CHAPTER 30 - FACILITIES Contents 31

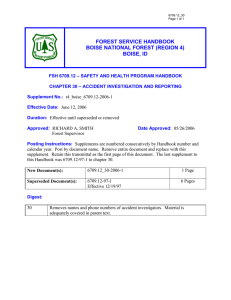

advertisement