LED N2RF Remote Emergency Lighting Fixture IF 1605 Installation & Maintenance Information APPLICATION

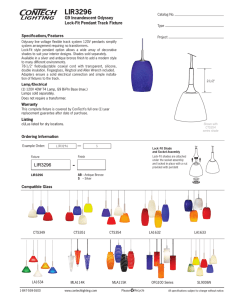

advertisement

LED N2RF Remote Emergency Lighting Fixture IF 1605 Installation & Maintenance Information SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE APPLICATION LED N2RF Remote Emergency Lighting Fixture is a corrosion-resistant Noryl® thermo-plastic assembly which is fully adjustable and houses a high output LED lamp housing assembly. RATING FIXTURE HEAD REPLACEMENT 12V - 3 watt LED sealed lamp assembly. WARNING All electrical power must be turned OFF before and during installation and maintenance. Area should be free of hazardous atmospheres before maintenance is performed to reduce the risk of accidental explosion due to inadvertent shorting of battery during maintenance. IMPORTANT SAFEGUARDS (READ AND FOLLOW ALL SAFETY INSTRUCTIONS) CAUTION 1. 2. 3. 4. 5. 6. 7. 1. Disconnect AC power by opening the supply circuit at the distribution panel. Do not use this equipment for other than intended use. The use of accessory equipment not recommended by the manufacturer may cause an unsafe condition. Electrical power must be turned OFF before and during installation and maintenance. Equipment should be mounted in locations and at heights where it will not readily be subjected to tampering by unauthorized personnel. Do not mount near heat producing equipment. Install only grounded wiring systems to supply the N2RF fixture. To avoid the possibility of static discharge, do not attach any ungrounded metal tags, decals, or marking labels to the non-metallic N2LPS enclosure. MOUNTING ADJUSTING LIGHTING FIXTURE 4. Disconnect battery lead from charger board. 5. Disconnect fixture head wire leads, noting color coding of wires. 6. Remove nut from underside of fixture head threaded stem and remove fixture head/CGB fitting assembly from the power supply housing. NOTE: Do not discard the nut, which will be used with the replacement fixture head. 8. Install the nut (removed in Step 6) while holding the fixture head assembly in the desired position. WIRE SIZING FOR REMOTE INSTALLATION (For Copper Wire) Loosen (do not remove) the gland nut and the lock nut at the mounting bracket center. Running Distance* (ft.) Between Power Supply and Remote Lighting Fixture Adjust fixture head and bracket to the desired position and re-tighten the two nuts. b. 3. After removing all AC and DC power to the fixture, loosen (do not remove) the captive cover screws of the N2LPS power supply enclosure and carefully place the cover aside for reassembly later. 7. Insert wiring for new fixture head assembly through the power supply opening, and insert the fixture CGB fitting. Select a suitable mounting location to provide strength and rigidity for supporting fixture. a. 2. Disconnect DC power by turning designated disconnect selector switch to “OFF.” Ambient Temp. ºC Loosen (do not remove) the screws on both sides of the light fixture (adjusting screws). Adjust fixture head to desired position and re-tighten the two screws. WIRING DIAGRAM WARNING All electrical power must be turned OFF before and during installation and maintenance. Installation area should be free of hazardous atmospheres before wiring to reduce the risk of accidental explosion. Lighting Fixture Load-Max. Watts Wire Size • 14 AWG • 12 AWG • 10 AWG • 8 AWG 25 40 55 12 24 30 12 24 30 12 24 30 125 198 317 505 63 99 158 253 50 79 127 202 117 185 295 471 58 92 148 235 47 74 118 188 109 173 276 440 55 87 138 220 44 69 110 176 *Maximum distance to limit line voltage drop to 5%. WARNING Make wiring connections using methods that comply with the NEC® and any local codes. (COM) YELLOW NOTE Up to four (4) remote LED lamp assemblies can be connected to the N2LPS12222. Up to six (6) remote LED lamp assemblies can be connected to the N2LPS12220. FIXTURE JUNCTION BOX LED LAMP (12 VOLT) (GREEN) PURPLE GROUND All statements, technical information and recommendations contained herein are based on information and tests we believe to be reliable. The accuracy or completeness thereof are not guaranteed. In accordance with Crouse-Hinds “Terms and Conditions of Sale,” and since conditions of use are outside our control, the purchaser should determine the suitability of the product for his intended use and assumes all risk and liability whatsoever in connection herewith. Cooper Industries, Inc. IF 1605 Crouse-Hinds Division Revision 1 P.O. Box 4999, Syracuse, New York 13221 • U.S.A. New 10/09 Copyright © 2009, Cooper Industries, Inc.