Enclosures Section E

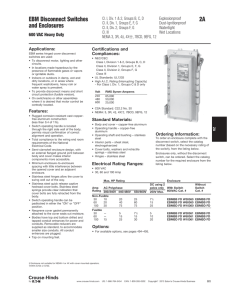

advertisement