HEXX-LOK Single Pole Plugs IM 1025

advertisement

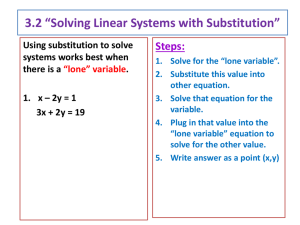

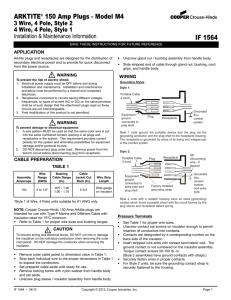

7. Center hose clamp on the end of the insulator sleeve and tighten snugly. HEXX-LOKTM Single Pole Plugs To Mate Plug & Receptacle 1. Insert plug fully into the receptacle. 2. Rotate the plug clockwise until it stops. IM 1025 Installation and Maintenance Information OPERATION SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE APPLICATION Cooper Interconnect’s Hexx-LokTM Plug and Receptacle designs feature improved engagement, easy assembly and heavy duty construction. Our high dielectric insulating sleeve provides superior strength and environmental resistance to ensure trouble free and reliable use in any challenging environment. Hexx-LokTM Plugs and Receptacles are rated to a maximum of 600 Volts and 690 Amps continuous use. Actual operation must comply with the information stipulated on the unit’s nameplate. Figure 7a OR To Unmate Plug & Receptacle 1. Depress Positive Latch Button on the Plug. 2. Rotate Counterclockwise until it stops. 3. Pull Plug out of receptacle. 7. Center cold shrink tube over the end of the insulator sleeve and pull loose tab. INSTALLATION 4. Slide hose clamp onto cable approximately 6in. MAINTENANCE Figure 7b OR 4. Slide cold shrink proximately 6in. Figure 4a tube onto cable ap- INSULATOR SLEEVE REMOVAL Note: Use Copper (CU) Conductors Only. 1. Figure 3 Remove 1-7/8in to 2in of the cable jacket 5. Lubricate contact and inside of insu- Figure 4b lator sleeve, ten align insulator retaining screw with contact retaining screw hole and slide insulator sleeve onto cable. 1. Loosen hose clamp and slide off insulator. Figure 1 2. Wrap strain relief wire. Figure 5 *A Lubricant is available from: Chemtrend, Inc. 1445 West McPherson Park Dr Howell, Michigan 48843 Part # CT-39F Note: Perform visual, electrical and mechanical checks of all components on a regular schedule. This should be determined by the environment and frequency of use, but it is recommended that it occur at least once per year. 1. Make sure retaining screw is tight. (See Fig 6) 2. Make sure hose clamp is tight. (See Fig 7a) 3. Clean contact thoroughly. 4. Clean all external parts of the connector thoroughly. OR 1. Carefully cut off cold shrink tube and slide off insulator. 2. Loosen retaining screw. 3. Slide insulator off cable. Figure 2 6. Tighten retaining screw to 25-35 in-lbs. 3. Crimp contact using T&B No. 106H Crimp Nest. Figure 3 IM 1025 Copyright © 2009, Cooper Industries, Inc. Figure 6 Page 1 All statements, technical information and recommendations contained herein are based on information and tests we believe to be reliable. The accuracy or completeness thereof are not guaranteed. In accordance with Cooper Interconnect’s “Terms and Conditions of Sale,”and since conditions of use are outside our control, the purchaser should determine the suitability of the product for his intended use and assumes all risk and liability whatsoever in connection therewith. Cooper Industries, Inc. Cooper Crouse-Hinds Division 4758 Washington Street, LaGrange, NC 28551 USA Copyright © 2009, Cooper Industries IM 1025 SBA 213 9/17/09