Cooper Bussmann Project Specifications 3/31/03 SECTION 164XX FUSED DISTRIBUTION PANELBOARDS

advertisement

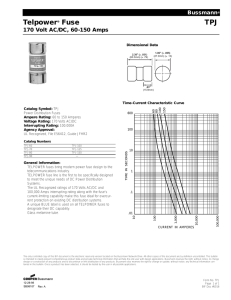

Cooper Bussmann Project Specifications 3/31/03 SECTION 164XX FUSED DISTRIBUTION PANELBOARDS PART 1 GENERAL 1.1 SUMMARY A. 1.2 RELATED SECTIONS A. 1.3 1.5 Panelboards shall comply with the following: 1. NEMA KS 1 2. NEMA PB 1 3. NEMA FU 1 4. UL 98 5. UL 67 SUBMITTALS A. Submit ten copies of items B-D B. Detail panelboard construction drawings including: 1. Overall, wiring gutter, and interior mounting dimensions 2. Conduit entrance/exit locations, size, number/phase, and termination types 3. Main/feeder/branch device, neutral, and ground locations 4. Assembly and component device nameplate information C. Assembly ratings including: 1. Voltage, ampacity, and short-circuit current (bracing) rating D. Component device ratings including: 1. Voltage, ampacity, and interrupting ratings 2. Switch and fuse type 3. Product data sheets or bulletins CLOSEOUT SUBMITTALS A. 1.6 Section 16491 - Fuses. REFERENCES A. 1.4 Furnish and install distribution panelboards as shown on the drawings. Submit ten copies of: 1. Final as-built drawings, assembly and component device ratings as required with Section 1.4. 2. Operation and maintenance manuals including replacement parts list. QUALIFICATIONS A. The equipment manufacturer shall have a minimum five years experience in producing electrical distribution equipment. Fused Distribution Panelboards 164XX - 1 Cooper Bussmann Project Specifications 1.7 1.8 1.9 3/31/03 DELIVERY, STORAGE, AND HANDLING A. Equipment shall be shipped without fuses installed, furnish separately. B. Inspect equipment for possible damage during delivery and prior to installation. C. Handle and store equipment in accordance with manufacturer’s instructions. MAINTENANCE MATERIALS A. Furnish two sets of fuse pullers. B. Furnish operating/maintenance tools/key(s) as supplied by manufacturer. ADDITIONAL MATERIALS A. Furnish three sets of each rating and type of fuse installed and spare fuse cabinet where not already provided. PART 2 PRODUCTS 2.1 2.2 GENERAL A. Manufacturers: 1. Square D Model - QMB 2. Cutler-Hammer Model – PRL-4F 3. GE Electrical Model – Spectra Series 4. Siemens Model – Sentron F1 or F2 B. Ratings 1. Panelboards shall have a voltage and current rating as indicated on the drawings. 2. Panelboards shall have a short-circuit current rating of 200,000A rms symmetrical at the voltage indicated on the drawings. 3. Series ratings are not permitted with main or feeder devices unless supplying lighting and appliance panelboards. CONSTRUCTION A. Box shall be Type1 galvanized steel with interior mounting studs as standard B. Trim shall be Type 1 dead-front, surface mount standard C. Type 3R or 12 shall be supplied where indicated on drawings D. Interiors shall be factory assembled E. Main bus shall be plated copper sized in accordance with UL 67 heat-rise tests. F. Main bus shall be fully rated at the ampacity indicated on drawings. G. Fully rated solid neutral bus shall be provided for panelboards with neutral. H. Solidly bonded copper equipment ground bar shall be provided. Fused Distribution Panelboards 164XX - 2 Cooper Bussmann Project Specifications 2.3 MAIN DEVICE A. 2.4 3/31/03 Provide main lugs only or main fused device as shown on the drawings. See Section 2.4 for requirements for main fused device. MAIN/FEEDER/BRANCH DEVICES A. Provide main, feeder, and branch fused devices as indicated on drawings in accordance with requirements below: 1. Load interrupter knife blade switch rated up to 200,000A rms symmetrical with Cooper Bussmann LPN-RK/LPS-RK, LPJ, or KRP-C Fuses. 2. Interlocks to prevent the opening of the cover when the switch is in the ON position. Interlock shall be defeatable for testing purposes. 3. Handle lockable in OFF position. PART 3 EXECUTION 3.1 3.2 3.3 INSTALLATION A. Equipment shall be installed in accordance with NEMA PB 1.1 and manufacturer’s recommendations. B. Equipment shall have a nameplate installed and mounted to the front cover and indicate: panelboard type, ampere rating, voltage rating, short-circuit rating, and load served for each disconnect switch. C. Verify connected load(s) and selection of fuse sizes prior to selection and installation. Install fuses in accordance with Section 2.4. Refer to Section 16941 for product requirements. Install labeling that identifies replacement fuse type/class and rating. D. Install filler plates or covers for unused spaces in panelboards. E. Inspect completed installation for physical damage, alignment, and support. FIELD ADJUSTMENTS AND TESTING A. Tighten bolted bus, switch, and termination connections in accordance with manufacturer’s recommendations. B. Measure load currents for each feeder and branch device and balance phase loads where possible. CLEANING A. Touch up scratched or marred surfaces to match original finish. END OF SECTION Fused Distribution Panelboards 164XX - 3