From: AAAI Technical Report SS-94-04. Compilation copyright © 1994, AAAI (www.aaai.org). All rights reserved.

ManufacturingControl System Principles supporting Error Recovery

Peter Loborg and Anders Tiirne

Dept. of Computer and Information Science,

Link0ping University,

S-58183 Link0ping, SWEDEN

E-mail:petlo@ida.liu.se,andto@ida.liu.se

January24, 1994

Abstact

This paper argues that manufacturingcontrol systems

shouldbe structuredto retain informationusedwhilespecifying the systemso it maybe reusedduringerror recovery

situations. Anexampleof such a system(the Aramissystem)andits proposederror recoverycapabilities is presented.

Introduction

MostManufacturingControl Systems0VICS)commercially

availablelack supportfor error recovery.Evennormalconstructs for encodingexceptionhandling,a natural part of

manycomputerlanguages,are absent. Althoughseveral

proposalshavebeensuggested,there are still shortcomings:

¯ althoughmanyproposalscontain supportfor error

recoveryor fault tolerant operation,mostof the support

only concernsthe assemblyplan/activities of the manufacturing process, suchas whatto do whena graspoperation falls (e.g. [Caoand Sanderson,1992;Delchambre

and Coupez,1988;Gaspartet. al., 1989]). However,

after a structural failure suchas a brokenair pressure

hose, andsubsequentrepair, parts of the machinerymay

be in an abnormal

state (i.e. not passedduringnormal

execution),or in a normalstate but not corresponding

to

the ’state’ of the programexecution- a situation seldom

addressed.

¯ they are often tediousto instruct, not to mentionthe

effort neededto modifythe system.Oneproblemis that

the knowledge

used wheninstructing a MCS

is to a large

extentlost at coding/compile

time- i.e. it is not explicitly needed/represented

in the systemsnormalinstruction formalism,andthus not availablefor further usage.

Asa result of this, manyearlier attemptsto providesupport for error recoveryoften result in multiplerepresentation of the knowledge

(e.g. [Leeet. al., 1983;Schmidt,

1992;Srinivas, 1977;Srinivas, 1978;TaylorandTaylor,

1988;Tayloret. al., 1990),implyingextra overhead

whenthe systemchangesand the knowledge

base is to

be updated.Aprimeexampleis the usageof an external

expert systemresponsiblefor detecting anomaliesand

for producingrecoveryactions, hookedon to an existing

101

controller. Asmallchangeof the programin the controller results in majorrewritingsof the expertsystem.

However,there are approacheswhereknowledgeis

reused(e.g. [Gini, 1983])or integratedas a part of the

instruction formalism([ChenandTrivedi, 1991;Delchambreand Coupez,1988;Gaspartet. al., 1989;Meijer

andHertzberger,1988;Meijeret. al., 1991]).

¯ the competence

of the user of these systems,i.e. the

operatorat the shopfloor, is seldomreused. Mostproposals presentedare designedto solve the problemautomatically,thus limitingtheir applicability.

Thearea of error recoverymaybe subdividedin detection,

diagnoseandrecovery.Weare primarilyinterested in providingsupportin the recoveryphase,or moreprecisely,

providingsupportto changethe state of the machine

to be a

legal one, andto synchronize

the state of the currentexecution with the state of the machine.Thegoal is to minimize

the time andmaterialloss duringthe recoveryprocess.

Themeansare twofold:Firstly, the usageof an explicitly

representedmodelof the underlyingsystem,providingrobust servicefor a task level instructionsystemas wellas a

semanticframework

for anyplanningor plan repair activity.

Secondly,

a task level wherethe activities, their causalrelation andwhatobjector typeof objectthey use are loggedin

order to extract informationabout the normalbehaviorof

the system.

Thenext section presents an overviewof Aramis(A Robot AndManufacturing

Instruction System),whichis

specification, programming

and executionenvironmentfor

manufacturing

applications. Thefollowingsection describes the recoverysupport(whichwill be1) providedby

the system.

Aramis - An Overview

TheAramissystemhas beendesignedwith a layered archi1. Theprogrammingenvironment

exists as describedherein,used

in a robotcell equipped

withvision,tactilesensorsetc. [Loborg

et.

aL, 1994;Loborg

et. aL, 1993;LoborgandT6me,1991;T6rne,

1990].Theerror recoverysupportaspresented

hereinis under

development,

andwill be presentedin a forthcoming

licentiate

thesis.

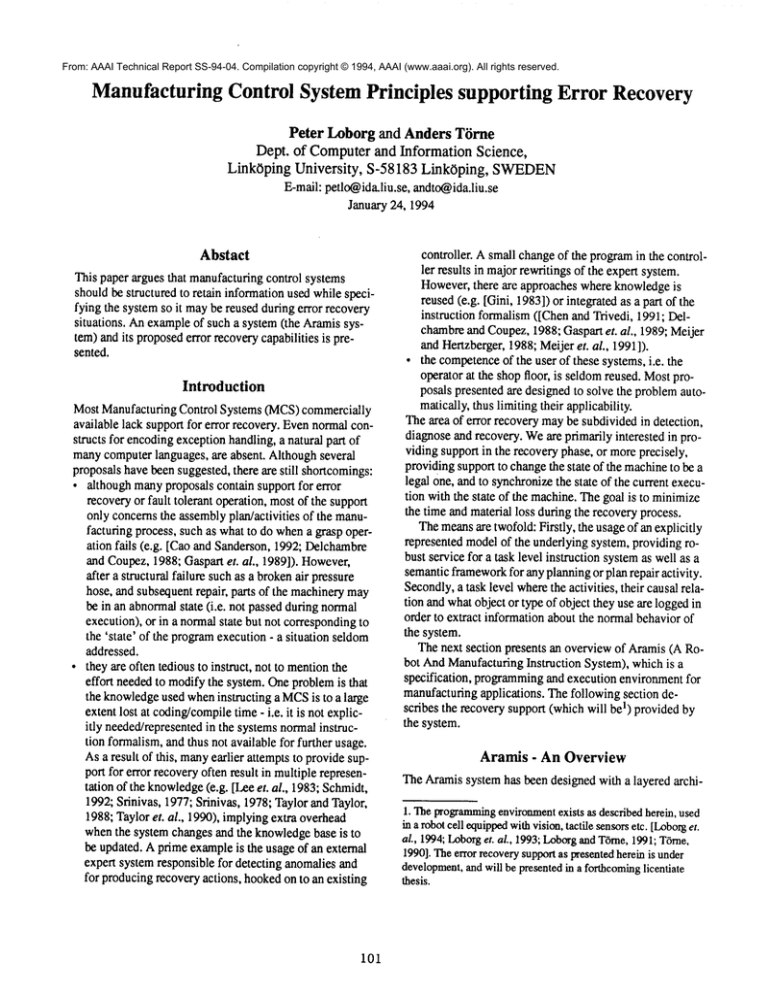

tecture, basedondifferentlevels of abstraction.It consists

of three different levels; task programming

level, the control level andthe physicallevel (Fig.I). It useswo

rld

model(WM)as interface betweenthe task level andthe

controllevel.

Atthe task level the operatorspecifies whatoperationsor

actions should be performeduponthe WM

and under what

conditions, usinga graphicalhybridrule basedlanguage

[Loborgand TOme,1991]. Thephysical environmentis

modelledas a set of objects in the WM,

whereeach object

has a set of state variables. Thetask programexecutesby

setting referencevaluesfor the objects(their state variables), therebyrequestingthe objectsto changetheir state.

Thecontrol level acts as a servomechanism

and is responsible for keepingthe real worldin a state representedin the

WM,

as the WM

reference values are changedby task programexecution.

Theprogramming

at the control level is typically doneby

control engineers,andconsists mainlyof specifyinghow

devicesin the real worldshould be viewedin the WM,

and

whatcontrol algorithmsis neededto implementthe servo

mechanism.

Thephysicallevel is the actual connectionto the real

world,whereexplicit I/O, requestedby control level algorithms, is performed

with sensorsand actuators.

speed= stop

speed = slow AND

direction = forward

speed = fast AND

direction = forward

..............

TaskProgramming

for coordinatingthe operationof all objects involved.

Eachobject contain an internal slate I andinformation

aboutits properusage.This will preventthe task level programmer

fromabusingthe object unnoticed- an exception

will occur. Thisprinciple is best explainedthroughthe followingexample,wherea two speedbidirectional electrical

engineis modelled

(fig 2). This deviceis representedin the

WM

by an object containing two state variables, named

speed and direction. The domainof speed is a set of

the three symbolsstop, low and high. The domainof

direction consists of forward and backward. This

results in an objectwithsix possiblestates. Weuse a set of

constraintsto groupthe state spaceinto a set of interesting

states (e.g. whenthe value of speedequals stop, the value of direction is uninteresting, andthus five states is

adequateto describe the engine).Afinite state machine

(FSM)

definedover the set of interestingstates is usedto describe howthese variable values maybe combinedand

changed

in this object. Toeachtransition definedin the

ARAMIS

Program)

Set . ~= ~ R e~ad, .

Figure 2 An electrical, bidirectional two speed engine is

modeledby two variables, direction and speed. Its behaviour

is modeled by a FSMwith five interesting states, each

representing a combinationof variable values according to its

constraint. The ares between the states describe legal

transitions, rouling out the posibility to reverse the engine

without requesting it to stop in between.

oo°,,o

<.v.

IOo.tro,

l-.. ......... 7

.:;........ ff7

..........................

~

indicatesinformation

flow) I R’lea~Wor~d

Figure 1 The world model is viewed as a set of reference

values whichis set by the Aramisprogramand used by a servo

controller (sensing/control) to invoke correct control

algorithms in the ’real world’. The WMalso support the

reading of actual values.

Theremainderof this section is devotedto the worldmodel

(howobjects are modelled,etc.), the controllevel andits

connection

to the real world,andfinally there is a brief

presentationof the task level language.

World model based programming

In Aramis,weadopt an object centeredviewof the world,

whereeachobjectis responsiblefor its owninternal state

andits consistency.Thetask level programis responsible

102

FSMthere mightbe an associated control algorithmresponsible for achievingsomething

in the real worldwhichcorrespondsto the transitionof states in the object. Thisfunctionality is part of the controllevel andwill be detailedin next

subsection.

Thetask level programcontrols the object by requesting

changesof its variable values. Theobject will respondupon

a requestwith oneof the following:

¯ error - there is nodirect path fromthe currentstate to

anystate representingthe requestedvalues,i.e. a state

wherethe requestedvalueswill satisfy the constraint

(task level programming

error).

Or:. there are severaldirect pathsto states corresponding

1. Weuse the wordstate to denote a specific combinationof values

for a fixed set of variables. Eachvariable take its values froma

finite (andthusdiscrete)domain.

to requestedvariable values(object modelling

error

should never occur)

¯ failed - the object did not succeedin reachingthe

requestedvariable values. This maybe dueto an engine

overloadsituation, somefault in the engineor the electrical hardwarefromthe I/O boardand onwards,or a

programming

error in the algorithmresponsiblefor

achievingthe state. Thisreply also indicatesthat any

built in recoveryactionshavefailed.

¯ succeed- the newstate is reachedand the worldhas a

state whichcorresponds

to the requestedstate.

Eachrequest fromthe task level programwill be suspended

until the objectreturns the result, in whichcasethe execution of the requesting’process’continuesas normalor an

exception/erroris raised.

This modelof an object is well suited for specifyingaspects of real time behaviour,suchas transition completion

timeI andalgorithmperiodicity. This is vital whendesigning controllers for anycontinuousphysicalprocess.

Control layer - implements objects

Thecontrol layer hardwareconsists of a set of computing

devicesandperipheral hardwareorganizedin a topologyof

communication

channels, whichshould provide real time

computationalpowerand I/O to the world model.

Although

this has not beena part of the project, the modeling of this topologyas wellas the analysisof computational needs(basedon the object models)and schedulingof the

actual computation

are topics that needto be addressedin

order to build a completesystem.Majorcontributionshave

already beenmadein the areas of real time communication

systemsandprotocols(e.g. [Thomesse

et. al., 1991]),scheduling algorithmsapplicable both to communication

and

processscheduling(e.g. [Leinbaughand Yamini,1982;Rajkumaret. al., 1988;Stancovicet. al., 1990;Fohler, 1992;

ShaandSathaye,1992])as well as distributionof time with

boundedaccuracy(e.g. [Kopetzand Ochsenreiter,1987;

Kopetz,1992]). Theproblemof allocating processornodes

for different sets of processesdepending

on both their computational and communicational

needandthe needfor processor specific services(suchas an I/O device)has also been

investigated(e.g. [Maet. aL, 1982;Verhoosel

et. al., 1991]).

Ourconcernhas beento find a suitable specificationfor

the computational

needsthat supportboth the schedulingalgorithmsandanalytical methodsused, andan abstraction/

interfaceto a task level language.

Theinterfaceconsistsof a set of objectsandtheir state

variables,anda principlefor howthe task level interacts

with objects. However,

if the sameabstractionof the physical worldas presentedby availablesensorsandactuators

I. Themaximal

amount

of timethe transitionwill useonceit is

actually

started.

103

wouldbe usedat the task level, the resulting state space

wouldbe enormousas wouldthe amountof communication

neededto keepthe worldmodelupdatedin a distributed system.

Thus,eachobjecttype is describedin twoparts. Firstly

an abstract modelof the objectis specified, as presentedin

previoussubsection.Secondly,the implementation

of it is

specified. This includesthe specificationof whattypes of

actuatorsandsensorsare used,whichalso implieswhatdata

types are usedat this level, codeto extract information

and

controlthe device,etc.

Thesetwo parts are then connectedby describinga mappingfromselected variablesor sensorsof the object to the

state variablesdescribingthe interface. Appropriate

parts of

the codedefinedin the objectare associatedwithtransitions

andnodesof the FSM

of the object - to be usedto accomplish a transition or maintaina reachedstate.

Example:

If the enginein Fig.2 is equippedwith a speedometerproducingvaluesas integers in the rangeof

0..3000,the cardinalityof the state spaceat the control

level is 3001x2. In the state spaceas viewedin the WM

(presentedin Fig.2) the variablespeedis reducedto range

over3 values,andthus the state spaceis reducedto a cardinality of 6. Thisstate spaceis thengrouped

into 5 interesting states, over whicha behaviouris definedin terms

of legal transitions, constitutinga FSM.Achangeof

valueof the speedometer

sensorat the controllevel is not

propagated

to the worldmodeluntil it impliesa changein

the correspondingWM-variable

of the object.

Formally,the state space as viewedby the sensors and

actuators available (SRT)is reducedor mapped

onto an exportedstate space(SE- the onepresentin or exportedto the

WM)

by a surjective functionf: SRT---~S

E. Thereforeall

low level states havea mapping.Thesamemappingalso denotes an inverse, injective functionfl : SE--OSRTimplying that state changingrequestsissuedat the task level have

a uniquecounterpartat the control level. Whether

the control algorithmsresponsiblefor achievinga state changein

SRTsuchthat fl(sF, request)equalsSRTresult, the resulting state, actuallywill do that or not is implementation

dependant.Whatis requiredis that]~SRTresult) equalssF, request. Theconstraints usedto specifythe mappingfromthe

exportedstate spaceto the set of interestingstates, also

called the abstractstate space,mustdenotea surjective

functionf’: SE"~S,,t, thus specifyingthe constraintsto be

non overlapping.

In this twolevel abstraction,the formerabstractionis

usedto decreasethe descriptionof the object to something

usefulat the tasklevel, andthe latter to definethe semantics

of the object andto providea base for error recovery.

Since the state of an object maynowbe abstractedto an

abstractstate for that object- a singlevariable- the state

spaceused in anyplanningeffort wouldnot increase exponentially withthe number

of state variablesusedto control

the system,only with the number

of objects it contains.

Task level programming- coordinating object

activities

Sincethis supportwill mainlydependon the object specification, it is expectedthat manytask level languagesthat

resemblesthe Aramislanguageas presented abovemayuse

a similar aproach.

Execution and error semantics

Thetask level languagehas the role of coordinatingobject

activities. Themostprimitivewayto do this is to requesta

single objectto changethe valueof oneor severalof its

WM

variables. This is a primitive action. A user defined

actionis a collectionof calls to primitiveand/orto user

definedactions, and a partial temporalorder (PTO)over

them.ThePTOconsists of a set of temporalrestrictions

overpairs of these action calls. Atemporalrestriction

betweentwoaction calls specifies that theymustexecutein

sequenceandwhichof themthat shouldexecutefirst.

When

executinga user definedaction, the default is to execute all its parts in parallel, exceptwhenthe PTOprohibits

this. Whether

parallel actions actuallywill be executedin

parallel or not, dependson resource management.

Thecontrol level maynot be powerfulenoughto executeall

requestedalgorithmsin parallel, or someobject maybe

occupiedbyother activities andthe requestedaction will

haveto wait.

Thepurposeof usingthis schemeis to promotethe encodingof whatorderingrestrictions of the applicationthat

really exists, andleaveto the systemto handlefurther restrictions imposedby resource management.

Aset of processes(called workers)repeatedlyactionsto

solvetheir tasks. Theseworkersare activatedanddeactivated by a humanoperator, acting as a foreman,decidingwhat

to performat the shopfloor.

Thedescriptionaboveis not complete.Thereexists constructs usedwithinan actionto definealternatives, andrecursiveactionsare usedto expressiterations. Thereare constructs to expressdata flowbetweenactions andtransformations of data throughthe use of functions.For a complete

description, se [TOme,1990; Loborgand TOme,

1991].

Error Recovery - exception handling and

planning

Examplesof commonplace

corrective actions in a manufacturingcontextare to replacewhatis faulty or free what

has accidentally got stuck. However,

this maynot always

be accomplishedautomatically, and humanintervention

mayleave the machinery

in anotherstate than a state appropriate for continuedexecution.

Thefollowingsectionswill briefly presentthe exception

handlingto be usedin a layeredsystemas describedabove,

and present someideas about howto supportthe user when

the state of the machineryno longercorrespondsto whatis

appropriateto continueexecution.

104

Basedon previoussections, the followingdefinitions are

straight forward:

¯ Thereferential closureof a task level process1 p (RCp)

is the set of all state variablesfromobjectswhichare

referencedby p. Theidea is to limit the worldto be concideredduringrecoverysituations. Theabstractreferential clousure(ARCp)

is the set of objects referenced

p.

¯ A processstate for a processp is a vectorof valuesfor

the variablesin the RCp.Anabstractprocessstate is a

vectorcontainingthe currentabstract state for each

object in the ARCp.

¯ Theprocess

state spaceis the set of all possiblestates of

a process,andis dividedin three subsets:

¯ Theillegal state spaceis the subset wheresomeof

the objectsare in an illegal state

¯ the abnormal

state spaceis the set of legal process

states not normallypassedduringexecution

¯ the normalstate spaceis the set of legal process

states passedduringsomeexecution

Analogous,

there is an abstract counterpart.

¯ Anexecutionpath for a process p denotes anysequence

of processstates forp that maybe passedduringsome

2. All possible executionpaths for p formsan

execution

executiongraphforp (F_X3p).A normalexecutionpath

(NEPp)

denotesthe trace of an executionof an errorfree

program,i.e. a programwhichsucceedsin accomplishing its task. Thesubset of the EGpthat is normallyused

is denoteda normalexecutiongraphfor p (NEGp).The

abstract versions (AEGp

and ANEGp)

are defined analogously.

¯ An error occurs whenan executiondeviates fromthe

EGpandthere is no exceptionhandlerthat succeedsin

redirect the executionbackinto the EGp.Theerror will

manifestitself in anyof the followingthree alternatives:

¯ the executionenters the illegal state space

¯ the executionhalts prematurely

¯ explicit monitoring

of the processstate detects the

deviation

This definition is basedon the assumption

that the model

of the worldis correct, but not complete(thus the second

1. Actually,

onlya toplevel process,a worker.

Although

action

calls insidethe worker

are performed

in parallelandthusconstitutesprocesses,

theyare regarded

as actioncalls - notprocesses.

2. Withthe term’someexecution’wedonot includeexecution

of

exception

handlers!

point above).

¯ An exception occurs whenan executiondeviates from

the EGpbut is redirectedinto the EGp(withoutentering

the illegal state space)by someexceptionhandler.

Asa result of this definition, problems

duringthe assembly

processcausedby damaged

parts or parts slightly out of

specificationare not regardedas errors if there exists a procedureto recoverfromthese situations.

Generally,recoveringfroman error correspondsto

changingthe state of the machinery

so it will correspond

to

anyprocessstate in the EG.It is preferableto recoverto a

processstate in EO’close’to the currentprocessstate - providedit is possibleto associatea cost functionto the transitions of objects. Usingthis approach,the followingissues

must be concidered:

¯ decidingwhethera processstate is in the F_X3

or not is

nontrivial, compared

with decidingwhetherthe state is

inside a NEG

- a matterof comparing

with the execution

log.

¯ simplychangingthe state of the machinerywill most

likely conflict with physicalor other restrictions on how

to operate the machinery.Theinformationabout such

restrictions is encodedin the task level program,explicitly or implicitly. Thatinformationmustbe extractedto

guide the planningof howto changethe state of the

machinery.

Thefollowingsubsectionswill present suggestionson how

to implement

exceptionhandlinganda restricted version of

recoveryfromerrors, basedon the definitions anddiscussion above.

Exceptionhandling in the control level

Exceptionhandling at the task level

Providingexceptionhandlingat the task level maybe

viewedas simplyprovidingsomesyntactic construct to

catch a signal andtransfer control to somepredefinedpiece

of code. Examplesof such exceptionhandlingconstructs

can be foundin several different programming

languages.

Mostof themhave in common

that they describe howto

handleexceptionsin a sequentialset of instructions- not

parallel activities nor higherlevel instructions/activities.

In the data base community,the notion of SAGAS

or

nested SAGAS

[Garcia-Molinaand Salem, 1987; GarciaMolinaet. al., 1991] has beendevelopedandproposedfor

modelling

parallel, nestedactivities in a corporation,suchas

receivingorders, billing the customerwhileupdatingthe inventory,andso on. In principle,it is a scheme

for specifying

compensating

activities to be usedin case of an abortionof

an ongoingactivity. It also specifieshowthe abortionof one

activitythat is a part of a nestedstructureof activitiesshould

affect the other activities. Thereare no meansto describe

that an alternative activity shouldbe performed

whenan activity aborts.

In a moregeneralsetting, as describedin previoussections, it mightalso be valuableto be able to specifyadditional and/oralternativeactionsto use, as wellas howto return to normalexecution.Thelatter is uncommon

in normal

programming

languagessuch as ADA,wherethe exception

handler’takes over’ the remainingexecutionin the module

that experiencedthe error. If the exceptionhandlersucceeds,the modulewill return as normal,otherwiseit will

propagatethe sameor a modifiederror to its caller.

Error Recoveryat the task level

Fromthe task level point of view,it is preferableif the control level couldbehavein a transactionalway,i.e. either

accomplishrequestedstate changesor report a failure without changinganything.This is not alwayspossible - a half

doneseamweldmaynot easily be undone- but should be

desired whenever

possible.

Astraight forwardapproachis to label transitions of an

object as undoableand/orrestartable, either by specifying

other algorithmsto use in orderto achievethat, or by specifyingthe objectto use anotherexistenttransition andits algorithmas undoor recovertransition. This is analogousto

the notion of ’compensating

actions’ andhas beenproposed

in manufacturing

applications by, e.g. [Schmidt,1992].A

further functionalityis to specifythe transitionas interruptable, i.e. specifyingthat the task level is to executesome

preparedbut exceptionaltask beforereturningthe control

backto the controllevel.

Thedefinition of objectsas proposedherein is easily

adaptedto sucha solution, but experiments

with different

applicationsis neededto evaluatethis approach.

105

Whenthe exceptionhandlingfails, the error is propagated

up to the user, the human

operator. Heor she has to understandthe originalfault andcorrect it in orderto continue

execution.In order to correct the fault, it is not uncommon

that the state of the machinery

is changedmerelyin order

to access the failing device, nor is it uncommon

to remove

someof the workpiecesdueto a defect - either causingthe

problem

or a result of it. Theeffect of this activityis, that

the machinery

is not alwaysin the samestate as it was

wheninterrupted. Asspecifiedpreviously,the processstate

after the failed action maynowbe either illegal, abnormal

or normal.

Usingthe currentdefinitionof an objectthere is no support for howto changean illegal processstate into a legal

one, i.e. the systemcan not proposehowto doit. It can

merelypresentthe fact andinformthe user aboutthe expectedstate.

If the processstate is abnormal,

it indicatesthat noexecution passedthis state yet. Thusthe state mustbe changed

to be a normalonein orderto be certainthat it is possibleto

continueexecution.If this normalstate doesnot correspond

to the onewherethe fault occurred,it is likely that continued

execution

will fail. Thereasonis that the internalstate of the

controllingcomputer

is not correct with respectto continued

executionfromthis new,normalstate.

Theexecutionlog - a sourceoflnformation

It is a basic

assumptionin this presentationthat the informationneeded

to performrecoveryplanningis either explicitly availableor

maybe extracted by observingthe systemexecutingunder

normalconditions.This section will discussthe secondpart

of that assumption.

Thereferential closureof a processp (RCp)is an interesting notionsince mostproblemstend to be local to the processk Astraight forwardmethodto identify a RCpused in an

applicationis to log the activities of processp. TheRCpmay

also be analyzedfromthe sourcecodefor p.

As stated previously, the normalexecutiongraph(NEG)

is usefulfor decidingwhethera legal processstate is normal

or abnormal,i.e. if there exists a programwhichcan be used

to continueexecutionfromthat processstate. Byloggingthe

process state the NEG

(and the ANEG)

is obtained. Since

loggingisprocesslocal,the log will start to repeatitself, i.e.

as processescontinueto executecyclically, the log of each

processwill containrepeatingseries of log records. When

that happens,newlog records will no longerbe appendedto

the log. Theexisting log will be reused, expanded

with

branchesif the path starts to deviatefromthe previously

knowncycle. Extra care mustbe taken whenhandlingvariables referring to materialin flow,since they maypoint to

differentobjectinstancesat differentpointsin time.

Apartfromloggingthe state of the system,the state of the

controller mustbe loggedin order to supportresynchronization of programexecutionwith a state of the machinery.

Theresult of this loggingschemeis a knowledge

base

with informationaboutthe normalbehaviourof the application, i.e. knowledge

aboutdata andcontrol flow. Thusimplicit knowledge

is extractedandmadeexplicitly available

for reuse.

Planningfor error recoveryPlanningis neededin order

to supportthe user in situations whenthe machinery

is in an

abnormal

state. Ratherthan creating a plan fromthe current

(abnormal)state to the last known

normalstate, wesuggests

that a plan shouldbe generatedto the closest normalstate.

Normal

executionis then restarted fromthat newstate, using the loggedcontroller informationto synchronizethe

controllerwiththe state.

Theexpectedadvantageof usingthis approach,is that it

will excludethe needto plan for a repetitive sequence

of actions - thus reducingplanningcomplexity.Themotivationis

postponed

to the endof this subsection.

1. Thecasewhen

processsynchronization

is a part of the problem

is postponed

as futurework.

106

Thecost functionimpliedby the termclosest usedabove

is definedas follows:

¯ for eachobjectthere is a cost associatedwith eachtransition between

abstract states of that object

¯ givena currentabstract state for an object, the distance

twostates in that objectis definedas the minimal

sumof

transition costs between

the states. Sincetransitions

havea direction, the distance betweenstate AandB of

an object maydiffer fromthe distance betweenB andA.

Thedistanceis infinite if there is no sequence

of transitions fromAto B.

¯ the distance betweentwoabstract processstates is the

sumof the distancefor the components,

i.e. the individual objects.

Usingthis definition the distancebetweento processstates

is defined,usingthe abstractstate space,as the shortestdistance betweenthe corresponding

abstract processstates.

Producinga planto reachthe selected goal state amounts

to selectingthe orderin whichthe differenttransitionsfrom

the participating objectsshouldbe executed.If no ordering

couldbe found,there are physicalrestrictions in the machinery that prohibitsthe currentsolution.In sucha casethe next

2.

cheapestgoalstate is selectedandthe processrestarts

When

the orderingis found,the plan is refined fromthe abstract state spaceto the full state spaceas represented

in the

worldmodel.Thisrefinement

is safe, i.e. it will not invalidate the plan achievedat the abstract level.

Normally,decidingwhenit is safe to use a planningoperator impliesverifyingpre- andprevail-conditions

for that

operator.In this approach,eachtransition can be viewedas

an operator. Byanalyzingthe log, pre- andpost-conditions

as well as a pessimisticversionof the prevail conditioncan

be extractedfor eachtransition. Sincethe planningis performedin the abstract state space,these conditionswill express the currentabstract states of other objectsin the RCp,

or a "don’t-care"value.

This approachdoesnot permitanyobject to re-enter a

state it hasalreadyvisited.Thisrestrictionis natural- if the

applicationimpliesa partly repetitive behaviour,

i.e. that an

objectcyclicallyreturnsto the samestate, there will alsoexist programsused duringnormalexecutionto accomplish

this behaviour.Thusthese programsmaybe used from

whateverstate in the loop the plannerchooseas goalstate.

In [Klein, 1993;B~lckstrOm,

1992;Backstrt3m

andKlein,

1991]a planingformalismcalled simplified action struc÷) is presenttures (SAS)andan extendedversionof it (SAS

ed. Usingthis formalism,somerestricted planningproblemsis shown

to be tractable, i.e. solvablein polynomial

time. Theapproachpresentedherein is close to but doesnot

fully correspond

to these restricted classes. Themainadvan2. In orderto includeaaalternative,moreexpensive

set of traasifionsleadingto the same

goalstate, the definitionof distancemust

be rephrased.

rage with this approachis that the actual planningproblems

as posedby a real applicationis expectedto be limited, both

in termsof the state space (dependingon howprocessesare

structured) andin the length of producedplans.

Resynehronizatlon A seldom addressed problem when

dealing with an error recoverysituation in the automation

context is, that evenif the humanoperator is capableof

manuallymodifying

the state of the machineryto be a legal

one, it is almostimpossibleto continueexecutionfromthat

state. The reason is that it is non trivial to change the interhal state of the controller to correspond to the new state of

the machinery. However, if there is a well defined separation between different processes in a controller, and if interprocess communication is formalized, it is possible to

support the change of the internal state for one such process.

As described above, logging of a process implies saving

the values for the state of the process (all variables in the

RCp) as well as information about the current activation

records used by the process (the internal state), i.e. both data

and control information. Using this information, it is

straight forward to modify the internal state I to be in accordmacewith any state present in the log; Find the entry in the

log corresponding to the state, and replace the process internal control information by the one found in that entry.

[Delchambre and Coupez, 1988] A. Delchambre and D. Coupez.

Knowledgebased error recovery in robotized assembly In

Proceedings of the 9th International

Conference on

Developments in Assembly Automation - Japan vs Europe;

Product Design for Assembly; Assembly Automation. p.349-66.

IFS Publications, Kempston,Bedford, UK, 1988

[Fohler, 1992] G. Fohler. Realizing Changes of Operational

Modes with Pre Run-Time Scheduled Hard Real-Trine

Systems. In Proceedingsof the Second International Workshop

on Responsive Computer Systems, Saitama, Japan, October

1992.

[Gaspart et. aL, 1989] P. Gaspart and A. Delchambre and A.

Coupezand P. Brouillard. Rule based procedures for diagnosis

and error recovery. In Proceedings of MIV-89- International

Workshopon Industrial Applications of MachineIntelligence

and ~r~sion (Seiken Symposium).p.88-93, 1989

[Gini, 1983] M. Gini. Recovering from Failures.

A New

Chalengefor Industrial Robotics. In Proceedingsof the 25’th

IEEE Computer Society

International

Conference

(COMPCON-83).

p.220-227, Arlington 1983

[Garcia-Molina and Salem, 1987] H. Garcia-Molina, K. Salem.

SAGAS.Proc. SIGMOD

int. conf. on Management of Data,

pp.249-259, May 1987

[Garcia-Molina et. aL, 1991] H. Garcia-Molina, D. Gawlick, J.

Klein, K. Kleissner and K. Salem. Coordinating MultiTransaction Activities. Data Engineering Bulletine 1991 (also

in COMPCOM91)

[Klein, 1993] I. Klein. Automatic Synthesis fo Sequential

Control Schemes. PhD-theses no.305, Link6ping University,

1993

Conclusion

In this paper,a proposalis presented

of howto structurea

manufacturing

controlsystemin orderto achievean open,

flexible andmodular

systemwhichis capableof reusing

the knowledge

encodedfor executionto providesupport

for errorrecovery.Theknowledge

is of the sametypeas

frequentlyusedin proposalsfor detection/monitoring

and

diagnose,thusenablingits reusefor thosepurposes

as well.

[Kopetz, 1992] H. Kopetz. Sparse Time versus Dense Time in

Distributed Reai-TimeSystems. Proc. 12th Int. Conference on

Distributed ComputingSystems, Japan, June 1992

[Kopetz and Ochsenreiter, 1987] H. Kopetz, W. Ochsenreiter.

Clocksynchronization in Distributed Real-I~me Systems, IEEE

Transactions on Computers,Vol C36, No. 8, pp. 933-940, Aug.

1987

[Lee et. al., 1983] M.H. Le, and D.P.Barnes and N.W. Hardy.

Knowledge Based Error Recovery in Industrial Robots. In

Proceedingsof the International Joint Conferenceon Artificial

Intelligence. pp.824-826, 1983

References

[B~ckstr6m, 1992] C. B~ckstr6m. Computational Complexity of

Reasoning about Plans. PhD-thesis no.281, Link6ping

University, 1992

[Leinbaugh and yamini, 1982] D.W. Leinbaugh and M. Yamlni.

Guaranteed response tinae in a distributed hard real-time

environment, Proc. Real-time systems symposium,Dec. 1982.

[B.~ckstr6mand Klein, 1991] C. B/ickstr6m, I. Klein. Planning in

polynomial time, the SAS-PUBSclass. Computational

Intelligence, 7:181-197, August1991.

[L,oborg et. al., 1994] E Loborg, P. Holmbom,M. Sk61d and A.

T6me.A Model for the Execution of Task Specifikations for

Intelligent and Flexible Manufacturing Systems, accepted for

publication in Integrated Computer-AidedEngineering (special

issue about AI in Manufactoring and Robotics to appear

somewhereduring 94).

[Chert and Trivedi, 1991] C.-X. Chert and M.M.Trivedi. A task

planner for sensor-based inspection and manipulation robots.

In Proceedings of the SPIE - The International Society for

Optical Engineering, vol. 1571, p. 591-603, 1991

[Cat and Sanderson, 1992] T. Cat and A.C. Sanderson. Sensorbased Error Recovery for Robotic Task Sequences Using Fuzzy

Petri Nets. In Proceedingsof lEEEInternational Conferenceon

Robotics and Automation, p. 1063-9, 1992

[Loborg et. ai., 1993] P. Loborg, T. Risch, M. Sk61d and A.

T6rne. Active tO Databases in Control Applications, in

Microproeessing and Microprogramming, Vol. 38, No 1-5,

p.255-264, proceedings of the 19th Euromicro Conference,

Barcelona, sept 1993.

1. Providedthat the executing systemis well defined, using modifiable data structures to hold such information. If the executing

code is compiledto machinecode, this maynot be the case.

107

[Loborg and T0me, 1991] P. Lobor8 and A. T6me. A Hybrid

Language for the Control of Multimachine Environments, in

Proceedings of EIA/AIE-91,Hawaii, June 1991.

[Maet. al., 1988] P.R. Ma, E. Y. S. Lee and M. Tsuchiya. A Task

Allocation Model for Distributed Computing Systems, Hard

ReallimeSystems,

Eds.SytankovichlRamamritham,

pg.249255,IEEEComp.Soc.Press,

1988.

[Meijerand Hertzberger,

1988]G. R. Meijerand L. O.

Hertzberger.

Off-Line

Programming

of Exception

Handling

Strategies.

In Proceedings

of IFAC Symposium

on Robot

Control.

p.431-436,

Karlsruhe

1988

[Meijer

et.al.,1991]G.R.Meijer

andL.O.Hertzberger

andT.

L. MaiandE. Ganssens

andF. Arlabosse.

Exception

Handling

SystemforAutonomous

RobotsBasedon PES.In Journal

of

Robotics

andAutonomous

Systems.

p. 197-209,

no.7,1991

[Rajkumar

et.al.,1988]R. Rajkumar,

L. Sha,J.P. Lehoczky,

Real-Time

Synchronization

protocols

formulti-processors.

Proc.IEEEReal-~me

systems

syrup.,

CS Press,

LosAlamitos,

Calif.,

pp.259-269,

1988

[Schmidt,

1992]U. Schmidt.

A Framework

for Automated

Error

Recovery

in FMS.In Proceedings

of the2’ndInternational

Conference on Automation, Robotics and Computer Vision.

p.IA.3.4.1-5, 1992

[Sha and Sathaye, 1992] L. Sha and S. Sathaye. Distributed

Real-Time System Design using Generalized Rate Monotonic

theory, Second Int. Conf. on Automation, Robotics and

Computer Vission, SINGAPORE,

1992

[Srinivas, 1977] S. Srinivas. Error Recovery in Robot Systems

PhDthesis California Inst. of Tech., Pasadena,1977

[Srinivas, 1978] S. Srinivas. Error Recovery in Robots Through

Failure ReasoningAnalysis. In Proceedingsof AFIP. National

ComputerConference, p.275-282, 1978

[Stankovic et. al., 1990] J.A. Stankovic, K. Ramamritham,and

P.-E Shiah. Efficient Scheduling Algorithms for Reai-Ttme

Muitiprocessor Systems. IEEE Transactions on Parallel and

Distributed Systems, pages 184-194, April 1990

[Taylor and Taylor, 1988] G. E. Taylor and P. M. Taylor.

Dynamicerror probability vectors: a framework for sensory

decision making. In Proceedings of the 1988 IEEE

International Conferenceon Robotics and Automation, p. 1096100 vol.2, 1988

[Taylor et. al., 1990] P. M. Taylor and I. Halleron and X. K.

Song. The application of a dynamicerror frameworkto

robotic assembly. IEEEInternational Conference on Robotics

and Automation, pp170-5. IEEE Comput. Soc. Press, Los

Alamitos, CA, USA 1990.

[Thomesseet. al., 1991] J.-P. Thomesse,P. Lorenz, J. P. Bardinet

and T.Valentin, Factory Instrumentation Protocol: Model,

Products and Tools, Control Engineering, pp65-67, Sept 1991.

[T6rne, 1990] A. T6me. The Instruction and Control of MultiMachine Environments, in Applications of Artificial

Intelligence in EngineeringV, vol. 2, pp. 137-152,prec. of the

5th Int. Conf. in Boston July 90, Springer-Verlag,1990.

[Verhoosel et. al., 1991] J. P. C. Verlaoosel, E. J. Luit, D. K.

Hammer, E. Jansen. A Static Scheduling Alghorithm for

Distributed Reai-TimeSystems, Journal of Real-?ime Systems,

3, pp.227-246, KluwerAcad. Pub. 1991.

108