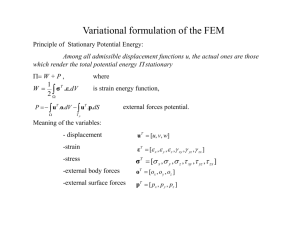

Basic Energy Principles in Stiffness Analysis

advertisement

Basic Energy Principles

in Stiffness Analysis

E = Elastic (or Young’s) modulus

G = Shear modulus

= Poisson ratio

Stress-Strain Relations

Normally, the shear modulus is

expressed in terms of the elastic

modulus and Poisson ratio as

The application of any theory

requires knowledge of the physical

properties of the material(s)

comprising the structure. We are

limiting our attention to linear

elastic structural response.

Further assuming that the material

is homogenous and isotropic, we

only need to know two of the

following three material constants:

1

Fig. 1: Typical Stress () – Strain (e)

Curves for (a) Steel and (b) Concrete

with a pronounced permanent

elongation at a stress ym (Fig.1a).

High strength steels yield gradually, which requires an arbitrary

definition of its yield strength yh,

such as the commonly used 0.2%3

G

E

2 (1 )

The most widely used civil

engineering structural materials,

steel and concrete, have uniaxial

stress-strain diagrams of the types

shown in Fig. 1. Mild steels yield

2

offset criterion. Yield strengths for

steel vary from less than 250 MPa

to more than 700 MPa. For

practical purposes, steel behaves

as an ideal material in both tension

and compression below the yield

or buckling stress. The elastic

modulus and Poisson ratio for

steel are always close to 200,000

MPa and 0.3, respectively.

Concrete is less predictable, but

under short-duration compressive

stress not greater than u/3 – u/2,

its behavior is reasonably linear 4

1

(Fig. 1b in which typical values for

u are: 30 MPa ≤ u ≤ 50 MPa). An

elastic modulus of E = 22,000 MPa

and Poisson ratio of = 0.15 are

typical for concrete. In using

concrete for analysis, the ACI code

specifies using the gross cross

area properties to perform

analyses to determine the force

distributions in frame structures,

i.e., ignore the reinforcing steel

and tension cracking in calculating

the force distributions.

Work and Energy

The principle of conservation of

energy is fundamentally important

in structural analysis. This

principle, expressed as energy or

work balance, is applicable to both

rigid and deformable structures.

Rigid structures only require

multiplying the external forces by

the respective displacements.

Deformable structures also require

the summation of the internal

stresses acting through the

5

respective deformations. Internal

work is called strain energy and

must be accounted for in the

energy balance.

The work dW of a force F acting

through a change in displacement

d in the direction of F is

dW Fd

(1)

Over 1, the total work is

W

1

0

Fd

6

Limiting attention to gradually

applied forces, i.e., ignoring inertial

forces caused by dynamic loads,

and linear elastic response leads

to

W

1

0

Fd k

1

0

d

1

1

k 1 2 F1 1

2

2

(3)

F

(2)

F1

k

1

7

1

8

2

Expanding to a vector of forces

and displacements leads to

1

W F {}

2

(4)

The special case shown

in the right figure:

u 1

W 12 Fx 0 Fx u

v 2

where U = strain energy for the

element. Equation (5) is a

homogeneous, quadratic polynomial in terms of the local coordinate element displacements {u}

or global coordinate element

displacement {v}.

Expanding (4) for a single element

({F} = [k] {u} or {F} = [K] {v}):

W 12 u [k]{u}

12 v [K]{v} U

(5)

9

Principle of Virtual Displacements

In prior chapters we established

the relationships of framework

analysis directly utilizing the basic

conditions of equilibrium and

displacement continuity. Henceforth, we will use energy principles,

specifically the principle of virtual

displacements since it permits

mathematical manipulations that

are not possible with direct

procedures. We restrict our

attention to virtual displacements

since this principle is applicable 11

10

to constructing stiffness equations.

The principle of virtual

displacements can be stated as

If a deformable structure is in

equilibrium and remains in

equilibrium while it is subject to a

virtual distortion, the external

virtual work done by the external

forces acting on the structure is

equal to the internal virtual work

done by the stress resultants.

Recall: virtual imaginary, not

real, or in essence but not in fact12

3

The principle of virtual displacements

is expressed mathematically as

(6)

Wext = Wint

F

F1

Wext

W

1

Equation (6) is based on the

conservation of energy principle,

i.e. the work done by the external

forces going through a virtual

displacement equals the work

done by the internal forces due to

the same virtual displacement.

The external virtual work can be

generalized to a system of forces

as

s

where Wext = F1 = external

virtual work (shaded blue area in

the figure) and Wint = internal

13

virtual work.

The internal virtual work (Wint) is a

function of the structure type.

Since this course focuses on frame

members, only axial and bending

deformations will be considered.

Axial Deformation

Consider the axial force system

shown in Fig. 2. The differential

Wext q dx ( i ) Pi

14

internal virtual work (dWint) is

dWint

d(u)

Fx dx

dx

15

(8a)

where u = virtual axial displacement and Fx = real axial force.

Recalling from your mechanics of

materials class that axial strain ex =

du/dx and the axial force Fx = x A

(axial stress times area), (8a) can

be rewritten as

dWint e x x A dx

Fig. 2: Axial Deformation

(7)

i 1

(8b)

Integrating (8b) over the length of

the element and substituting 16

4

work is

Hooke’s law (x = Eex) leads to

L

0

L

0

L 2

0

(9)

d (v)

0

For the beam bending (flexure)

case (Fig. 3), the internal virtual

Fig. 3: Bending Deformation

L

Wint z M z dx z EI z dx

Wint e x EA e x dx

d(u)

du

EA dx

dx

dx

0

L

dx 2

EI

d2v

dx 2

(10)

dx

where v = virtual transverse

displacement; z = d(v)/dx =

virtual rotation; Mz = real moment

about the z-axis; z = d2v/dx2 =

curvature strain about the z-axis;

and Mz = EI kz.

18

17

NOTE: A difficulty in applying the

principle of virtual displacements is

that functions must be assumed or

developed for the real and virtual

displacement functions in (9) and

(10). Development of these

expressions will follow finite

element mechanics, which is

covered in a later section.

Analytical Solutions Using

Principle of Virtual Displacements

Consider the simple axial force

structure shown in Fig. 4. The real

L

1

2

x, u

Fx2, u2

Fig. 4: Axial Deformation Structure

displacement u:

u = x/L u2

The real strain is

ex = du/dx = u2/L

Imposing a virtual displacement

19

20

5

u2 results in an external virtual work

of

Wext = u2 Fx2

In order to calculate the internal

virtual work

L

d( u)

du

Wint

EA dx

dx

dx

0

expressions for u and u over the

length of the axial deformation

structure must be assumed. We

will consistently assume the real

displacement u:

u = (x/L) u2

We will consider various

expressions for the virtual

displacement to demonstrate the

principle of virtual displacements.

First, consider

u = (x/L) u2

The internal virtual work:

L

Wint

u

u

EA

2 dx EA 2 u 2

u2

L 0

L

L

Equating the external and internal

virtual works gives

u2 Fx2 = u2 (EA/L) u2

or

21

The internal virtual work:

u2 = Fx2 L/EA

which is exact.

Consider next:

u = (x/L)2 u2

The internal virtual work:

Wint

2u 2

2

L

L

u

x dx EA L2

u 2

0

22

L

Wint

u 2

x

u

cos

dx EA 2

2L 0

2L

L

EA

u2

L

Which again gives the exact

solution:

u2 = Fx2 L/EA

u 2

EA

u2

L

Which again gives the exact

solution:

u2 = Fx2 L/EA

These three virtual displacement

expressions all resulted in an exact

solution since the real displacement solution was exact. If the

chosen real displacements

Lastly, consider:

u = u2 sin(x/2L)

23

24

6

correspond to stresses that

identically satisfy the conditions

of equilibrium, any form of

admissible virtual displacement

will suffice to produce the exact

solution.

Notice the adjective “admissible” in

front of virtual displacement.

Admissible means that the

chosen function is physically

continuous and satisfies all

essential boundary conditions, i.e.,

is appropriately zero at all

25

supports.

3EA1

u2

4L

Equating the external and internal

virtual works leads to

4F L

u 2 x2

3EA1

Wint u 2

Considering the second virtual

displacement expression:

u = (x/L)2 u2

leads to

L

2u 2

x2

u2

x

dx

EA

1

2L

L

L2 0

EA1

2u 2

u2

3L

A = A1(1-x/2L)

1

Fx2

2

x, u

L

Fig. 5: Nonprismatic Axial Deformation

Structure

Consider next the nonprismatic

axial deformation structure of Fig.

5. We will repeat the process

considered for Fig. 4 with

reference to the geometry of Fig.

5. Considering the first case:

u = (x/L) u2

L

Wint

u

x )dx E u 2

2 A1 (1 2L

L 0

L

26

Equating the external and internal

virtual works leads to

3F L

u 2 x2

2EA1

Considering the third virtual

displacement expression:

u = u2 sin(x/2L)

leads to

L

Wint

Wint

27

u 2

x

x

u

dx EA1 2

1

cos

2L 0 2L

2L

L

1 1 EA

u 2 1 u 2

2 L

EA

u 2 (0.818) 1 u 2

L

28

7

Again, equating the external and

internal virtual works leads to

u2

1.222Fx2 L

EA1

NOTE: None of the three solutions

match. This is because neither the

real or virtual displacements are

exact. However, we produced

three good approximate solutions.

The exact solution for Fig. 5 is

u2

1.387Fx2 L

EA1

The principle of virtual

displacements has its greatest

application in producing

approximate solutions.

The standard procedure is to

adopt a virtual displacement of

the same form as the real

displacement. Adopting different

forms for the real and virtual

displacements can lead to

unsymmetric stiffness matrices.

29

Special Transformations

in Analysis

Congruent Transformation

A matrix triple product in which the

pre-multiplying matrix is the

transpose of the post-multiplying

matrix, e.g.

[C] [A]T [B] [A] or [D] [A] [B] [A]T

Significance of the transformation is

that [C] and [D] will each be symmetric if [B] is symmetric, which is

one of the reasons all our stiffness

matrices were symmetric.

31

30

Contragradience Principal

If one transformation is known, e.g.,

the local to global displacements,

the force transformation will be

transpose of the displacement

transformation provided both sets

of forces and displacements are

conjugate and vice versa. Such a

transformation is known as

contragradient (or contragredient)

under the stipulated conditions of

conjugacy. Conjugate simply

means that the force-displacement

pair only produce work in the

32

direction of the displacement.

8

For linear analysis, this is always

the case when using orthogonal

coordinate systems. A good

example are the coordinate

transformations for a truss member

(17.21) in which the transformation

matrices are rectangular:

{ua} = [Ta] {va}

{Fa } [Ta ]T {Qa }

0

0

cos sin

[Ta ]

0

cos sin

0

33

9