N SECTION 1 www.eaton.com

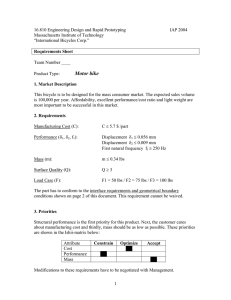

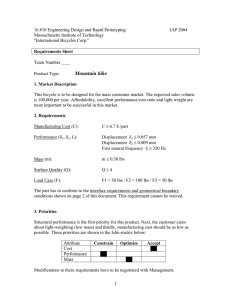

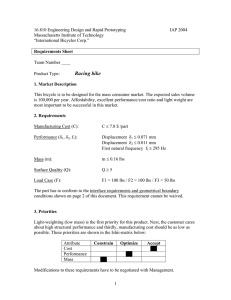

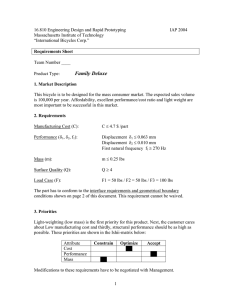

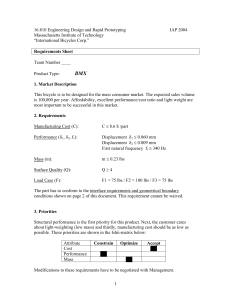

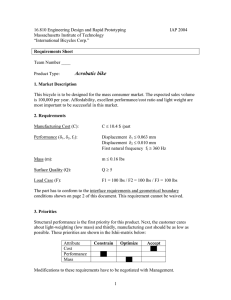

advertisement