Seasoning and Machining Degrade in Young-growth Douglas-fir Dimension Lumber B. G. Anderson

advertisement

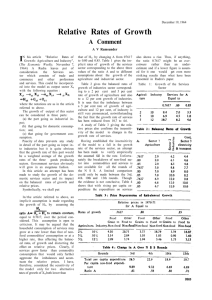

I, Seasoning and Machining Degrade in Young-growth Douglas-fir Dimension Lumber By B. G. Anderson A. C. Knauss R. G. Frashour Reporf No. D-1 May 1954 OREGON FOREST PRODUCTS LABORATORY State Board of Forestry and School of Forestry, Oregon State College, Cooperating Corvallis TABLE OF CONTENTS Page ACKNOWLEDGEMENTS S1J1'14ARY 1 . INTRODUCTION STUDY ChARGES . . 8 . 10 10 RESULTS AND DISCUSSION Degrade Black-knotted pieces . . Shipping weight. Specific gravity and ring count. . Drying rate-kiln schedules . N 5 . . . . . 12 13 . . . . . . . ........... . 13 . 14 . . . Greenmoisturecontent........ Uniformity of final moisture èonterit Moisture-meter readirig Shrinkage during kiln-drying . . . . Residu.1 shrinkage . . . . . . . .......14 14 . . . . . . . . . . . . . . 15 15 15 CONCLUSIONS 16 REI'4APJcS 17 BIBLIOGBAPRY 18 TABLES Total Degrade in No. 1 and 2 Common Young-growth Douglas-fir Dimension Lumber 19 Kiln-dried S4S Recovery in Grade from No. 1 Ccnnnon Younggrowth Douglas-fir Dimension Lumber 20 Kiln-dried 54S Recovery in Grade from No. 2 Conm-ion Younggrowth Douglas-fir Dimeision Lumber 21 Table 4, Effects of Low EMC Step in Schedule on Degrade Percentages 22 Table 5. Effects of Low of Degrade Table 1. Table 2. Table 3. Table 6. 4C Step in Schedule on Various Causes 23 Effects of Final Average Kiln-dried Moisture Content on Degiade Percentages 2 IISUOR 3/00 30805-200 JLE 24 Page Table 7. Table 8. Effects of final Average Kiln-dried Moisture Content on Various Causes of Degrade Effects of Initial Dry-bulb Temperature on Degrade Percentages. . . . Table 9, . . . . . . Table 11. . . . . . . . . 26 ffe cts of Initial Dry-bulb Temperature on Various Causes ....,..... 27 ofDegrade Table 10. . 25 Effects of Low ENC Step in Schedule on Doflar Recovery per Thousand Board Feet of Kiln-dried Dimension Lumber 28 Percentages of Green Pieces Containing Black Knots of Over 3/4-inch Diameter 29 FIGURES Figure 1. Relationship of Shipping Weght to Average MOICtUT? Content Figure 2. Relationship of Rough Weight to Average Mo4.sture Contei't, Figure 3. Cumulative Distribution of Green Density Values. Figure 4. Cumulative Distribution of Specific Gravity Values. Figure 5-15. Photographs of End-grain Kiln Samples. Figures 16-22. Photographs of Knot Condition; Charges 3 through 9. Figures 23-32. Drying Rate and Kiln Schedule Charts; Charges 2 through 10. Figure 33. Cumulative Distribution of Green Moisture Contents. Figures 34-43. Cumulative Distribution of Moisture Meter Readings: through 10. Charges 2 Figure 44. Moisture Meter Readings Compared with Oven-test Moisture Content Values. Figure 45. Cumulative Distribution of Green and Kiln-dried Thickness Values. Pigure 46, Cumulative Distribution of Shrinkage Values During Kiln-drying. Figure 47. Average Residual Shrinkage Values. Figure 48. Cumulative Distribution of Residual Shrinkage Values. igure 49. End Grain View of 343 Dimension: Charges 4 and 5A. Figure 50. End Grain View of 345 Dimension: Charges 6 Figure 51. End Grain View of 34$ Dimersion: Charge 8. Grain View of $43 Dimension: Charge 9. 'igure 52. End and 7. ACKNOWLEDGNTS The authors express their sincere appreciation for the great amount of assistance and àervice extended by the f'oUowing persons and organizations: S. Brown and A. D. Johztson, of the West Coast Bureau of Lumber Grades and Inspection, for grading service on all the lumber used in the study. Don Johnson, Alberteon Lumber Company, Philornath, and C, R. Bayless, Bayless Lumber Company, Philomath, who furnished about 52 M board feet of lumber for the study. Ted Huntley, Corvallis Lumber Company, who furnished planing and storage facilities for a large percentage of the lumber used in the study. R. Clark and C. W. Crenshaw, Clear Lumber Sales Company, Lebanon, who furnished lumber and planing facilities for one study charge. W. G. Hanley and Gene Durlam, Douglas Fir Products Company, Lebanon, who furnished lumber, dry-kiln facilities and planing facilities for one study charge. Oscar Meland and Robert Short, Timber Structures, Inc., Portland, who furnished lumber, dry-kiln facilities and planing facilities for one study charge. Raymond 1eitz and Elmer Matson, U. S. Forest Service, for constructive suggestions. Robert Eby, West Coast Lumbermen's Association, Portland, H. '. Jefferson, Nettleton Lumber Company, Seattle, T.E. Heppenstal, Long-Bell Lumber Company, Lougview, and H. E. Morgan, Weyerhaeuser Lumber Company, Longview, for their constructive suggestions and discusàion during the planning of this project. 0. R. Randall, of the Laboratory ataff, for assisting in the experimental work and drawing of the graphs. SUMMARY The increasing volume of young-growth Douglas-fir timber cut in the Pacific Northwest emphasizes the need for more knowledge on the characteristics of lumber sawed from these trees. The study described here was initiated to learn the extent arid causes of degrade resulting from kiln-drying young-growth Douglas-fir dimension lumber. At the same time it was possible to determine the degree of shrink- age during and after kiln-drying, and to check the final shipping weights of the lumber after drying. Degrade was measured in ten kiln charges of approximately 6500 ftn (feet board measure) each, of 2- by 8-inch by 16-foot young-growth Douglasfir dimension lumber which were kiln-dried and surfaced to 1-5/8 by 7-1/2 inches. An additional charge was surfaced green to determine the change in grade caused by machining alone. Neither the average final moisture content to which the charges were dried (approximate range 12-18 per cent) nor the temperatures used in drying the charges seemed to have an appreciable effect on the amount of degrade. The anount of degrade was greater, however, when a low EMC* level was main- tained during the schedule, as shown by the following table: * Equilibrium moisture content; the moisture content which wood will attain after long exposure to given aimospheric conditions. -- ENC of low humLdity step (range) Average total basis)' No. 1 Common No. 2 Comon degradeJ Per cent 3.3-4.4 Per cent Shake & grain separation Loose knots & edge knots Planer split and warp Season checks Knotholes 0.7 0.6 1.9 0.4 5.7 1.4 3.2 3.8 0.2 1,0 6.0 Tpta]. 7 7-U .0 Shake & grain separation Loose knots & edge knots Planer split and warp Season checks Knotholes Total 1 Per cent 0.7 0.8 1.9 0.7 1.2 0.0 2.1 1.1 0.1 0.5 5.9 3.2 Degrade from shrinkage (skips in dressing) is not included. Total degrade in the Select Structural grade was consistently higher than degrade in No 10 (Number 1 Common). The amount of lumber in the select structural grade, however, was too small for full analysis. Although young-growth Douglas-fir lumber is relatively free from the black knots found characteristica11y in old-growth, an average of 18 per cent of the green pieces in both No. 10 and No. 20 contained black knots over 3/4 inches in diameter. Despite this fact, the average degrade from knot damage including knotholes was only about 4 1/2 per cent in No. 10 and about 1 1/3 per cent in No. 2C. Some of the knotholee that developed during seasoning o' machining were too small to lower the original grade. The pieces containing these small knotholes averaged 2.9 per cent in No. 10 and 5.5 per cent in No. 20. -3- Degrade from planer split and warp in lumber dried using a high minimum ENC step in the kiln schedule averaged 1.2 per cent in No. 10 and 1.1 per cent in No. 20. Using a low minimum EMC step in the schedule led to an average degrade from planer split and warp of 5.7 per cent in No. 1C and 3.8 per cent in No. 20. Prices received at the mill are usually higher for kiln-dried than for green dimension lumber, Not all of this premium is gained by the mill, however, because of the drop in grade of some pieces during drying and machining. Miii prices1 Green Kiln-dried Grade Se]. Str No. 10 No 20 A summary of these factors is shown below. $78.50 68.50 65.25 $92.00 82.00 76.00 Recovery value of kiln-dried lumber_ Low EMC High EMC $88.24 79.66 74.19 Loss from degrade Low EMC High ENC $89 .81 $3 .76 81.30 75.13 2.34 1.81 $2.19 0 70 0.87 Prices per N fbm based on Crow's Price Reporter, 20 August 1953. Average of "Most Sales." A price differential of $10.00 is assumed between Select Structural and No. 10. Average shrinkage in thickness and width during kiln-drying to 12 per cent average moisture content was 3.5 per cent, with 80 per cent of the pieces shrinking 4.1 per cent or less. When lumber which had been kiln-dried to 18 per cent average moisture content and surfaced was allowed to dry further to about 12 per cent moisture content, the average additional shrinkage was found to be about 0.9 per cent, with 90 per cent of the pieces shrinking 1.5 per cent or less. The average residual shrinkage when dried from 18 to 5 per cent moisture content was 2.5 per cent. The shipping weight of S48 green dimension ranged from 2500 to 2800 pounds per thousand board feet. When kiln-dried to 18 per cent average moisture content, the surftced lumber averaged 2170 pounds per thousand, and when dried to 12 per cent moiture content averaged 2O0 pounds per thousand board feet. Time required for drying to a final average moisture content of l per cent ranged from 4 to 90 hours. Th shorter interval was reeded for kiln schedules with a constant dry-bulb temperature of 200 deg F. Drying time to 12 per cent average moisture content was 110-120 hours. A general picture of drying times may be gained by comparing charges 2 and 5A with charges 6 and 7. Dry-bulb _temperatur_ Charge 2 Initial ) )135 5A Final ENC Initial Final 175 16 ) 7 /. -22-54 11 ) 180 180 12 Avg final MC (75 18 ( 110 12 ( 72 18 120 12 4 ) ) Drying time Hours 9 ( ( SEkSONING A.ND NCHINING DEGRADE IN YOUNG-GROWTH DOUGlAS-FIR DIME1SICN LUMBER by B. G. Anderson Oregon Forest Products Laboratory A. C. Knauss Forest Utilization Service Pacific Northwest Forest Ecperiinent Station and R. G. Frashour Oregon Forest Products LaboratQry INTRODUCTION No one seems to know what the annual cut of second-growth, or, more properly, young-growth Douglas-fir, is at present. But it is known that the propor- tion of young-growth sawed to the total cut is increasingl yearly in the Douglas- fir region, and that small sawmills are being built each year to cut small-diameter logs from young stands. The Douglas-fir lumber industry is beginning the European countries and transition from an old-growth to a young-growth economy. the southern pine region in the United States have made this transition, and have been confronted with problems quite different from those encountered when the lumber production was entirely from old-growth timber. A volume estimate of staxiding Douglas-.fir timber in Oregon and Washington in 194.5 placed the old- growth stand at 185 billion fbm and the young-growth stand at 80 billion fbm-defining young growth as under 160 years old.* As the annual cut of young-growth timber increases, it is inevitable that more young-growth lumber will be kiln-dried. Consequently, interest is increas- ingly maaifested in the problems which wl1 appear as more mills go into the * Kirk1aid Report fo the Amerioan Forestry Association, 1945. production of such lumber. with a higher cut of thi One might speculate on seasoning problems to arise type of lumber, such as: Small-diameter logs mean greater ring curvature. Should more cupping be expected during kiln-drying, and consequently more planer split during machining? Young-growth frequently has ccse grain. Should ceason checks be expected, and uore grain separation during machining? 3 Young-growth may have a higher percentage of tight knots than does old-growth. Does a possibility exist of drying this tight-knotted lumber to moisture content levels lower than 18-20 per cent without. excessive increases in degrade from knot damage? Ioung-groi4h may contain more abnormal wood than does old-growth. Will this result in more warp during kiln-drying? The smaller the it is found. og diameter, the higher the percentage of sapwood, Will this increase the incentive to kiln-dry young- growth dimension in order to avoid higher green shipping weights? A higher percentage of sapwood means more susceptibility to stain, nold, and decay of green lumber during bulk shinent and storage. Will this provide another incentive for the kiln-drying of younggrowth dimension? Shrinkage of young-growth Douglas-fir lumber may differ from that of old-growth. Will this necessitate an adjustment in width and thickness of rough-green lumber? To answer some of these questions the Oregon Forest Products Laboratory, in cooperation with the Pacific Northwest Forest and Range Experiment Station, the West Coast Lumbermens Assqciation, the West Coast Bureau of Lumber ades and Inspection, and several lumber companies located in the Willamette Valley, -7- recently completed the initial phase of a long-term investigation into effects of seasoning and machining young-growth Douglas-fir lumber. The first part of this study has been concerned with 2- by 3-inch by 16-foot young-growth Douglasfir dimension lumber, in the grades of Select Structural, No. 1 Common and No. 2 Common. Most of the Douglas--fir dimension now cut is machined and shipped green. However, for around 25 years some Douglas-fir mills have been kiln-drying commofl grades of Douglas-fir in order to preshrink the pieces at least partially and remove the risk of stain and decay during bulk shipment and storage. Other reasons for kiln-drying have been to obtain reductions in shipping weights, and highei- prices for kiln-dried lumber. Twenty-seven years ago A. C. Knauss and his co-workers at Vernonia, Oregon, conducted a study of degrade in kiln-dried old-growth Douglas-fir dimersion. The results of this study con.ftrmed a prior conclusion of the Oregon American Lumber Company that kiln-drying of this type of lumber would be a practical operation.1'2'3 This study established the present practice of kiln-drying dimension to a moisture content level of 18-20 per cent. One reason for drying to this level is to limit the degrade from loss of black or encased knots in old-growth lumber. As it is expected that sewer black knots will be found in young-growth, the present study was so planned as to gain information on degrade at various average moisture content levels between 12 and 18 per cent, in order to ascertain if tight-knotted stock could be dried to lower moisture content levels without excessive increase in degrade from knot damage. The objectives of this study on seasoning and machining degrade in younggrowth Douglas-fir dimension lumber are, in part, as follows: 1. To determine the amount and causes of degrade in several grades of young-growth Douglas-fir dimension lumber resulting from kiln-drying i.iith various 1dm schedules to moisture content levels between 12 and 18 per cent. To obtain shrinkage measurements from green to kiln-dried moisture content level. To obtain residual shrinkage from the kiln-dried, surfaced dimension to that reached in use. To obtain shipping weights of lumber dried to various moisture content levels. To determine the effects of kiln-schedule modifications. To determine specific gravity and ring count of lumber used in the study charges. STUDY CHPRGES There were eleven study charges, each of approximately 65(X) Ibm. Charge 1 was planed green to determine the effect on grade of machining only. All other charges were kiln-dried before machining as follows: Schedules and Drying Times for Kiln-dried Cha±ges. Charge Location of kiln Dry-bulb temperature Initial. Final Initial Final Drying time Average Moisture content Initial Final Hours 2 3 4 5 5A 6 7 8 9 10 D.Fir Prod Co OEPL OFPL Timber Struct. OFPL OFPL OFPL OFPL OFPL OFPL 135 135 134 160 135 180 180 200 200 130 175 180 175 190 175 180 180 200 200 130 17.2 15.9 15.9 14.2 15.9 12.1 4.4 7.8 4.3 3.3 4.3 9.0 8.8 7.7 12l 7.7 7.7 11.0 * Equilibrium moisture content level was 77* 11.0 13.2 75 77 48.9 86 51.6 44.7 188 110 119 117 52 64 90 per cent during 44.6 44.8 48.0 47.8 48.0 40.8 18.4 18.0 14.9 7.8 12.4 12.1 12.5 18.0 17.0 17.9 33.3 last 13 hours. -9- The two conmiercial kline used in the study, and the experimental kiln at the Oregon Forest Products Laboratory, were steam-heated, cross-circulation, compartmenttype with reversible fans. The loading on kiln cars of all study charges was by the unit package system with fork lift. 1 5/8 inches; sticker spacing was 4 feet. Sticker size was 3/4 by All the lumber used in the study was Total length flat-piled inT4nit packages which varied from 2 to 4 feet in height. of air travel through the lumber as it was piled on kiln cars was 8 feet. Air velocity through the loads of lumber in the kiln was between 350 and 450 feet Air circulation was reversed apDroxirnately every twelve hours. per minute. Charge 1 was planed at Clear Lumber Sales Company, Lebanon. kiln-dried and planed at Douglas Fir Products Company, Lebanon. kiln-dried and planed at Timber Structures, Inc., Portland. Charge 2 was Charge 5 was All the rest of the study charges were kiln-dried at the Oregon Forest Products Laboratory, and planed at Corvallis Lumber Company, Corvallis. The lumber for the latter charges was obtained at the Bayless Sawmill, Philomath, through the courtesy of the Albertsen Lumber Company, Philomath. The planer at Corvallis Lumber Company operated at a feed rate of 290 feet Both the side heads and face heads turned at 3700 revolutions per per minute. minute, the side heads with 6 knives and the face heads with 8 knives. The knives on the face heads were set at a cutting angle of 28 degrees, the same cutting angle being used for both green and kiln-dried dimension. The planer at Douglas Fir Products Company had a 10-knife head turning at 3450 rpm. The knives were ground with a back-bevel. Feed rate was 360 feet per minute, and the knife angle was 27 degrees. The planer at Timber Structures in Portland had an 8-knife head turning at 3400 rpm. beveled. Top arid side knives were back-beveled; bottom knives were not back- Feed rate was 250 feet per minute. Knife angle was 30 degrees. -10- AU lumber in the study was planed to American Lumber Standards size of ]. 5/8 inches by 7 1/2 inches. The lumber used in the study charges was graded three times by inspectors from the West Coast Bureau of Lumber Grades and Inspection. The first grading was done on the rough-green lumber, the second on the rough-dry, and the third on the surfaced-dry lumber. Such pertinent data as degrade, final moisture content, drying rates, rough weights, shipping weights, shrinkage, and specific gravity were kept on each charge. RESULTS AND DISCUSSION Degrade Charge 1, which was machined green, showed that no change in grade occurred between the rough-green and the 54S (surfaced-four-sides) green conditions. For this reason all the degrade which developed in the kiln-dried S4S lumber was charged to seasoning, even though most of such degrade developed during the machining operation. Table 1 shows the degrade percentages found £ or Number 1 Common and Number 2 Common. in the kiln-dried 54S charges The average total degrade found in Number 1 Common was about twice that found in Number 2 Common, although the ratio did not hold very consistently within individual charges. The degrade found in Select Structural averaged about twice that in Number 1 Common. Table 2 shows the percentage recovery in S4S grade based on the roughgreen footage of Number 1 Common in individual charges. for Number 2 Common is presented in Table 3. The same information Tables 4 through 9 show the effects of three different variables on the degrade found in Number 1 and Number 2 Common. were (1) the lowest The three variables considered 4C step in the schedule, (2) the average kiln-dried moisture content of the charge, and (3) the initial dry-bulb temperature in the schedule. An examination of these data revealed that the lowest 1C step in the schedule was the only one of the three variables which had an important effect on the amount of degrade. When degrade was subdivided according to types of defect it was seen that degrade because of knot damage was rather constant regardless of moisture content to which the stock was dried or how the dry-bulb temperature arid EIV1C were manipulated. In Iumber 1 Common, knot damage was usually the most Important source of degrade. Planer split and warp were affected by the lowest EMC step as well as by the moisture content to which the stock was dried, but not by the initial dry-bulb temperature. An examination of Table 4 shows that total degrade in both Number 1 and 2 Common was doubled by use of a low-humidity schedule. Charges dried with schedules having high initial dry-bulb temperatures did not have higher degrade percentages than did charges dried with low initial dry-bulb temperatures (Table 8). Table 10 presents degrade in terms of dollar value, based on current prices during the summer of 1953. The loss from degrade in the low-humidity schedules was higher than loss in high-humidity schedules by about fbm for Select Structural, l.60 for Number 1 Common and i.60 per M l.00 for Number 2 Common. Degrade is a function of EMC and time. function of iC and time. Final moisture content IS also a It would be misleading, however, to conclude that degrade is a function of final average moisture content, because final average moisture contents a wide range of be obtained using iow-humid ty schedules. -12- It appeared that the effect of a low 1C schedule on degrade took place much faster than its effect on average moisture content. For further information on this point refer to the section entItled 'Reniarkstt. Because of the importance of knot damage, a supplementary study was made to determine the influence of drying temperature on the development of damage to tight knots. Two small matched charges were dried at a constant EMC of 12 per cent; one of the charges with a constant dry-bulb temperature of 125 deg F, and the other at 175 deg F. No difference cOuld be detected In the development of damage to tight knots as the two charges dried. An attempt was made in charge 9 to reduce the amount of knot degrade by steaming the charge before unloading, as well as by wetting down the individual boards as they were unstiekered. No noticeable reduction in total degrade was experienced as a result of this treatment. However, this charge suffered the least amount of degrade from planer split and warp of any of the kiln-dried charges. No ill effects from the wetting were noted. Reports of lumber sales showed that in August 1953 kiln-dried Douglas-fir dimension sold at a premium ranging from $10.75 for No. 2 Common to 13.50 for Select Structural arid No. J. Common over the same item shipped green. * As the result of degrade, the dry surfaced lumber failed to fully supply this premium. Results of this study showed that with properly chosen kiln-drying schedules, young-growth Douglas-fir dimension could be kiln-dried to a moisture content Of 12 per cent with the degrade reducing, the full premium return by $0.70 for No. 1 Common and 0.87 for No. 2 Common, the principal grades produced at the mill, Black-knotted pieces The percentages of pieces within individual charges which contained black knots c oier /4-inch diameter ranged from 10 to 28 per cent (Table 11). Crow's Price 'August 20, 1953. Degrade -13- from knot damage of all types averaged about 4 1/2 per cent in No, 1C and about 1 1/3 per cent in No. 2C. Some damage to appearance, however, was caused by knot- holes which were too small or too few to lower the grade of the piece. Somewhat less than 10 per cent of the pieces within individual charges contained knotholes which affected the appearance but did not lower the grade; the average in all charges was 2.9 per cent in No, IC and 5e6 per cent in No. 2C. Shipping weight Figure 1 shows the relationship of 54S shipping weight to average moisture content in 2- by S-inch by 16-foot young-growth Douglas-fir dimension. Approxi- mately 20 per cent of the pieces in each charge were weighed rough-green, roughdry and surfaced-dry. individual charges. Figure 1 is based on the average surfaced-dry weight for It can be seen that kiln-drying will result in a shipping- weight saving of from 350 to 650 pounds per N fbm of surfaced dimension lumber, depending upon the initial green moisture content and the moisture content to which it is dried. Figure 2 shows the relationship of weight to moisture content in rough 2- by 8-inch by 16-foot dimension. The water removal during kiln-drying varied from 700 to 1000 pounds per N fbm of rough dimension, depending upon the green moisture content and the moisture content to which it was dried. Figure 3 gives a cumulative distribution of green weight per cubic foot representing 556 individual pieces. Sixty per cent of the pieces measured had green weights between 35 and 45 pounds per cubic foot. Specific gravit and ring count Specific gravity determinations were made on 20 specimens from each of 10 of the test charges, An average specific gravity value of 0.424 was obtained using the oven-dry weight and green volume. Sixty per cent of the specific grav- ity values fell between about 0.39 and 0.46 (Figure 4). -14- Figure 5 through 15 are end-grain photographs of the kiln samples used in the kiln-dried charges. The individual sections are marked with their specific gravity values. An indication of the variation in ring count can be obtained by an examination of these photographs. count of 14 rings per inch (Figure 9). Section number 5 from charge 5 had a ring Section number 19 from charge 9 had a ring count of 2 1/2 rings per inch (Figure 14). These sections represented the extreme ring-count values found in kiln samples from all charges. Drying rate--kiln schedules Figures 23 through 32 show kiln schedules and drying rates for 20 kiln samples per charge. Drying time to 18 per cent average moisture content for charges 2, 4 and 5A was about 72-75 hours. Drying time to 18 per cent average moisture content for high temperature-high humidity schedules (charges 8 and 9) was about 50 hours. Drying time for a low temperature-high humidity schedule (charge 10) was about 90 hours to an average moisture content at 18 per cent. This charge had a low average green moisture content of about 34 per cent. If the green moisture content of charge 10 had been from 40 to 45 per cent, the drying time to 18 per cent would have been much longer. Green moisture content Figure 33 shows the variation in green moisture content of lumber in the 10 charges which were kiln-dried. The median green moisture content value was 40 per cent, with 60 per cent of the boards having green moisture contents between 35 and 52 per cent. Uniformity of final moisture content Figures 34 through 43 show moisture-meter readings in the kiln-dried charges. Charge 2 showed more uniformity in final moisture content than did charge 3, probably because charge 2 was subjected. to three-week winter storage -15- period in the cooling shed before uristickering. In general, the schedules using high final humidities showed mere uniformity in final moisture content than did those with low final humidities. Moisture-meter readings Figure 44 gives a comparison of moisturemeter readings and oven-test moisture-content values found in the kiln-dried lumber. Close correlation was obtained between oven-test values on kiln samples and moisture-meter readings on an S4S boards within iridividu]. charges. Shrinkage during kiln-drying Cumulative distribution curves for rough-green and rough-dry thicknesses of the lumber used in the study are shown in Figure 45. The rough-dry measure- ments were made on lumber which was dried to an average of about 12 per cent moisture content. An exaijnation of this curve will show an average shrinkage in thickness of about 3.5 per cent in drying from green to 12 per cent average moisture content. Figure 46 gives a cumulative distribution of shrinkages in width from green to two different moisture-content levels. When drying to 1 per cent average moisture content the median shrinkage value was about 2.2 per cent, with 80 per cent of the boards shrinking less than 2.8 per cent. When drying to 12 per cent average moisture content the median shrinkage value was about 3.4 per cent, with 80 per cent of the boards shrinking less than 4.1 per cent. Residual shrink. In order to determine the extent of additional shrinkage which dimension lumber would undergo when drying from the kiln-dried moisture content to that reached in use, sections were cut from 20 kiln samples in each charge and measured in width beore and after being conditioned to equilibrium with 65 per cent rela- -16- tive humidity at 70 deg F (approximately 12 per cent equilibrium moisture content). The average residual-shrinkage values obtained are shown in Figure 47. When lum- ber was kiln-dried to 18 per cent average moisture content the average additional shrinkage was found to be about 1.0 per cent. When kiln-dried to 15 per cent average moisture content, the average additional shrinkage was found to be about 0.6 per cent. Average residual shrinkage values for lumber dried to equilibrium with 25 per cent relative humidity at 100 deg F also are shown in Figure 47. Figure 48 gives a cumulative distribution curve for residual shrinkage of lumber which was kiln-dried to 16-18 per cent moisture content. The median residual-shrinkage value on this curve is about 0.65 per cent, with 90 per cent of the boards having less than 1.5 per cent residual shrinkage in width. CONCLUSIONS Young-growth Douglas-fir dimension lumber was dried to moisture contents down to 12 per cent without excessive degrade when the lowest EMC level in the schedule was kept at 8 per cent or higher. The lower the ENC during the low relative humidity step in the schedule, the higher the resulting degrade was found to be. Of three variables which affected degrade in young-growth Douglas-fir dimension--the EMC of the low-humidity step in the schedule, the initial drybulb temperature, and the final average moisture content--the most important was the 4C of the low-humidity step. Temperatures up to 200 deg F were used in drying this material without excessive degrade when EMC was closely controlled at a sufficiently high level. -17- REMARKS Because of the important effect on degrade of the low EMC step in the schedule, it would be wise to keep the EMC during the kiln schedule as high as possible consistent with a reasonable drying time, in the drying of young-growth Douglas-fir dimension. The dry-bulb temperature should also be kept as high as possible during the schedule, within limits that permit accurate cortrol of the desired EMC as well as reasonable steam consumption. Certain kiln schedules which have been observed in use for kiln-drying young-growth Douglas-fir dimension lumber could be modified to reduce degrade by: Raising the EMC used during the low-humidity step of the schedule, Raising the initial dry-bulb temperature to overcome the retarding effect which a higher EMC has on drying time. It must be recognized that in dry kilns which exhibit large longitudinal or cyclic variations in dry-bulb temperature, the substitution of a high-temperature schedule for a satisfactory low- or medium-temperature schedule might lead to excessive- ly high degr1e percentages because of loss of control over EMC, Drying of young-growth Douglas-fir dimension to an average of 16-18 per cent moisture content is believed to be satisfactory if the lumber is to be used for general construction purposes, for the following reasons: An average moisture content of 16-18 per cent can be obtained in a short time using a kiln schedule which results in low degrade. Shipping weight is not decreased greatly by drying to moisture content levels below 18 per cent. Residual shrinkage of lumber which has been dried to an average of 18 per cent moisture content is low enough to be satisfactory for most construction uses. -18- BIBLIOGRAYHY Herman, Albert and Gould, Clark W. . Common Douglas Kiln-drying Fir Boards and Dimension. Forest Products Laboratory, U. S. Forest Service, 11adison, Wisconsin. Johnson, Herman N. Degrade in Kiln Drying of Douglas-fir Common and Finish. U. S. Forest Service, 1927. Knauss, A. C. "Can Common Grades of Douglas-fir Lumber be Successfully Kiln-dried?" Unpublished Report, West Coast Lumbermen's Association, 1927. Anon. "Resulting Degrade from Kiln Drying and Machining Douglas-fir Common." Oregon_American Lumber Corporation. 1939. -19- Table 1. Total Degrade in No. 1 and No. 2 Common Young-growth Douglas-fir Dinension Lumber. Charge Final average moisture content Total degrade fbrn basis) No. 1 Common No. 2 Common Per cent Per cent Per cent 2 18.4 10.7 4.8 3 18.0 9.7 5.5 4 14.9 13.5 11.3 5 7.8 21.2 5.1 SA 12.4 6.4 2.8 6 12.1 8.3 1.1 7 12.5 4.0 3.0 8 16.4 4.1 3.7 9 16.1 5.6 3.3 10 17.6 3.6 2.4 8.7 4.3 AU Charges -20- Table 2. Charge Kiln-dried 848 Recovery in Grade from No. 1 Common Young-growth Douglas-fir Dimension Lumber. Final average moisture content Recovery in'ade (fbm basis) No. 30 No. 20 No. 40 No. 10 Loss Per cent --- 2 18.4 89.3 1.8 8.8 3 18.0 90.3 7,4 2.2 4 14.9 86.5 7.8 5.7 - 5 7.8 78.8 14.3 4.9 -- 5A 12.4 93.6 5.6 0.7 6 12.1 91.7 8.3 0.0 7 12.5 96.0 2.6 0.9 8 16.4 95.9 3.8 0.0 9 16.1 94.4 5.6 0.0 10 17.6 96.4 0.9 2.4 0.1 0.1 0.0 20 0.1 -- - 0.0 0.5 0.3 0.0 0.3 -21- Table 3. Kiln-dried 54S Recovery in Grade from No. 2 Common Dimension Lumber. Ioung-growth Douglas-fir Charge Final average moisture contort Recovery in grade (fbm basis) No. 4C No. 3C Loss No. 2C Per cent 2 18.4 95.2 4.8 0.0 0.0 3 18.0 94.5 4.6 0.8 0.1 4 14.9 88.7 11.3 0.0 0.0 5 7.8 94.9 1.6 0,0 3.5 5A 12.4 97.2 2.7 0.0 0.1 6 12.1 98.9 0.5 0.5 0.1 7 12.5 97.0 3.0 0.0 0.0 a 16.4 96.3 3.2 0.0 0.5 9 16 1 96.7 3.1 0.0 0.2 10 17.6 97,6 2.1 0.0 0.3 -22- Table 4. Charge low relative humidity step Effects of Low W Step in Schedule on Degrade Percentages. Faildown below No. 2C Total degrade No .1C No.2C Avg No,1C No.2C Avg No .1C Degrade from other than knot damage* No.2C vg No.1C No.20 Avg Per cent Per cent 7.8 8.9 4.8 6.8 3.8 1.8 2.8 6.9 3.0 4.9 11.3 12.4 57 11.3 8.5 6.2 4.0 5.1 7.3 7.3 73 5.1 13.1 6.9 5.1 6.0 6.2 0.0 3.1 15.0 5.1 10.0 6.4 2.8 4.6 Q 2,8 12.9 6.0 9.5 56 6.0 5.8 5.1 1.4 3.3 7.8 4.5 6.2 2 4.4 10.7 4 4.3 13.5 5 3.3. 21.2 5k 4.3 Average above group Degrade from knot damage 4.8 2.2 Q,Q 2.5 3 7.8 9.7 5.5 7.6 2.3 5.5 3.9 6.0 1.6 3.8 3.7 3.9 3..8 6 9.0 8.3 1.1 4.7 0.0 1.1 0.5 7.4 0.0 3.? 0.9 1.1 1.0 7 8.8 4.0 3.0 3.5 1.4 3.0 2.2 2.6 0.6 1.6 1.4 24 1.9 8 7.7 4.1 3.7 3.9 0.3 3.7 2.0 2.3 0.0 1.1 LB 3.? 2.7 9 7.,? 5.6 3.3 4.4 0.0 3.3 1.7 4.9 3,1 4.0 0.? 0.2 0.4 10 11 0 3.6 2.4 3.0 2.7 2,4 2.5 0.9 1.6 1.2 2.7 0.8 1.7 5.9 3.2 4.5 1,1 3.2 2.1 4.0 1.1 2.6 1.8 2.0 1.9 Average above group * Includes degrade from planer split, warp, season checks, shake and grain separation. -23'- Table 5. Effects of Low HIC Step in Schedule on Various Causes of Degrade. Degrade from various causes* EaVIC of low relative hunu.dity Charge step Planer split and warp Loose knots and ege nots No.IC No.2C Avg No.10 No.20 Season checks Avg No.10 Knotholes No.20 Avg No.10 No.20 Avg Per cent Per cent 2 4.4 1.0 0.9 0.9 2.0 1.8 1.9 4.8 0.9 2.9 2.8 0.9 l. 4 4.3 3.0 0.8 1.9 4.1 5.2 4.6 0.? 0.0 0.3 3.2 3.2 3.2 5 3.3 2.4 0.0 1.2 14.6 5.1 9.8 0.0 0.0 0.0 3.8 0.0 1.9 5A 4.3 1.4 0.0 0.7 2.2 2.7 2.5 0.0 0.0 0.0 2,8 0 0 1.4 1.9 0.4 1.2 5.7 3.8 4.7 1.4 0.2 0.8 3.2 1.0 2.1 Average above group 3 7.8 3.7 0.8 2.2 0.7 0.1 0.4 0.0 0.0 0.0 2.3 0.8 1.5 6 9.0 1.8 0.0 0.9 0.9 0.6 0.7 0.0 0.0 0.0 5.6 0.0 2.8 7 E.8 0.9 0.6 0.7 1.4 1.2 1.3 0.0 0.6 0.3 1.7 0.0 0.8 8 7.? 0.8 0.0 0.4 1.8 3.6 2.7 0.0 0.0 0.0 1.5 0.0 0.7 9 7.7 3.3 1.2 2.2 0.0 0.2 0.,1 0.0 0.0 0.0 1.6 1.9 1.7 10. 11.0 0.9 1.6 1.2 2.7 0.8 1.7 0.0 0.0 0.0 0.0 0.0 0.0 1.9 0.7 1.3 1.2 1.1 1.1 0.0 0.1 0.05 2.1 0.45 1.2 Average above group *Degrade from shake and grain separation is riot inc1ued. -24Table 6. Charge Average moisture content Effects of Final Average Kiln-dried Moisture Content on Degrade Percentages. Total degrade Avg No.20 No.1C Falidown below No 2C No.20 Avg No.1C Degrade from knot damage No.1C No.20 Avg Degrade from other than knot damage* No.2C No.10 AvI Per cent Per cent 2 18.4 10.7 4.8 7.8 8.9 4.8 6.8 3,8 1.8 2.8 6.9 3.0 4.9 3 18.0 9.7 5.5 7.6 2.3 5.5 3,9 6.0 1.6 3.8 3.7 3.9 3.8 10 17.6 3.6 2.4 3.0 2.7 2.4 2.5 0.9 1.6 1.2 2.7 0.8 1.7 8 16.4 4.1 3.7 3.9 0.3 3.7 2.0 2.3 0.0 1.1 1.8 3.7 2.7 9 16.1 5.6 3.3 4.4 0.0 3.3 1.7 4.9 3.1 4.0 0.7 0.2 0.4 4 14.9 13.5 11.3 12.4 5.7 11.3 8.5 6.2 4.0 5.). 7,3 7.3 7.3 7.9 5.2 6.5 3.3 5.2 4.2 4.0 2.0 3.0 3.8 3.1 3.5 Average above group 7 12. 4.0 3.0 3.5 1.4 3.0 2.2 2.6 0.6 1.6 1.4 2.4 1.9 5A 12.4 6.4 2.8 4.6 0.8 2.8 1.8 4.2 0.0 2.1 2.2 2.8 2.5 6 12.1 83 1.1 4.7 0.0 1.1 0.5 7.4 0.0 2.7 0.9 1.3. 1.0 5 7.8 21.2 5.1 13.1 6.9 5.1 6.0 6.2 0.0 3.1 15.0 5.1 10.0 10.0 3.0 .6.5 23 3.0 2.6 5.1 0,1 2.4 4.9 2.8 3.8 Average above group * Includes degra2e from planer split, warp, season checks, shake and grain separation. -25- Tb10 7. Charge Average moisture content Effects of Final Average Kiln-dried Moisture Content on Various Causes of Degrade. Loose knots and edge knots No.20 No.10 Avg Degrade from various causes Planer split and warp Season checks No.10 No.2C Avg No.1C No.20 Avg Per cent No.10 Knotholes No.2C Avg Per cent 2 18.4 1.0 0.9 0.9 2.0 1.8 1.9 4.9 0.9 2.9 2.8 0.9 1.8 3 18.0 3.7 0.8 2.2 0.7 0.1 0.4 0.0 0.0 0.0 2.3 0.8 1.5 10 7.6 0.9 1.6 1.2 2.7 0.8 1.7 0.0 0.0 0.0 0.0 0.0 0.0 8 16.4 0.8 0.0 0.4 1.8 3.6 2.7 0.0 0.0 0.0 1.5 0.0 0.7 9 16.1 3.3 1,2 2.2 0.0 0.2 0.1 0.0 0.0 0.0 1.6 1.9 1.7 4 14,9 3.0 0.8 1.9 4.1 5.2 4.6 0.7 0.0 0.3 3.2 3.2 3.2 2.1 0.9 1.5 1.9 1.9 1.9 0.9 0.1 0.5 1.9 1.1 1.5 Average above group 7 12.5 0.9 0.6 0.7 1.4 1.2 1.3 0.0 0.6 0.3 1.7 0.0 0.8 5A 12.4 1.4 0.0 0.7 2.2 2.7 2.5 0.0 0.0 0.0 2.8 0.0 1.4 6 12.1 1.8 0.0 0.9 0.9 0.6 0.7 0.0 0.0 0.0 5.6 0.0 2.8 5 7.8 2.4 0.0 1.2 14.6 5.1 9.8 0.0 0.0 0.0 3.8 0.0 1.9 1.6 0.1 0.9 4.8 2.4 3.5 0.0 0.15 0,]. 3,5 0.0 1.7 Average above group * D'grade from shake and grain separation is not included. -26Table 8. Charge Initial dry bulb temp Effect of Initial Dry-bulb Temperature on Degrade Percentages. Total degrade No.2C Avg No.10 Faildown below No. 2C No.10 No.20 Avg Degrade from knot damage No.1C No.20 Avg Degrade from other than knot damage* No.10 No.20 Avg Percent gF 5 160 21.2 5.1 13.1 6.9 5.1 6.0 6.2 0.0 3.1 15.0 5.1 10.0 6 180 8.3 1.1 4.7 0.0 1.1 0.5 7.4 0.0 3.7 0.9 1.1 1.0 7 180 4.0 3.0 35 1.4 3.0 2.2 2.6 0.6 1.6 1.4 2.4 1.9 8 200 4.1 3.7 3.9 0.3 3.7 2.0 2.3 0.0 1.1 1.8 3.7 2.7 9 200 5.6 3.3 44 0.0 3.3 1.7 4.9 3.1 4.0 0.7 0.2 0.4 8.6 3.2 5.9 1.7 3.2 2.5 4,7 0.7 2.7 4.0 2.5 3.3 Average above group 2 135 10.7 4.8 7.8 8.9 4.8 6.8 3.8 1.8 2.8 6.9 3.0 4.9 3 135 9.7 5.5 7.6 2.3 5.5 3.9 6.0 1.6 3.8 3.7 3.9 3.8 4 135 13.5 11.3 12.4 5.7 11.3 8.5 6.2 4.0 5.1 7.3 7.3 7.3 5A 135 6.4 2.8 4.6 0.8 2.8 1.8 4.2 0.0 2.1 2.2 2.8 2.5 130 3.6 2.4 3.0 2.7 2.4 2.5 0.9 1.6 1.2 2.7 0.8 1.7 8.8 5.3 7.0 4.1 5.4 4,7 4.2 1.8 3.0 4.6 3.6 4.1 10 Average above group * Includes degrade from planer split, warp, season checks, shake and grain separation. -2?- Table 9. Effect of Initial Dry-bulb Temperature on Various Causes of Degrade. Degrade from various causes* Charge Initial dry-bulb temp Loose knots and edge knots Avg No.2C No.1C Planer split and warp Avg No.2C No.1C Season checks No.1C No.2C Avg No.10 Knotholes No.20 Avg L cent 5 160 2.4 0.0 1.2 14.6 5.1 9.8 0.0 0.0 0.0 3.8 0.0 1.9 6 180 1.8 0.0 0.9 0.9 0.6 0.7 0.0 0.0 0.0 5.6 0.0 2.8 7 180 0.9 0.6 0.7 1.4 1.2 1.3 0.0 0.6 0.3 1.7 0.0 0.8 8 200 0.8 0.0 0.4 1.8 3.6 2.7 0.0 0.0 0.0 1.5 0.0 0.7 9 Average 200 3.3 1.2 2.2 0.0 0.2 0.1 0.0 0.0 0.0 1.6 1.9 1.7 1.8 0.4 1.1 3.7 2.2 2.9 0.0 0.1 0.06 2.8 0.4 1.6 above group 2 135 1.0 0.9 0.9 2.0 1.8 1.9 4.9 0.9 2.9 2.8 0.9 1.8 3 135 3.7 0.8 2.2 0.7 0.1 0.4 0.0 0.0 0.0 2.3 0.8 1.5 4 135 3.0 0.8 1.9 4.1 5,2 4.6 0.7 0.0 0.3 3.2 3.2 3.2 5A 135 1.4 0.0 0.7 2.2 2.7 2.5 0.0 0.0 0.0 2.8 0.0 1.4 130 0.9 1.6 1.2 2.7 0.8 1.7 0.0 0.0 0.0 0.0 0.0 0.0 2.0 0.8 1.4 2.3 2.1 2.2 1.1 0.2 0.6 2.2 1.0 1.6 10 Average above group * Degrade from shake and grain separation is not included. -28Table 10. Effect of Low aVIC Step in Schedule on Dollar Recovery per Thousand Board Feet of Kiln-dried Dimension Lumber. EMC of low relative humidity step L Grade of kiln-dried, planed lumber Value per N fbm of rough-green lumber after kiln-drying and nrnehining Select Str No.1 Common No.2 Common cent Se]. Str $69.74 No, 10 12.79 $71.34 No. 2C 5.32 5.62 $71.44 No. 30 0.27 2 70 2.75 No.40 0.12 3.3-4.4 All grades $88.24 Se]. Str 7.7-11.0 $74.19 78.75 No. 1C 7.87 77.16 No. 20 3.19 3.65 73.57 0.49 1.51 No. 30 No, 40 0605 All grades $89.8]. $81.30 $75.13 SUNNARY Total value per N fbzu (848) Grade Low ENC schedule High ENC schedule Se? Str $88.24 $89.8]. $92.00 $78 .50 No. 1C 79.66 81.30 82.00 68.50 No. 2C 74.19 75.13 76.00 65.25 No. 30 54600 48.00 No. 40 23.00 18.50 KD value with no degrade* Green value with no degrade* * Prices based on Crows Price Reporter, August 20, 1953, average of "Most Sales". A price diferential of $10 was assumed between Number 1 Commo and Select Structural, -29- Table 11. Percentages of Green Pieces Containing Black Knots of Over 3/4-inch Diameter. Lumber grade Charge Sal Str and No. 1C No. 2C Per cent Per cent 3 16.9 20.7 4 13.5 U.8 5A 15.4 12.1 6 24.2 17.3 7 22.3 22.0 8 11.6 10.1 9 22,6 26.1 10 Above charges 28.2 18.1 18.5 FIGURE I. RELATIONSHIP OF SHIPPING WEIGHT TO AVERAGE MOISTURE CONTENT IN 2- by 8- INCH YOUNG-GROWTH DOUGLAS-FIR , SURFACED FOUR SIDES (AVERAGE OF NO I AND 2 COMMON). FIGURE 2. WEIGHT PER M FBM BY MOISTURE CONTENT; ROUGH 2-by 8- INCH by 16-FOOT YOUNG-GROWTh DOUGLAS-FIR (AVERAGE OF NO. I AND NO. 2 COMMON). 2800 0 38 700 0 0 0 U) Li 36 2600 LU aU) U) U- 0) 2 500 . .0 34 0 0 z S 32 24 00 I 0 0 LU - 30 0 I0 2 300 I.- (D z LU aa- U) 0 0 I.- I S LU 0 a- 0 0 0 28 0 2200 0 00 0 21 00 0 2 . 10 S. S. S S 0 24 2000 0 S 0 30 20 MOISTURE CONTENT , 40 50 PER CENT 60 65 0 10 30 20 MOISTURE CONTENT, 40 50 PER CENT 6 FIGURE 3. CUMULATIVE DISTRIBUTION OF DENSITY VALUES IN 2-by8-INCH GREEN DOUGLAS-FIR. S S S S S S 0 S C) NOTE 556 INDIVIDUAL MEASUREMENTS REPRESENTED S S I S_S. ) 0 25 30 FIGURE 4. I 35 40 45 50 GREEN WEIGHT, LB PER CU FT 55 60 CUMULATIVE DISTRIBUTION OF SPECIFIC GRAVITY VALUES IN 2- B'( 8-INCH BY 16-FOOT YOUNGCHARGES GROWTH DOUGLAS-FIR: 5A, 6, I- 7, I, 3, 4, 5, 8, 9 AND 10. 100 z Ui U Ui a>- AVERAGE SPECIFIC GRAVITY I> OF 197 PIECES, BASED ON GREEN VOLUME AND OVEN-DRY WEIGHT, WAS 0 0 0. 424 LI- U Ui 54O 9 Ui Ui -J 0 0 0.35 040 045 SPECIFIC 050 GRAVITY 0.55 0.60 0.65 & .p.- r- 0*. END GRAIN AND SPECIFIC GRAVITY OF KILN SAMPLES,FROM CHARGE I. 3fl9IJ END GRAIN OF KILN SAMPLES FROM CHARGE 2. II F OP 6 AND OF KILN SAMPLES 3II33dS END GRAIN -O 3. !WA FIGURE p - 6f al END GRAIN AND SPECIFIC GRAVITY OF KILN SAMPLES FROM CHARGE 3. zt. () - FIGURE 5. GRAVITY CHARGE 4. GI4AROE 5 PlO.IE1 2 h4 K074%AvMC AvSpG. 0.4 A PflQ,JECT I2M - 53 .. IL Z'I.3I 1.41 eIIT 5. 4 HIW/ '.7 Ii))))))iIJ ' : 4. 8. 80 FIGURE 9. END GRAIN AND SPECIFIC GRAVITY FIGURE 4 9 END GRAIN 10. AND SPECIFIC GRAVITY OF KILN SAMPLES FROM CHARGE 5A. OF KILN SAMPLES FROM CHARGE 5. CHAROt 6 P'OIET 5h(.') RD e%AMc ASpG. C4I Sl FIGURE II. r 035-52 END GRAIN AND SPECIFIC GRAVITY OF KILN SAMPLES FROM CHARGE 6. FIGURE 2 END GRAIN AND SPECIFIC GRAVITY OF KILN SAMPLES FROM CHARGE 7. VVL '9'JEUI 32l6) 31;% 4,M1; 1;pO. 44 4 4 Ai 38 r' 3 ,; 3' Tiri % L. 39 2 38 '4 FIGURE END GRAIN AND SPECIFIC GRAVITY OF KILN SAMPLES FROM CHARGE 13. FIGURE 5 FIGURE 14. 8. END GRAIN AND SPECIFIC GRAVITY OF KILN SAMPLES FROM CHARGE FIGURE END GRAIN AND SPECIFIC GRAVITY OF KILN SAMPLES FROM CHARGE 9. 16. CONDITION SURFACING: OF KNOTS AFTER CHARGE 3. FIGURE 17. FIGURE CONDITION OF KNOTS AFTER SURFACING: CHARGE 4. lB. CONDITION OF KNOTS SURFACING: AFTER CHARGE 5A. S FIGURE II. CONDITION OF KNOTS SURFACING: CHARGE AFTER 6. FIGURE 20. CONDITION OF KNOTS AFTER SURFACING; CHARGE 7. FIGURE 23. YOUNG-GROWTH 2-by 8- INCH DOUGLAS-FIR. . ..-. . - Iu,J FIGURE 24. YOUNG-GROWTH 2-by 8-INCH DOUGLAS-FIR, 2, CHARGE . 3, CHARGE DRYING RATE & KILN SCHEDULE. . DRY BULB U- 160 DRY 40 WET BULS_\ ioo SAMPLE hlH BULBThH\ 1\ F- I 0 80 I- 2 UJ 60 w 40 ___ SAMPLES Iz 40 z0 C.) III 20 LOW SAMPLE 0 0, 0 20 o 60 80 TIME, HOURS IHSAMPJ 0 , AVERAGE OF TWENTY 100 120 20 ' LOW SAMPLE AVERAGE OF TWENTY SAMPLES 10 0 20 40 60 80 TIME , HOURS 120 140 FIGURE 25. YOUNG-GROWTH 2-by 8INCH DOUGLAS- FIR; CHARGE 4, DRYING RATE & KILN SCHEDULE. 180 FIGURE 26. YOUNG-GROWTH 2-by 8- INCH DOUGLAS-FIR CHARGE 5, DRYING RATE & KILN SCHEDULE. DRY BULB I Ll 0 WET BULB 140 Cl) z 20 .r-J Lu I . 80 HIGH SAMPLE I- z w 0 60 cr 60 AVERAGE OF TWENTY Lii SAMPLES1 24O zLii z0 Lii 4 20 Ii 0 4 I- 4 Iii Z WET BULB HIGH SAM PLE AVERAGE OF TWENTY SAMPLES LOW SAMPLE LOW SA C,, 0 0 L' U- 2 I- 0 LI DRY BULB 20 40 TIME , 60 HOURS 80 0 100 120 40 80 TIME , 120 160 200 220 1 FIGURE 27 YOUNG-GROWTH 2-by8-INCH DOUGLAS-FIR; CHARGE 5A, DRYING RATE 8 KILN SCHEDULE FIGURE 28. DRY YOUNG-GROWTH 2- BY 8-INCH DOUGLAS-FIR; CHARGE 6, DRYING RATE & KILN SCHEDULE. BULB 180 0 U C rwET BULB zU U Ii I- cr I- IWET BULB BULB 160 0 U 140 I- 80 6 AVERAGE OF TWENTY SAMPLES r 0. \DRY Lii 6O Iii I HIGH SAMPLE z 40 4 Ui I.- z HIGH SAM PLE 0 0 AVERAGE OF TWENTY 20 20 - 0 LOW SAMPLE 0 0 20 40 60 TIME, HOURS 80 tOO 120 140 20 40 60 TIME, HOURS 80 100 120 FIGURE 30. FIGURE 29. YOUNG-GROWTH 2-by 8-INCH DOUGLAS-FIR CHARGE 7, DRYING RATE & KILN SCHEDULE. U- YOUNG-GROWTH 2- BY 8-INCH DOUGLAS-FIR; CHARGE 8, DRYING RATE & KILN SCHEDULE. 20 180 BULB U- jWET BULB Ui DRY ITO LDRY BULB ,-WET 160 - BULB Lz UU- 0 120 UU- 0 U) 2 ,_ 2 LQ C-) 80 I- zUi I- 0 HIGH SAMPLE Ui - 0 10 100 60 -- 80 I- z Ui C.) a. TWENTY SAMPLES 40 20 0 20 60 U AVERAGE OF C-) . I- zU z0 0 w 20 : LOW 40 60 80 TIME , HOURS 00 120 SAMPLE '.:HIGH AVERAGE 0 LOW TWENTY SAMPLES SAMPLE 0 0 20 40 60 TIME, HOURS 80 100 120 FIGURE 31, YOUNG-GROWTH 2-by 8-INCH DOUGLAS-FIR, 9, CHARGE DRYING RATE 8 KILN SCHEDULE U. 200 FIGURE 32. YOUNG-GROWTH 2- BY 8-INCH DOUGLAS-FIR; CHARGE 10, DRYING RATE & KILN SCHEDULE. DRY BULB LU f-WET BULB U. 140 LU 0 1-DRY BULB Lu 120 NOTE: 2 HOURS STEAM AND WATER SPRAY a- BEFORE OPENING KILN too k-WET BULB Lu L&1 '- 100 I- z U- z 0 80 Ci) z Lu HIGH SAMPLE Lu a. Lu 0. i- 60 zLu Iz0 I-. z Lu 0 0 80 LU C, 40 60 HIGH SAMPLE 40 AVERAG - . 20 S LOW 0 20 - 20 0 0 S S S SAMPLE 40 60 TIME , HOURS 80 100 120 20 40 60 TIME , HOURS 80 tOO 120 FIGURE 33. CUMULATIVE PERCENTAGES OF PIECES ACCORDING TO MOISTURE CONTENT IN GREEN 2- BY 8-INCH YOUNG-GROWTH DOUGLAS-FIR; I- TEN CHARGES. I0O U 0 LU a- 8O LU NOTE z0 201 INDIVIDUAL OBSERVATIONS REPRESENTED 0 i6O D I(1) 0 z 40 LU ILl 20 ILl U) LU 0 LU a-0 40 FIGJJRE 60 80 100 120 140 GREEN MOISTURE CONTENT , PER CENT 34. DISTRIBUTION OF MOISTURE METER READINGS IN 2-by8-INCH YOUNG -GROWTH DOUGLAS-FIR, CHARGE 2, KILN-DRIED TO 18.4 % AVG M.C. I- 0 bc . w 0 a- (8C 2 0 4 LU S 6C I- (Li 2 LU . 4C NOTE MOISTURE METER READINGS ON 51 WEIGH PIECES ONLY -J 2C LU U) LU 0 0 LU0 0 14 24 22 18 20 PER CENT MOISTURE METER READINGS 16 160 FIGURE 35. DISTRIBUTION OF MOISTURE METER READINGS IN 2-by8-INCH YOUNG-GROWTh DOUGLAS-FIR, CHARGE 3, KILN-DRIED TO 18.0 04 AVG MC. I- z 100 uJ U a: . LU a- z 80 0 . LU a: A 6O ILU LU 4O S . 20 LU U) LU U LU 0 8 10 14 12 IR I MOISTURE METER READ NGS, 99 21) 2 PER CENT FIGURE 36. DISTRIBUTION OF MOISTURE METER READINGS IN 2- BY 8INCH YOUNG-GROWTR DOUGLAS-FIR; CHARGE 4, KILN-DRIED TO 15.2 %AVG M C. I- z Iii 10 C-) a: LU a- 0 8O 322 PIECES IN CHARGE LU a: a: . W I- 60 LU Ui S a: 40 C,) 0 S 0 -J LLI S Cl) LU 0 LU a- IA I-, IJ MOISTURE le METER READINGS, )0 10 IQ PER CENT 0 c4 FIGURE 37. DISTRIBUTION OF MOISTURE METER READINGS IN 2-by8- INCH YOUNG -GROWTH DOUGLAS-FIR; CHARGE 5, KILN-DRIED TO 7.8 % AVG N C. I- z 100 Ui a- 0 z 80 0 Lii 2O Ui U) U 0 U 0 ' 8 10 12 4 16 MOISTURE METER READINGS, PER CENT 18 20 FIGURE 38. DISTRIBUTION OF MOISTURE METER READINGS IN 2- BY 8-INCH YOUNG-GROWTH DOUGLAS-FIR; CHARGE 5-A, KILN-DRIED TO 12.4 % AVG MC. WI 'Ju 0 W a- z 0 W W I- W W I- 40 (1) 0 NOTE 309 PIECES IN CHARGE Ui 2: U) Ui 0 Ui 0 6 8 10 12 14 16 MOISTURE METER READINGS, PER CENT 18 FIGURE 39. DISTRIBUTION OF MOISTURE METER READINGS IN 2- BY 8-INCH YOUNG-GROWTH DOUGLAS-FIR; CHARGE 6, KILN-DRIED TO 12.1 % AVG MC. I2 IOO LU 0 . ii: LU 0 z 80 I LU 0 60 2 307 LU NOTE PIECES IN CHARGE 40 0 520 LU U) LU 0 LU ö0Q . 4 S 8 10 IS 14 12 U MOISTURE METER READINGS, PER CENT FIGURE 40. DISTRIBUTION OF MOISTURE METER READINGS IN 2- BY 8-INCH YOUNG-GROWTH DOUGLAS-FIR; CHARGE 7, KILN-DRIED TO 12.5 % AVG MC. I.- 2I Lii 0 S Lii S a- 2 90 Iii . Lii 60 I.- LU S 2 w I- 40 U) NOTE 0 2 307 PIECES IN CHARGE S 20 LU U) LU 0 LU a- 0j 0 0 S 8 10 12 14 16 MOISTURE METER READINGS, PER CENT 18 2 FIGURE 41. DISTRIBUTION OF MOISTURE METER READINGS IN 2-by8- INCH YOUNG-GROWTH DOUGLAS-FIR, CHARGE 8, KILN- DRIED TO 16.4 % AVG M C. I- 2 w U w 0 (. 2 0 80 w Lu I- NOTE Lu 3I3 PIEC ES IN CH ARGE U IU, 0 10 12 14 20 18 16 22 24 MOISTURE METER READINGS, PER CENT FIGURE 42. CHARGE 9, KILN-DRIED TO 16.1 % AVG MC. I.- 2 Ui o DISTRIBUTION OF MOISTURE METER READINGS IN 2-by 8- INCH YOUNG -GROWTH DOUGLAS-FIR, . .1 . '.,- Lu 0 2 0 ) Ui Lu ) Lu Lii N OTE 316 PIECES IN CHARGE, 0 0 0 -J Lu 0¼ U) Lu 0 Lii 0 0 '4 tA MOISTURE METER READINGS, 2ô PER CENT 2 2 FIGURE 43. DISTRIBUTION OF MOISTURE METER READINGS IN 2- BY 8INCH YOUNG-GROWTH DOUGLAS-FIR; CHARGE 10, KILN-DRIED TO 17.6 S AVG MC F- zIO LU 0 0 a: LU 0 0' z Iii a: a: LU I- LU 0 LU a: 4 U) o. 0 LU NOTE 314 PIECES IN CHARGE 2' 0 Ln U) LU C., LU . a- 10 14 12 MOISTURE FIGURE 44. 20 18 16 METER READINGS, 22 24 PER CENT MOISTURE METER READINGS COMPARED TO OVEN-TEST MOISTURE CONTENT VALUES IN 2-by 8- INCH YOUNG-GROWTH DOUGLAS-FIR, IN PER CENT. I.- Z20 LU C) a: LU 0' aC, 'I 0 z LU a: a: 12 LU F- NOTE LU Lii a: OVEN-TEST SECTIONS CUT FROM ROUGH KILN SAMPLES; MOISTURE 8 METER READINGS TAKEN AT IU., 3/8-INCH DEPTH ON ALL PIECES 0 LU C., IN CHARGE AFTER SURFACING. 4 a: LU 0 4 16 8 12 20 AVERAGE MOISTURE CONTENT, PER CENT (OVEN TEST) FIGURE 45. CUMULATIVE DISTRIBUTION, IN PER CENT, OF THICKNESS IN 2BY 8-INCH YOUNG-GROWTH DOUGLAS-FIR; GREEN AND KILNDRIED. r I- z LU C.) A Ui 0 LU -J 60 U) U) z REPRESENTED (ROUGH,GREEN) -r___ A 40 20 U) Ui 0 Ui a- 577 INDIVIDUAL MEASUREMENTS ! LU 0 17 18 184 INDIVIDUAL MEASUREMENTS REPRESENTED (ROUGH DRY) AVERAGE MOISTURE CbNTENT 12 PER CENT 19 THICKNESS, 20 22 21 23 INCHES FIGURE 46. CUMULATIVE DISTRIBUTION OF SHRINKAGE VALUES DURING KILN-DRYING OF GREEN 2-by 8-INCH YOUNG-GROWTH DOUGLAS-FIR. 100 LU 0 LU °8o DRIED TO IS PER CENT AVERAGE LU -J MC . . 60 4 DR z Cl) ED TO 12 CENT AVERAGE PER MC. 40 20 0 .4 .i 1U 6 4 5 3 2 SHRINKAGE DURING KILN-DRYING, PER CENT (GREEN WIDTH BASIS) 2.4 FIGURE 47. I- RESIDUAL SHRINKAGE OF 2- BY 8-INCH YOUNGGROWTH DOUGLAS-FIR FROM KILN-DRIED WIDTH TO EQUILIBRIUM WITH 25 AND 65 PER CENT RELATIVE HUMIDITY. 3.0 zUi 0 Ui. aLii 0 4 z 1.0 I U) 0 10 12 14 16 18 20 AVERAGE KILN-DRIED MOISTURE CONTENT, PER CENT FIGURE 48. CUMULATIVE DISTRIBUTION OF RESIDUAL SHRINKAGE VALUES IN 2-by 8-INCH KILN-DRIED,YOUNG-GROWTH DOUGLAS-FIR WHEN DRIED FROM AVERAGE MOISTURE CONTENT OF 16- 18 PER CENT TO EQUILIBRIUM WITH 65 PER CENT RELATIVE HUMIDITY. I- zuJ 0 0 U LII o NOTE w 99 INDIVIDUAL MEASUREMENTS REPRESENTED 46 . uJ 0 4 . z 0 U) '' . S 2 0 . U) w 0 Ui a- 0 0 2 RESIDUAL SHRINKAGE, 3 4 5 6 PER CENT (KILN-DRIED WIDTH BASIS) 7 E FIGURE 49. FIGURE 51. END GRAIN VIEW OF S4S CHARGES 4 AND 5A. DIMENSION: OF S4S DIMENSIONt END GRAIN VIEW CHARGE 8. FIGURE 50 END GRAIN VIEW OF CHARGES FIGURE 52. 6 AND 7. S4S 0 MENSION END GRAIN VIEW OF S4S DIMENSION: CHARGE 9.