Post Farm) by R D Graham Oregon Forest Products Laboratory Progress Report 3, December 1949. 54 The Influence of Depth of Immersion on End Penetration in Douglas Fir Heartwood when Cold soaked in Pentachlorophenol by H J Raphael Journal of Forestry Vol 48 No 1 January 195 (Abstract of thesis). 55 Wood sugar Molasses as a Feed for Livestock and Poultry by J R Stillinger Proceedings Eighth Annual Nutrition Conference Oregon Feed & Seed Dealers Association and Oregon State College, Cooperating, February 3, 1950. * No longer available. THE OREGON FOREST PRODUCTS LABORATORY 21 56. The Soaking Method for the Preservative Treatment of Fence Posts, by R. D. Graham. Oregon Forest Products Laboratory Information Circular 4, February 1950. *57 Tannin from Pine Bark, by E. F. Kurth. Reprint from Leather and Shoes, Vol. 119, No. 5. 1950. The Composition of the Wax in Douglas-Fir Bark, by E. F. Kurth. Reprint from Journal of the American Chemical Society, Vol. 72. April 1950. Wax from Douglas-Fir Bark, by E. F. Kurth and H. S. Kiefer. Reprint from Tappi, Vol. 33. April 1950. Manufacture of Consolidated Products from Wood Residues, by M. D. Macdonald. Proceedings of the Forest Products Research Society, Vol. 4. 1950. Resin Coated Electrodes, by Robert D. Graham. Reprint from Wood, Vol. 5, No. 9. September 1950. The Chemical Analysis of Western Woods: Part III, by E. F. Kurth. Reprint from Tappi, Vol. 33. October 1950. Products Obtained by Destructive Distillation of Douglas-Fir Bark, by E. F. Kurth and C. V. S. Ratnam. Reprint from Tappi, Vol. 33. October 1950. The Utilization of No. 3 Douglas-Fir Lumber for Prefabricated Panels, by M. D. Macdonald. Oregon Forest Products Laboratory Information Circular 5, October 1950. Service Life of Treated and Untreated Fence Posts (1950 Progress Re- port on the T. J. Starker Post Farm), by R. D. Graham. Oregon Forest Products Laboratory Progress Report 4, October 1950. Methyl Ester of Dihydroperillic Acid, an Odoriferous Constituent of Western Red Cedar, by E. F. Kurth. Reprint from Journal of the American Chemical Society, Vol. 72. December 1950. Some Factors Involved in the Promotion of Alder-using Industries in Tillamook, Oregon, by W. J. Baker. Oregon Forest Products Laboratory Special Report 1, January 1951. Chemicals from Douglas-Fir Bark, by E. F. Kurth. Paper presented at the February 6, 1951 meeting of the Pacific Northwest Section, Forest Products Research Society, Corvallis, Oregon. Published in Journal of the Forest Products Research Society, Vol. 1, No. 1. September 1951. Levulinic Acid from Wood Cellulose, by T. R. Frost and E. F. Kurth. Reprint from Tappi, Vol. 34, No. 2. February 1951. Compression of Douglas Fir Veneer During Pressing, by M. D. Macdonald. Reprint from The Timberman, Vol. 52, No. 4, February 1951, and Vol. 52, No. 5, March 1951. Extractives from Ponderosa Pine Bark, by E. F. Kurth and J. K. Hubbard. Reprinted from Industrial and Engineering Chemistry, Vol. 43, No. 4. April 1951. Some Strength and Related Properties of Old-growth Douglas Fir Decayed by Fomes pini, by J. R. Stillinger. Reprint from American Society for Testing Materials Bulletin, No. 173. April 1951. The Longitudinal Penetration of Petroleum Oils in Douglas Fir Heartwood after a Fifteen-minute Immersion, by H. J. Raphael and R. D. Graham. American Wood-Preservers Association Proceedings, Vol. 47. 1951. No longer available. 22 INFORMATION CIRCULAR 3 Round Timber Peeling and Incising Machine, by Robert D. Graham. Reprint from Cheinurgic Digest, Vol. 11, No. 6. June 1951. The Effects of Machine Head Speed and Specimen Span on Modulus of Rupture Values Obtained in Static Bending Tests of a Nominal 5/32inch Douglas-Fir Hardboard, by Hugh Wilcox; Reprint from Tappi, Vol. 34, No. 7. July 1951. Dihydroquercetin as an Antioxidant, by E. F. Kurth and Frank L. Chan. Reprint from The Journal of the American Oil Chemists' Society, Vol. 28, No. 10. October 1951. Service Life of Treated and Untreated Fence Posts (1951 Progress Re- port on the T. J. Starker Post Farm), by R. D. Graham. Oregon Forest Products Laboratory. PrOgress Report 5, October 1951. The Seasoning of Oregon Hardwoods, by Leif D. Espenas. Oregon Forest Products Laboratory Information Circular 6, December 1951. The Chemical Nature of the Cork from Douglas-Fir Bark, by Herbert L. Hergert and E. F. Kurth. Reprint from Tappi, Vol. 35, No. 2. February 1952.