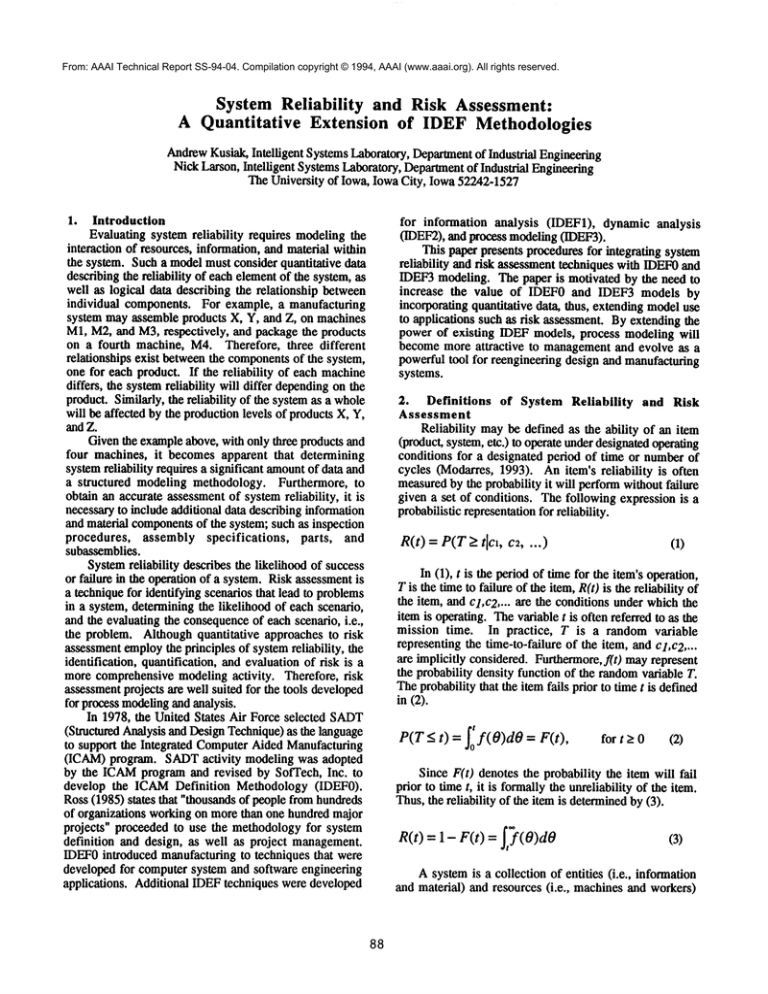

From: AAAI Technical Report SS-94-04. Compilation copyright © 1994, AAAI (www.aaai.org). All rights reserved.

System Reliability

and Risk Assessment:

A Quantitative

Extension of IDEF Methodologies

AndrewKusiak, Intelligent Systems Laboratory, Departmentof Industrial Engineering

Nick Larson, Intelligent SystemsLaboratory, Deparlmentof Industrial Engineering

The University of Iowa, Iowa City, Iowa 52242-1527

1.

Introduction

Evaluating system reliability requires modeling the

interaction of resources, information, and material within

the system. Such a model must consider quantitative data

describing the reliability of each element of the system, as

well as logical data describing the relationship between

individual components. For example, a manufacturing

system may assemble products X, Y, and Z, on machines

M1, M2, and M3, respectively, and package the products

on a fourth machine, M4. Therefore, three different

relationships exist between the componentsof the system,

one for each product. If the reliability of each machine

differs, the systemreliability will differ dependingon the

product. Similarly, the reliability of the systemas a whole

will be affected by the production levels of products X, Y,

and Z.

Given the exampleabove, with only three products and

four machines, it becomes apparent that determining

systemreliability requires a significant amountof data and

a structured modeling methodology. Furthermore, to

obtain an accurate assessment of system reliability, it is

necessary to include additional data describing information

and material componentsof the system; such as inspection

procedures, assembly specifications,

parts, and

subassemblies.

Systemreliability describes the likelihood of success

or failure in the operation of a system. Risk assessmentis

a technique for identifying scenarios that lead to problems

in a system, determining the likelihood of each scenario,

and the evaluating the consequenceof each scenario, i.e.,

the problem. Although quantitative approaches to risk

assessmentemploythe principles of systemreliability, the

identification, quantification, and evaluation of risk is a

more comprehensive modeling activity. Therefore, risk

assessmentprojects are well suited for the tools developed

for process modelingand analysis.

In 1978, the United States Air Force selected SADT

(Structured Analysis and DesignTechnique) as the language

to support the Integrated ComputerAided Manufacturing

(ICAM) program. SADTactivity modeling was adopted

by the ICAMprogram and revised by Sofrech, Inc. to

develop the ICAMDefinition Methodology (IDEF0).

Ross (1985) states that "thousands of people from hundreds

of organizations working on more than one hundred major

projects" proceeded to use the methodology for system

definition and design, as well as project management.

IDEF0introduced manufacturing to techniques that were

developed for computer system and software engineering

applications. Additional IDEFtechniques were developed

88

for information analysis (IDEF1), dynamic analysis

(IDEF2), and process modeling (IDEF3).

This paper presents procedures for integrating system

reliability and risk assessment techniques with IDEF0and

IDEF~modeling. The paper is motivated by the need to

increase the value of IDEF0 and IDEF3 models by

incorporating quantitative data, thus, extending modeluse

to applications such as risk assessment. By extending the

power of existing IDEF models, process modeling will

become more attractive to managementand evolve as a

powerful tool for reengineering design and manufacturing

systems.

2. Definitions

of System Reliability

and Risk

Assessment

Reliability maybe defined as the ability of an item

(product, system, etc.) to operate underdesignated operating

conditions for a designated period of time or number of

cycles (Modarres, 1993). An item’s reliability is often

measuredby the probability it will perform without failure

given a set of conditions. The following expression is a

probabilistic representationfor reliability.

R(t) = P(T > tlc~, c2, ...)

(1)

In (1), t is the period of time for the item’s operation,

T is the time to failure of the item, R(t) is the reliability of

the item, and Cl,C2 .... are the conditions under whichthe

item is operating. Thevariable t is often referred to as the

mission time. In practice, T is a random variable

representing the time-to-failure of the item, and Cl,C2 ....

are implicitly considered. Furthermore, fit) mayrepresent

the probability density function of the randomvariable T.

The probability that the item fails prior to time t is defined

in (2).

P(T < t) = I~ f( O)dO = F(t),

for

t>0

(2)

Since F(t) denotes the probability the item will fail

prior to time t, it is formally the unreliability of the item.

Thus, the reliability of the item is determinedby (3).

R(t) = 1- F(t)= It’f(O)dO

(3)

A systemis a collection of entities (i.e., information

and material) and resources (i.e., machines and workers)

whichinteract to performa set of activities in a given

process. Successfulcompletionof the process is dependent

uponpropercompletionof the individual activities in the

process. Therefore, it is necessary to model the

relationshipbetweenvariousitems(entities andresources),

as well as the reliability of individualitemsto assess the

reliability of the system. Complexmanufacturingsystems

producemanydifferent products through manydifferent

sequences of manufacturing activities. The system

reliability is a function of the activities performedand,

thus, is product dependent.Therefore, if the production

volumeof a product exhibiting low systemreliability is

increased,the reliability of the entire manufacturing

system

will decrease. At this point, the necessity for evaluating

system reliability in a manufacturingsetting becomes

obvious.

Manyof the common

techniques for modelingsystem

reliability are difficult to applyto complexmanufacturing

systems with multiple product types. Therefore, the

principles of such tools are moreuseful whenapplied to

modelingschemesdevelopedfor manufacturingsystems,

such as IDEF0and IDEF3.Also, the task of evaluating

system reliability in a manufacturingsetting is more

attractive if performed

as a component

of a risk assessment

study.

Risk is a measureof the probability and severity of

adverse effects (Lowrance,1976). Several types of risk

associated with project planningand softwaredevelopment

havebeencited in the literature, see Angand Gay(1993)

and Chittister and Haimes (1993). The following

manufacturingrisks are generalized from those cited in

variousengineeringdisciplines.

1. Requirementsrisk. Theconceptof whatthe

productis intendedto accomplish

is not accurate.

2. Technicalrisk. Theproductdoes not adhereto the

requirements

set forth by its design.

3. Schedulerisk. Theproductwill not be completed

by the deadlineset forth by productionplanning.

4. Costrisk. Theproductioncost will overrunits

budget.

5. Networkrisk. The mechanism

for linking various

productionactivities will not performas intended.

Risk assessmentis a process that attempts to answer

three questions: (1) Whatcan go wrong?(2) Whatis

likelihood that it will go wrong?(3) Whatare the

consequences?(Kaplanand Garrick, 1981). Basedon these

questions,(4) is a quantitativedefinitionof risk, whereSi

is a scenario of eventsthat leads to a problem,Pi is the

likelihood of scenario i, and Ci is the consequenceof

scenarioi.

R = {Si, Pi, C~}

i =1, 2 ..... n

(4)

This section has provided definitions of system

reliability and risk assessment. Section 4 discusses

89

techniques for determining system reliability and

integrating risk assessmentand IDEFmodels. Section 5

discusses issues related to risk assessment, such as

developingquantitative risk modelsbased on IDEF0and

IDEF3.

3.

Fundamentals of IDEF0 and IDEF3

IDEF0was developedfor modelinga wide variety of

systems which use hardware, software, and people to

perform activities (U. S. Air Force, 1981). An IDEF0

modelconsists of three components,diagrams,text, and a

glossary, all cross-referencedto each other. Thebox and

arrow diagramsare the major components

of the model. In

a diagram, a box represents a function and an arrow

represents an interface. Abox is assignedan active verb

phrase to represent the function. Aninterface maybe an

input, an output, a control, or a mechanism,and is

assigneda descriptivenounphrase. Inputs (I) enter the box

fromthe left, are transformedby the function, andexit the

boxto the right as an output(O). Acontrol (C) enters

top of the box and influences or determinesthe function

performed. A mechanism

(M) is a tool or resource which

performsthe function. Theinterfaces are generallyreferred

to as the ICOMs

(see Figure1).

Control (C)

Input(I)

Output (0)

FUNCTION

Mechansim(M)

Figure1. IDEF0function box and interface arrows

Eachdiagramhas betweenthree andsix function boxes

placed on a diagonal. Theboxeseach havea specific node

numberandare connectedby all relevant interfaces. Each

box on the diagrammaybe decomposed

into a lower level

of detail. This feature restricts the amountof information

that maybe containedin the modelon a single level. The

resulting diagramsforma hierarchy of informationwhich

is summarized

in a nodetree.

IDEF0provides a structured representation of the

functions,information,andobjects whichare interrelated in

a manufacturingsystem. IDEF3wascreated specifically to

model the sequence of activities

performed in a

manufacturingsystem. AnIDEF3modelenables an expert

Reject

proposal

Evaluate

Negotiate

Award

contract

Accept

Figure 2. IDEF3process flow diagram(Mayeret al. 1992)

to communicatethe process flow of a system through

defining a sequenceof activities and the relationships

betweenthose activities. There are two basic components

of the IDEF3process description language, the process

flow description and the object state transition network

description. The two componentsare cross-referenced to

build IDEF3diagrams(Mayeret al., 1992).

The IDEF3process flow description is madeup of

units of behavior (UOBs),links, and junction boxes.

UOBrepresents a function or activity occurring in the

process. For example,assembleparts, performinspection,

or evaluate proposal are all activities which maybe

represented as UOBsin a process model. Relationships

between UOBsare modeledwith three types of links,

precedencelinks, relational links, and object flowlinks.

Precedence links express simple temporal precedence

betweenUOBs.Relational links highlight the existence of

a relationship between two or more UOBs,however, no

temporalconsWaint

is implied. Objectflowlinks providea

mechanism

for capturing object related constraints between

UOBsand carry the same temporal semantics as a

precedencelink. Thelogic of branchingwithina processis

modeledusing junctions. Several classifications are used

to def’mejtmctionboxes.Junctionsare classified according

to logical semanticsas and(&), or (O), and exclusive or

(X). Multipleprocesspaths are classified as fan-in or fanout corresponding to converging and diverging paths,

respectively. The relative timing of process paths that

converge or diverge at a junction are classified as

synchronous or asynchronous. An example of an IDEF3

process flow diagramis shownin Figure 2 (Mayeret al.,

1992).

4. Integrating System Reliability Techniques

and IDEF Models

Asstated in section 2, systemreliability tools maybe

quite useful whenapplied to modelingschemesdeveloped

for manufacturingsystems, such as IDEF0and IDEF3.In

this section, several systemreliability modeling

techniques

90

are integrated with IDEF0and IDEF3.For a detailed

discussionof each technique,see Modarres

(1993).

4.1

Reliability Block Diagrams

Reliability block diagrams model the effect of

component

failure on systemperformanceby capturing the

physical arrangement of the system. Typical system

configurations include series systems, parallel systems,

standby redundantsystems, shared load systems, complex

parallel-series systems, and complexnonparallel-series

systems (Modarres, 1993). Additional system

configurationsmaybe identified in various applications,

however, most manufacturingsystems maybe accurately

described using those listed above. Figure 3 shows

reliability blockdiagramsfor series andparallel systems

and Figure 4 illustrates complexsystems. Thereliability

of complexsystems maybe calculated using various

analytical methods, however, such methods become

computationally intensive as the numberof components

increases (Shooman,1990).

Thesystemconfigurationsillustrated in Figures3 and

4 mayalso be used to describe IDEF0and IDEF3models.

Angand Gay(1993) discuss extensions to IDEF0models

whichenable project risk assessment. Several project

situations are described whichmaybe generalized to the

systemconfigurationsdescribedabove. Theextensionsare

efficient for includingquantitativedata in an IDEF0

model,

such as a probability of occurrence. However,due to the

decomposition

principle of IDEF0,it is difficult to identify

complex system configurations in the model. The

concepts of reliability block diagrams are more easily

adapted to IDEF3models. Consider Figure 2; the five

activities in the modelare arrangedin a complexparallelseries configuration. UnlikeIDEF0models,the numberof

activities (i.e., functions)in IDEF3

modelsis not restricted

to six per level. AlthoughIDEF3allows for elaboration

on a particular UOB

(i.e., activity), the entire processflow

maybe constructedon a single level. This representation

is moresuitable for IDEFapplications of risk assessment

whichare based on the principles of reliability

diagrams.

l

ll

block

+

(a)

(a)

Co)

Figure3. Series(a) andparallel (b) systemconfigurations

In IDEF3,series systems(or the series components

of

a complexsystem) are identified by UOBsconnected by

precedenceand/or object flow links. A series of UOBs

may

not contain a junction of any type, however,a junction

box maybegin or terminate a series. Furthermore,a UOB

is independentif it is not connectedto another UOB

by a

relational link. Thereliability of a series of independent

UOBs

is definedby (5), whereRs(t) is the reliability of the

system, the system contains N UOBs,and Ri(t) is the

reliability of the ith UOB.

N

R,(t) = Rl(t) × R:(t)X...×RN(t)

= H Ri(t) (5)

i=l

Parallel systemsare defined in IDEF3using junction

boxes. Each UOBimmediately following an and (&)

junction box will be performedin parallel. Therefore,the

reliability of the parallel systemfollowingan & junction

box is determinedby (5) as well. However,only one UOB

immediatelyfollowingan exclusive or (X) junction box

performed.Thus, the systemreliability for parallel UOBs

followingan Xjunction box is defined by (6), wherethe

systemcontains NUOBs,

Ri(t) is the reliability of the ith

UOB,and Pi is the probability of occurrenceof the ith

UOB(PI+P2+...+PN= 1).

Co)

Figure4. Complex

parallel-series (a) and

nonparallel-series(b) systems

Thesystemreliability for parallel UOBs

followingan

or (O) junctionbox is moredifficult to determine.At least

one, and as manyas all, of the UOBsfollowing an O

junction box maybe executed. Unlike the & and X cases,

the numberof different UOBsperformedin parallel is

unknown.However,if the system contains N UOBs,RiO)

is the reliability of the ith UOB,

andPi is the probability

of occurrenceof the ith UOB(Pi < 1), a lower boundon

the systemreliability is given by (7). This describesthe

worst case, whereall UOBsare executed and subject to

failure. If the reliability is to be evaluatedfor a known

set

of MUOBsin the parallel system (M < N), (5) may

used. Figure 5 illustrates parallel systemUOBs

for &, X,

and 0 junction boxes in IDEb3.

R,(t) = (PI x Rl(t)) X (P: R2(t))x...x(Pn x

Rn

N

Rift) = (PI x Rl(t)) (P: x Rz(t))+...+(Pn x R~

= H ( P, x R,(t))

= E(P~ X Ri(t))

(7)

i=1

N

(6)

Twoor moreUOBsconnected by relational links may

be considered a single UOBwhencalculating system

reliability in IDEF3models. In Figure 2, UOBs3 and 4

i=l

91

are connectedby a relational link, implyingan interaction

with UOB4 if UOB3 is executed. In this example,

successfullyexecutingUOB

3 will also require successful

completion of UOB4 (i.e., R3(t) = R3(t) x R4(t)

However,UOB

4 does not require executionof UOB3 and,

therefore, is not dependentuponits success.Thedirection

of the relational link determinesthe reliability of the

connected UOBs.In general, if UOBi is connected to

UOB

(i + 1) with a relational link in the direction of UOB

(i + 1), the successor failure of UOB

i will determine

success or failure of UOB

(i + 1). In IDEF3applications

of system reliability modeling,relational links maybe

avoidedby combining

related activities into a single (JOB.

models. A path set is a set of units (i.e., activities,

functions, UOBs)

that form a connectionbetweeninput and

output whentraversed in the direction of the arrows

(Modarres, 1993). For each path through an IDEF3model,

a minimalpath set will exist containing only the UOBs

on

the path. Onceagain, consider Figure 2. Thereare three

minimalpath sets in the IDEF3model;P1= (1, 2), P2ffi

(1, 3, 5), andP3 = (1, 4, 5). Eachpath set represents

event that wouldsuccessfully accomplishthe objective of

the system if each of the UOBson the path execute

successfully. Therefore, the union of all m path sets

definesthe set of all successfulcompletions

of the system.

Theprobability of this unionrepresents the reliability of

the system,as shownin (8).

R~(t) Pr ob(Pl u P2U...UPm)

Unfortunately,(8) requires that the path sets (Pi)

disjoint and, in practice, this is seldomtrue. Anupper

bound on the system reliability maybe determined by

assuming that the path sets are disjoint, as in (9).

However,for reliability values greater than 0.9 for the

missiontime, as in mostpractical applications, (9) does

not yield a useful bound(Modarres,1993).

(a)

Rs(t) < Prob(P0 + Prob(Pz)+...+Prob(Pm)

Acut set is a set of units (i.e., activities, functions,

UOBs)

that interrupt all possible connectionsbetweenthe

input and output points in the diagram(Modarres,1993).

In IDEF3process flow models,the minimalcut set is the

smallest set of UOBswhich prevent flow from input to

output. Failure of all UOBsin the minimumcut set

results in systemfailure. Theminimum

cut sets in Figure

2 are C1= (1), C2= (2, 3, 4), andC3 ffi (5). If the model

has n minimalcut sets andCi represents the event that all

UOBs

in the cut set fall prior to the missiontime t, the

system reliability is obtained from (10). Since the

probabilitythat all the UOBs

fall in at least oneof the cut

sets is the probabilitythat the systemfails, this valueis

subtractedfrom1 to obtainthe reliability of the system.

0,)

R,(t) = 1 - Prob(C,u C2w...uC~)

(10)

Asin (8), the unionin (10) is not usually disjoint,

thus, (11) gives the lowerboundfor systemreliability.

Sincethe probabilityof failure is usedto evaluatethe cut

sets and, in practice, these values are muchlower than

reliabilities,

the lower bound in (11) is a better

representationof systemreliability.

(c)

Figure 5. Parallel systemsmodeledusing IDEF3notation

for and(a), exclusiveor Co),andor (c) junctionboxes

4.2 Path Set and Cut Set Methods

Path set and cut set methods were developed to

determinethe reliability of complexsystemsdescribedby

reliability block diagrams. However,the principles of

these methodsare very useful in the analysis of IDEF3

92

R,(t) > 1 - [Prob(C0+ Prob(C2)+...

+Prob(Cn)]

(11)

Theprinciples of path sets maybe adaptedto evaluate

decision making processes modeledwith IDEF3.Each

minimalpath set identified in an IDEF3modelcorresponds

to a set of decisions in the operation of the system.

Junction boxes identify points where decisions are made

within a system. The decision set corresponding to path

set P3 = (1, 4, 5) is 3 ={do not re ject pr oposal, ac cept

proposal}. Twodecisions are made in the process; one

corresponding to each diverging (or fan ou0 junction box.

The first decision is to "not reject the proposal" and the

second is to "accept the proposal." Therefore, the

reliability of the decision set maybe easily determinedby

calculating the probability of successfully completingall

UOBsin the corresponding path set.

Cut sets maybe used to expose critical activities in

the system. UOBsin the intersection of all or manyof the

cut sets maybe considered critical to the operation of the

system. Furthermore, a cut set with a high probability of

failure (i.e., there are few UOBs

in the cut set and each has

a high probability of failure) maybe considered a critical

group of UOBs.

Applying system reliability

techniques to IDEF3

modelsrequires incorporating quantitative data regarding

probability of occurrence of UOBsand probability of

failure for each UOB.Reliability values for each of the

ICOMs in IDEF0 models may be used to obtain

probability of failure data for the correspondingUOBof an

IDEF3model. Diverging (or fan-ou0 junction boxes in

IDEF3mayalso contain probability of occurrence values

for each UOBthat immediatelyfollows the junction box.

It must be realized that the values for Pi and Ci are

based on approximations and assumptions and, thus,

possess a high level of uncertainty. Formal methods for

treating uncertainty analysis are discussed in the literature

(Morganand Henrion, 1990).

Uponcalculating the expected risk in the system, two

courses of action may be taken; (1) explore alternative

managementdecisions to avoid risk (i.e., decrease the

likelihood of high risk scenarios), and (2) reengineer

processes to mitigate the consequences.

IDEF0 and IDEF3 were developed to provide a

mechanism for evaluating the performance of complex

manufacturing systems. System reliability

and risk

assessment are applications which provide a useful

opportunity

for extending

the power of these

methodologies.

Acknowledgment

This research

has been partially supported by grant No.

DAAE07-93-C-R080

from the U.S. Army Tank

Automotive Command.

References

Ang, C. L. and R. g. L. Gay (1993). "IDEF0 modeling

for project risk assessment," Computersin Industry,

22, pp. 31-45.

Chittister, C. and Y. Y. Haimes(1993). "Risk associated

with software development: A holistic frameworkfor

assessment and management,"IEEE Transactions on

Systems, Man, and Cybernetics, 23(3), pp. 710-723.

Kaplan, S. and B. J. Garrick (1981). "Onthe quantitative

definition of risk," Risk Analysis, 1(1), 1981.

Lowrance, W. W. (1976). Of Acceptable Risk, William

Kaufmann, Los Altos, CA.

Mayer, R. J., T. P. Cullinane, P. S. deWitte, W. B.

Knappenberger,B. Perakath and M. S. Wells (1992).

Information Integration for ConcurrentEngineering

(lICE) IDEF3Process Description Capture Method

Report, ArmstrongLaboratory, Wright-Patterson

AFB, Ohio 45433, AL-TR-1992-0057.

Modarres, M. (1993). What Every Engineer Should Know

About Reliability and Risk Analysis, Marcel Dekker,

Inc., NewYork, NY.

Morgan, M. G. and M. Hem’ion (1990). Uncertainty: A

Guide to Dealing with Uncertainty in Quantitative

Risk and Policy Analysis, CambridgePress,

Cambridge, U.K.

Ross, D. T. (1985). "Applications and extensions

SADT," Computer, April, pp. 25-34.

Shooman,M. L. (1990). Probabilistic Reliability: An

Engineering Approach,2nd Ed., Kreiger, Melbourne,

FL.

U. S. Air Force (1981). Integrated ComputerAided

Manufacturing (ICAM)Architecture Part I1, Volume

W-Functional Modeling Manual(IDEFO), Air Force

Materials Laboratory, Wright-Patterson AFB,Ohio

45433, AFWAL-tr-81-4023.

5.

Risk Assessment in IDEF Models

Evaluating risk in IDEFmodels requires identifying

scenarios, determining the likelihood of these scenarios,

and estimating the consequences.This set of objectives is

often called the "risk triplet." The first two componentsof

the risk triplet are related to the techniquesfor determining

system reliability discussed in Section 4. Path sets maybe

used to identify scenarios in the system. Each scenario is

qualitatively evaluated to identify possible problemsthat

mayresult. The likelihood of each scenario is determined

by the probability of occurrence of the UOBsin the path

set.

Determiningthe consequencesof the scenario requires

estimating the impact on a set of performance measures.

Typical performance measures in manufacturing systems

are in-process inventory levels, lead times, set-up times,

scrap, rework, and resource utilization. Whenpossible,

consequences related to different performance measures

should be converted to a single unit of measurement,such

as dollar loss.

The total expected risk in the systemis calculated by

(12), wherePi is the probability of scenario i, and Ci is the

consequence,or cost, of the scenario.

n

R=~(P,

xC,)

(12)

iffil

93