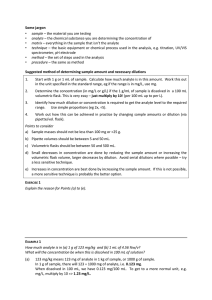

METHOD 200.7 BY INDUCTIVELY COUPLED PLASMA-ATOMIC EMISSION SPECTROMETRY

advertisement