July 28, 2015 To: Bussmann® series Fuse Customers Subject: Fuse Time-Current Curves

advertisement

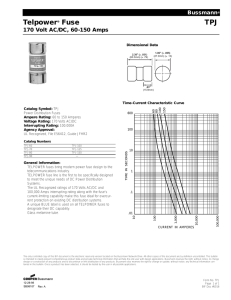

Bussmann Division 114 Old State Road Ellisville, MO 63021 tel: 636-394-2877 fax: 800-544-2570 www.eaton.com/bussmannseries July 28, 2015 To: Bussmann® series Fuse Customers Subject: Fuse Time-Current Curves This document covers our general policy regarding time-current curves and the basic testing conditions upon which these curves are developed. This applies to all Bussmann series Class L, Class R, Class H, Class K, Class J, Class T, Class CC, Supplemental (miscellaneous, miniature, micro and surface mount) and plug fuses. The opening time tolerances are not listed on the curves as they differ between fuse designs and the percentage of the overload relative to the amp rating. The following table shows the tolerances per design and the corresponding overload percentage. Fuse Type Fast/Normal Acting Dual Element/Time Delay Percent of Rated Current 200% ±20% ±25% 500% ±10% ±20% 1000% ±10% ±10% All time-current curves must meet the same basic testing requirements when attempting to duplicate a curve as well as adhering to specific testing conditions relative to each type of curve. Listed below are the basic conditions required to be followed for accurate verification: 1. 2. 3. 4. 5. 6. 7. 8. Fuses shall be tested in a single pole fuse block mounted in the horizontal plane. Fuses shall be tested one at a time. The ambient temperature shall be +25°C, ±2°C. The fuse and fuse mounting shall be at +25°C, ±2°C prior to the test. The conductor size shall be in accordance with the table below. The fuse block shall be selected based on the appropriate fuse class and current rating. The test current shall be calibrated using a dummy fuse. For longer opening times, greater than 3 seconds, the current applied to the test fuse shall be increased, if necessary, to the correct value within 3 seconds of its inception. 9. The test time shall be from when the current is turned on until the fuse melts open. Page 2 of 2 Temperature Test Conditions per UL 248 a Fuse Current Ratings In , A 0 - 30 31 - 60 61 - 100 Minimum Length a, m (ft) 0.6 (2) 0.6 (2) 0.6 (2) Wire Size, AWG or kcmil (mm2) 8 (8.4) 4 (21.2) 1 (42.4) 101 - 200 201 - 400 0.6 (2) 1.2 (4) 4/0 (107.2) 500 (253) 401 - 600 1.2 (4) 1000 (507) Any connection to the source of supply shall not be less than 1.2 m (4 ft) long. The current ratings covered in the testing procedure will include the maximum ampere rating for each physical size and any construction breaks within a specific size. If you have any questions, please contact our Application Engineering team at 1-855-BUSSMANN or e-mail fusetech@eaton.com. Sincerely, Eaton’s Bussmann Division Application Engineering