Proceedings of IMECE2005 2005 ASME International Mechanical Engineering Congress and Exposition

advertisement

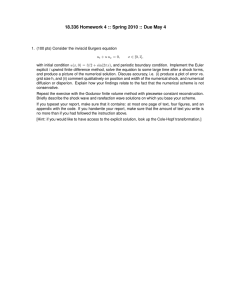

Proceedings of IMECE2005 2005 ASME International Mechanical Engineering Congress and Exposition Orlando, Florida, USA, November 5-11, 2005 IMECE2005-79542 PERFORMANCE COMPARISON OF NUMERICAL PROCEDURES FOR EFFICIENTLY SOLVING A MICROSCALE HEAT TRANSPORT EQUATION DURING FEMTOSECOND LASER HEATING OF NANOSCALE METAL FILMS Ravi Ranjan Kumar∗ J. M. McDonough M. P. Mengüç Department of Mechanical Engineering University of Kentucky Lexington, Kentucky, 40506 Illayathambi Kunadian Center for Applied Energy Research University of Kentucky Lexington, Kentucky 40511 Email: ikuna0@engr.uky.edu ABSTRACT An alternative discretization and solution procedure for implicitly solving a 3-D microscale heat transport equation during femtosecond laser heating of nanoscale metal films has been developed (Kunadian et al. [1]). The proposed numerical technique directly solves a single partial differential equation, unlike other techniques available in the literature which splits the equation into a system of two equations and then apply discretization. The present paper investigates performance of its split and unsplit methods of solution via numerical experiments using Gauss– Seidel, conjugate gradient, generalized minimal residual and δform Douglas–Gunn time-splitting methods to compare the computational cost involved in these methods. The comparison suggests that the unsplit method [1] employing δ-form Douglas– Gunn spatial time-splitting is the most efficient way in terms of CPU time taken to complete the simulation of solving the 3-D time dependent microscale heat transport equation. relativity). In order to ensure finite propagation of thermal disturbances a hyperbolic heat conduction equation (HHCE) was proposed (Vernotte, Cattaneo [2, 3]). However, since the classical and hyperbolic models neglect the thermalization time (time for electrons and lattice to reach thermal equilibrium) and relaxation time of the electrons, their applicability to very short pulse laser heating (Qui,Qui [5, 6]) becomes questionable. Anisimov et al. [7] proposed a two-step model to describe the electron temperature Te and the lattice temperature Tl during short-pulse laser heating of metals. Later, Qiu and Tien [5, 6] rigorously derived the hyperbolic two-step model from the Boltzmann transport equation for electrons. They numerically solved the equations of this model in the context of a 96 f s duration laser pulse irradiating a thin film of thickness 0.1µm. Predicted temperature change of the electron gas during the picosecond transient agreed well with experimental data, supporting the validity of the hyperbolic two-step model for describing heat transfer mechanisms during short-pulse laser heating of metals. Tzou proposed the dual phase-lag (DPL) model [8–11] that reduces to diffusion, thermal wave, phonon-electron interaction [5, 6], and pure phonon scattering (Guyer et al. [12]) models under special values of timescale parameters τq and τT . Over the years, various numerical methods have been investigated for solving the DPL equation. Most early numerical studies involved only the 1-D equation, often using explicit discretization [21]. Recent studies have considered 2-D and 3-D DPL equations, em- INTRODUCTION Fourier’s law predicts thermal disturbances propagating at infinite velocities, implying that a thermal disturbance applied at a certain location in a solid medium can be sensed immediately anywhere else in the medium (violating precepts of special ∗ Address all correspondence to this author. 1 c 2005 by ASME Copyright heating of the sample is expressed as ploying implicit discretizations [16, 17, 19, 20]. Dai and Nassar [13–17] have developed an implicit finite-difference scheme in which the DPL equation is split into a system of two equations with the individual equations discretized using the CrankNicolson scheme and solved sequentially. Dai showed by the discrete energy method [13–18] that the scheme was unconditionally stable. Zhang and Zhao [19, 20] employed the iterative techniques Gauss–Seidel, successive overrelaxation (SOR), conjugate gradient (CG), and preconditioned conjugate gradient (PCG) to solve a Dirichlet problem for the 3-D DPL equation. Kunadian et al. [1] developed an alternative discretization and solution procedure for implicitly solving a 3-D microscale heat transport equation and applied to simulation of this and related femtosecond laser heating of nanoscale metal films. They found that the δform Douglas–Gunn time-splitting method outperformed other numerical techniques available in the literature in terms of computational time taken to complete the simulation. The purpose of this paper is to more thoroughly investigate the computational cost involved in the split and the unsplit methods by employing Gauss–Seidel, conjugate gradient, generalized minimal residual (GMRES) and δ-form Douglas–Gunn timesplitting methods. Performance comparison of this sort over a wide range of currently-used numerical methods has high applicability in making a wise choice of an efficient numerical method for solution of large scale time-dependent problems. First, we present the discretization of the split and unsplit 3D DPL equations. Next, we outline a numerical solution strategy for the solution of discretized equations and compare the numerical results with the experimental results of Brorson et al. [23] and Qiu and Tien [5, 6] corresponding to the transient temperature distribution obtained during short pulse laser heating of thin metal films. Finally we present the performance data for both split and the unsplit methods in terms of computational time requirements observed for the above-noted methods. x 1.992 | t − 2t p | 1−R , S(x,t) = 0.94J exp − − tpδ δ tp (2) where J is the laser fluence, t p describes laser heating of the electron-phonon system from a thermalization state; δ is laser penetration depth, and R is reflectivity [21]. Dai and Nassar [13–17] split Eq. (1) by introducing an intermediate function u(T,t), discretized the individual equations using the Crank– Nicolson scheme and solved them sequentially. The intermediate function is defined as u(T,t) = T + τq ∂T , ∂t (3) which upon substitution into Eq. (1) and discretization we obtain n+1 n+1 n+1 n+1 C4 Ti,n+1 j,k +C5 Ti+1, j,k + Ti−1, j,k +C6 Ti, j+1,k + Ti, j−1,k n n+1 + T +C7 Ti,n+1 j,k+1 i, j,k−1 = F , (4) where n n F n = C8 Ti,nj,k +C9 Ti+1, + T j,k i−1, j,k n n +C10 Ti, j+1,k + Ti, j−1,k +C11 Ti,nj,k+1 + Ti,nj,k−1 +2uni, j,k + ∆tG∗ . (5) The various constants are defined as follows: DISCRETIZATION OF SPLIT AND UNSPLIT 3-D DPL EQUATION The governing transport equation used to describe the thermal behavior of microstructures in 3D is expressed as [8] τq 1 ∂T + − τT 2 α ∂t α ∂t ∂2 T ∂(∇2 T ) ∂t = ∇2 T + ∂S 1 S + τq k ∂t ∆t 1 C5 = − τT + , 2 ∆x2 1 ∆t , C6 = − τT + 2 ∆y2 ∆t 1 C7 = − τT + , 2 ∆z2 1 2τq + − 2(C5 +C6 +C7 ) C4 = α α∆t ∆t 1 C9 = −τT + , 2 ∆x2 (1) for (x, y, z) ∈ Ω ⊂ R3 and t ∈ (t0 ,t f ]. Here k, α, τT and τq are conductivity, diffusivity, phase lag temperature gradient and phase lag of heat flux, respectively. In one dimension the volumetric 2 (6a) (6b) (6c) (6d) (6e) c 2005 by ASME Copyright 1 ∆t , 2 ∆y2 ∆t 1 C11 = −τT + , 2 ∆z2 1 2τq − 2(C9 +C10 +C11 ), C8 = − + α α∆t " n+1 # n Si, j,k + Si,n j,k Si,n+1 j,k − Si, j,k ∗ G = + τq 2 2 2τq 2τq n+1 n+1 Ti, j,k + 1 − Ti,nj,k − uni, j,k . ui, j,k = 1 + ∆t ∆t C10 = −τT + NUMERICAL SOLUTION STRATEGY To test performance of the numerical methods listed above, consider use of Neumann boundary conditions, (7a) ∂T =0 ∂n (7b) (10) (7c) on all of ∂Ω, where n = x, y, z, and initial conditions (7d) T (x, y, z) = To and (7e) ∂T (x, y, z, 0) = 0. ∂t (11) It is convenient to rearrange Equation (4) to the form In the case of the unsplit method, Eq. (1) is solved directly using Trapezoidal integration [1]. The final form of the discretized equation remains the same as the split method Eq. (4) except for details of the coefficients and the RHS term F n . In this case coefficients are 1 ∆t C5 = − τT + , 2 ∆x2 1 ∆t , C6 = − τT + 2 ∆y2 ∆t 1 C7 = − τT + , 2 ∆z2 τq 1 + − 2(C5 +C6 +C7 ) C4 = α α∆t ∆t 1 C9 = −τT + , 2 ∆x2 1 ∆t C10 = −τT + , 2 ∆y2 1 ∆t , C11 = −τT + 2 ∆z2 1 2τq C8 = − 2(C9 +C10 +C11 ), + α α∆t " n+1 # n+1 n n S − S S + S i, j,k i, j,k i, j,k i, j,k G∗ = + τq . 2 2 n+1 n+1 n+1 n+1 C7 Ti,n+1 j,k−1 +C6 Ti, j−1,k +C5 Ti−1, j,k +C4 Ti, j,k +C5 Ti+1, j,k + n+1 n C6 Ti,n+1 j+1,k +C7 Ti, j,k−1 = F , which can be written in matrix form as AT = F. The matrix A is a sparse 7-band matrix, which can be stored in a N ×7 array, with N (= Nx × Ny × Nz ) being number of grid points in the physical domain. Thus Eq. (12) can be grouped in matrix form as follows (8a) (8b) (8c) T n+1 Fi,nj,k−1 j,k−1 2C7 i,n+1 Fi,nj−1,k T j−1,k C7 i,n+1 n T j,k Fi−1, . j,k i−1, n+1 n Fi, j,k . Ti, j,k = n n+1 . Fi+1, Ti+1, j,k j,k Fn . Ti,n+1 i, j+1,k j+1,k n 0 n+1 F Ti, j,k+1 i, j,k+1 (13) where T is the solution vector, and F is the known RHS vector. Hence the system of linear equations (13) is strictly diagonally dominant. The coefficient matrix A is a nonsymmetric positive semi-definite seven banded matrix. The system of linear equations AT = F arising from finite difference discretization for both split and unsplit procedures has been solved using Gauss–Seidel, conjugate gradient, generalized minimal residual and δ-form Douglas–Gunn time-splitting methods. Equation (4) is three-level in time, and it can be efficiently solved using a Douglas–Gunn time splitting method [22]. By dividing both sides of Eq. (4) by 0 C7 . . . . 2C7 (8d) (8e) (8f) (8g) (8h) (8i) and the right-hand side function is n n F n = C8 Ti,nj,k +C9 Ti+1, j,k + Ti−1, j,k +C10 Ti,nj+1,k + Ti,nj−1,k +C11 Ti,nj,k+1 + Ti,nj,k−1 − τq n−1 T + ∆tG∗. α∆t i, j,k (12) 0 C6 . . . . 2C6 0 C4 C5 C4 . C4 . C4 . C4 . C4 2C5 C4 2C5 C5 . . . . 0 2C6 C6 . . . . 0 τq 1 + α α∆t (9) 3 (14) c 2005 by ASME Copyright we obtain 1.0 Analytical, Chiu Experimental, Qui & Tien n+1 n+1 0 1 − 2C50 − 2C60 − 2C70 Ti,n+1 j,k +C5 Ti+1, j,k + Ti−1, j,k n+1 0 n+1 n+1 n +C60 Ti,n+1 + T +C T + T 7 j+1,k i, j−1,k i, j,k+1 i, j,k−1 = S , (15) Normalized Temperature Change Experimental, Brorson et al. where, Sn = C50 = C60 = C70 = Fn τq , 1 α + α∆t C5 τq , 1 α + α∆t C6 τq 1 + α α∆t C7 τq . 1 α + α∆t (16a) (I + Ay )T (I + Az )T (3) =T =T (2) − Ay T Figure 1. (16d) (17b) n (17c) (1) = δT 2.5 +T , 0.1µm thick gold film. NUMERICAL EXPERIMENTS We conducted numerical experiments on a 3.4GHz Xeon em64t processors@2GB machine using time step ∆t = 0.001ps and t = 2.5ps to test performance of the split and unsplit methods. Convergence tests were performed using L2 (Ω) norm of the difference between successive iterates with a convergence tolerance of 10−7 . Figure 1 shows the comparison between the numerical (explicit and implicit scheme), analytical [21] and the experimental results of Brorson et al. [23] and Qiu and Tien [5, 6] corresponding to the front surface transient response for a 0.1µm thick gold film. The laser heat source term given by Eq. (2) is used for this purpose. The thermal properties (α = 1.2 × 10−4m2 s−1 , k = 315W m−1 K −1 , τT = 90ps, τq = 8.5ps) are assumed to be constant. The temperature change is normalized by the maximum value that occurs during the short-time transient. The results from the present numerical scheme compare well with experimental and analytical results. The HHCE and the parabolic heat conduction models neglect the microstructural interaction effect in the short-time transient, rendering an over estimated temperature in the transient response as seen in the figure. Tables 1 and 2 show the CPU time required for entire 3-D simulation using split and unsplit methods for the explicit procedure and iterative schemes, and the direct δ-form Douglas– (19a) (19c) n Front surface transient response for a We remark that this form is the most efficient of the forms found in the literature. Again, the implicit part of the above equations (19d) is tridiagonal, and is thus easily solved using LU decomposition. (19b) (I + Az )δT (3) = δT (2) T 2.0 315Wm−1 K −1 , τT = 90ps, τq = 8.5ps. (17a) n (I + Ax )δT (1) = Sn − (I + A)T n (3) 1.5 Comparison between numerical (explicit and implicit schemes), analytical [21] and experimental results [6, 23]. α = 1.2 × 10−4m2 s−1 , k = T (1) , T (2) and T (3) denote intermediate estimates of T n+1 with T n+1 = T (3) . The implicit part T n+1 of the above equations (17c) is tridiagonal, and is thus easily solved using LU decomposition. By applying δ-form Douglas–Gunn time-splitting [22] we can represent Eq. (15) as follows n+1 1.0 (16c) − Az T , = δT 0.5 Time (ps) (1) (1) (1) (I + Ax )T (1) = 1 − 2C50 Ti, j,k +C50 Ti+1, j,k + Ti−1, j,k (18a) (2) (2) (2) (I + Ay )T (2) = 1 − 2C60 Ti, j,k +C60 Ti, j+1,k + Ti, j−1,k (18b) (3) (3) (3) (I + Az )T (3) = 1 − 2C70 Ti, j,k +C70 Ti, j,k+1 + Ti, j,k−1 (18c) (I + Ay )δT Numerical, HHCE 0.4 0.0 0.0 where (2) 0.6 Numerical, DPL (16b) (I + Ax )T (1) = Sn − Ay T n − AzT n (1) Numerical, Parabolic 0.2 This equation is in the general form required for construction of a multilevel Douglas and Gunn time splitting [22]. Applying Douglas–Gunn time-splitting technique to Eq. (15) we have (2) 0.8 (19d) 4 c 2005 by ASME Copyright Numerical techniques N=21 N=41 N=51 N=101 Explicit Scheme 4.88 147.62 450.26 7920.00 Gauss–Seidel 13.46 175.1 415.86 7800 GMRES 13.56 133.98 267.8 2873.2 Conjugate gradient 12.12 110.5 233.96 2733.4 δ-form D-G 9.15 75.22 153.3 1638 Table 1. split method [1] employing δ-form Douglas–Gunn time-splitting is the most efficient way of solving the 3-D time dependent microscale heat transport equation in terms of CPU time taken to complete the simulation. Total CPU time taken in seconds REFERENCES [1] Kunadian, I., McDonough, J. M., Kumar, R. R., 2005, An efficient numerical procedure for solving a microscale heat transport equation during femtosecond laser heating of nanoscale metal films, InterPACK ’05, San Francisco, CA, USA. [2] Vernotte, P., 1958, Les panadoxes de la theorie continue de l’equation de la chaleur, C.r.acad.Sci.Paris, 246, pp.31543155. [3] Cattaneo, M.C., 1958, Sur une forme de l’equation de la chaleur eliminant le paradox d’une propagation instantanee, Comptes Rendus Hebd. Seances Acad. Sci., 247, pp.431-433. [4] Y. Taitel, On the Parabolic, hyperbolic and discrete formulation of the heat conduction equation, International Journal of Heat and Mass Transfer, 15, 369 (1972). [5] T. Q. Qiu, C. L. Tien, Short-pulse laser heating on metals, International Journal of Heat and Mass Transfer, 35, 719 (1992). [6] T. Q. Qiu, C. L. Tien, Heat transfer mechanisms during short-pulse laser heating of metals, ASME Journal of Heat Transfer, 115, 835 (1993). [7] S. I. Anisimov, B. L. Kapeliovich, and T. L. Perel’man, Electron emission from metal surfaces exposed to ultrashort laser pulses, Sov. Phys. JETP, 39, 375 (1974). [8] D. Y. Tzou, Macro-to-Microscale Heat Transfer: The Lagging Behavior, Taylor and Francis, Washington, DC (1996). [9] D. Y. Tzou, A unified approach for heat conduction from macro-to micro scales, ASME Journal of Heat Transfer, 117, 8 (1995). [10] D. Y. Tzou, The generalized lagging response in smallscale and high-rate heating, International Journal of Heat and Mass Transfer, 38, 3231 ( 1995). [11] D. Y. Tzou, Experimental support for lagging behavior in heat propagation, J. Thermophysics and Heat transfer, 9, 686 (1995). [12] Guyer, R. A., and Krumhansl, J. A., 1966, Solution of the linearized Boltzmann equation, Physical Review, 148, pp. 766-778. [13] W. Dai, and R. Nassar, A finite difference method for solving the heat transport equation at the microscale, Numer. Methods Partial Differential Equations, 15, 698 (1999). [14] W. Dai, and R. Nassar, A compact finite difference scheme for solving a one-dimensional heat transport equation at the Performance comparison of different numerical methods for solving the discretized 3-D DPL equation using split method. Numerical techniques Total CPU time taken in seconds N=21 N=41 N=51 N=101 Explicit Scheme 4.88 147.62 450.26 7920.00 Gauss–Seidel 14.14 253.42 627.03 11343.06 Conjugate Gradient 12.33 124.83 270.3 3614.69 GMRES 13.86 145.00 270.8 2996.0 δ-form D-G 8.54 70.5 140.92 1344.4 Table 2. Performance comparison of different numerical methods for solving the discretized 3-D DPL equation using unsplit method. Gunn time-splitting method for different values of the spatial discretization parameter N. Here N = Nx = Ny = Nz . We can make several observations from Tables 1 and 2. When N = 21 the explicit method consumes significantly less CPU time than the rest of the numerical techniques, but for the spatial discretization parameter N > 21, all implicit methods except the GS procedure perform better than the explicit method employed in this numerical experiment. The poor performance of the iterative methods namely GS, CG and GMRES in the unsplit approach owes to the fact that the coefficient matrix A (Eq. (13)) is less diagonally dominant than that of the split method. Clearly, for highresolution calculations on grids having greater than a million grid points, the splitting method will be significantly more efficient for time-dependent problems than any iterative technique. SUMMARY AND CONCLUSIONS We have investigated performance of split and unsplit techniques for solving the DPL equation by conducting numerical experiments using Gauss–Seidel, conjugate gradient, generalized minimal residual, and δ-form Douglas–Gunn methods and determined the computational cost involved in each approach. The un5 c 2005 by ASME Copyright [15] [16] [17] [18] [19] [20] [21] [22] [23] micro-scale, Journal of Computational and Applied Mathematics, 132, 431 (2001). W. Dai, and R. Nassar, A finite difference scheme for solving a three dimensional heat transport equation in a thin film with micro-scale thickness, International Journal for Numerical Methods in Engineering, 50, 1665 (2001). W. Dai, and R. Nassar, An unconditionally stable finite difference scheme for solving 3-D heat transport equation in a sub-microscale thin film, Journal of Computational and Applied Mathematics, 145, 247 (2002). W. Dai, and R. Nassar, A compact finite difference scheme for solving a three-dimensional heat transport equation in a thin film, Numerical Methods for Partial Differential Equations, 16, 441 (2000). M. Lee, Alternating direction and semi-explicit difference scheme for parabolic partial differential equations, Numer Math, 3, pp. 398-412 (1961). J. Zhang, J. J. Zhao, Unconditionally stable finite difference scheme and iterative solution of 2D microscale heat transport equation, Journal of Computational Physics, 170, pp. 261-275 (2001). J. Zhang, J. J. Zhao, Iterative solution and finite difference approximations to 3D microscale heat transport equation, Mathematics and Computers in Simulation, 57, 387 (2001). K. S. Chiu, Temperature dependent properties and microvoid in thermal lagging, Ph. D. Dissertation, University of Missouri-Columbia, Columbia, Missouri (1999). J. Douglas, J. E. Gunn, A general formulation of alternating direction methods, Numer. Math. 6, 428 (1964). Brorson, S.D., Kazeroonian, A., Moodera, J. S., Face, D.W., Cheng, T.K., Ippen, E.p., Dresselhaus, M.S., and Dresselhaus, G., 1990, Femtosecond room temperature measurements of the electron-phonon coupling constant λ in metallic superconductors, Phys. Rev. Lett., 64, pp. 21722175. 6 c 2005 by ASME Copyright