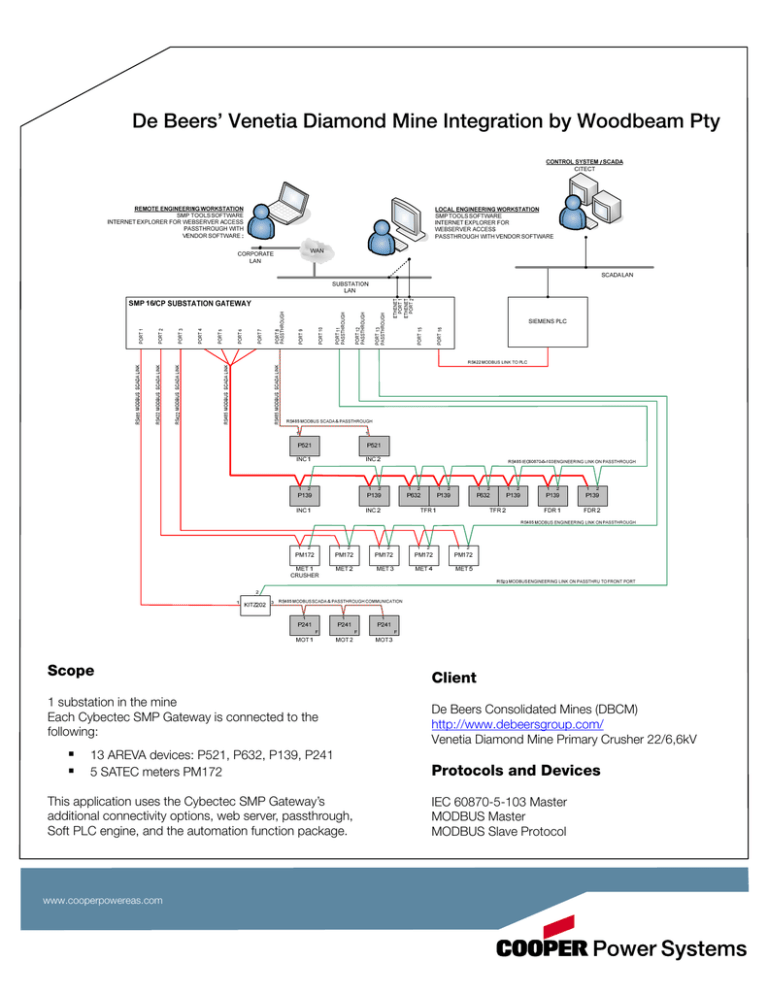

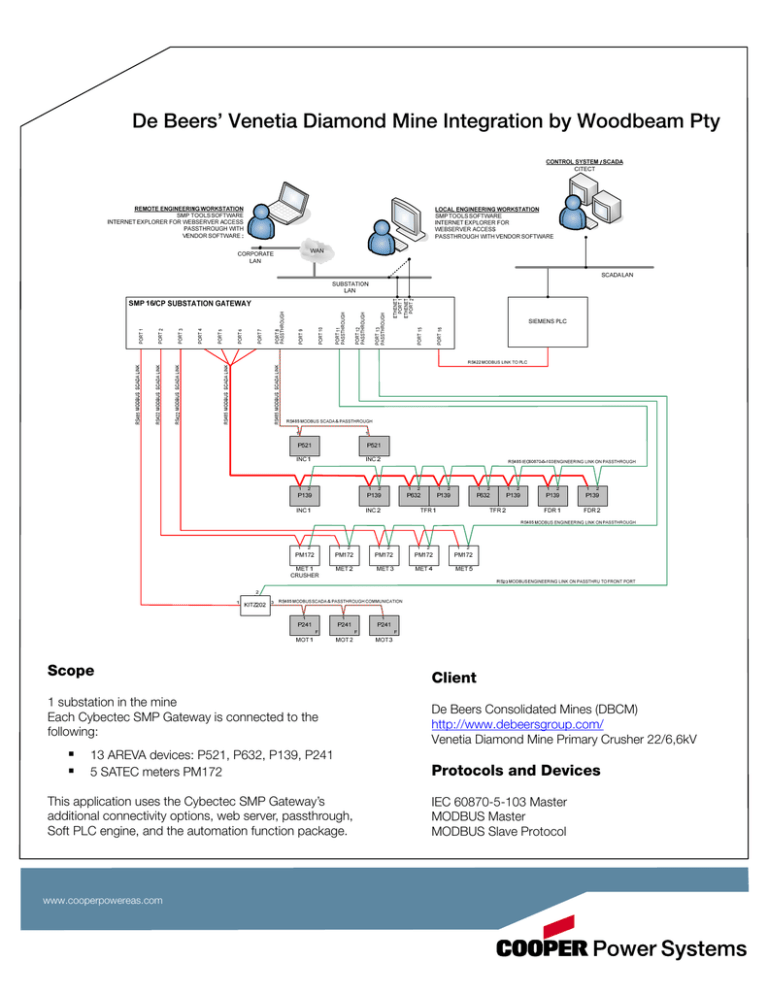

De Beers’ Venetia Diamond Mine Integration by Woodbeam Pty

Scope

1 substation in the mine

Each Cybectec SMP Gateway is connected to the

following:

13 AREVA devices: P521, P632, P139, P241

5 SATEC meters PM172

This application uses the Cybectec SMP Gateway’s

additional connectivity options, web server, passthrough,

Soft PLC engine, and the automation function package.

www.cooperpowereas.com

Client

De Beers Consolidated Mines (DBCM)

http://www.debeersgroup.com/

Venetia Diamond Mine Primary Crusher 22/6,6kV

Protocols and Devices

IEC 60870-5-103 Master

MODBUS Master

MODBUS Slave Protocol

The Solution

De Beers’ Problem

De Beers’ project engineer, Mr Kurt Hamman

explains, “The mine needed to replace its existing

primary crushing facility due to a capacity increase

driven by market demand. The project to replace the

existing primary crusher required the building of a

crusher, in an area outside of the predicted mining

cuts. The new primary crusher installation is a

modernized duplicate of the old crusher installation,

that is, we chose to use modern technologies in the

construction.”

The crusher requires high voltage input, hence the

high voltage indoor switchgear panels were equipped

with AREVA digital protective relays supplied and

SATEC meters. This combination of protective relays

and meters provides accurate measurement

information. All the information needed to be

transmitted to De Beers’ SCADA.

De Beer’s Requirements

The project required protective relays that could

communicate over a field bus network. This was an

opportunity to eliminate the traditional need for

discrete digital status I/Os for the switchgear panels

(open, closed, tripped, and earthed). On top of

transmitting status, setting up a communications

network between the relays and control centers would

also give the client access to a host of other useful

information, such as event files and statistics for other

groups such as maintenance, planning and

engineering.

“We required a relatively simple, substation class

system solution which would also allow for future

expansion at a competitive price since. One of the

major justifications in using a communication system

was to reduce on the cost of a traditional digital I/O

solution in the substation,” says Kurt Hamman.

Quebec City

730 Commerciale Street, Suite 200

Saint-Jean-Chrysostome, Quebec

Canada G6Z 2C5

Technical Support:

P: +1.418.834.0009

support@cybectec.com

Montreal

1290 St. Denis Street, Suite 300

Montreal, Quebec

Canada H2X 3J7

Sales:

P: +1.514.845.6195

sales@cybectec.com

All Cooper logos and Cooper Power Systems are trademarks of Cooper US, Inc., in the U.S. and other countries.

You are not permitted to use Cooper trademarks without the prior written consent of Cooper US, Inc.

©2009 Cooper US, Inc. All Rights Reserved

B1100-09039 • April 2009 • New Issue

The Cybectec SMP Gateway proposed by

WoodBeam (Pty) Ltd was selected to create a

communication network between the protection and

metering relays and the SCADA via a Siemens S400

PLC.

The system was successfully commissioned in March

2006 and has performed according to De Beers’

expectations.

Besides providing the information that would have

been obtained via normal digital I/O, the Cybectec

SMP Gateway added intelligence to the SCADA

system. This provides greater diagnostic information

for the artisan and engineer alike and reduces down

time and unnecessary call outs.

The Challenge

WoodBeam’s system engineer, Wynand Coetzee, had

to overcome a number of technical challenges that

were not originally envisaged, to achieve the required

objective.

“While all of the substation protective relays and

meters were supplied from two manufacturers (AREVA

and SATEC), we discovered that the relays originated

from different European factories and did not offer a

uniform system communication interface with regard

to SCADA and engineering support. Fortunately the

flexibility and power of the SMP Gateway allowed us

to be able to accommodate these differences and

ultimately provide De Beers with a homogenous and

uniform integrated substation communications

system,” explains Wynand Coetzee.

About Venetia Diamond Mine

The Venetia Mine is located in the far North of South

Africa, close to the Limpopo River and the border of

Zimbabwe. The mine is the largest contributor to De

Beers Consolidated Mines (DBCM).