Sales Engineering Technical Paper Series T-Nut Grounding System

advertisement

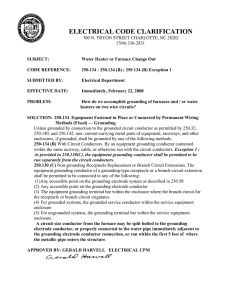

BLTPS-18 Sales Engineering Technical Paper Series T-Nut Grounding System Grounded Conductors. The grounded conductor shall not be less than the minimum size as required by 250.241 Grounding Conductor, Equipment. The conductor used to connect the nocurrent-carrying metal parts of equipment, raceways, and other enclosures to the system grounded conductor, the grounding electrode conductor, or both, at the service equipment or at the source of a separately derived system.2 Bonding of Electrical Equipment. Noncurrent-carrying conductive materials enclosing electrical conductors or equipment, or forming part of such equipment, shall be connected together and to the supply system grounded equipment in a manner that creates a permanent, low impedance path for ground-fault current that is capable of carrying the maximum fault current likely to be imposed on it.3 General. The connection shall be made at any accessible point from the load end of the service drop or service lateral to and including the terminal or bus to which the grounded service 1 230.42 (C)- Minimum Size and Rating, National Electric Code 2002 Edition. 2 Article 100- definitions, National Electric Code 2002 Edition. 3 Article 250.4 (B) (2)- Bonding of Electrical Equipment, National Electric Code 2002 Edition. conductor is connected at the service disconnecting means.4 The T-Nut Grounding System is a new to world design incorporating the grounding conductor connection into the cap of the grounded conductor lug. The low tolerance dovetail cap provides adequate bonding means of the grounding and grounded connections. It meets all applicable requirements of the National Electric Code, ANSI, and UL. Testing proves that the T-Nut Grounding System is comparable to other forms of attaching the grounding conductor to the meter socket. The test was performed per the UL dielectric testing procedures. The test allows no more than 5ma @ 2210 volts AC to pass from the device to any current carrying surfaces. The test was conducted on both the T-Nut Grounding System and the industry standard, side mounted grounding system. The table below shows the results of this test. We found that the results between the two systems were identical. In addition, note the added clearance of the conductor to either phase using the T-Nut Grounding System. The T-Nut Grounding System provides that much more protection against possible short circuits. The simple design also allows the cap to be added to existing 4 Article 250.24 (A) (1)- Grounding Service-Supplied Alternating Current Systems, National Electric Code 2002 Edition. Cooper B-Line, Inc. ٠ 509 West Monroe Street ٠ Highland, IL 62249 USA ٠ Phone: 618-654-2184 ٠ Fax: 618-654-1917 ٠ Email: blineus@cooperbline.com © 2003 Cooper B-Line, Inc. BLTPS-18 systems when additional grounding means are needed. Test Results: Dielectric to Line A Dielectric to Line B Dielectric to Load A Dielectric to Load B Min. Distance from ground wire to nearest energized component Ma @ 2210 VAC Side T-Nut Mount .019ma .019ma .020ma .020ma .020ma .020ma .019ma .019ma 1 5/8” 7/8” Pictures of Test set-up: Cooper B-Line, Inc. ٠ 509 West Monroe Street ٠ Highland, IL 62249 USA ٠ Phone: 618-654-2184 ٠ Fax: 618-654-1917 ٠ Email: blineus@cooperbline.com © 2003 Cooper B-Line, Inc.