From: AAAI Technical Report FS-96-03. Compilation copyright © 1996, AAAI (www.aaai.org). All rights reserved.

View to Product Configuration Knowledge

Modelling and Evolution

Tomi M/innis~,

Hannu Peltonen and Reijo Sulonen

Helsinki University of Technology

HAResearchCentre and Laboratoryof InformationProcessing Science

Otakaari 1, FIN--02150Espoo, FINLAND

{Tomi.Mannisto,

Hannu.Peltonen,Reijo.Sulonen}@hut.fi

Abstract

Knowledgemanagementhas been a major problem

in the implemented

configurationsystems. Onereason for the difficulties is the complexityof the

product descriptions in these systems. Theproduct

experts can no longer understandproductthe wayit

is described.Theproblemis addressedin the objectoriented spirit by looking for waysof makingthe

configuration product structure modelsmorecomprehensible. A data modelfor describing generic

productstructures is defined. It formsa basis for

modellingthe evolution of both product configuration knowledge

and deliveredproducts.

Introduction

Manyknowledgeintensive systems have had problems

with knowledgemaintenance. Product configuration

systems are no exception in this respect, e.g., XCON

(Barker & O’Connor1989, McDermott1993). There

no universal agreement on the knowledgeneeded in

productconfigurators,let alone on the representationof

this knowledge.Wetherefore find it impossibleto discuss configuration knowledgemanagement

without reference to whatkind of knowledgeis being managed.

The basic issue in configuration modelling is a

mechanism

for describingstructures of multiple product

variants within a single data model. Manydifferent

methodshavebeenused for modellingthis generality in

product descriptions (Scht~nsleben& Oldenkott 1992,

van Veen 1991, Cunis et al. 1989, Mittal & Frayman

1989and Heinrich & Jungst 1991). Weidentify two basic product structure modellingmethodsin these approaches, whichwe refer to as explicit and implicit

methods. Wethen define a data modelwhichuses both

these methodsin combination.

There is no single wayof looking at products of a

company.

Productscan be classified accordingto various

criteria. Aclassification criterion suitable for onepurpose mayturn out to be awkwardin another context. We

try specifically to avoid this kind of problemby constructing our modelexplicitly for productconfiguration

purposes.

After definition of the modelwediscuss the configuration knowledgemanagementproblemin the environmentwherethe modelwouldbe used. Finally weoutline

our vision for a researchagendafor the evolutionof configuration models.

This paper reports ongoingworkof the Product Data

Management

Groupat Helsinki University of Technology.

Short Definitions of Basic Terms

A physical product is manufacturedaccording to a specific productstructure. A specific productstructure is a

collection of component

descriptionsorganisedin a partof hierarchy. Eachcomponentdescription contains the

necessary information for makingor ordering a component. Aspecific productstructure is sometimescalled a

bill-of-materials (BOM)

or configuration.

In manycompaniesa product can be varied according

to customerrequirementsandtherefore actually refers to

a set of similar products.This set can be describedwith a

generic productstructure, whichcorrespondsto a number of different specific productstructures. In a generic

productstructure a genericcomponent

referencerefers to

a set of alternative components.

A configurationprocess starts with a generic product

structure and customerrequirements.Customerrequirements are mappedto a technical specification, which

describes the customerneeds in the languageunderstood

in the configurationprocess. Thegoal of the configuration process is to fred a suitable (valid, completeand

possibly optimal) specific product structure that is

amongthe alternatives described by the generic product

structure. Wedo not assumeany particular kind of configuration process, it maybe fully automatic or rely

partly or entirely on decisionsmadeby a human.

A product can be described from many different

points of view, each potentially defining a different

product structure. In this paper, the generic product

structure, or configuration modelas it is sometimes

called, describes only those aspects of the productthat

are relevant duringa configurationprocess.

iii

Modelling Generic Product Structures

Thereare several possible waysof modellinggenerality

in product structures. Wedivide themhere roughly in

explicit and implicit productstructure descriptionmethods. Thetermsexplicit andimplicit indicate howdirectly

the generic product smactureidentifies the components

used. Weuse terms explicit or implicit modelfor a data

modelthat is based on an explicit or implicit product

structure description method,respectively. A single genetic product structure can also employboth -kinds of

methods.

Weuse the term ’productstructure’ here, althoughall

implicit methodsdo not aim at describingthe organisafion of the components

in a part-of hierarchy. Theymay

connect the componentsin someother way than in a

part-of hierarchy or perhapsdescribe only the component

set andassumethe structure to be well knownor fixed.

In an explicit methodthe generic productstructure is

describedby stating the components,their organisation

in the part-of hierarchy and possible choices for them.

For example, a MountainBikeX

has part frame which is

either MBFrameX

or MBFrameY.

In an implicit method,the description consists of

knowledgeabout the compatibility of components,connectivity of components

or other constraints. For example, in description of a display unit, the component

’monitor’maystate that it needsa high resolution video

signal, anda particular graphicscard maystate that it

providesexactly that kind of signal. AT-connectormay

state that it takes onevideoinput signal andprovidestwo

outputs of the samesignal. Thereis no explicit description of the components

of a workingdisplay unit. If two

monitorsare neededfor a certain system, one graphics

card and a T-connectorwith two monitors will do the

job.

It is also possible to use both explicit and implicit

methodsin a single model.For example,on the explicit

side one maystate that a product P has componentsa

and b, wherea is either A1or A2and b is either B1or

B2. Implicit knowledge

in B2maythen say that it is incompatiblewith A1and they should, therefore, not be

usedin the sameproduct.

In explicit modelsit is typically straightforwardto

enumerateall possible specific productstructures. Finding the desired structure maystill take too muchtime if

all the possibilitiesneedto be investigated.

In a purelyexplicit modela selection betweenalternative componentscan be madewithout considering other

component

selections. In practice, however,the alternafives in somecomponentsdependon each other. Sometimes these dependenciescan be solved with a global

context, whichis establishedat the beginningof the configurationprocess.

For example, suppose a product has component

’motor’ with alternatives ’220V’and ’ 110V’,and component’powerswitch’ with analogousalternatives. The

global context for this product could include attribute

112

’operating voltage’. After the context has been established, the motorand the switch can be chosenwith explicit rules. Alternatively one could use implicit rules

such as:/f the producthas a llOV (220V)motor, it must

have a 110V (220V) switch, or alternatively a 110V

(220V) motor cannot be combinedwith a 220V(110V)

switch.

Explicit modelthus more directly tells what components must be chosen for a valid configuration whereas

implicit modeldefines conditionsthat mustbe satisfied

by valid configurations.

Webelievethat explicit productstructures are in many

cases easier to construct and understandthan implicit

ones. Nevertheless, manyproducts include validity conditions that require implicit methods.Thedata model

that is outlinedlater in the paperthereforehas an explicit

basis that is extendedwith implicit constraints.

In the following we give someexamplesof both explicit andimplicit productstructure descriptionmethods.

Sample Explicit

Methods

Set of BOMs.

This is a trivial case andnot actually a real

generic product structure model. The methodis, however, widely used in the industry for modelling even

large numbersof variants.

Generic, Variant and ParametricBOMs.These define

alternatives for certain components

of a BOM

and possibly global variables for determining the choice.

(Sch~nsleben& Oldenkott 1992, van Veen1991)

AND-OR

Graphs. At each level of an AND-OR

graph a

node breaks downto either its components(AND)or

one selection between choices (OR). The ANDand

levels alternate, so that an AND

level is followedby an

ORlevel and vice versa.

Combined

Classification and Component

Hierarchies.

This is a sophisticated version of an AND-OR

graph as a

combinationof component

and classification hierarchies.

There each non-leavenodecan be either divided into its

components

(just like AND)

or it can be specialisedto its

subclass (a kind of an OR).This approachis used in SAP

Configurator(SAP1994) and is a close relative of the

PLAKON

model (Cunis et al. 1989).

Composite

InstanceVariable.Compositeinstance variables are usedin object-orientedmodelsfor representing

components(Kim, Bertino, & Garza1989). Such a variable representsactually a set of components

ff its domain

is a class that has subclasses;anyof its subclassbeingan

eligible component.

Sample Implicit Methods

If-then Rules. In manyexpert systemsif-then rules can

be used for implicitly describing productstructure. For

example, IF component A OR B is in configuration

THENcomponentX must be included, too.

"7

/

t

c-classification]

,

N

1

.........

!

!

........

\

[Configuration-[

componentdescriptions /

t

compm< { S }

compn -< {Y, Z}

ResSum(ResX~

prtrauct .

data base ,

main

,. ¯

,

, J

, ,

,

/

I

I

!

¯

",

mS{Sl} nS {Y, Z2}

n_<{Y,Zl}

-"

"’

¯ "\

compI < {A}

’ : /\,"

I

I

ResX:int

I

I

"--’~

--

[

~

//////II

..

..

,’

I

/

~’/

mediator

I .

I related

I c°mp°nent

data

/,//

/ I

/ 1

I

~ l

I< {A2!.

" /

~’"

I "11

ResJ(:=-160~F~_7

I

~

Rosx:=-18o

Resx:=-no

ResX:= 200 ResX:= 150

Figure 1. Examplegeneric product structure in the model.

out the invalid cases. In the following we ftrst give an

example of a generic product structure using the model

and then explain the conceptsin detail.

Incompatibility and Compatibility Constraints. One

wayof stating the possible uses of componentsis to state

which components can or cannot be with other components in a configuration. These facts can be recorded as

n-ary tuples.

Interfaces,

Ports and Connectors. These provide

deeper modelling for compatibility of components. The

basic idea is that in a configuration certain components

need, can or cannot be connected. This is modelled, for

example, by ports and connectors that must fit together

in a valid configuration (Mittal &Frayman1989).

Resource-based Modelling. In resource based generic

product structure modelling the idea is that somecomponents consumesomething, such as, power, fuel, ventilation, etc., while certain components supply these resources. In a valid specific product structure all resources

need to be in balance. For example, the total produced

net power must be more than maximumconsumption.

(Heinrich & Jungst 1991)

Generic

Product

Structure

An Example of a Generic Product Structure in

the Model

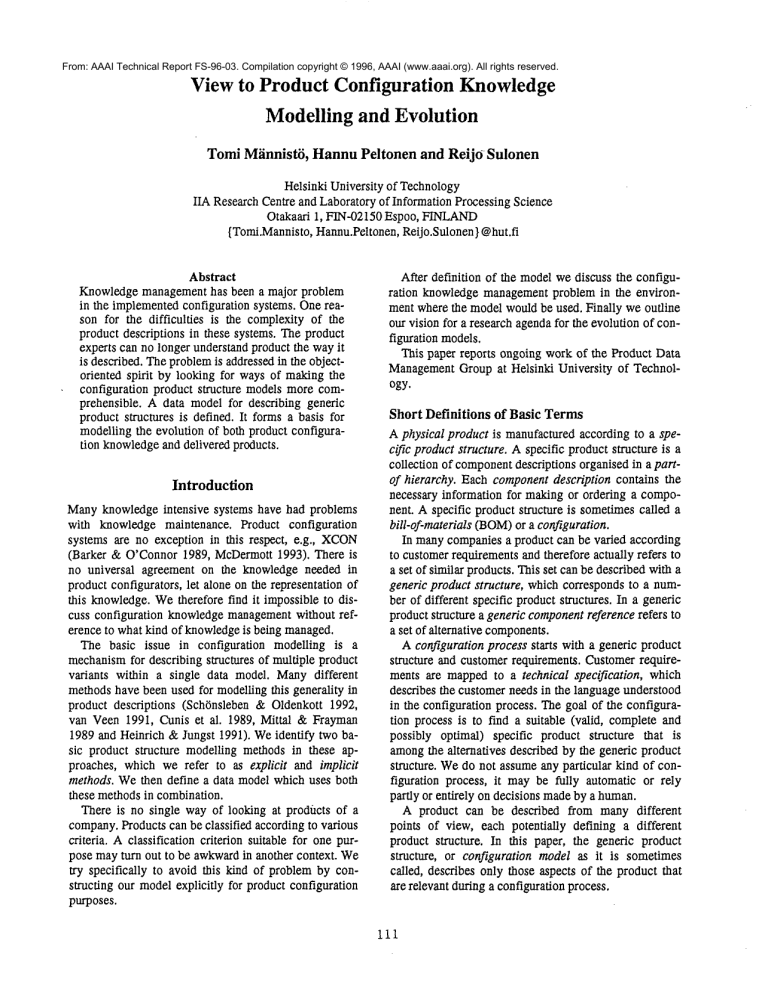

Generic product structure description of P in Figure 1

declares that P has two componentsm and n. Component

mshould be an S, while n should be either Y or Z. This

is an explicit product structure description. Thesedefinitions are refined in subclasses P1 and P2. ComponentS

is a generic product structure of its own;it has one component I. Finally, Y and subclasses of A and Z have no

components.In the figure, solid line represents is-a relationship; componentrelationships are not represented

graphically.

As an exampleof implicit constraints we use here resources. In Figure 1 there is an exampleresource ResX.

It is a resource that is supplied by A1 and A2and consumed by Y, Z1 and Z2. Suppliers and consumers are

linked to the resource by dashedlines. These classes may

assign a value to ResX; a negative value meaningconsumption. A balance constraint for the resource is defined in product P; it states that the componentsof P

cannot consumeresource ResXmore than they supply.

The explicit product structure limits the possible component combinations, no other components but the declared ones are allowed. Therefore, one can enumerate

Model

This section gives an overview description of the properties of a data model. It is based on our earlier work

(Peltonen et ai. 1994). The modelincludes both implicit

and explicit product structure description methods. The

explicit description defines a superset of all valid specific

product structures and implicit methodsare used to prune

113

all the possible components

for the tuple (m, n, l) in P2

accordingto the explicit productstructure:

(S1, Y, A1),(S1, Y, A2),(S1, Y,

(SI, Z2, A1),(S1, Z2, A2), (S1, Z2,

(S2, Y, A2),

($2, Z2, A2).

Theimplicit resourceconstraint then prunesout the ones

whereResXconsumptionis greater than production. We

assumethat ResSumin P returns zero if ResXis not

found in a component.The only valid combinationsin

P2 for the component

3-tuple (m, n,/) are:

(S1, Y, A1),

($1, Z2, A1),(S1, Z2, A2),

(S2, Z2, A2).

After enumeration,each possible specific productstructure of a configuration modelcan be checkedagainst

applicableconstraints, includingtechnicalspecification.

This providesa trivial methodfor finding a solution for

particular customerrequirements.Theexistence of the

trivial methodonly showsthat a solu~on,if one exists,

can be found;the methodis hardlyuseful for a real con.figuration process.Moreefficient heuristics is neededin

a practicalapplication.

Main Concepts of Data Model

Classification Hierarchy. Our model is based on

classes. Theyare organisedinto a classification hierarchy. Theproperties of a class are inherited along the

classificationhierarchy.

A large set of componentscannot be managedwithout

organisingit somehow.

Classification is a useful tool in

productmodelling;it providesmeansfor organising, but

one mustdecide on the classification criteria. Components can be classified, for example,according to the

functionsthey performor the types of the manufacturing

processes producingthem.

Wetherefore require that a classification of component descriptionsis createdspecificallyfor configuration

modelling. Wecall this classification hierarchy cclassification.

Although,wehere discuss only one c-classification, a

company

mayrequire different c-classifications for different product families. This meansthat same components mayhavedifferent classification and evendifferent

properties in different product families. Thesecomponents should perhaps be somehow

related or shared betweenthe classifications. This is, however,an issue we

will not addressin this paper.

Thec-classification has oneparticular propertythat we

call componentsubtyping. Component

subtyping states

that subclassesof a class C mayalwaysbe used in place

of C in componentdescriptions of a generic product

structure. For example,if class MBFrame

has subclasses

MBFrameX

and MBFrameY,

a generic componentreference ’MountalnBikeXhas part MBFrame’

meansthat a

MountainBikeX may have either MBFrameXor

MBFrameY

as its frame.

114

Generic ComponentReferences. In basic objectoriented product modelscomponentsare represented by

instance variables, whichare used for referring to the

components.The domainof an instance variable is a

class. If the class has subclasses, the instancevariable

mayalso take as its valuean instanceof any of the subclasses (Banerjeeet al. 1987). This is a propertyknown

as subtyping.

Subtyping is a generic concept and, as such, has

nothing to do with components.For example,if A1and

A2are subtypesof A, this alone doesnot implythat they

are valid as componentrepresentations in place of A.

Thereforewehavea morespecific subtypingconceptfor

a classification whereclasses represent components.

That

is what wecall componentsubtyping. Component

subtypingis not a propertyof anyclassification by accident.

Aclassification hierarchy, the c-classification in this

case, mustbe specifically constructed, with the help of

productexperts, so that it is valid withrespect to component subtyping.

Component

subtypingdefines a one formof generality

for componentdescriptions--a componentis not necessarily fromthe domainclass, since also the subclasses

providevalid choices. Genericproductstructure descriptions, however,also needa moregeneral mechanism

for

defining component

alternatives. For example,assumea

class Athat has three subclassesA1, .4.2 andA3.For one

product A1and A2 are valid componentalternatives,

while for another A2and A3are the ones. There are no

classes that could directly be usedas component

domains

for these products, nor is there a simplewayof defining

them.

In our modela generic componentreference is described as an instance variable and its domainas a nonemptyset of classes. This meansthat the value of the

variable mustbe a referenceto oneof the listed classes

or their descendants.If an ancestorof a class is also in

the domain,the class itself is redundantandcan therefore

be removed.For these domainswe use a special notation: c ~ {A,B}.This is a short for a constraint{c ~Av c

B}, wherec ~ Ameansthat c is a component

instance

fromclass Aor its decsendant.

Oneparticular property wewant to have for generic

component

references is refinement. A subclass can refine a componentattribute by makingits domainmore

specific than in the superclass.Moreprecisely, there are

two operations: 1) domainset maybe replaced by its

propersubset and2) in place of a class onecan write its

subclasses. Both operations maybe applied multiple

times. This allows definition of an abstract component

reference whichmaybe refined in subclasses into more

concretedescriptions.

For example,component

c in class C mayhave set {A,

B} as its componentdomain.This meansthat c must be

either an A or a B. If A has subclasses A1, A2and A3,

the possible refinementsfor the domainof c in the subclasses of C include {A}and {A1, A2, B }. Refinement

of generic component

references is present in only some

generic product structure models, e.g., in PLAKON

In the balanceconstraint sumof resourcesin the com(Cuniset al. 1989).

ponentsof a particular specific productstructure is used.

The sumis calculated by a special function ResSum,

Other Component Data

whichgoes through all the components

starting fromthe

one

for

which

the

balance

constraint

is

defined. For each

Thec-classification is not be suitable for modellingall

component

it

checks

whether

the

resource

is visible in

the properties neededin configuration.Twoclasses that

the

component

and

a

value

is

assigned

to

it.

If so, it adds

share common

properties maybe placed far apart from

the assignedvalue to the sumand otherwisenothing.

each other and cannot therefore inherit the common

Evaluationof a balance constraint involves recursive

properties along the c-classification. This is a consetransversal of all componentsof a specific product

quenceof strictly enforcingcomponent

subtypingin the

structure. Evaluationas such is easy for a known

specific

constructionof the c-classification. Thereis also another,

perhaps even moreimportant, reason whyall component product structure. Computationalproblemsmay, howthat tries to fred an appropridata cannotbe definedin the c-classification. Component ever, arise for a mechanism

ate

structure

with

a

given

initial

constraints,i.e., a techdata is usedwidelyin a company,

andin this picture connical specification. Wedo not address here the problem

figuration is only one player. Onecannotassumethat all

of satisfying a balance constraint or fixing it wereit

component

data neededin a configuration process would

false. In fact we assume the same as for the whole

also be primarily modelledand maintained in the cmodel;

the modelonly describes a set of valid specific

classification.

product

structures, not howto find a particular one in a

For these reasons weinclude in the modeltwo other

configuration

process.

sources for component

data: mainproductdata base and

additionalconfigurationrelated data.

Amainproductdata base represents here all the comEvolution in Generic ProductStructuresn

igonentdata that is maintainedelsewherein a company.

It

A Research Agenda

neednot be a single data baseandits detailedstructure is

not of great importancehere. Themainissue is that cerThis section gives someguidelines for our future work

tain data items can be importedfrom the mainproduct

on configuration knowledgemanagement.

data baseto the c-classification. In Figure1 importingof

Ourspecial interest is to understandconceptsneeded

propertiesfromthe mainproductdata base is illustrated

to describe the evolution of products and related combydottedlines.

puter representations. In principle, wecan distinguish

For coupling the mainproduct data base and the cbetweentwo different kinds of changeprocess. Onone

classification a mediatoris introducedbetweenthe two.

hand,duringtheir life-time the physical productsas real

Thismediatorprovidespropertiesfor the classes in the cworldobjects are modifiedfor a numberof reasons: they

classification;a class mayrefer to a propertythat is visiare being serviced, their functionality maybe upgraded,

ble in the mediator. Suchreference is effectively the

faulty componentsare being replaced by correct ones,

sameas if the property wasdeclared in the class. As a

etc.

difference, however,the relation to the origin of the

Modificationsare in manycases madenot by the orpropertyin the mainproductdata base is maintained.

ganisation that madethe products but by the customer

Additionalconfigurationrelated data defines properitself or by somemoreor less independentservice or

ties that are tightly connectedwith the c-classification,

maintenancecompany.Dueto the increasing importance

but do not have a single place there. As an examplea

of after sales activities andlong life-cyclesof productsit

resource is an implicit product structure modelling

has becomeincreasingly more important to maintain

methodthat cannotalwaysbe easily expressedas a propconsistent representationof productsomewhere.

erty of a single class in the c-classification. Thisis beOnthe other hand, the generic productstructures have

causesuppliers andconsumers

of a resourceare not typilife of their own. The ownercompanyintroduces new

cally subclasses of the same parent class in the cproducts, enhances existing models, replaces compoclassification; for instance,components

that either supply

nents with newerones clue to the numberof different

or consume

electric current maybe quite different.

reasons. Onsomeindustries, such as electronics andinResourcesserve here only as an exampleof additional

formationtechnology,these renewalprocesses are quite

configurationrelated data that cannotbe nicely inherited

hectic.

in the c-classification, they shouldnot be takenas a key

Boththese changeprocessesare difficult as such. We

characteristic of the model.Resourcesmaybe modelled

have seen only few examples of systems capable of

on top of the explicit productstructure as additionaldata

maintainingaccurate representationsof deliveredone-ofitems that can be importedin the c-classification. This

a-kind products. Themaintenanceof the generic product

waya resource can be defined in single place and then

structures without exploding their complexity needs

related to arbitrary component

descriptions in the cpowerfultools and policies whichguarantee that they

classification. In Figure1 this is shownbydashedlines.

remainmanageable

duringtheir life-cycle. Unfortunately

these two processesare not, at least in theory, always

115

!

I

It1

prod I

I .st.~cture

21

I prod II

I structgre

nI

I[structure

P 2’ {I

/

{ProductII

m’rJ

I

~c~p~o~

phy~

Of~

~1

f

/ ~

~

l

~

rodu~s

lP

\v ~~

("<"2<._

) di:ciplined"--~~

/

/

/_maintenance

independentmaintenance

~

modernisation

upgrade

~ rad~oTf~ration

~ .......

Figure2. Evolutionof GenericProductStructureandPhysical Products.

independent.A product designed and manufacturedlong

time ago under the presumptionsof the generic product

structure effective at that time maybe broughtbackto

the factory years later for functional upgrade. Howto

relate the old productstructures, i.e., physicaland generic, to the currently used generic productstructure?

Wewouldlike to look for conceptual frameworkwhich

mightcopewith problemsof this nature at least in certain conditions.

Evolution of Physical Products

Byphysical products we meanthe products that have

beenmanufactured

and deliveredto the customers.In the

following wediscuss different kinds of modification

operationson physicalproducts.

Figure 2 showsgeneric product structure, i.e., a cclassification, at times T and T’. At the bottomof the

figure there is a roundedboxfor descriptionsof physical

products. Therea dot in a roughlyshapedcircle represents a physical product delivered to a customer.Each

"circle" encloses descriptions of physical productsrelated to onespecific productstructure. Modifications

that

changethe structure of a physicalproductare illustrated

by arrowswhichmovea description awayfromits original specific product structure, Somemodifieddescriptions are still close to a "circle". Thissuggestssimilarity,

116

e.g., functional equivalence,to the productsof the related specific productstructure.

Independent Maintenance. These include typical onfield operations. Onemodifiesthe product accordingto

the need without considering the relation to generic

productstructure or other information.It is very difficult

for a product management

systemto support this kind of

operations in any other waythan by recordingmodifications andcurrent state of physicalproducts.At anyrate,

the description of a physical product shouldbe updated

to reflect the modifiedphysicalproduct.

Disciplined Maintenance. A company may define

service kits that do not modifythe functionality of the

productsbut replace, for example,certain parts that may

suffer from ageing. If individual components are

changed, a companymay, for example,have the policy

that each new componentversion must be compatible

with older ones, i.e., any old component

version can be

replaced by a newerversion. Theresulting newspecific

product structure is close to the original with a known

difference.

Upgrade

or Modernisation.

These are true reconfiguration operations,wherethe functionality of the productis

changed. Anupgrade enhances the functionality of a

product, for example, by increasing certain maximum

capacity. A modernisationbrings an old physical product

to the level of functionality of a newerproductgeneration. One problem is that upgraded and modernised

products are different from the newconfigured ones,

evenif they havethe samefunctionality. Thatis because

the modifiedproducts consist of a mixture of old and

new components, while new products are madefrom

new componentsonly. An upgraded product becomes

typically close to anotherproductthat offers higher capacity and a modernisedproducthas the fimctionality of

a productof a later generation,typically the currentgeneration at the timeof the modernisation.

AdvancedReconfiguration. A configuration process

creates a specific productstructure for a customerspecification. Similarly, an advancedreconflgurationprocess

can producea newspecific product structure starting

froman old physical product. In general, advancedreconfigurationcan producean entirely different product

from any previouslydesignedone.

Evolution of Generic Product Structures

Wedistinguish betweenthree maturity levels for configuration managementenvironments on the road towards a dreamenvironment. A ftrst level environment

has the capability of describingconfigurationknowledge

in a waythat it can be maintained.Asecondlevel environmentstores, in addition, the full history of both generic product structures and descriptions of physical

products. Then,a third level environment,i.e., a dream

environment,also includes knowledgeabout the nature

of modifications. Onewould knowin detail howtwo

generic productstructures differ andbe able to operate

with productstructures of different times, e.g., upgrade

old physical products using newcomponents.

Currently most configuration systems struggle with

the problemsrelated to the first level. Knowledge

managementis still a real problemin configurationsystems.

Muchof the problemstems from the complexityof the

configuration models--they are "programmed"by computer specialists and not understoodby the product experts. Oneof the goals wehopeto achieveis a structured

and understandablemethodfor describing configuration

knowledge.

Modificationsto the generic product structure result

from various sources. These include market situation,

customer demands,different regulations in different

marketareas, advancesin technology,corrections of old

designs, just to mention few. A companymust have a

clear policy howthese changesare incorporated to the

configurationknowledge.Definition of goodpractices is

a panof the overall solution.

Management

of changes is essentially based on decisions, typically madeby humans.Thesedecisions need

to be recorded and they can be used for describing the

relevant history of the wholemodel.

It is not clear whichconceptsare neededfor storing

the evolutionof generic productstructures. Astraightforwardwayis to create a copyof the wholeconfiguration modelafter each modification.In this muchof the

informationon changesis lost. For a better modellingof

the evolution one should record the changesof smaller

pieces of information. Classes, for example,could be

changedby creating newversions of them. Theproblems

arise thenhowclass versionsrelate in classificationhierarchy and howto incorporateversions in generic product

structures.

In addition, the history of changesto the descriptions

of physical productsneedsto be retained. Thereal challenge is to incorporate the evolution of generic and

physicalproductstructures in a useful manner.

For example,imaginethe followingscenario. A customer has two products fromthe company:one three and

the other five years old. Last year a capacity upgrade

wasmadefor the newerone. Nowthe customerwantsto

knowwhether a similar upgradewouldbe possible for

the olderoneas well.

Giventhe full historical data, one can find out the

product configuration environment,e.g., configuration

modeland components,at the time the upgrade of the

newerproduct took place, and naturally the current

situation. In addition, there wouldalso be a full history

of service modifications.

Typically, the answerto the customerinquiry would

be positive, but usuallyan engineeris requiredto design

the neededmodifications almost fromscratch. Withan

ideal environmentthe engineermightfind the following

possibility: There is an modernisationpackagefor the

old productto the level X and fromthere a modernisation packageto the current level wherethe requested

capacity upgradeis directly possible with newestcomponents. These two modernisationscan be combined,but

one mustmanuallycheckthe versions of components

q, s

andI for compatibility.

Conclusions

Productconfigurationmodellingis essentially based on

description of generality in productstructures. Wedivided the used methodstwocategories: explicit and implicit and discussed briefly howprevious approaches

relate to these. Our ownapproachuses both methods:a

generic product structure description has an explicit

structure as basis andimplicit rules are usedfor pruning

out invalid structures. Webelieve that this wouldmake

the generic productdescriptions moreclearer andtherefore easier to constructandmaintain.

Themanagement

of evolution of configuration knowledgeis a critical longtermgoal for a configurationmodelling environment.Weapproachedthe problemby describing the keyelementsin the state of the practice and

then painteda vision for the future work.This is an area

117

with plenty of open questions; manyof themfundamentally difficult. Wetry to emphasisthe needsof the industry as criterion for selecting the courseof future research in the field of product data modellingand management.

Acknowledgements

This research has beenpartly funded by the Academy

of

Finland.

References

Banerjee, J.; Kim,W.; Kim, H.-J.; and Henry, F. K.

1987. Semantics and implementationof schemaevolution in object-oriented databases.In Proceedingsof the

International Conference on Managementof Data

(SIGMOD).

Barker, V. E., and O’Connor,D.E. 1989. Expert systems for configuration at Digital: XCON

and beyond.

Communications

of the ACM32(3):298-318.

Curtis, R.; Gtinter, A.; Syska,I.; Peters, H.; andBode,

H. 1989. PLAKON--an approach to domainindependentconstruction. In Proceedingsof the Second

International Conferenceon Industrial & Engineering

Applicationsof Artificial Intelligence &ExpertSystems

IEA/AIE-89.

Heinrich, M., and Jungst, E. W. 1991. A resourcebasedparadigmfor the configuringof technical systems

from modularcomponents.In Proceedingsof the seventh

~I~.Econferenceon Artificial IntelligenceApplications.

Kim,W.; Bertino, E.; and Garza, J. F. 1989.Composite objects revisited. In Proceedings

of the International

Conference on Managementof Data (SIGMOD).

McDermott,J. 1993. R1("XCON")

at age 12: Lessons

floman elementaryschoolachiever. Artificial Intelligence, 59(1-2):241-247.

Mittal, S., and Frayman,F. 1989. Towardsa generic

modelof configuration tasks. In Proceedingsof IJCAI

89.

Peltonen,H.; Mannistt~,T.; Alho,K.; and Sulonen,R.

1994. Productconfiguration--anapplication for prototype object approach. In MarioTokoroand RemoPareschi, editors, Object Oriented Programming,

8th European Conference,ECOOP’94.

Springer-Verlag.

SAP1994. Der SAPKonfigurator (Reference Manual).

Sch0nsleben,P., and Oldenkott, H. 1992. Enlarging

CADand interfaces between PPCand CADto respond

to productconfigurationrequirements.In Pels H. L, and

Wortmann,

J. C., eds., Integration in ProductionManagementSystems.:Elsevier SciencePublishersB.V.

van Veen,E. A., 1991. ModellingProduct Structures

by generic Bills-of-Material. Ph.D. diss., Technische

Universiteit Eindhoven.

118