Channel Metal framing channel is cold formed on our modern rolling... , 14 Ga. , and 16 Ga.

advertisement

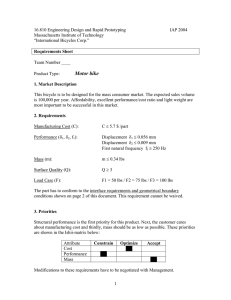

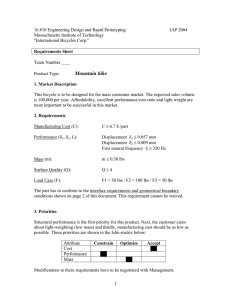

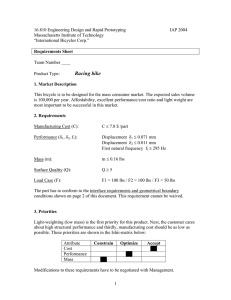

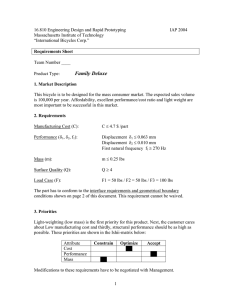

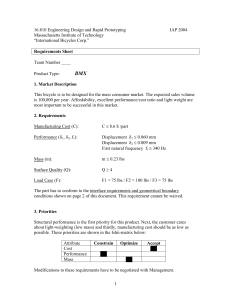

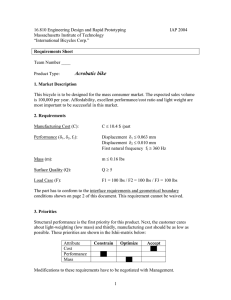

Channel & Combinations Metal Framing Channels Channel Metal framing channel is cold formed on our modern rolling mills from 12 Ga. (2.6mm), 14 Ga. (1.9mm), and 16 Ga. (1.5mm) low carbon steel strips. A continuous slot with inturned lips provides the ability to make attachments at any point. Lengths & Tolerances All channels excluding ‘SH’ style ± 1/8” (3.2mm) on 10’ (3.05m) and ± 3/16” (4.76mm) on 20’ (6.09m) All ‘SH’ channels only ± 1/4” (6.35mm) on 10’ (3.05m) and ± 1/2” (12.70mm) on 20’ (6.09m) Custom lengths are available upon request. Slots Slotted series of channels offer full flexibility. A variety of pre-punched slot patterns eliminate the need for precise field measuring for hole locations. Slots offer wide adjustments in the alignment and bolt sizing. Holes A variety of pre-punched 9/16” (14.3 mm) diameter hole patterns are available in our channels. These hole patterns provide an economical alternative to costly field drilling required for many applications. Knockouts When used with series B217-20 Closure Strips, knockout channels can be used to provide an economical U.L. listed surface raceway. Channels are furnished with 7/8” (22.2 mm) knockouts on 6” (152 mm) centers, allowing for perfect fixture alignment on spans up to 20’ (6.09 m). Materials & Finishes (Unless otherwise noted) Steel: Plain & Pre-galvanized 12 Ga. (2.6), 14 Ga. (1.9) and 16 Ga. (1.5) Finish Code PLN Finish Plain Note: A minimum order may apply on special material and finishes. GRN GLV DURA GREEN™ Pre-Galvanized HDG Specification ASTM A1011, 33,000 PSI min. yield ASTM A653 33,000 PSI min. yield Hot-Dipped Galvanized ASTM A123 Yellow Zinc Chromate ASTM B633 SC3 Type II Stainless Steel Type 304 ASTM A240 Stainless Steel Type 316 ASTM A240 Aluminum Aluminum 6063-T6 Design Load (Steel & Stainless Steel) YZN The design loads given for strut beam loads SS4 are based on a simple beam condition using SS6 an allowable stress of 25,000 psi. This AL allowable stress results in a safety factor of 1.68. This is based upon virgin steel minimum yield strength of 33,000 psi cold worked during rolling to an average yield stress of 42,000 psi. For aluminum channel loading multiply steel loading by a factor of 0.38. Welding Weld spacing is maintained between 21/2 inches (63.5 mm) and 4 inches (101.6 mm) on center. Through high quality control testing of welded channels and continuous monitoring of welding equipment, we provide the most consistent combination channels available today. Metric Metric dimensions are shown in parentheses. Unless noted, all metric dimensions are in millimeters. 15 Strut Systems Channel Selection Chart for Channels, Materials and Hole Patterns Channel Dimensions Channel Type Height Material & Thickness * Stainless Steel Width Type 316 2 3 4 .105 .105 .105 .080 – – – – .080 – – – – – 12 Ga. 14 Ga. – 12 Ga. 12 Ga. 12 Ga. 14 Ga. – – – – – 12 Ga. 14 Ga. – – – 12 Ga. 14 Ga. – – – 1 B11 B12 B22 B24 B26 B32 B42 B52 B54 B56 B62 B72 31/4” 27/16” 15/8” 15/8” 15/8” 13/8” 1” 13/16” 13/16” 13/16” 13/16” 13/32” (82.5) (61.9) (41.3) (41.3) (41.3) (34.9) (25.4) (20.6) (20.6) (20.6) (20.6) (10.3) 15/8” 15/8” 15/8” 15/8” 15/8” 15/8” 15/8” 15/8” 15/8” 15/8” 13/16” 13/16” (41.3) (41.3) (41.3) (41.3) (41.3) (41.3) (41.3) (41.3) (41.3) (41.3) (20.6) (20.6) 12 12 12 14 16 12 12 12 14 16 18 18 Ga. Ga. Ga. Ga. Ga. Ga. Ga. Ga. Ga. Ga. Ga. Ga. 9/16” x 11/8” Channel Hole Pattern ** TH S H17/8 KO6 13/32” x 3” 9/16” 9/16” 7/8” slots diameter holes diameter on 17/8” centers diameter knockouts slots on 2” centers 1 1 1 12 1 12 – – 12 1234 1 3 1234 1 12 1234 1 1234 – 12 1 1 1 – 1 13 1 13 – 1 1 13 1 13 – 134 1 1 1234 1 1234 – – – – – 1 1 1 – – – – – – 1 1 12 1 – – The selection has been prepared to provide a reference for available channel, materials and hole patterns. Material types available for various hole patterns are defined by numbers 1 thru 4. Some stainless steel channels with hole patterns are available on special order only. *Metric equivalent for thicknesses shown in chart. 12 Ga. = 2.6 mm 18 Ga. = 1.2 mm 14 Ga. = 1.9 mm .105 = 2.6 mm 16 Ga. = 1.5 mm .080 = 2.0 mm **1 - Steel 2 - Aluminum 3 - Type 304 Stainless Steel 4 - Type 316 Stainless Steel Properties may vary due to commercial tolerances of the material. Channel Part Numbering Example: B22 SH - 120 SS4 Channel Type B11 B12 B22 † B24 † B26 B32 B42 B52 † B54 † B56 B62 B72 Hole Patterns Length Material/Finish SH (pg. 40) 120 GRN S (pg. 40) 240 GLV H178 (pg. 40) HDG TH (pg. 41) YZN K06 (pg. 41) SS4 SHA (pg. 41) SS6 S58 (pg. 42) AL M (pg. 42) H25 (pg. 43) H112 † (pg. 42) * Leave blank for no hole pattern Reference page 15 for general fitting and standard finish specifications. Strut Systems 16 Channel & Combinations Steel Alum. Type 304 SH B11 Channel, Combinations & Load Data B11 15/8” • Thickness: 12 Gauge (2.6 mm) • Standard lengths: 10’ (3.05 m) & 20’ (6.09 m) • Standard finishes: Plain, DURA GREEN™, Pre-Galvanized, Hot-Dipped Galvanized, Aluminum • Weight: 3.05 Lbs./Ft. (4.54 kg/m) (41.3) 3/8” (9.5) 3/8” (9.5) 7/8” 9/32” (22.2) (7.1) Y 31/4” X X (82.5) Note: Aluminum loading, for B11, can be determined by multiplying load data times a factor of 0.38 1.5190 (38.6) 13/16” Y (20.5) Section Properties Channel & Combinations Channel B11 B11A Weight X - X Axis Areas of Section lbs./ft. kg/m sq. in. cm2 3.059 (4.55) 6.119 (9.11) .900 (5.81) 1.800 (11.61) Momentof Inertia (I) in.4 cm4 Y - Y Axis Section Radius of Modulus (S) Gyration (r) in.3 cm3 1.1203 (46.63) .6472 (10.61) 6.3931(266.10) 1.9671 (32.24) in. cm 1.116 (2.83) 1.885 (4.79) Moment of Section Radius of Inertia (I) Modulus (S) Gyration (r) in.4 cm4 .4357 (18.14) .8714 (36.27) in.3 cm3 in. .5362 (8.79) 1.0725(17.58) cm .696 (1.77) .696 (1.77) Calculations of section properties are based on metal thicknesses as determined by the AISI Cold-Formed Steel Design Manual. Beam Loading Beam Span In. mm 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) 144 (3657) 168 (4267) 192 (4877) 216 (5486) 240 (6096) Channel Style B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A Uniform Load and Deflection Lbs. 5130 5130* 3488 5130* 2616 5130* 2093 5130* 1744 5130* 1495 4552 1308 3983 1163 3541 1046 3187 872 2656 747 2276 654 1992 581 1770 523 1593 kN In. mm (22.82) (22.82) (15.51) (22.82) (11.63) (22.82) (9.31) (22.82) (7.76) (22.82) (6.65) (20.25) (5.82) (17.72) (5.17) (15.75) (4.65) (14.17) (3.88) (11.81) (3.32) (10.12) (2.91) (8.86) (2.58) (7.87) (2.32) (7.08) .029 .005 .065 .017 .117 .040 .183 .079 .263 .136 .358 .191 .468 .250 .592 .317 .731 .391 1.053 .563 1.433 .766 1.871 1.001 2.368 1.267 2.924 1.564 (.73) (.13) (1.65) (.43) (2.97) (1.01) (4.65) (2.00) (6.68) (3.45) (9.09) (4.85) (11.89) (6.35) (15.03) (8.05) (18.57) (9.93) (26.74) (14.30) (36.40) (19.45) (47.52) (25.42) (60.15) (32.18) (74.27) (39.72) Uniform Load @ Deflection = 1/240 Span 1/360 Span Lbs. 5130 5130* 3488 5130* 2616 5130* 2093 5130* 1744 5130* 1460 4552 1118 3983 884 3541 716 3187 497 2656 365 2078 280 1591 221 1257 179 1018 kN (22.82) (22.82) (15.51) (22.82) (11.63) (22.82) (9.31) (22.82) (7.76) (22.82) (6.49) (20.25) (4.97) (17.72) (3.93) (15.75) (3.18) (14.17) (2.21) (11.81) (1.62) (9.24) (1.24) (7.08) (0.98) (5.59) (0.79) (4.53) Lbs. kN 5130 5130* 3488 5130* 2616 5130* 1908 5130* 1325 5130* 974 4552 745 3983 589 3353 477 2716 331 1886 243 1386 186 1061 147 838 119 679 (22.82) (22.82) (15.51) (22.82) (11.63) (22.82) (8.49) (22.82) (5.89) (22.82) (4.33) (20.25) (3.31) (17.72) (2.62) (14.91) (2.12) (12.08) (1.47) (8.39) (1.08) (6.16) (0.83) (4.72) (0.65) (3.73) (0.53) (3.02) Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) in accordance with MFMA, with adequate lateral bracing (see page 12 for further explanation). Actual yield point of cold rolled steel is 42,000 psi (289 MPa). To determine concentrated load capacity at mid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. *Failure determined by weld shear. Reference page 15 for general fitting and standard finish specifications. 17 Strut Systems B11 Beam & Column Loading Data Y 31/4” (82.5) 61/2” (165.1) Y X X X 31/4” (82.5) 15/8” (41.3) X Y Y 13/16” (82.5) (38.6) (41.3) B11B Wt. 6.10 Lbs./Ft. (9.08 kg/m) Wt. 6.10 Lbs./Ft. (9.08 kg/m) Column Loading Unbraced Height In. mm 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) 144 (3657) 168 (4267) 192 (4877) 216 (5486) 240 (6096) Channel Style Max. Column Loading K = .80 Loaded@ Loaded@ C.G. Slot Face Lbs. B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A B11 B11A 8190 17701 7311 17416 6214 17016 4988 16503 3816 15876 3063 15135 2564 14279 2213 13310 1953 12226 1591 9717 1347 7183 1167** 5499** 1026** 4345** 910** 3520** kN Lbs. kN (36.43) (78.74) (32.52) (77.47) (27.64) (75.69) (22.19) (73.41) (16.97) (70.62) (13.62) (67.32) (11.40) (63.51) (9.84) (59.20) (8.69) (54.38) (7.08) (43.22) (5.99) (31.95) (5.19) (24.46) (4.56) (19.33) (4.05) (15.66) 4477 8267 4183 8189 3783 8079 3279 7727 2444 6160 1897 4961 1532 4045 1273 3337 1081 2784 816 1990 642 1464 519 1121 429 885 360 717 (19.91) (36.77) (18.61) (36.42) (16.83) (35.94) (14.58) (34.37) (10.87) (27.40) (8.44) (22.07) (6.81) (17.99) (5.66) (14.84) (4.81) (12.38) (3.63) (8.85) (2.85) (6.51) (2.31) (4.98) (1.91) (3.93) (1.60) (3.19) Max. Column Loading (Loaded @ C.G.) K = .65 Lbs. 8446 17778 7838 17590 7053 17327 6140 16988 5146 16574 4133 16084 3398 15520 2886 14880 2514 14164 2011 12508 1687 10550 1459 8330 1285** 6582** 1148** 5331** kN (37.57) (79.08) (34.86) (78.24) (31.37) (77.07) (27.31) (75.56) (22.89) (73.72) (18.38) (71.54) (15.11) (69.03) (12.84) (66.19) (11.18) (63.00) (8.94) (55.64) (7.50) (46.93) (6.49) (37.05) (5.71) (29.28) (5.10) (23.71) K = 1.0 Lbs. 7783 17572 6503 17127 4988 16503 3595 15701 2790 14721 2291 13563 1953 12226 1708 10712 1522 9019 1251** 6257** 1058** 4597** 910** 3520** – – – – K = 1.2 kN (34.62) (78.16) (28.93) (76.18) (22.19) (73.41) (15.99) (69.84) (12.41) (65.48) (10.19) (60.33) (8.69) (54.38) (7.60) (47.65) (6.77) (40.12) (5.56) (27.83) (4.70) (20.45) (4.05) (15.66) – – – – **Where the slenderness ratio KL exceeds 200, and K = end fixity factor, L = actual length and r = radius of gyration. r Reference page 15 for general fitting and standard finish specifications. Strut Systems 18 Lbs. 7311 17416 5612 16774 3816 15876 2790 14721 2213 13310 1846 11642 1591 9717 1401 7725 1251** 6257** 1026** 4345** 859** 3192** – – – – – – kN (32.52) (77.47) (24.96) (74.61) (16.97) (70.62) (12.41) (65.48) (9.84) (59.20) (8.21) (51.78) (7.08) (43.22) (6.23) (34.36) (5.56) (27.83) (4.56) (19.33) (3.82) (14.20) – – – – – – Channel & Combinations 15/8” B11A 31/4” 1.5190 (20.5) B12 Channel & Combinations B12 • Thickness: 12 Gauge (2.6 mm) • Standard lengths: 10’ (3.05 m) & 20’ (6.09 m) • Standard finishes: Plain, DURA GREEN™, Pre-Galvanized, Hot-Dipped Galvanized, Aluminum • Weight: 2.47 Lbs./Ft. (3.67 kg/m) 15/8” (41.3) 3/8” (9.5) 3/8” (9.5) 7/8” 9/32” (22.2) (7.1) Y 27/16” X X (61.9) 1.1197 (28.4) Note: Aluminum loading, for B12, can be determined by multiplying load data times a factor of 0.38 Y 13/16” Channel & Combinations (20.5) Section Properties Channel B12 B12A X - X Axis Areas of Section Weight lbs./ft. kg/m sq. in. cm2 2.484 (3.70) 4.969 (7.40) .731 (4.71) 1.462 (9.43) Momentof Inertia (I) in.4 cm4 Y - Y Axis Section Radius of Modulus (S) Gyration (r) in.3 cm3 .5349 (22.26) .4061 (6.65) 2.9036(120.86) 1.1915 (19.52) in. Moment of Section Radius of Inertia (I) Modulus (S) Gyration (r) in.4 cm .856 (2.17) 1.409 (3.58) cm4 .3377 (14.06) .6756 (28.12) in.3 cm3 .4156 (6.81) .8315 (13.63) in. cm .680 (1.73) .680 (1.73) Calculations of section properties are based on metal thicknesses as determined by the AISI Cold-Formed Steel Design Manual. Y 27/16” (61.9) X Y 47/8” (123.8) 31/4” X X (82.5) 15/8” X (41.3) Y Y 13/16” (20.5) 15/8” 1.1199 27/16” (28.4) (61.9) (41.3) B12A B12B Wt. 4.94 Lbs./Ft. (7.35 kg/m) Wt. 4.94 Lbs./Ft. (7.35 kg/m) Reference page 15 for general fitting and standard finish specifications. 19 Strut Systems B12 Beam & Column Loading Data Beam Loading Beam Span mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Uniform Load @ Deflection = 1/240 Span 1/360 Span Uniform Load and Deflection Lbs. 3880 3880* 3273 3880* 2182 3880* 1636 3880* 1309 3847* 1091 3206 935 2748 818 2404 727 2137 655 1924 B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A kN In. mm (17.26) (17.26) .009 .001 .038 .008 .086 .028 .153 .067 .240 .130 .345 .188 .470 .255 .614 .334 .777 .422 .959 .521 (.23) (.02) (14.56) (17.26) (9.70) (17.26) (7.28) (17.26) (5.82) (17.11) (4.85) (14.26) (4.16) (12.22) (3.64) (10.69) (3.23) (9.50) (2.93) (8.56) Lbs. kN 3880 3880* 3273 3880* 2182 3880* 1636 3880* 1309 3847* 947 3206 696 2748 533 2404 421 2137 341 1844 (.96) (.20) (2.18) (.71) (3.88) (1.70) (6.09) (3.30) (8.76) (4.77) (11.94) (6.48) (15.59) (8.48) (19.73) (10.72) (24.36) (13.23) Lbs. (17.26) (17.26) (14.56) (17.26) (9.70) (17.26) (7.28) (17.26) (5.82) (17.11) (4.21) (14.26) (3.09) (12.22) (2.37) (10.69) (1.87) (9.50) (1.52) (8.20) 3880 3880* 3273 3880* 2182 3880* 1421 3880* 909 3847* 632 3206 464 2509 355 1921 281 1518 227 1229 kN (17.26) (17.26) (14.56) (17.26) (9.70) (17.26) (6.32) (17.26) (4.04) (17.11) (2.81) (14.26) (2.06) (11.16) (1.58) (8.54) (1.25) (6.75) (1.01) (5.47) Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) in accordance with MFMA, with adequate lateral bracing (see page 12 for further explanation). Actual yield point of cold rolled steel is 42,000 psi. To determine concentrated load capacity at mid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. *Failure determined by weld shear. Column Loading Unbraced Height In. Channel Style mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A B12 B12A Max. Column Loading K = .80 Loaded@ Loaded@ C.G. Slot Face Max. Column Loading (Loaded @ C.G.) K = .65 K = 1.0 K = 1.2 Lbs. kN Lbs. kN Lbs. kN Lbs. kN Lbs. kN 10140 20820 9244 20519 7933 20017 6386 19315 4785 18412 3717 17309 3052 16005 2600 14500 2271 12795 2019 10889 (45.10) (92.61) 4752 8023 4514 7956 4137 7844 3638 7688 2963 6941 2197 5334 1717 4176 1391 3328 1155 2692 977 2202 (21.14) (35.69) 10247 20854 9639 20655 8711 20324 7562 19861 6285 19265 4964 18536 3994 17675 3350 16682 2893 15556 2553 14298 (45.58) (92.76) 9965 20763 8629 20293 6786 19509 4785 18412 3523 17002 2806 15278 2345 13240 2019 10889 1773 8610 1577 6974 (44.32) (92.36) 9756 20694 7933 20017 5572 18889 3717 17309 2806 15278 2271 12795 1913 9884 1650 7567 1446 5979 1279** 4843** (43.40) (92.05) (41.12) (91.27) (35.29) (89.04) (28.40) (85.92) (21.28) (81.90) (16.53) (76.99) (13.57) (71.19) (11.56) (64.50) (10.10) (56.91) (8.98) (48.43) (20.08) (35.39) (18.40) (34.89) (16.18) (34.20) (13.18) (30.87) (9.77) (23.73) (7.64) (18.57) (6.19) (14.80) (5.14) (11.97) (4.34) (9.79) (42.87) (91.88) (35.75) (90.40) (33.64) (88.34) (27.96) (85.69) (22.08) (82.45) (17.76) (78.62) (14.90) (74.20) (12.87) (69.19) (11.35) (63.60) (38.38) (90.27) (30.18) (86.78) (21.28) (81.90) (15.67) (75.63) (12.48) (67.96) (10.43) (58.89) (8.98) (48.43) (7.88) (38.30) (7.01) (31.02) **Where the slenderness ratio KL exceeds 200, and K = end fixity factor, L = actual length and r = radius of gyration. r Reference page 15 for general fitting and standard finish specifications. Strut Systems 20 (35.29) (89.04) (24.78) (84.02) (16.53) (76.99) (12.48) (67.96) (10.10) (56.91) (8.51) (43.96) (7.34) (33.66) (6.43) (26.59) (5.69) (21.54) Channel & Combinations In. Channel Style B22 Channel B22 • Thickness: 12 Gauge (2.6 mm) • Standard lengths: 10’ (3.05 m) & 20’ (6.09 m) • Standard finishes: Plain, DURA GREEN™, Pre-Galvanized, Hot-Dipped Galvanized, Stainless Steel Type 304 or 316, Aluminum • Weight: 1.90 Lbs./Ft. (2.83 kg/m) 15/8” (41.3) 3/8” 3/8” (9.5) (9.5) 7/8” 9/32” (22.2) (7.1) Y 15/8” X X (41.3) .7252 Note: Aluminum loading, for B22 & B22A, can be determined by multiplying load data times a factor of 0.38 (18.4) Y 13/16” Channel & Combinations (20.5) Section Properties Channel B22 B22A B22X Weight X - X Axis Areas of Section lbs./ft. kg/m sq. in. cm2 1.910 3.820 6.649 .562 (3.62) 1.124 (7.25) 1.956 (12.62) (2.84) (5.69) (9.89) Momentof Inertia (I) in.4 cm4 Y - Y Axis Section Radius of Modulus (S) Gyration (r) in.3 cm3 .1912 (7.96) .2125 (3.48) .9732 (40.51) .5989 (9.81) 4.1484(172.67) 1.7019 (27.89) in. cm .583 (1.48) .931 (2.36) 1.456 (3.70) Moment of Section Radius of Inertia (I) Modulus (S) Gyration (r) in.4 cm4 .2399 (9.99) .4798 (19.97) 1.1023 (45.88) in.3 cm3 .2953 (4.84) .5905 (9.68) 1.2027 (19.71) in. cm .653 (1.66) .653 (1.66) .751 (1.91) Calculations of section properties are based on metal thicknesses as determined by the AISI Cold-Formed Steel Design Manual. Y 15/8” (41.3) 31/4” X X (82.5) Y 13/16” (20.5) B22A 15/8” Wt. 3.80 Lbs./Ft. (5.65 kg/m) (41.3) Reference page 15 for general fitting and standard finish specifications. 21 Strut Systems B22 Combinations 15/8” 1.3833 (35.1) 1.3540 (41.3) Y Y Y 31/4” 31/4” (82.5) X (82.5) X (82.5) Y (33.7) Y .725 15/8” (41.3) (18.4) (82.5) (82.5) (82.5) 1.3250 Y 31/4” 31/4” (41.3) (82.5) X X Y 15/8” 31/4” (41.3) 31/4” X X X (41.3) Y 31/4” X 15/8” 15/8” (34.4) B22A3 B22A4 B22AD3 B22B Wt. 5.70 Lbs./Ft. (8.48 kg/m) Wt. 7.60 Lbs./Ft. (11.31 kg/m) Wt. 5.70 Lbs./Ft. (8.48 kg/m) Wt. 3.80 Lbs./Ft. (5.65 kg/m) 27/16” (61.9) Y 15/8” (41.3) Y Y 31/4” X 31/4” (82.5) X (82.5) X 47/8” (123.8) X X X (48.9) 31/4” (41.3) Y 13/16” .8416 (20.5) 15/8” (82.5) (21.4) (41.3) B22B3 Wt. 5.70 Lbs./Ft. (8.48 kg/m) 15/8” (41.3) B22C B22C3 Wt. 3.80 Lbs./Ft. (5.65 kg/m) Wt. 5.70 Lbs./Ft. (8.48 kg/m) 27/16” 15/8” 2.467 (61.9) (62.7) 1.5813 (41.3) (40.2) Y Y Y 31/4” (82.5) X X X 47/8” (123.8) Y 31/4” X X (82.5) X X X Y .769 Y (19.5) .842 15/8” (21.4) (41.3) Y .769 Y (19.5) 47/8” (123.8) 13/16” 15/8” 15/8” (20.5) (41.3) (41.3) B22D B22D3 Wt. 3.80 Lbs./Ft. (5.65 kg/m) Wt. 5.70 Lbs./Ft. (8.48 kg/m) 15/8” (41.3) B22E B22E3 Wt. 3.80 Lbs./Ft. (5.65 kg/m) Wt. 5.70 Lbs./Ft. (8.48 kg/m) 27/16” (61.9) (31.3) (29.7) 1.730 1.730 Y (45.6) Y X 4” X (101.6) X Y .105 (2.6) Y 213/16” .105 4” (101.6) (71,3) .104 (2.6) 2” (50.8) 47/8” (123.8) (2.6) X X 1.795 (43.9) (43.9) X Y 1.231 1.168 .918 Y (23.3) B22LPL B22PL Wt. 2.90 Lbs./Ft. (4.31 kg/m) Wt. 3.35 Lbs./Ft. (4.98 kg/m) 1.835 B22X 7/16” (11.1) (46.6) Wt. 6.70 Lbs./Ft. (9.97 kg/m) Reference page 15 for general fitting and standard finish specifications. Strut Systems 22 Channel & Combinations 15/8” Y 1.9249 Y B22 Beam Loading Data Beam Loading Beam Span In. mm 12 (305) 18 (457) 24 (609) 30 (762) 36 (914) 42 (1067) Channel & Combinations 48 (1219) 54 (1371) 60 (1524) 66 (1676) 72 (1829) 78 (1981) 84 (2133) 90 (2286) 96 (2438) 102 (2591) 108 (2743) 114 (2895) 120 (3048) Channel Style B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X Uniform Load and Deflection Lbs. 2610 2610* 5790* 2269 2610* 5790* 1702 2610* 5790* 1361 2610* 5790* 1135 2610* 5790* 972 2610* 5790* 851 2405 5790* 756 2138 5790* 681 1924 5645 619 1749 5132 567 1603 4704 524 1480 4342 486 1374 4032 454 1283 3763 425 1202 3528 400 1132 3320 378 1069 3136 358 1013 2971 340 962 2822 kN In. mm (11.61) (11.61) (25.75) (10.09) (11.61) (25.75) (7.57) (11.61) (25.75) (6.05) (11.61) (25.75) (5.05) (11.61) (25.75) (4.32) (11.61) (25.75) (3.78) (10.70) (25.75) (3.36) (9.51) (25.75) (3.03) (8.56) (25.11) (2.75) (7.78) (22.83) (2.52) (7.13) (20.92) (2.33) (6.58) (19.31) (2.16) (6.11) (17.93) (2.02) (5.71) (16.74) (1.89) (5.35) (15.69) (1.78) (5.03) (14.77) (1.68) (4.75) (13.95) (1.59) (4.50) (13.21) (1.51) (4.28) (12.55) .014 .002 .001 .031 .007 .003 .056 .017 .008 .087 .033 .017 .126 .057 .029 .172 .091 .046 .224 .125 .068 .284 .158 .097 .351 .195 .130 .424 .236 .158 .505 .281 .188 .593 .330 .220 .687 .383 .255 .789 .440 .293 .898 .500 .334 1.013 .565 .377 1.136 .633 .422 1.266 .706 .471 1.403 .782 .521 (.35) (.05) (.02) (.79) (.18) (.07) (1.42) (.43) (.20) (2.21) (.84) (.73) (3.20) (1.45) (.73) (4.37) (2.31) (1.17) (5.69) (3.17) (1.73) (7.21) (4.01) (2.46) (8.91) (4.95) (3.30) (10.77) (5.99) (4.01) (12.83) (7.14) (4.77) (15.06) (8.38) (5.59) (17.45) (9.73) (6.48) (20.04) (11.17) (7.44) (22.81) (12.70) (8.48) (25.73) (14.35) (9.57) (28.85) (16.08) (10.72) (32.15) (17.93) (11.96) (35.63) (19.86) (13.23) Uniform Load @ Deflection = 1/240 Span 1/360 Span Lbs. 2610 2610* 5790* 2269 2610* 5790* 1702 2610* 5790* 1361 2610* 5790* 1135 2610* 5790* 972 2610* 5790* 758 2405 5790* 599 2138 5790* 485 1924 5645 401 1749 5132 337 1603 4704 287 1455 4342 248 1255 4032 216 1093 3763 190 961 3528 168 851 3320 150 759 3136 134 681 2971 121 615 2706 kN (11.61) (11.61) (25.75) (10.09) (11.61) (25.75) (7.57) (11.61) (25.75) (6.05) (11.61) (25.75) (5.05) (11.61) (25.75) (4.32) (11.61) (25.75) (3.37) (10.70) (25.75) (2.66) (9.51) (25.75) (2.16) (8.56) (25.11) (1.78) (7.78) (22.83) (1.50) (7.13) (20.92) (1.27) (6.47) (19.31) (1.10) (5.58) (17.93) (0.96) (4.86) (16.74) (0.84) (4.27) (15.69) (0.75) (3.78) (14.77) (0.67) (3.37) (13.95) (0.59) (3.03) (13.21) (0.54) (2.73) (12.04) Lbs. kN 2610 2610* 5790* 2269 2610* 5790* 1702 2610* 5790* 1294 2610* 5790* 899 2610* 5790* 660 2610* 5790* 505 2405 5790* 399 2024 5790* 323 1640 5645 267 1355 5132 225 1139 4704 191 970 4270 165 837 3682 144 729 3207 126 640 2819 112 567 2497 100 506 2227 90 454 1999 81 410 1804 (11.61) (11.61) (25.75) (10.09) (11.61) (25.75) (7.57) (11.61) (25.75) (5.75) (11.61) (25.75) (4.00) (11.61) (25.75) (2.93) (11.61) (25.75) (2.24) (10.70) (25.75) (1.77) (9.00) (25.75) (1.44) (7.29) (25.11) (1.19) (6.03) (22.83) (1.00) (5.06) (20.92) (0.85) (4.31) (18.99) (0.73) (3.72) (16.38) (0.64) (3.24) (14.26) (0.56) (2.85) (12.54) (0.50) (2.52) (11.11) (0.44) (2.25) (9.90) (0.40) (2,02) (8,89) (0.36) (1.82) (8.02) Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) in accordance with MFMA, with adequate lateral bracing (see page 12 for further explanation). Actual yield point of cold rolled steel is 42,000 psi. To determine concentrated load capacity at mid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. *Failure determined by weld shear. Reference page 15 for general fitting and standard finish specifications. 23 Strut Systems B22 Column Loading Data Column Loading Unbraced Height mm 12 (305) 18 (457) 24 (609) 30 (762) 36 (914) 42 (1067) 48 (1219) 54 (1371) 60 (1524) 66 (1676) 72 (1829) 78 (1981) 84 (2133) 90 (2286) 96 (2438) 102 (2591) 108 (2743) 114 (2895) 120 (3048) B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X B22 B22A B22X Max. Column Loading K = .80 Loaded@ Loaded@ C.G. Slot Face Max. Column Loading (Loaded @ C.G.) K = .65 Lbs. kN Lbs. kN Lbs. kN 10454 21625 46948 9950 21433 46531 9311 21164 45947 8582 20819 45198 7801 20397 44282 6998 19898 43198 6193 19322 41948 5392 18669 40530 4718 17940 38948 4202 17134 37198 3791 16251 35281 3456 15291 33197 3176 14255 30947 2936 13141 28529 2728 11951 25945 2545 10678 23182 2381 9524 20676 2234 8548 18558 2101 7715 16749 (46.50) (96.19) (208.83) (44.26) (95.34) (206.98) (41.42) (94.14) (204.38) (38.17) (92.61) (201.05) (34.70) (90.73) (196.97) (31.13) (88.51) (192.15) (27.55) (85.95) (186.59) (23.98) (83.04) (180.28) (20.99) (79.80) (173.25) (18.69) (76.21) (165.46) (16.86) (72.29) (156.94) (15.37) (68.02) (147.67) (14.13) (63.41) (137.66) (13.06) (58.45) (126.90) (16.58) (53.16) (115.41) (11.32) (47.50) (103.12) (10.59) (42.36) (91.97) (9.94) (38.02) (82.55) (9.34) (34.32) (74.50) 4276 7002 18975 4153 6959 18859 3993 6898 18693 3802 6821 18485 3589 6728 18233 3360 6620 17940 3118 6496 17604 2864 6263 16973 2631 5340 14471 2434 4587 12431 2264 3968 10753 2116 3456 9366 1984 3028 8206 1867 2667 7227 1761 2359 6393 1664 2093 5672 1575 1867 5059 1494 1675 4539 1418 1512 4097 (19.12) (31.14) (84.40) (18.47) (30.95) (83.90) (17.76) (30.68) (84.44) (16.91) (30.34) (82.22) (15.96) (29.93) (81.10) (14.94) (29.45) (79.80) (13.87) (28.89) (78.30) (12.74) (27.86) (75.50) (11.70) (23.75) (64.37) (10.83) (20.40) (55.29) (10.07) (17.65) (47.83) (9.41) (15.37) (41.66) (8.82) (13.47) (36.50) (8.30) (11.86) (32.15) (7.83) (10.49) (28.44) (7.40) (9.31) (25.23) (7.00) (8.30) (22.50) (6.64) (7.45) (20.19) (6.31) (6.72) (18.22) 10598 21677 47061 10253 21551 46787 9801 21373 46401 9268 21145 45906 8676 20866 45300 8048 20537 44586 7401 20157 43761 6746 19276 42825 6093 19244 41779 5441 18712 40624 4869 18129 39358 4412 17496 37984 4037 16812 36499 3724 16077 34903 3456 15291 33197 3225 14455 31382 3022 13568 29456 2842 12630 27420 2680 11642 25275 (47.14) (96.42) (209.34) (45.62) (95.86) (208.12) (43.60) (95.07) (206.40) (41.22) (94.06) (204.20) (38.59) (92.81) (201.50) (35.80) (91.33) (198.33) (32.92) (89.66) (194.57) (30.01) (87.74) (190.49) (27.10) (85.60) (185.84) (24.20) (83.23) (180.70) (21.66) (80.64) (175.07) (19.62) (77.82) (168.96) (17.96) (74.78) (162.35) (16.56) (71.51) (155.25) (15.37) (68.02) (147.67) (14.34) (64.30) (139.59) (13.44) (60.35) (131.03) (12.64) (56.18) (121.97) (11.92) (51.78) (112.43) K = 1.0 Lbs. kN 10222 (45.47) 21539 (95.81) 46761 (208.00) 9481 (42.17) 21239 (94.47) 46110 (205.11) 8582 (38.17) 20819 (92.61) 45198 (201.05) 7601 (33.81) 20279 (90.20) 44026 (195.84) 6595 (28.33) 19619 (87.27) 42593 (189.46) 5595 (24.89) 18840 (83.80) 40901 (181.94) 4718 (20.99) 17940 (79.80) 38948 (173.25) 4090 (18.19) 16920 (75.26) 36733 (163.39) 3616 (16.08) 15781 (70.20) 34260 (152.39) 3242 (14.42) 14521 (64.59) 31525 (140.23) 2936 (13.06) 13141 (58.45) 28529 (126.90) 2680 (11.92) 11642 (51.78) 25275 (112.43) 2461 (10.95) 10076 (44.82) 21875 (97.30) 2270 (10.10) 8778 (39.04) 19057 (84.77) 2101 (9.34) 7715 (34.32) 16749 (74.50) 1951 (8.68) 6834 (30.40) 14836 (65.99) 1816 (8.08) 6096 (27.11) 13234 (58.87) 1694 (7.53) 5471 (24.33) 11877 (52.83) 1583** (7.04) 4937 (21.96) 10718 (47.67) **Where the slenderness ratio KL exceeds 200, and K = end fixity factor, L = actual length and r = radius of gyration. r Reference page 15 for general fitting and standard finish specifications. Strut Systems 24 K = 1.2 Lbs. 9950 21433 46531 8955 21001 45593 7801 20397 44282 6595 19619 42593 5392 18669 40530 4444 17546 38092 3791 16251 35281 3310 14782 32092 2936 13141 28529 2634 11328 24593 2381 9524 20676 2166 8115 17617 1980 6998 15192 1816 6096 13234 1671 5357 11630 1542** 4746 10303 1426** 4233 9190 1322** 3799** 8247 1228** 3429** 7444 kN (44.26) (95.34) (206.98) (39.83) (93.42) (202.81) (3470) (9073) (196.97) (29.33) (87.27) (189.46) (23.98) (83.04) (180.28) (19.77) (78.05) (169.44) (16.86) (72.29) (156.94) (14.72) (65.75) (142.75) (13.06) (58.45) (126.90) (11.71) (50.39) (109.39) (10.59) (42.36) (91.97) (9.63) (36.10) (78.36) (8.81) (31.13) (67.58) (8.08) (27.11) (58.87) (7.43) (23.83) (51.73) (6.34) (21.11) (45.83) (68.60) (18.83) (40.88) (5.88) (16.90) (36.68) (5.46) (15.25) (33.11) Channel & Combinations In. Channel Style B24 Channel & Combinations B24 • Thickness: 14 Gauge (1.9 mm) • Standard lengths: 10’ (3.05 m) & 20’ (6.09 m) • Standard finishes: Plain, DURA GREEN™, Pre-Galvanized, Hot-Dipped Galvanized, Stainless Steel Type 304 or 316, Aluminum • Weight: 1.40 Lbs./Ft. (2.08 kg/m) 15/8” (41.3) 3/8” 3/8” (9.5) (9.5) 7/8” (22.2) 9/32” Y 15/8” Note: Aluminum loading, for B24, can be determined by multiplying load data times a factor of 0.38 (7.1) X (41.3) X .7304 (18.6) 13/16” Y Channel & Combinations (20.5) Section Properties Channel B24 B24A X - X Axis Areas of Section Weight lbs./ft. kg/m sq. in. cm2 1.442 (2.15) 2.884 (4.29) .424 (2.74) .848 (5.47) Momentof Inertia (I) in.4 cm4 Y - Y Axis Section Radius of Modulus (S) Gyration (r) in.3 cm3 .1494 (6.22) .1670 (2.74) .7514 (31.28) .4624 (7.58) in. cm .594 (1.51) .941 (2.39) Moment of Section Radius of Inertia (I) Modulus (S) Gyration (r) in.4 cm4 .1857 (7.73) .3713 (15.45) in.3 cm3 in. .2286 (3.75) .4570 (7.49) cm .662 (1.68) .662 (1.68) Calculations of section properties are based on metal thicknesses as determined by the AISI Cold-Formed Steel Design Manual. 15/8” (41.3) Y Y 31/4” Y (82.5) 31/4” X X X (82.5) X X X Y Y 15/8” (41.3) 13/16” (82.5) Y 15/8” (41.3) .730 13/16” (18.6) (20.5) 31/4” (20.5) 15/8” 15/8” (41.3) (41.3) 15/8” (41.3) B24A B24B B24C Wt. 2.80 Lbs./Ft. (4.16 kg/m) Wt. 2.80 Lbs./Ft. (4.16 kg/m) Wt. 2.80 Lbs./Ft. (4.16 kg/m) Reference page 15 for general fitting and standard finish specifications. 25 Strut Systems B24 Beam & Column Loading Data Beam Loading Beam Span mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Uniform Load @ Deflection = 1/240 Span 1/360 Span Uniform Load and Deflection Lbs. 1750 1750* 1379 1750* 919 1750* 689 1750* 551 1518 460 1265 394 1084 345 949 306 843 276 759 B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A kN In. mm (7.78) (7.78) .014 .002 .057 .014 .128 .048 .227 .115 .355 .195 .511 .281 .695 .383 .908 .500 1.149 .633 1.419 .782 (.35) (.05) (6.13) (7.78) (4.09) (7.78) (3.06) (7.78) (2.45) (6.75) (2.04) (5.63) (1.75) (4.82) (1.53) (4.22) (1.36) (3.75) (1.23) (3.37) Lbs. kN 1750 1750* 1379 1750* 919 1750* 607 1750* 389 1518 270 1265 198 990 152 758 120 599 97 485 (1.45) (.35) (3.25) (1.22) (5.76) (2.92) (9.02) (4.95) (12.98) (7.14) (17.65) (9.73) (23.06) (12.70) (29.18) (16.08) (36.04) (19.86) Lbs. 1750 1750* 1379 1750* 720 1750* 405 1750* 259 1294 180 898 132 660 101 505 80 399 65 323 (7.78) (7.78) (6.13) (7.78) (4.09) (7.78) (2.70) (7.78) (1.73) (6.75) (1.20) (5.63) (0.88) (4.40) (0.67) (3.37) (0.53) (2.66) (0.43) (2.16) kN (7.78) (7.78) (6.13) (7.78) (3.20) (7.78) (1.80) (7.78) (1.15) (5.75) (0.80) (3.99) (0.59) (2.93) (0.45) (2.24) (0.35) (1.77) (0.29) (1.44) Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) in accordance with MFMA, with adequate lateral bracing (see page 12 for further explanation). Actual yield point of cold rolled steel is 42,000 psi. To determine concentrated load capacity at mid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. *Failure determined by weld shear. Column Loading Unbraced Height In. mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Channel Style B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A B24 B24A Max. Column Loading K = .80 Loaded@ Loaded@ C.G. Slot Face Max. Column Loading (Loaded @ C.G.) K = .65 K = 1.0 K = 1.2 Lbs. kN Lbs. kN Lbs. kN Lbs. kN 6441 13212 5874 12993 5038 12627 4043 12115 3008 11456 2324 10651 1898 9700 1608 8602 1397 7358 1236 6024 (28.65) (58.77) 3077 4988 2896 4924 2619 4819 2272 4675 1873 4020 1562 3048 1340 2362 1175 1866 1046 1498 942 1216 (13.69) (22.19) 6509 13237 6124 13092 5535 12851 4800 12512 3978 12078 3123 11546 2502 10918 2089 10194 1796 9373 1578 8455 (28.95) (58.88) 6330 13171 5483 12828 4302 12256 3008 11456 2200 10427 1740 9169 1444 7683 1236 6024 1078 4760 953** 3856 (28.16) (58.59) (26.13) (57.79) (22.41) (56.17) (17.98) (53.89) (13.38) (50.96) (10.34) (47.38) (8.44) (43.15) (7.15) (38.26) (6.21) (32.73) (5.50) (26.79) (12.88) (21.90) (11.65) (21.43) (10.10) (20.79) (8.33) (17.88) (6.95) (13.56) (5.96) (10.50) (5.22) (8.30) (4.65) (6.66) (4.19) (5.41) (27.24) (58.23) (24.62) (57.16) (21.35) (55.65) (17.69) (53.72) (13.89) (51.36) (11.13) (48.56) (9.29) (45.34) (7.99) (41.69) (7.02) (37.61) (24.39) (57.06) (19.13) (54.52) (13.38) (50.96) (9.78) (46.38) (7.74) (40.78) (6.42) (34.17) (5.50) (26.79) (4.79) (21.17) (4.24) (17.15) **Where the slenderness ratio KL exceeds 200, and K = end fixity factor, L = actual length and r = radius of gyration. r Reference page 15 for general fitting and standard finish specifications. Strut Systems 26 Lbs. kN 6198 (27.57) 13121 (58.36) 5038 (22.41) 12627 (56.17) 3516 (15.64) 11804 (52.51) 2324 (10.34) 10651 (47.38) 1740 (7.74) 9169 (40.78) 1397 (6.21) 7358 (32.73) 1168 (5.19) 5464 (24.30) 1000 (4.45) 4184 (18.61) 870** (3.87) 3306 (14.70) 764** (3.40) 2677** (11.91) Channel & Combinations In. Channel Style B26 Channel & Combinations B26 • • • • Thickness: 16 Gauge (1.5 mm) Standard lengths: 10’ (3.05 m) & 20’ (6.09 m) Standard finishes: Plain, DURA GREEN™, Pre-Galvanized Weight: 1.12 Lbs./Ft. (1.66 kg/m) 15/8” (41.3) 3/8” (9.5) 3/8” (9.5) 7/8” (22.2) 9/32” 27/64” Y (7.1) (10.7) X 15/8” X (41.3) .7745 27/64” (19.7) (10.7) 13/16” Y Channel & Combinations (20.5) Section Properties Channel X - X Axis Areas of Section Weight sq. in. cm2 lbs./ft. kg/m B26 B26A 1.234 (1.84) 2.467 (3.67) .363 (2.34) .726 (4.68) Momentof Inertia (I) in.4 cm4 Section Radius of Modulus (S) Gyration (r) in.3 .1337 (5.57) .7086 (29.49) Y - Y Axis cm3 in. .1581 (2.59) .4361 (7.15) cm .607 (1.54) .988 (2.51) Moment of Section Radius of Inertia (I) Modulus (S) Gyration (r) in.4 cm4 in.3 .1564 (6.51) .3128 (13.02) cm3 in. .1925 (3.15) .3850 (6.31) cm .656 (1.67) .656 (1.67) Calculations of section properties are based on metal thicknesses as determined by the AISI Cold-Formed Steel Design Manual. Y 15/8” Y (41.3) (41.3) (41.3) 31/4” X Y 15/8” 15/8” X (82.5) 31/4” X (82.5) Y Y Y 13/16” .774 (20.5) (19.7) 15/8” (82.5) X X X 31/4” 13/16” (20.5) 15/8” (41.3) (41.3) (41.3) 15/8” B26A B26B B26C Wt. 2.24 Lbs./Ft. (3.33 kg/m) Wt. 2.24 Lbs./Ft. (3.33 kg/m) Wt. 2.24 Lbs./Ft. (3.33 kg/m) Reference page 15 for general fitting and standard finish specifications. 27 Strut Systems B26 Beam & Column Loading Data Beam Loading Beam Span mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Uniform Load @ Deflection = 1/240 Span 1/360 Span Uniform Load and Deflection Lbs. 1220 1220* 1163 1220* 775 1220* 581 1220* 465 1220* 388 1052 332 902 291 789 258 702 233 631 B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A kN In. mm (5.43) (5.43) .014 .001 .057 .012 .128 .040 .228 .096 .357 .188 .514 .281 .699 .383 .913 .500 1.156 .633 1.427 .782 (.35) (.02) (5.17) (5.43) (3.45) (5.43) (2.58) (5.43) (2.07) (5.43) (1.72) (4.68) (1.48) (4.01) (1.29) (3.51) (1.15) (3.12) (1.03) (2.17) Lbs. kN Lbs. 1220 (5,43) 1220* (5,43) 1163 (5,17) 1220* (5,43) 775 (3,45) 1220* (5,43) 509 (2,264) 1220* (5,43) 326 (1,45) 1220* (5,43) 226 (1,45) 1052 (4,68) 166 (0.74) 824 (3.66) 127 (0.56) 631 (2.81) 101 (0.45) 498 (2.21) 81 (0.36) 404 (1.80) (1.45) (.30) (3.25) (1.01) (5.79) (2.44) (9.07) (4.77) (13.05) (7.14) (17.75) (9.73) (23.19) (12.70) (29.36) (16.08) (36.24) (19.86) 1220 1220* 1163 1220* 603 1220* 339 1220* 217 1076 151 747 111 549 85 420 67 332 54 269 kN (5.43) (5.43) (5.17) (5.43) (2.68) (5.43) (1.51) (5.43) (0.96) (4.78) (0.96) (3.32) (0.49) (2.44) (0.38) (1.87) (0.30) (1.48) (0.24) (1.19) Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) in accordance with MFMA, with adequate lateral bracing (see page 12 for further explanation). Actual yield point of cold rolled steel is 42,000 psi. To determine concentrated load capacity at mid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. *Failure determined by weld shear. Column Loading Unbraced Height In. Channel Style mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A B26 B26A Max. Column Loading K = .80 Loaded@ Loaded@ C.G. Slot Face Max. Column Loading (Loaded @ C.G.) K = .65 K = 1.0 K = 1.2 Lbs. kN Lbs. kN Lbs. kN Lbs. kN 4002 8151 3740 8051 3336 7883 2828 7648 2251 7346 1705 6977 1358 6541 1129 6038 967 5467 847 4830 (17.80) (36.26) 2216 3630 2109 3591 1941 3528 1725 3441 1469 3066 1203 2385 1011 1884 871 1512 766 1231 684 1015 (9.86) (16.15) 4032 8163 3857 8096 3579 7986 3217 7831 2793 7631 2326 7388 1851 7100 1513 6767 1277 6391 1105 5970 (17.93) (36.31) 3952 8133 3554 7975 2962 7713 2251 7346 1603 6874 1233 6298 1003 5616 847 4830 734 3940 648 3192 (17.58) (36.18) (16.63) (35.81) (14.49) (35.06) (12.58) (34.02) (10.01) (32.67) (7.58) (31.03) (6.04) (29.09) (5.02) (26.86) (4.30) (24.32) (3.77) (21.48) (9.38) (15.97) (8.63) (15.69) (7.61) (15.30) (6.53) (13.64) (5.35) (10.61) (4.50) (8.38) (3.87) (6.72) (3.41) (5.47) (3.04) (4.51) (17.16) (36.01) (15.92) (35.52) (14.31) (34.83) (12.42) (33.94) (10.34) (32.86) (8.23) (31.58) (6.73) (30.10) (5.68) (28.43) (4.91) (26.55) (15.81) (35.47) (13.17) (34.31) (10.01) (32.67) (7.13) (30.58) (5.48) (28.01) (4.46) (24.98) (3.77) (21.48) (3.26) (17.52) (2.88) (14.20) **Where the slenderness ratio KL exceeds 200, and K = end fixity factor, L = actual length and r = radius of gyration. r Reference page 15 for general fitting and standard finish specifications. Strut Systems 28 Lbs. kN 3891 (17.31) 8109 (36.07) 3336 (14.84) 7883 (35.06) 2546 (11.32) 7505 (33.38) 1705 (7.58) 6977 (31.03) 1233 (5.48) 6298 (28.01) 967 (4.30) 5467 (24.32) 797 (3.54) 4486 (19.95) 680 (3.02) 3463 (15.40) 592** (2.63) 2736 (12.17) 523** (2.32) 2216** (9.86) Channel & Combinations In. Channel Style B32 Channel & Combinations B32 • Thickness: 12 Gauge (2.6 mm) • Standard lengths: 10’ (3.05 m) & 20’ (6.09 m) • Standard finishes: Plain, DURA GREEN™, Pre-Galvanized, Hot-Dipped Galvanized, Stainless Steel Type 304 • Weight: 1.70 Lbs./Ft. (2.53 kg/m) 15/8” (41.3) 3/8” 3/8” (9.5) (9.5) 7/8” (22.2) 9/32” Y 13/8” (7.1) X X (34.9) .6052 (15.4) Y 13/16” Channel & Combinations (20.5) Section Properties Channel B32 B32A X - X Axis Areas of Section Weight lbs./ft. kg/m sq. in. cm2 1.733 (2.58) 3.467 (5.16) .510 (3.29) 1.020 (6.58) Momentof Inertia (I) in.4 cm4 Section Radius of Modulus (S) Gyration (r) in.3 .1252 (5.21) .6238 (25.96) Y - Y Axis cm3 in. .1626 (2.67) .4537 (7.43) cm .496 (1.26) .782 (1.99) Moment of Section Radius of Inertia (I) Modulus (S) Gyration (r) in.4 cm4 .2098 (8.73) .4195 (17.46) in.3 cm3 in. .2582 (4.23) .5163 (8.46) cm .642 (1.63) .642 (1.63) Calculations of section properties are based on metal thicknesses as determined by the AISI Cold-Formed Steel Design Manual. 15/8” 15/8” (41.3) (41.3) Y 13/8” Y (34.9) X X Y X 23/4” 31/4” X (69.8) 31/4” X (82.5) (82.5) X Y Y (20.5) .687 .605 13/16” (15.4) 15/8” Y (17.4) 13/8” 13/8” (41.3) (34.9) (34.9) B32A B32B B32C Wt. 3.40 Lbs./Ft. (5.06 kg/m) Wt. 3.40 Lbs./Ft. (5.06 kg/m) Wt. 3.40 Lbs./Ft. (5.06 kg/m) Reference page 15 for general fitting and standard finish specifications. 29 Strut Systems B32 Beam & Column Loading Data Beam Loading Beam Span mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Uniform Load @ Deflection = 1/240 Span 1/360 Span Uniform Load and Deflection Lbs. 2210 2210* 1299 2210* 866 2210* 649 1817 520 1454 433 1211 371 1038 325 909 289 808 260 727 B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A kN In. mm (9.83) (9.83) .016 .003 .065 .022 .147 .076 .262 .148 .410 .231 .590 .333 .803 .453 1.049 .591 1.327 .749 1.639 .924 (.40) (.07) (5.78) (9.83) (3.85) (9.83) (2.89) (8.08) (2.31) (6.47) (1.92) (5.39) (1.65) (4.62) (1.44) (4.04) (1.28) (3.59) (1.15) (3.23) Lbs. kN 2210 2210* 1299 2210* 866 2210* 495 1817 317 1454 220 1092 162 802 124 614 98 485 79 393 (1.65) (.56) (3.73) (1.93) (6.65) (3.76) (10.41) (5.87) (14.98) (8.46) (20.39) (11.50) (26.64) (15.01) (33.70) (19.02) (41.63) (23.47) Lbs. 2210 2210* 1299 2210* 587 2210* 330 1638 211 1048 147 728 108 535 83 410 65 324 53 262 (9.83) (9.83) (5.78) (9.83) (3.85) (9.83) (2.20) (8.08) (1.41) (6.47) (0.98) (4.86) (0.72) (3.57) (0.55) (2.73) (0.43) (2.16) (0.35) (1.75) kN (9.83) (9.83) (5.78) (9.83) (2.61) (9.83) (1.47) (7.28) (0.94) (4.66) (0.65) (3.24) (0.48) (2.38) (0.37) (1.82) (0.29) (1.44) (0.23) (1.16) Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) in accordance with MFMA, with adequate lateral bracing (see page 12 for further explanation). Actual yield point of cold rolled steel is 42,000 psi. To determine concentrated load capacity at mid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. *Failure determined by weld shear. Column Loading Unbraced Height In. mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Channel Style B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A B32 B32A Max. Column Loading K = .80 Loaded@ Loaded@ C.G. Slot Face Max. Column Loading (Loaded @ C.G.) K = .65 Lbs. kN Lbs. kN Lbs. kN 10278 21320 9104 20806 7640 19950 6151 18751 4778 17210 3870 15326 3243 13100 2774 10525 2403 8316 1993 6736 (4.572) (94.83) 4036 6557 3732 6431 3323 6228 2877 5954 2435 4692 2089 3448 1817 2609 1594 2014 1407 1592 1221 1289 (17.95) (29.17) 10432 21378 9600 21039 8479 20474 7265 19682 6060 18665 4923 17421 4114 15951 3531 14256 3083 12334 2723 10203 (46.40) (95.09) (40.49) (92.55) (33.98) (88.74) (27.36) (83.41) (21.25) (76.55) (17.21) (68.17) (14.42) (58.27) (12.34) (46.82) (10.69) (36.99) (8.86) (29.96) (16.60) (28.60) (14.78) (27.70) (12.80) (26.48) (10.83) (20.87) (9.29) (15.34) (8.08) (11.60) (7.09) (8.96) (6.26) (7.08) (5.43) (5.73) (42.70) (93.58) (37.71) (91.07) (32.31) (87.55) (26.95) (83.02) (21.90) (77.49) (18.30) (70.95) (15.70) (63.41) (13.71) (54.86) (12.11) (45.38) K = 1.0 Lbs. 10035 21224 8387 20421 6520 19083 4778 17210 3693 14801 2994 11858 2489 8798 1993 6736 1574** 5322 1275** 4311 K = 1.2 kN (44.64) (94.41) (37.31) (90.84) (29.00) (84.88) (21.25) (76.55) (16.43) (65.84) (13.32) (52.75) (11.07) (39.13) (8.86) (29.96) (7.00) (23.67) (5.67) (19.17) **Where the slenderness ratio KL exceeds 200, and K = end fixity factor, L = actual length and r = radius of gyration. r Reference page 15 for general fitting and standard finish specifications. Strut Systems 30 Lbs. kN 9753 (43.38) 21106 (93.88) 7640 (33.98) 19950 (88.74) 5425 (24.13) 18023 (80.17) 3870 (17.21) 15326 (68.17) 2994 (13.32) 11858 (52.75) 2403 (10.68) 8316 (36.99) 1807** (8.04) 6110 (27.18) 1384** (6.15) 4678 (20.81) 1093** (4.86) 3696** (16.44) 886** (3.94) 2994** (13.32) Channel & Combinations In. Channel Style B42 Channel & Combinations B42 • Thickness: 12 Gauge (2.6 mm) • Standard lengths: 10’ (3.05 m) & 20’ (6.09 m) • Standard finishes: Plain, DURA GREEN™, Pre-Galvanized, Hot-Dipped Galvanized, Stainless Steel Type 304 • Weight: 1.44 Lbs./Ft. (2.14 kg/m) Note: Also available in 14 gauge (1.9mm) material as B44 15/8” (41.3) 3/8” 3/8” 7/8” (9.5) (9.5) (22.2) 9/32” Y 1” (7.1) X X (25.4) .4226 (10.7) Y 13/16” Channel & Combinations (20.5) Section Properties Channel Areas of Section Weight lbs./ft. kg/m B42 B42A X - X Axis Momentof Inertia (I) sq. in. cm2 1.468 (2.18) 2.936 (4.37) .432 (2.79) .864 (5.57) in.4 cm4 .0554 (2.31) .2689 (11.19) Y - Y Axis Section Radius of Modulus (S) Gyration (r) in.3 cm3 .0968 (1.59) .2689 (4.41) in. Moment of Section Radius of Inertia (I) Modulus (S) Gyration (r) in.4 cm .358 (.91) .558 (1.42) cm4 in.3 .1645 (6.85) .3292 (13.70) cm3 .2025 (3.32) .4052 (6.64) in. cm .617 (1.57) .617 (1.57) Calculations of section properties are based on metal thicknesses as determined by the AISI Cold-Formed Steel Design Manual. Y Y 1” (25.4) 2” (50.8) X X 15/8” Y (41.3) 13/16” (20.5) 31/4” (82.5) X X Y 15/8” (41.3) .428 (10.9) 1” (25.4) B42A B42B Wt. 2.88 Lbs./Ft. (4.28 kg/m) Wt. 2.88 Lbs./Ft. (4.28 kg/m) Reference page 15 for general fitting and standard finish specifications. 31 Strut Systems B42 Beam & Column Loading Data Beam Loading Beam Span mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Uniform Load @ Deflection = 1/240 Span 1/360 Span Uniform Load and Deflection Lbs. 1538 1590* 769 1590* 513 1428 384 1071 308 857 256 714 220 612 192 535 171 476 154 428 B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A kN In. mm (6.84) (7.07) .022 .005 .088 .038 .198 .114 .352 .203 .550 .318 .792 .457 1.079 .623 1.409 .813 1.783 1.029 2.202 1.271 (.56) (.13) (3.42) (7.07) (2.28) (6.35) (1.71) (4.76) (1.37) (3.81) (1.14) (3.17) (0.98) (2.72) (0.85) (2.38) (0.76) (2.12) (0.68) (1.90) Lbs. kN 1538 1590* 769 1590* 388 1428 218 1053 140 674 97 468 71 344 55 263 43 208 35 168 (2.23) (.96) (5.03) (2.89) (8.94) (5.15) (13.97) (8.08) (20.11) (11.61) (27.40) (15.82) (35.79) (20.65) (45.29) (26.13) (55.93) (32.28) Lbs. 1538 1590* 582 1590* 259 1248 145 702 93 449 65 312 48 229 36 176 29 139 23 112 (6.84) (7.07) (3.42) (7.07) (1.72) (6.35) (0.97) (4.68) (0.62) (3.00) (0.43) (2.08) (0.31) (1.53) (0.24) (1.17) (0.19) (0.92) (0.15) (0.75) kN (6.84) (7.07) (2.59) (7.07) (1.15) (5.55) (0.64) (3.12) (0.41) (2.00) (0.29) (1.39) (0.21) (1.02) (0.16) (0.78) (0.13) (0.62) (0.10) (0.50) Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) in accordance with MFMA, with adequate lateral bracing (see page 12 for further explanation). Actual yield point of cold rolled steel is 42,000 psi. To determine concentrated load capacity at mid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. *Failure determined by weld shear. Column Loading Unbraced Height In. mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Channel Style Max. Column Loading K = .80 Loaded@ Loaded@ C.G. Slot Face Lbs. B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A B42 B42A kN 9138 (40.65) 21094 (93.83) 8137 (36.19) 19757 (87.88) 7050 (31.36) 18094 (80.48) 5405 (24.04) 16139 (71.79) 3512 (15.62) 13906 (61.86) 2439 (10.85) 11387 (50.65) 1792 (7.97) 8645 (38.45) 1372** (6.10) 6619 (29.44) 1084** (4.82) 5230 (23.26) 878** (3.90) 4236 (18.84) Lbs. kN 3493 5834 3145 5585 2722 5237 2227 4818 1718 4352 1351 3856 1087 3332 891 2873 743 2495 628 2182 (15.54) (25.95) (13.99) (24.84) (12.11) (23.29) (9.90) (21.43) (7.64) (19.36) (6.01) (17.15) (4.83) (14.82) (3.96) (12.78) (3.30) (11.10) (2.79) (9.70) Max. Column Loading (Loaded @ C.G.) K = .65 Lbs. kN 9283 (41.23) 21304 (94.76) 8540 (37.99) 20299 (90.29) 7657 (34.06) 19067 (84.81) 6786 (30.18) 17632 (78.43) 5272 (23.45) 16008 (71.21) 3694 (16.43) 14200 (64.16) 2714 (12.07) 12206 (54.29) 2078 (9.24) 10012 (44.53) 1642 (7.30) 7922 (35.24) 1330** (5.91) 6417 (28.54) K = 1.0 Lbs. 8916 20793 7589 18964 5925 16654 3512 13906 2247 10710 1561** 7531 1147** 5533 878** 4236 – 3347 – 2711** K = 1.2 kN (39.66) (92.49) (33.76) (84.35) (26.35) (74.08) (15.62) (61.86) (9.99) (47.64) (6.94) (33.50) (5.10) (24.61) (3.90) (18.84) – (14.89) – (12.06) **Where the slenderness ratio KL exceeds 200, and K = end fixity factor, L = actual length and r = radius of gyration. r Reference page 15 for general fitting and standard finish specifications. Strut Systems 32 Lbs. kN 8670 (38.56) 20469 (91.05) 7050 (31.36) 18094 (80.48) 4335 (19.28) 15057 (66.98) 2439 (10.85) 11387 (50.65) 1561** (6.94) 7531 (33.50) 1084** (4.82) 5230 (23.26) 796** (3.54) 3842 (17.09) – – 2942** (13.08) – – 2324** (10.34) – – 1883** (8.37) Channel & Combinations In. Channel Style B52 Channel & Combinations B52 • Thickness: 12 Gauge (2.6 mm) • Standard lengths: 10’ (3.05 m) & 20’ (6.09 m) • Standard finishes: Plain, DURA GREEN™, Pre-Galvanized, Stainless Steel Type 304 or 316, Hot-Dipped Galvanized • Weight: 1.27 Lbs./Ft. (1.89 kg/m) 15/8” (41.3) 3/8” (9.5) 3/8” (9.5) 7/8” 9/32” (22.2) 13/16” (20.5) (7.1) Y X X Y .3366 13/16” (8.5) Channel & Combinations (20.5) Section Properties Channel X - X Axis Areas of Section Weight lbs./ft. kg/m B52 B52A Momentof Inertia (I) sq. in. cm2 1.313 (1.95) 2.627 (3.91) .386 (2.49) .773 (4.99) in.4 cm4 .0320 (1.33) .1517 (6.31) Y - Y Axis Section Radius of Modulus (S) Gyration (r) in.3 cm3 .0673 (1.10) .1868 (3.06) in. cm .288 (.73) .443 (1.13) Moment of Section Radius of Inertia (I) Modulus (S) Gyration (r) in.4 cm4 in.3 .1404 (5.84) .2809 (11.69) cm3 in. .1728 (2.83) .3457 (5.67) cm .603 (1.53) .603 (1.53) Calculations of section properties are based on metal thicknesses as determined by the AISI Cold-Formed Steel Design Manual. 1.241 (31.5) Y Y 13/16” 27/16” (20.5) X 31/4” (61.9) X X Y X 15/8” X 15/8” (41.3) (41.3) X Y Y Y 13/16” 13/16” (20.5) (82.5) 13/16” (20.5) 15/8” 15/8” (41.3) (20.5) 15/8” (41.3) (41.3) B52A B52B3 B52B4 Wt. 2.54 Lbs./Ft. (3.78 kg/m) Wt. 3.81 Lbs./Ft. (5.67 kg/m) Wt. 5.08 Lbs./Ft. (7.56 kg/m) Reference page 15 for general fitting and standard finish specifications. 33 Strut Systems B52 Beam & Column Loading Data Beam Loading Beam Span In. mm (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Uniform Load @ Deflection = 1/240 Span 1/360 Span Uniform Load and Deflection B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A Lbs. kN In. mm 1079 1270* 539 1270* 360 1013 270 759 216 608 180 506 154 434 135 380 120 338 108 304 (4.80) (5.65) .026 .006 .106 .052 .240 .141 .427 .250 .667 .391 .960 .563 1.307 .766 1.707 1.001 2.160 1.267 2.667 1.564 (.66) (.15) (2.40) (5.65) (1.60) (4.50) (1.20) (3.37) (0.96) (2.70) (0.80) (.225) (0.68) (1.93) (0.60) (1.69) (0.53) (1.50) (0.48) (.135) Lbs. kN 1079 1270* 506 1270* 225 1013 126 607 81 388 56 270 41 198 32 152 25 120 20 97 (2.69) (1.32) (6.09) (3.58) (10.84) (6.35) (16.94) (9.93) (24.38) (14.30) (33.20) (19.45) (43.36) (25.42) (54.86) (32.18) (67.74) (39.72) Lbs. 1079 1270* 337 1270* 150 719 84 404 54 259 37 180 28 132 21 101 17 80 13 65 (4.80) (5.65) (2.25) (5.65) (1.00) (4.50) (0.56) (2.70) (0.36) (1.72) (0.25) (1.20) (0.18) (0.88) (0.14) (0.67) (0.11) (0.53) (0.89) (0.43) kN (4.80) (5.65) (1.50) (5.65) (0.67) (3.20) (0.37) (1.80) (0.24) (1.15) (0.16) (0.80) (0.12) (0.59) (0.93) (0.45) (0.75) (0.35) (0.58) (0.29) Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) in accordance with MFMA, with adequate lateral bracing (see page 12 for further explanation). Actual yield point of cold rolled steel is 42,000 psi. To determine concentrated load capacity at mid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. *Failure determined by weld shear. Column Loading Unbraced Height In. Channel Style mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Max. Column Loading K = .80 Loaded@ Loaded@ C.G. Slot Face Lbs. B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A B52 B52A kN 8407 (37.36) 19160 (85.23) 7519 (33.44) 17444 (77.59) 5397 (24.01) 15275 (67.94) 3178 (14.13) 12692 (56.46) 2034 (9.05) 9683 (43.07) 1412** (6.28) 6780 (30.16) 1038** (4.62) 4981 (22.15) 794** (3.53) 3814 (16.96) 3013 (13.40) 2441** (10.86) Lbs. kN 3162 5290 2755 4955 2152 4496 1560 3963 1159 3383 891 2799 704 2337 570 1973 470 1684 394 1452 (14.06) (23.53) (12.25) (22.04) (9.57) (20.00) (6.94) (17.63) (5.15) (15.05) (3.96) (12.45) (3.13) (10.39) (2.53) (8.77) (2.09) (7.49) (1.75) (6.46) Max. Column Loading (Loaded @ C.G.) K = .65 Lbs. kN 8543 (38.00) 19425 (86.41) 7879 (35.05) 18144 (80.71) 6653 (29.59) 16547 (73.60) 4785 (21.28) 14667 (65.24) 3081 (13.70) 12516 (55.67) 2139 (9.51) 10084 (44.85) 1572 (6.99) 7545 (33.56) 1203** (5.35) 5777 (25.70) 951** (4.23) 4564 (20.30) 770** (3.42) 3697 (16.44) K = 1.0 Lbs. 8205 18777 6521 16412 3616 13376 2034 9683 1302** 6248 904** 4339 664** 3188 – 2441** – 1928** – 1562** kN (36.50) (83.52) (29.01) (73.00) (16.08) (59.50) (9.05) (43.07) (5.79) (27.79) (4.02) (19.30) (2.95) (14.18) – (10.86) – (8.57) – (6.95) **Where the slenderness ratio KL exceeds 200, and K = end fixity factor, L = actual length and r = radius of gyration. r Reference page 15 for general fitting and standard finish specifications. Strut Systems 34 K = 1.2 Lbs. kN 7989 (35.54) 18363 (81.68) 5397 (24.01) 15275 (67.94) 2511 (11.17) 11243 (50.01) 1412** (6.28) 6780 (30.16) 904** (4.02) 4339 (19.30) – – 3013 (13.42) – – 2214** (9.85) – – 1695** (7.54) – – 1339** (5.95) – – – – Channel & Combinations 12 Channel Style B54 Channel & Combinations B54 • Thickness: 14 Gauge (1.9 mm) • Standard lengths: 10’ (3.05 m) & 20’ (6.09 m) • Standard finishes: Plain, DURA GREEN™, Pre-Galvanized, Hot-Dipped Galvanized, Stainless Steel Type 304 or 316, Aluminum • Weight: .97 Lbs./Ft. (1.44 kg/m) 15/8” 3/8” (41.3) (9.5) 7/8” 3/8” (9.5) (22.2) (20.5) Channel & Combinations Y .3422 13/16” lbs./ft. kg/m B54 B54A X - X Axis Areas of Section 1.016 (1.51) 2.032 (3.02) sq. in. cm2 .299 (1.93) .598 (3.86) Momentof Inertia (I) in.4 (8.7) (20.5) Section Properties Weight (7.1) X X Note: Aluminum loading, for B54 & B54A, can be determined by multiplying load data times a factor of 0.38 Channel 9/32” Y 13/16” cm4 .0263 (1.09) .1226 (5.10) Y - Y Axis Section Radius of Modulus (S) Gyration (r) in.3 cm3 in. .0560 (.92) .1510 (2.47) cm .297 (.75) .453 (1.15) Moment of Section Radius of Inertia (I) Modulus (S) Gyration (r) in.4 cm4 .1106 (4.60) .2212 (9.12) in.3 cm3 .1361 (2.23) .2722 (4.46) in. cm .608 (1.55) .608 (1.55) Calculations of section properties are based on metal thicknesses as determined by the AISI Cold-Formed Steel Design Manual. 1.241 (31.5) Y Y 15/8” X Y 27/17” X (41.3) 31/4” X (41.3) X X X Y Y Y 13/16” 13/16” (20.5) (82.5) 15/8” (20.5) (41.3) 13/16” 13/16” (20.5) (41.3) 15/8” (20.5) 15/8” 15/8” (41.3) (41.3) B54A B54B3 B54B4 Wt. 1.94 Lbs./Ft. (2.89 kg/m) Wt. 2.91 Lbs./Ft. (4.33 kg/m) Wt. 3.88 Lbs./Ft. (5.77 kg/m) Reference page 15 for general fitting and standard finish specifications. 35 Strut Systems B54 Beam & Column Loading Data Beam Loading Beam Span In. mm (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Uniform Load @ Deflection = 1/240 Span 1/360 Span Uniform Load and Deflection Lbs. 870 870* 465 870* 310 832 233 624 186 499 155 416 133 357 116 312 103 277 93 250 B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A kN In. mm Lbs. (3.87) (3.87) .027 .005 .108 .043 .243 .141 .432 .250 .676 .391 .973 .563 1.324 .766 1.730 1.001 2.189 1.267 2.703 1.564 (.68) (.13) 870 870* 430 870* 191 832 108 499 69 319 48 222 35 163 27 125 21 98 17 80 (2.07) (3.87) (1.38) (3.70) (1.03) (2.77) (0.83) (2.22) (0.69) (1.85) (0.59) (1.59) (0.51) (1.39) (0.46) (1.23) (0.41) (1.11) (2.74) (1.09) (6.17) (3.58) (10.97) (6.35) (17.17) (9.93) (24.71) (14.30) (33.63) (19.45) (43.94) (25.42) (55.60) (32.18) (68.65) (39.72) kN Lbs. (3.87) (3.87) (1.91) (3.87) (0.85) (3.70) (0.48) (2.22) (0.31) (1.42) (0.21) (0.99) (0.15) (0.72) (0.12) (0.55) (0.93) (0.43) (0.75) (0.35) 870 870* 287 870* 127 591 72 332 46 213 32 148 23 109 18 83 14 66 11 53 kN (3.87) (3.87) (1.27) (3.87) (0.56) (2.63) (0.32) (1.48) (0.20) (0.95) (0.14) (0.66) (0.10) (0.48) (0.80) (0.37) (0.62) (0.29) (0.49) (0.23) Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) in accordance with MFMA, with adequate lateral bracing (see page 12 for further explanation). Actual yield point of cold rolled steel is 42,000 psi. To determine concentrated load capacity at mid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. *Failure determined by weld shear. Column Loading Unbraced Height In. Channel Style mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Max. Column Loading K = .80 Loaded@ Loaded@ C.G. Slot Face Lbs. B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A B54 B54A kN 6186 (27.51) 12763 (56.77) 5464 (24.30) 12135 (53.98) 4300 (19.13) 11087 (49.32) 2703 (12.02) 9620 (42.79) 1730 (7.69) 7734 (34.40) 1201 (5.34) 5571 (24.78) 883** (3.93) 4093 (18.20) 676** (3.01) 3134 (13.94) 534** (2..37) 2476 (11.01) – – 2006** (8.92) Lbs. kN 2586 4060 2254 3857 1816 3549 1341 3169 995 2745 763 2291 603 1913 487 1616 401 1380 336 1190 (11.50) (18.06) (10.02) (17.16) (8.08) (15.79) (5.96) (14.09) (4.42) (12.21) (3.39) (10.19) (2.68) (8.51) (2.16) (7.19) (1.78) (6.14) (1.49) (5.29) Max. Column Loading (Loaded @ C.G.) K = .65 Lbs. kN 6284 (27.95) 12835 (57.09) 5763 (25.63) 12420 (55.25) 5043 (22.43) 11728 (52.17) 3920 (17.44) 10759 (47.86) 2621 (11.66) 9514 (42.32) 1820 (8.09) 7992 (35.50) 1337 (5.95) 6200 (27.58) 1024** (4.55) 4747 (21.11) 809** (3.60) 3751 (16.68) 655** (2.91) 3038 (13.51) K = 1.0 Lbs. kN 6032 (26.83) 12645 (56.25) 4968 (22.10) 11663 (51.88) 3076 (13.68) 10026 (44.60) 1730 (7.69) 7734 (34.40) 1107** (4.92) 5134 (22.84) 769** (3.42) 3566 (15.86) 565** (2.51) 2620 (11.65) – – 2006** (8.92) – – 1585** (7.05) – – 1284** (5.71) **Where the slenderness ratio KL exceeds 200, and K = end fixity factor, L = actual length and r = radius of gyration. r Reference page 15 for general fitting and standard finish specifications. Strut Systems 36 K = 1.2 Lbs. kN 5857 (26.05) 12501 (55.61) 4300 (19.13) 11087 (49.32) 2136 (9.50) 8729 (38.83) 1201 (5.34) 5571 (24.78) 769** (3.42) 3566 (15.86) 534** (2.37) 2476 (11.01) – – 1819** (8.09) – – 1393** (6.19) – – 1100** (4.89) – – – – Channel & Combinations 12 Channel Style B56 Channel & Combinations B56 • Thickness: 16 Gauge (1.5 mm) • Standard lengths: 10’ (3.05 m) & 20’ (6.09 m) • Standard finishes: Plain, DURA GREEN™, Pre-Galvanized, Hot-Dipped Galvanized • Weight: .85 Lbs./Ft. (1.26 kg/m) 15/8” 3/8” (41.3) (9.5) 7/8” 3/8” (9.5) (22.2) 9/32” Y 13/16” (20.5) X (7.1) .3706 X (9.4) Y 27/64” Channel & Combinations (10.7) Section Properties Channel (20.5) X - X Axis Areas of Section Weight lbs./ft. kg/m B56 B56A 13/16” sq. in. cm2 .894 (1.33) 1.789 (2.66) .263 (1.70) .526 (3.39) Momentof Inertia (I) in.4 cm4 .0241 (1.00) .1205 (5.02) Y - Y Axis Section Radius of Modulus (S) Gyration (r) in.3 cm3 in. .0546 (.89) .1484 (2.43) Moment of Section Radius of Inertia (I) Modulus (S) Gyration (r) in.4 cm .303 (.77) .479 (1.22) cm4 .0966 (4.02) .1931 (8.04) in.3 cm3 in. .1189 (1.95) .2377 (3.89) cm .606 (1.54) .606 (1.54) Calculations of section properties are based on metal thicknesses as determined by the AISI Cold-Formed Steel Design Manual. Y 31/4” Y Y 15/8” X X (41.3) 27/16” (82.5) X (61.9) X X X 13/16” (20.6) Y 13/16” (20.6) 15/8” 1.207 Y Y (30.7) 13/16” 15/8” (41.3) 13/16” (20.6) 15/8” (41.3) (20.6) 15/8” (41.3) B56A B56B3 B56B4 Wt. 1.70 Lbs./Ft. (2.53 kg/m) Wt. 2.55 Lbs./Ft. (3.79 kg/m) Wt. 3.40 Lbs./Ft. (5.06 kg/m) (41.3) Reference page 15 for general fitting and standard finish specifications. 37 Strut Systems B56 Beam & Column Loading Data Beam Loading Beam Span In. mm (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Uniform Load @ Deflection = 1/240 Span 1/360 Span Uniform Load and Deflection Lbs. 610 610* 405 610* 270 610* 202 530 162 424 135 353 116 303 101 265 90 236 81 212 B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A kN In. mm Lbs. (2.73) (2.71) .027 .004 .109 .035 .245 .121 .435 .250 .680 .391 .980 .563 1.334 .766 1.742 1.001 2.205 1.267 2.722 1.564 (.68) (.10) 610 610* 372 610* 165 610* 93 423 59 271 41 188 30 138 23 106 18 84 15 68 (1.80) (2.71) (1.20) (2.71) (0.90) (2.36) (0.72) (1.88) (0.60) (1.57) (0.51) (1.35) (0.45) (1.18) (0.40) (1.05) (0.36) (0.94) (2.77) (.89) (6.22) (3.07) (11.05) (6.35) (17.27) (9.93) (24.89) (14.30) (33.88) (19.45) (44.24) (25.42) (56.01) (32.18) (69.14) (39.72) kN Lbs. (2.71) (2.71) (1.65) (2.71) (0.73) (2.71) (0.41) (1.88) (0.26) (1.20) (0.18) (0.83) (0.13) (0.61) (0.10) (0.47) (0.80) (0.37) (0.67) (0.30) 610 610* 248 610* 110 502 62 282 40 181 28 125 20 92 15 71 12 56 10 45 kN (2.71) (2.71) (1.10) (2.71) (0.49) (2.23) (0.27) (1.70) (0.18) (0.80) (0.12) (0.55) (0.89) (0.41) (0.67) (0.31) (0.53) (0.25) (0.44) (0.20) Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) in accordance with MFMA, with adequate lateral bracing (see page 12 for further explanation). Actual yield point of cold rolled steel is 42,000 psi. To determine concentrated load capacity at mid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. *Failure determined by weld shear. Column Loading Unbraced Height In. Channel Style mm 12 (305) 24 (609) 36 (914) 48 (1219) 60 (1524) 72 (1829) 84 (2133) 96 (2438) 108 (2743) 120 (3048) Max. Column Loading K = .80 Loaded@ Loaded@ C.G. Slot Face Lbs. B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A B56 B56A kN 4968 (22.10) 10237 (45.53) 4367 (19.42) 9762 (43.42) 3572 (15.89) 8969 (39.89) 2335 (10.38) 7860 (34.96) 1495 (6.65) 6434 (28.62) 1038 (4.62) 4731 (21.04) 763** (3.39) 3476 (15.46) 584** (2.60) 2661 (11.84) 461** (2.05) 2103 (9.35) – – 1703** (7.57) Lbs. kN 2182 3365 1903 3202 1557 2955 1164 2649 862 2307 661 1937 522 1619 422 1368 348 1169 291 1008 (9.70) (14.97) (8.46) (14.24) (6.92) (13.14) (5.18) (11.78) (3.83) (10.26) (2.94) (8.61) (2.32) (7.20) (1.88) (6.08) (1.55) (5.20) (1.29) (4.48) Max. Column Loading (Loaded @ C.G.) K = .65 Lbs. kN 5044 (22.44) 10291 (45.77) 4624 (20.57) 9977 (44.38) 4034 (17.94) 9454 (42.05) 3290 (14.63) 8722 (38.80) 2264 (10.07) 7780 (34.61) 1572 (6.99) 6629 (29.49) 1155 (5.14) 5269 (23.44) 884** (3.93) 4031 (17.93) 699** (3.11) 3185 (14.17) 566** (2.42) 2580 (11.47) K = 1.0 Lbs. kN 4845 (21.55) 10148 (45.14) 3985 (17.72) 9405 (41.83) 2658 (11.82) 8167 (36.33) 1495 (6.65) 6434 (28.62) 957 (4.26) 4360 (19.39) 664** (2.95) 3028 (13.47) 488** (2.17) 2224 (9.89) – – 1703** (7.57) – – 1346** (5.99) – – 1090** (4.85) **Where the slenderness ratio KL exceeds 200, and K = end fixity factor, L = actual length and r = radius of gyration. r Reference page 15 for general fitting and standard finish specifications. Strut Systems 38 K = 1.2 Lbs. kN 4702 (20.91) 10039 (44.65) 3572 (15.89) 8969 (39.89) 1845 (8.21) 7186 (31.96) 1038 (4.62) 4731 (21.04) 664** (2.95) 3028 (13.47) 461** (2.05) 2103 (9.35) – – 1545** (6.87) – – 1183** (5.26) – – 934** (4.15) – – – – Channel & Combinations 12 Channel Style Telescoping Channel BTS22TH • • • • • Can be secured at any point of system Order BTS22TH & B22TH separately Thickness: 12 Gauge (2.6 mm) Standard lengths: 10’ (3.05 m) Standard finishes: DURA GREEN™, Yellow Zinc Dichromate, Hot-Dipped Galvanized Slip Load Data Resistance to slip* 3600 lbs. Resistance to slip* 700 lbs. Channel & Combinations 1/4” thick 2-hole fitting with (2) 1/2” bolts & channel nuts. Typical of many standard fittings. 1/2” bolt & nut *With a safety factor of 3 BTS22TH Telescoping Strut Fits over all 15/8” x 15/8” channels 9/16” holes on 17/8” centers 12 gauge material thickness Cy 7/8” Section Properties Weight Area Channel 2 lbs./ft. BTS22TH 1.934 In Cx X-X Axis Ix Sx In In4 In3 rx In 0.4578 1.0009 0.2525 0.2523 0.7426 Cy Y-Y Axis Iy Sy ry In In4 In In3 Y 17/8” X X Cx CL 0.9375 0.2757 0.2941 0.7761 Y 17/8” Section properties are based on nominal metal thickness, and overall dimensions. B22TH Three Hole Strut 9/16” holes on 17/8” centers 12 gauge material thickness Section Properties Weight Area Channel 2 lbs./ft. B22TH 1.760 In Cy 7/8” Cx X-X Axis Ix Sx rx Cy Y-Y Axis Iy Sy ry In In4 In In In4 In In3 0.3863 0.8245 0.1596 0.1936 0.6400 In3 Y 15/8” X X Cx CL 0.8125 0.1719 0.2116 0.6642 Y 15/8” Section properties are based on nominal metal thickness, and overall dimensions. Combination of BTS22TH & B22TH Cy 7/8” Section Properties X-X Axis Y-Y Axis Ix Sx rx Cy Iy Sy ry Channel Weight Area Cx Combination lbs./ft. In2 In In4 In3 In In In4 In3 In BTS22TH/B22TH 3.597 0.8474 0.9773 0.4126 0.4222 0.6978 0.9375 0.4476 0.4774 0.7268 Section properties are based on nominal metal thickness, and overall dimensions. Y 17/8” X X Cx CL Y 17/8” Reference page 15 for general fitting and standard finish specifications. 39 Strut Systems Telescoping Channel Beam Loading Data B22TH Beam Load Data x-x Axis Beam Span Allowable Load Resulting Deflection Allowable Load @ Deflection=1/240 Span in lbs* in Lbs. kN 12 24 36 48 60 72 84 96 108 120 2225 1610 1071 800 637 528 449 390 344 306 0.015 0.061 0.136 0.243 0.379 0.546 0.743 0.970 1.228 1.516 3225 1610 1071 658 417 286 206 153 116 90 (14.34) (7.16) (4.76) (2.92) (1.85) (1.27) (0.91) (0.68) (0.51) (0.40) Beam Span B22TH BTS22TH Beam Load Data x-x Axis Allowable Load Resulting Deflection Allowable Load @ Deflection=1/240 Span in lbs* in Lbs. kN 12 24 36 48 60 72 84 96 108 120 4203 2099 1396 1044 831 689 587 510 450 401 0.012 0.050 0.112 0.200 0.312 0.450 0.612 0.799 1.012 1.249 4203 2099 1396 1044 664 456 330 248 190 149 (18.69) (9.33) (6.21) (4.64) (2.95) (2.03) (1.48) (1.10) (0.84) (0.66) Beam Span BTS22TH BTS22TH & B22TH Telescoping Members of Equal Length Beam Load Data x-x Axis Beam Span Allowable Load Resulting Deflection Allowable Load @ Deflection=1/240 Span in lbs* in Lbs. kN 12 24 36 48 60 72 84 96 108 120 7033 3511 2335 1745 1389 1151 980 851 749 668 0.013 0.051 0.115 0.205 0.320 0.460 0.627 0.819 1.036 1.279 7033 3511 2335 1705 1082 742 536 401 307 239 (31.28) (15.62) (10.38) (7.58) (4.81) (3.30) (2.38) (1.78) (1.36) (1.06) Beam Span BTS22TH & B22TH *Based on simple beam condition using an allowable design stress of 25,000 psi (172 MPa) with adequate lateral bracing (see page 12 for further explanation). To determine concentrated load capacity at mid span, multiply uniform load by 0.5 and corresponding deflection by 0.8. Reference page 15 for general fitting and standard finish specifications. Strut Systems 40 Channel & Combinations Beam Span Channel Hole Patterns B11SH thru B56SH SH Type Channel • For beam loads use 90% of Channel Loading Chart Height H Part No. B11SH B12SH B22SH B24SH B26SH B32SH B42SH B52SH B54SH B56SH Thickness 12 Ga. (2.6) 12 Ga. (2.6) 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) 12 Ga. (2.6) 12 Ga. (2.6) 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) Weight In. mm Lbs./Ft. kg/m 31/4” (82.5) (61.9) 2.97 2.39 1.82 1.34 1.07 1.62 1.36 1.19 .91 .80 (4.42) 27/16” 15/8” 15/8” 15/8” 13/8” 1” 13/16” 13/16” 13/16” (41.3) (41.3) (41.3) (34.9) (25.4) (20.6) (20.6) (20.6) (3.55) (2.71) (1.99) 2” (50.8) Typ. (1.59) (2.41) 9/16” (14.3) x 11/8” Slots (28.6) (2.02) H (1.77) (1.35) (1.19) B11S thru B56S Channel & Combinations S Type Channel • For beam loads use 90% of Channel Loading Chart Height H Part No. B11S B12S B22S B24S B26S B32S B42S B52S B54S B56S Thickness 12 Ga. (2.6) 12 Ga. (2.6) 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) 12 Ga. (2.6) 12 Ga. (2.6) 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) Weight In. mm Lbs./Ft. kg/m 31/4” 27/16” 15/8” 15/8” 15/8” 13/8” 1” 13/16” 13/16” 13/16” (82.5) 2.94 2.36 1.79 1.32 1.06 1.59 1.33 1.16 .89 .79 (4.37) (61.9) (41.3) (41.3) (41.3) (34.9) (25.4) (20.6) (20.6) (20.6) (3.51) 4” (101.6) Typ. (2.66) (1.96) (1.58) (2.36) 13/32” x 3” Slots (10.3) (76.2) (1.98) H (1.72) (1.32) (1.17) B11H17/8 thru B56H17/8 H17/8 Type Channel • For beam loads use 90% of Channel Loading Chart Height H Part No. Thickness B11H17/8 B12H17/8 B22H17/8 B24H17/8 B26H17/8 B32H17/8 B42H17/8 B52H17/8 B54H17/8 B56H17/8 12 Ga. (2.6) 12 Ga. (2.6) 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) 12 Ga. (2.6) 12 Ga. (2.6) 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) Weight In. mm Lbs./Ft. kg/m 31/4” 27/16” 15/8” 15/8” 15/8” 13/8” 1” 13/16” 13/16” 13/16” (82.5) 3.00 2.42 1.85 1.36 1.09 1.65 1.39 1.22 .93 .82 (4.46) (61.9) (41.3) (41.3) (41.3) (34.9) (25.4) (20.6) (20.6) (20.6) (3.60) (2.75) (2.02) 17/8” (47.6) Typ. (1.62) (2.45) 9/16” Dia. Holes (14.3) (2.07) H (1.81) (1.38) (1.22) Reference page 15 for general fitting and standard finish specifications. 41 Strut Systems Channel Hole Patterns B22TH TH Type Channel 9/16” • For beam loads use 90% of Channel Loading Chart Height H Part No. B22TH Thickness 12 Ga. (2.6) Dia. Holes (14.3) Weight In. mm Lbs./Ft. kg/m 15/8” (41.3) 1.76 (2.62) 17/8” Typ. (47.6) 15/16” (23.8) H 13/16” (20.6) B11KO6 thru B56KO6 KO6 Type Knockout Channel • For beam loads use 90% of Channel Loading Chart Thickness B11KO6 B12KO6 B22KO6 B24KO6 B26KO6 B32KO6 B42KO6 B52KO6 B54KO6 B56KO6 12 Ga. (2.6) 12 Ga. (2.6) 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) 12 Ga. (2.6) 12 Ga. (2.6) 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) Weight In. mm Lbs./Ft. kg/m 31/4” 27/16” 15/8” 15/8” 15/8” 13/8” 1” 13/16” 13/16” 13/16” (82.5) 3.05 2.47 1.90 1.40 1.12 1.70 1.44 1.27 .97 .85 (4.54) (61.9) (41.3) (41.3) (41.3) (34.9) (25.4) (20.6) (20.6) (20.6) Channel & Combinations Height H Part No. (3.67) 6” Typ. (2.83) (152.4) (2.08) (1.66) 3” Typ. (2.53) (76.2) (2.14) (1.89) 7/8” (22.2) H (1.44) (1.26) B22SHA Back to Back SH Type Channel 9/16” (14.3) • For beam loads use 90% of Channel Loading Chart Height H Part No. Thickness (28.6) Weight In. mm Lbs./Ft. kg/m B22SHA 12 Ga. (2.6) 31/4” (82.5) 3.64 (5.42) B52SHA 12 Ga. (2.6) 15/8” (41.3) 2.38 (1.77) 14 Ga. (1.9) 15/8” (41.3) 1.82 (1.35) B54SHA x 13/8” Slots 2” Typ. (50.8) H Reference page 15 for general fitting and standard finish specifications. Strut Systems 42 Dia. K.O. Channel Hole Patterns B11S58 thru B56S58 S58 Type Channel • For beam loads use 90% of Channel Loading Chart Height H Part No. B11S58 B12S58 B22S58 B24S58 B26S58 B32S58 B42S58 B52S58 B54S58 B56S58 Thickness 12 Ga. (2.6) 12 Ga. (2.6) 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) 12 Ga. (2.6) 12 Ga. (2.6) 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) In. mm Lbs./Ft. kg/m 31/4” 27/16” 15/8” 15/8” 15/8” 13/8” 1” 13/16” 13/16” 13/16” (82.5) 2.94 2.36 1.79 1.32 1.06 1.59 1.33 1.16 .89 .79 (4.37) (61.9) (41.3) (41.3) (41.3) (34.9) (25.4) (20.6) (20.6) (20.6) 13/8” (34.9) Typ. Weight (3.51) (2.66) 11/16” (1.96) (17.5) 11/16” x 25/8” (17.5) x (66.7) (1.58) (2.36) (1.98) Slots H (1.72) (1.32) (1.17) Channel & Combinations B22M thru B54M M (Marine Rung) Type Channel • For beam loads use 90% of Channel Loading Chart Height H Part No. B22M B24M B32M B42M B44M B52M B54M Thickness 12 14 12 12 14 12 14 Ga. (2.6) Ga. (1.9) Ga. (2.6) Ga. (2.6) Ga. (1.9) Ga. (2.6) Ga. (1.9) Weight In. mm Lbs./Ft. kg/m 15/8” 15/8” 13/8” 1” 1” 13/16” 13/16” (41.3) 1.79 1.32 1.59 1.33 0.98 1.16 .89 (2.66) (41.3) (34.9) (25.4) (25.4) (20.6) (20.6) 1” (25.4) (1.96) 1/4” x 11/16” (6.3) x (17.5) (2.36) (1.98) 1/2” (38.1) 1/2” (1.46) (1.72) (38.1) Slots 6” (152.4) (1.32) H B22H25 thru B56H25 H25 Type Channel • For beam loads use 90% of Channel Loading Chart Height H Part No. B22H25 B24H25 B26H25 B32H25 B42H25 B52H25 B54H25 B56H25 Thickness 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) 12 Ga. (2.6) 12 Ga. (2.6) 12 Ga. (2.6) 14 Ga. (1.9) 16 Ga. (1.5) Weight In. mm Lbs./Ft. kg/m 15/8” 15/8” 15/8” 13/8” 1” 13/16” 13/16” 13/16” (41.3) 1.85 1.36 1.09 1.65 1.39 1.22 .93 .82 (2.75) (41.3) (41.3) (34.9) (25.4) (20.6) (20.6) (20.6) (2.02) 2” (1.62) (50.8) (2.45) (2.07) 1” (1.81) (25.4) 9/32” Dia. Holes (7.1) (1.38) (1.22) H Reference page 15 for general fitting and standard finish specifications. 43 Strut Systems Channel Closure Strips B217-20 Snap Closure Strip for All 15/8” (41.3) Wide Channels • • • • • 17/16” (36.5) Refer to Raceway Fill Chart pages 231-232 Material: 20 Gauge (.9) Standard finishes: GRN, GALV, YZN Standard length: 120” (3.05m) Wt./CFT 36 Lbs. (16.3 kg) 19/32” 1/2” (15.1) (12.7) B217P Plastic Snap Closure Strip for All 15/8” (41.3) Wide Channels • • • • Refer to Raceway Fill Chart pages 231-232 Standard finishes: Green (GRN) or Gray (GRY) Plastic Standard length: 120” (3.05m) Wt./CFT 9.2 Lbs. (4.2 kg) 17/16” (36.5) B217-24 Snap Closure Strip for All 15/8” (41.3) Wide Channels • • • • • • 113/32” Refer to Raceway Fill Chart pages 231-232 For use with 7 or fewer conductors no larger than #12 AWG Material: 24 Gauge (.6) Standard finishes: GRN, GALV, YZN Standard length: 120” (3.05m) Wt./CFT 28 Lbs. (12.7 kg) (35.7) 15/32” 9/32” (11.9) (7.1) Reference page 15 for general fitting and standard finish specifications. Strut Systems 44 Channel & Combinations 5/8” (15.9)