PCT WO 861 01642 A1

advertisement

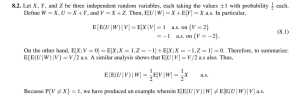

PCT WORLD INTELLECTUAL PROPERTY ORGANIZATION International Bureau INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT) (51) International Patent Classification4 : (11) International Publication Number: WO 861 01642 4 HOlM 4/90,4/96 A1 (43) International Publication Date: 13 March 1986 (13.03.86) so, 3000 Coimbra (PT). JAMIESON, Keith, Roderick [GB/GB]; St. Catherines College, Oxford OX1 3UJ (22) International Filing Date: 6 September 1985 (06.09.85) (GB). HAMNETT, Andrew [GB/GB]; 66 Margaret Road, Headington, Oxford OX3 8NQ (GB). MANO8422546 (31) Priority Application Numbers: HAFUN, Ramasamy [IN/GB]; 52 William Street, 8507185 New Marston, Oxford OX3 OER (GB). (32) Priority Dates: 6 September 1984 (06.09.84) (74) Agent- NEVILLE, Peter, Warwick; Patent Department, National Research Development Corporation, 20 March 1985 (20.03.85) 101 Newington Causeway, London SE1 6BU (GB). (21) International Application Number: (33) Priority Country: PCT/GB85/00400 GB (81) Designated States: DE (European patent), FR (Euro(71) Applicant f o r all designated States except US): NApean patent), GB (European patent), JP, SE (Euroi pean patent), US. TIONAL RESEARCH DEVELOPMENT CORPORATION [GB/GB]; 101 Newington Causeway, London Published SE1 6BU (GB). With international search report. Before the expiration of the time limit for amending the (72) Inventors; and claims and to be republished in the event of the receipt (75) Inventors/Applicants @or US onryl :GOODENOUGH, of amendments. John, Bannister TUS/GBl; 31 Linton Road, Oxford OX2.6UL (GB). SHUKLA, Ashok, Kumar -[IN/IN]; Solid State & Structural Chemistry Unit, Indian Institute of Science, Bangalore 560012 (IN). SILVA PALITEIRO, Carlos, Antonio da [c/PT Rua J;Cidade de St Clara da California No. 77-3DT0, Monte Formo. . (54) Title: ELECTRODE FOR REDUCING OXYGEN (57) Abstract An electrode for reducing oxygen has a substrate of low-ash carbon, such as coconut shells converted to charcoal. The substrate is loaded with a catalyst such as (i) platinum phtalocyanine or (ii) lead-ruthenium oxide. In case (ii), to make the electrode, lead ions are adsorbed onto the substrate, which is then treated with a solution of ruthenium (VI) oxide, to precipitate the catalyst on the substrate. FOR THE PURPOSES OFnVFOMATION ONLY Codes used to identify Statesparty to the PCT on the front pages ofpamphletspublishing international applications under the PCT. AT Austria AU Australia BB Barbados BE Belgium BG Bulgaria BR Brazil CF CG CH CM DE DK FI FR Central African Republic Congo Switzerland Cameroon Germany, Federal Republic of Denmark Finland France GA Gabon GB United Kingdom HU Hungary IT Italy Japan Democratic People's Republic of Korea KR Republic of Korea LI Liechtenstein LK SriLanka LU Luxembourg M C Monaco M G Madagascar M L Mali JP KE' MR Mauritania MW Malawi Netherlands Norway . Romania Sudan Sweden Senegal Soviet Union TD Chad TG Togo US United States of America NL NO RO SD SE SN SU WO 86/01642 - 1 - ELECTRODE FOR REDUCING OXYGEN T h i s i n v e n t i o n relates t o a n e l e c t r o d e f o r reducing oxygen, t o a f u e l c e l l i n c l u d i n g such an e l e c t r o d e , t o a method of reducing oxygen a t such a n e l e c t r o d e , and t o a method of making c e r t a i n such e l e c t r o d e s . 05 According t o t h e p r e s e n t i n v e n t i o n , a n e l e c t r o d e f o r reducing oxygen comprises a s u b s t r a t e which is an e l e c t r o n i c conductor c a p a b l e of reducing elemental oxygen t o water y i e l d i n g n o t more t h a n 5% ( p r e f e r a b l y n o t more t h a n I%, more p r e f e r a b l y n o t more t h a n 0.1%) hydrogen peroxide, t o which s u b s t r a t e i s a t t a c h e d a 10 c a t a l y s t which can reduce e l e m e n t a l oxygen t o water y i e l d i n g n o t more t h a n 5%, ( p r e f e r a b l y n o t more t h a n I%, more p r e f e r a b l y n o t more t h a n 0.1%) hydrogen peroxide when used a t c a t h o d i c p o t e n t i a l s of -300 mV a g a i n s t t h e Hg/HgO e l e c t r o d e i n a l k a l i n e o r non-alkaline s o ht i o n . 15 A preferred. s u i t a b l e s u b s t r a t e is carbon of an ash c o n t e n t less t h a n 0.1%, p r e f e r a b l y less t h a n 0.05%, p r e f e r a b l y n o t more t h a n 0.01%. An example of suchaa carbon i s 'coconut carbon', which is d e r i v e d from coconut s h e l l s by c o n v e r t i n g t h e s e t o charcoal., washing and comminuting t h e c h a r c o a l , and exposing t h e 20 comminuted charcoal. t o gas, p r e f e r a b l y f i r s t carbon d i o x i d e and, Another example is carbon which 2 i s of amorphous t y p e and h a s a s u r f a c e area of a t least 200 m / g , p r e f e r a b l y , a f t e r w a r d s , ammonia. a mean p a r t i c l e s i z e i n t h e range 5 nm t o 50 nm, and an a p p a r e n t 3 d e n s i t y of 80 t o 110 kg/m , which may be t r e a t e d b y comminuting i t 25 and exposing i t t o gas a t e l e v a t e d temperature. Preferably t h e carbon b e f o r e t h e treatment h a s a s u r f a c e area of n o t more 2 t h a n 300 m /g. P r e f e r a b l y t h e carbon b e f o r e t h e t r e a t m e n t h a s a pH below 7, The carbon may b e exposed t o only carbon d i o x i d e , f o r example a t 800C t o lOOOC, p r e f e r a b l y f o r 40 t o 90 minutes, 30 such as 9OOC f o r 1 hour. P r e f e r r e d s u i t a b l e c a t a l y s t s are: (i) macrocyclic d e r i v a t i v e s of t r a n s i t i o n metals o r of B-metals (i.e. Cu, Ag, Au, Zn, Cd, Hg, In, T1, Sn, Pb, Sb o r B i ) f o r example platinum phthalocyanine, and - WO 84101642 - 2 (ii) oxides containing ruthenium, f o r example Pb2+yRu206+x where 0 6 x 4 1 o r Pb2,xBixRu206+y where x i s from 0 t o 2 and y is- from 0 t o 1. L C a t a l y s t loadings in case ( i ) are 1 t o 15%by weight of t h e 05 s u b s t r a t e , p r e f e r a b l y 2 t o 12%. * H i t h e r t o , e f f o r t s i n t h e a r t of reducing oxygen a t an e l e c t r o d e have been d i r e c t e d mainly towards minimising o r circumv e n t i n g t h e harmful e f f e c t s of hydrogen peroxide which is evolved a t the e l e c t r o d e . 10 It has n o t h i t h e r t o been attempted t o select e l e c t r o d e materials on t h e b a s i s of t h e i r l o w production of hydrogen peroxide, except f o r a t t e m p t s t o i n h i b i t hydrogen peroxide e v o l u t i o n by gold- plating carbon. The i n v e n t i o n extends t o a f u e l c e l l i n c l u d i n g an e l e c t r o d e as set f o r t h above. 15 The i n v e n t i o n a l s o provides a method of reducing oxygen, comprising c o n t a c t i n g elemental oxygen w i t h a s o u r c e of hydrogen (such a s a hydroxide s o l u t i o n ) a t an e l e c t r o d e as set f o r t h above and applying t o t h e e l e c t r o d e a p o t e n t i a l of from 0.1 t o -0.2 v o l t s w i t h r e s p e c t t o t h e Hg/HgO e l e c t r o d e . For example, where t h e c a t a l y s t i s platinum phthalocyanine with an 20 e l e c t r o l y t e of 6M KOH, t h e p o t e n t i a l is p r e f e r a b l y from 0.1 t o -0.2 V, and where t h e c a t a l y s t is l e a d -r u t h e n a t e (nominally Ru 0 ) w i t h an e l e c t r o l y t e of 1M KOH, t h e p o t e n t i a l i s Pb2+y 2 6+x p r e f e r a b l y 0.2 t o -0.2 V; a t more p o s i t i v e p o t e n t i a l s , no a p p r e c i a b l e r e d u c t i o n c u r r e n t flows; 25 c u r r e n t s become excessive. a t more n e g a t i v e p o t e n t i a l s , A l t e r n a t i v e l y , t h e source of hydrogen may be an a c i d o r n e u t r a l aqueous s o l u t i o n . According t o a n o t h e r a s p e c t , t h e i n v e n t i o n provides a method of making an e l e c t r o d e as s e t f o r t h above, wherein t h e c a t a l y s t i s an oxide c o n t a i n i n g ruthenium and a n o t h e r metal, comprising adsorb- 30 i n g i o n s of t h e o t h e r m e t a l o n t o t h e s u b s t r a t e and t r e a t i n g t h e s u b s t r a t e w i t h a s o l u t i o n of ruthenium 0x0-anion complex (nominally ruthenium ( V I ) o x i d e ) , whereby t h e d e s i r e d c a t a l y t i c oxide is p r e c i p i t a t e d on, and is a t t a c h e d t o , t h e s u b s t r a t e . The i n v e n t i o n extends t o t h e e l e c t r o d e so made, and t o f u e l cells, methods of . 35 reducing oxygen etc. using it. For u s e in a l k a l i n e media, t h e WO 86101642 - 3 'coconut' carbon i s p r e f e r r e d , p r e f e r a b l y w i t h c a t a l y s t s of case ( i i ) above. For u s e in a c i d media, t h e amorphous carbon i s p r e f e r r e d , p r e f e r a b l y w i t h c a t a l y s t s of case ( i ) above o r e.g. . 05 thiocyanate. The i n v e n t i o n w i l l now be d e s c r i b e d by way of example. In t h e accompanying drawings, F i g u r e s 1 and 2 show t h e performance of e l e c t r o d e s according t o Examples 1 and 2 of t h e i n v e n t i o n respect i v e l y , compared w i t h o t h e r e l e c t r o d e s , under v a r i o u s c o n d i t i o n s . SUBSTRATE PREPARATION EXAMPLE A porous carbon e l e c t r o d e i s made u t i l i s i n g coconut s h e l l 10 charcoal. Active coconut s h e l l c h a r c o a l o b t a i n e d from T a l a u l i c a r carbons (P) Ltd., Londa, I n d i a , w a s Subjected t o r e p e a t e d g r a v i t y s e p a r a t i o n w i t h s a t u r a t e d calcium c h l o r i d e s o l u t i o n t o remove any d e n s e r i n g r e d i e n t s and t h e n s u b j e c t e d t o r e p e a t e d 'Soxhlet' 15 treat- ment w i t h a z e o t r o p i c h y d r o c h l o r i c a c i d and t h e n r e p e a t e d l y washed i n t h e 'Soxhlet' i t s e l f w i t h d i s t i l l e d water. After drying in a vacuum oven a t 15OoC, t h e a s h c o n t e n t of t h i s carbon was found t o be about 0.03%. This c h a r c o a l w a s s u b j e c t e d t o mechanical g r i n d i n g and s i e v i n g through a 400 mesh s i e v e . 20 T h i s carbon w a s g a s - a c t i v a t e d by h e a t i n g i n a carbon- dioxide atmosphere a t 900°C f o r 4 h o u r s and then i n an ammonia atmosphere a l s o a t 9OO*C f o r 4 hours. Gasa c t i v a t i o n w a s chosen i n s t e a d of f u r t h e r g r i n d i n g , t o minimise agglomeration. 25 S u b s t r a t e s f o r e l e c t r o d e s were prepared by h o t (1 40°C) -2 p r e s s i n g , under 0.05 tonne cm , t h i s gas- activated carbon mixed w i t h 20% by weight p o l y e t h y l e n e powder ( 5 micron average p a r t i c l e s i z e ) onto an expanded platinum mesh (0.06 mm diameter w i r e , a t 0.3 mm c e n t r e s ) . 2 The BET s u r f a c e area of such a s u b s t r a t e was about 600 m / g 30 and t h e r e s i s t i v i t y a b o u t 0.4 ohm cm. An e l e c t r o c h e m i c a l c e l l f o r measuring e l e c t r o c h e m i c a l p e r f o r mance parameters w a s set up c o n t a i n i n g t h i s s u b s t r a t e as a working e l e c t r o d e , a Hg/HgO, OH- r e f e r e n c e e l e c t r o d e , a high s u r f a c e area f l a t b e d c o u n t e r e l e c t r o d e , and a n e l e c t r o l y t e , which was a 27% KOH 35 s o l u t i o n i n d i s t i l l e d water. The c e l l w a s o p e r a t e d w i t h a c u r r e n t WO 86/01642 - 4 d e n s i t y of 100 mA/cm 2 on t h e working e l e c t r o d e a t a p o t e n t i a l of -0.125 V a g a i n s t t h e r e f e r e n c e e l e c t r o d e a t 3OoC, and oxygen w a s reduced t o water w i t h minimal (under 1%) by- production of hydrogen peroxide. 05 ELECTRODE EXAMPLE 1 Porous carbon f o r an e l e c t r o d e s u b s t r a t e was made as d e s c r i b e d i n t h e S u b s t r a t e P r e p a r a t i o n Example, up t o and including t h e gas- activation b u t excluding t h e h o t pressing. Platinum phthalocyanine w a s d i s s o l v e d i n t h e least p o s s i b l e 10 q u a n t i t y of c o n c e n t r a t e d s u l p h u r i c a c i d , and t h e n t h e carbon w a s d i s p e r s e d i n t o the s o l u t i o n . The s o l u t i o n w a s t h e n d i l u t e d slowly w i t h t h e least q u a n t i t y of d i s t i l l e d water t o o b t a i n a s l u r r y . The s l u r r y i s s t i r r e d w i t h t h e carbon f o r one hour, washed u n t i l 15 t h e s u p e r n a t a n t l i q u o r h a s a pH of 5 t o 7, and t h e n c e n t r i f u g e d . -2 with The carbon i s d r i e d and hot- pressed a t 0.05 tonne c m p o l y e t h y l e n e b i n d e r as i n t h e S u b s t r a t e P r e p a r a t i o n Example. In F i g u r e 1, t h e performance oxygen r e d u c t i o n of v a r i o u s e l e c t r o d e s is compared. In all cases, t h e e l e c t r o l y t e w a s 6M 0 aqueous KOH under a p r e s s u r e of gaseous oxygen o f 130 mB, at 35 C. 20 The performance of t h e e l e c t r o d e j u s t d e s c r i b e d is curve 1A (5% platinum phthalocyanine) and c u r v e ll3 (10%platinum phthalocyanine) The o t h e r curves r e p r e s e n t o t h e r e l e c t r o d e s : a = u n t r e a t e d carbon (= a of F i g u r e 2) b = a + 7% platinum (= b of F i g u r e 2) 25 c = carbon according t o S u b s t r a t e P r e p a r a t i o n Example (= c of F i g u r e 2) d = c + 7% platinum Curve 1A l i e s above t h e o t h e r s a t a l l c u r r e n t d e n s i t i e s 2 2 over 150 mA/cm , and 1B above t h e o t h e r s o v e r 400 mA/cm Life- . 30 time tests on 1A and 1B showed h i g h s t a b i l i t y a t c u r r e n t d e n s i t i e s 2 of up t o 400 mA/cm . ELECTRODE EXAMPLE 2 In t h i s Example, a novel method i s f e a t u r e d f o r a t t a c h i n g a catalyst t o a substrate. . PCT/G B85/00400 WO 86/01642 - 5 - A porous carbon s u b s t r a t e w a s made as d e s c r i b e d i n t h e S u b s t r a t e w a s p r e c i p i t a t e d on Ru 0 2+y 2 6+x 2+ t h e s u b s t r a t e by a s u r f a c e chemical r e a c t i o n between Pb pre- P r e p a r a t i o n Example. The c a t a l y s t Pb adsorbed on t h e s u b s t r a t e and a ruthenium complex in s o l u t i o n . 05 T h i s w a s achieved as follows: The s u b s t r a t e was dipped f o r 30 minutes i n a 0.001M aqueous s o l u t i o n of l e a d n i t r a t e Pb(N03)2. In t h i s way, lead i o n s Pb were adsorbed on t h e s u r f a c e of t h e s u b s t r a t e . 2+ . Meanwhile, a ruthenium s o l u t i o n w a s made by f u s i n g 0.1 g Ru02, 0.5 g NaOH 10 and 5 g KN03 f o r 5 minutes and d i l u t i n g t h e m e l t w i t h d i s t i l l e d water t o 250 m l . The dipped s u b s t r a t e was t h e n dipped for 30 minutes i n t h i s ruthenium s o l u t i o n , whereby t h e c a t a l y s t Pb2+yRu206+x was p r e c i p i t a t e d on, and bound t o , t h e s u r f a c e of t h e s u b s t r a t e . T h i s r e a c t i o n i s r a t h e r s e n s i t i v e t o pH; 15 t h e above q u a n t i t i e s e n s u r e a s u i t a b l e pH. After dipping and r i n s i n g i n d i s t i l l e d water, t h e r e s u l t i n g 0 e l e c t r o d e i s d r i e d a t 70 C. I n F i g u r e 2, t h e performance of v a r i o u s e l e c t r o d e s a t reducing oxygen is compared. 20 I n each case except c u r v e 2 t h e e l e c t r o l y t e w a s 6M aqueous KOH under p r e s s u r e of gaseous oxygen of 160 mB, a t 35OC. T h a performance of t h e e l e c t r o d e j u s t d e s c r i b e d is curve 2, i n which t h e e l e c t r o l y t e w a s 1M aqueous KOH under a 0 p r e s s u r e of gaseous oxygen o f 160 mB, a t 35 C. The o t h e r curves r e p r e s e n t o t h e r e l e c t r o d e s : 2s a = u n t r e a t e d carbon (= a of F i g u r e 1) b = a + 7% platinum (= b of F i g u r e 1) c = carbon according t o S u b s t r a t e P r e p a r a t i o n Example (= c of Figure 1) d = p r o p r i e t a r y t r e a t e d carbon +I 5% platinum. 30 e = t e f l o n (40%)-bonded u n t r e a t e d carbon. Although showing h i g h a c t i v i t y , t h i s sample i s s h o r t - l i v e d because it evolves hydrogen peroxide, which degrades i t ; e l e c t r o d e s c and d do n o t e x h i b i t such e v o l u t i o n . f = p y r o c h l o r e on u n t r e a t e d carbon s u b s t r a t e . ' WO 86/01642 - 6 SECOND SUBSTRATE PREPARATION EXAMPLE . High- surface- area Vulcan XC-72 carbon w a s o b t a i n e d from t*h e Cabot Corp., Billerica, MA. The a s h c o n t e n t of t h i s carbon w a s found t o b e about 0.05%. The o t h e r p h y s i c a l and chemical 05 parameters of t h i s carbon are as follows: 257 m2/g S u r f a c e area Mean p a r t i c l e s i z e 30 nm Approximate d e n s i t y 3 96 kg/m 5 PH T h i s carbon was s u b j e c t e d t o mechanical g r i n d i n g and t h e n 10 g a s - a c t i v a t e d by h e a t i n g i n a C 0 2 atmosphere a t 900°C f o r 1 hour. G a s a c t i v a t i o n r a t h e r t h a n continued g r i n d i n g w a s chosen t o minimise p a r t i c l e agglomeration; i t produced a 27%weight loss o f t h e carbon, i n c r e a s e d t h e e f f e c t i v e s u r f a c e area, and modified t h e 15 s u r f ace. The d e s i r e d q u a n t i t y of p l a t i n u m w a s d i s p e r s e d i n t o t h e gas- activated carbon by reducing c h l o r o p l a t i n i c a c i d w i t h sodium formate s o l u t i o n as d e s c r i b e d elsewhere. This p r o c e d u r e y i e l d s f i n e platinum p a r t i c l e s of uniform s i z e (about 63g diameter) on a 20 carbon s u b s t r a t e . C h l o r o p l a t i n i c acid s o l u t i o n c o n t a i n i n g t h e r e q u i r e d p r o p o r t i o n of platinum w a s t a k e n from a 2 weight -% s t o c k s o l u t i o n , mixed w i t h h a l f of i t s volume of isopropanol, and n e u t a l i s e d with a d i l u t e s o l u t i o n of sodium carbonate. An a p p r o p r i a t e q u a n t i t y of g a s - a c t i v a t e d Vulcan XC-72 carbon w a s 25 added, and t h e entire mixture w a s d r i e d i n an a i r oven b e f o r e i t w a s added, w i t h vigorous s t i r r i n g , t o a n excess of b o i l i n g 5 weight % sodium formate s o l u t i o n t o reduce t h e c h l o r o p l a t i n i c a c i d t o platinum metal. The r e s u l t i n g mass w a s f i l t e r e d and washed r e p e a t e d l y with h o t , d i s t i l l e d water b e f o r e b e i n g d r i e d i n a n a i r 30 oven. Teflon-bonded e l e c t r o d e s were prepared f o r e l e c t r o c h e m i c a l measurements under gas- fed c o n d i t i o n s . The Teflon b i n d e r p r o v i d e s t h e necessary mechanical s t r e n g t h t o p r e v e n t e l e c t r o d e c o l l a p s e . . . PCT/GBS5/00400 WO 86/01642 - 7 under t h e g a s p r e s s u r e r e q u i r e d f o r g a s - e l e c t r o l y t e i n t e r f a c e c o n t r o l i n a g a s - d i f f u s i o n e l e c t r o d e , and i t does s o w h i l e r e t a i n i n g t h e necessary e l e c t r o d e p o r o s i t y . e l e c t r o d e s were made as follows: 05 The Teflon-bonded Tetrahydrofuran (THF) w a s added t o a measured q u a n t i t y of c a t a l y s e d s u b s t r a t e powder i n a beaker, and t h e mixture w a s a g i t a t e d i n a n u l t r a s o n i c b a t h f o r a b o u t 30 minutes b e f o r e a few m l of d i l u t e suspension of Teflon emulsion (ICI GP2 Fluon d i s p e r s i o n , particle s i z e 0,1-0,2 microns) w a s added t o t h e m i x t u r e without i n t e r r u p t i o n of t h e a g i t a t i o n . 10 The product material w a s c e n t r i f u g e d r e p e a t e d l y w i t h THF and f i n a l l y s p r e a d on a platinum expanded-metal (Exmet) s c r e e n (0.076 mm -2 diameter w i r e , 1024 mesh cm ). The coated s c r e e n w a s a i r - d r i e d -2 f o r about 15 minutes b e f o r e i t w a s cold- pressed a t 125 kg cm f o r 5 minutes. 15 The pressed mass was d r i e d f o r 2 hours a t 11OC and t h e n cured i n a i r a t 360C f o r 30 minutes. The T e f l o n c o n t e n t of t h e e l e c t r o d e s w a s optimal a t 25 t o 35%by volume. Short- term p o l a r i s a t i o n c u r v e s were obtained f o r dioxygen r e d u c t i o n i n 5M H2S04 s o l u t i o n on v a r i o u s Vulcan XC-72 carbon electrodes. 20 P o l a r i s a t i o n curves were o b t a i n e d a t 2OoC f o r u n p l a n t i n i s e d carbon e l e c t r o d e s t h a t were n o t gas- activated. Although t h e e l e c t r o d e s f u n c t i o n a t c u r r e n t d e n s i t i e s of 400 t o 600 mA cm-2, t h e i r p o l a r i s a t i o n v a l u e s are high. F u r t h e r curves were o b t a i n e d on gas- activated Vulcan XC-72 25 s u b s t r a t e s impregnated w i t h 7 weight % d i s p e r s e d metal and loaded w i t h 30%T e f l o n and c l e a r l y show a s u f f i c i e n t l y reduced masst r a n s f e r p o l a r i s a t i o n f o r l o a d i n g of t h e e l e c t r o d e s t o h i g h These e l e c t r o d e s could be loaded i n t e r m i t -2 t e n t l y a t c u r r e n t d e n s i t i e s of 1 . 1 A c m f o r p e r i o d s of several current densities. 30 minutes. This enhanced performance i n d i c a t e s t h a t t h e high- temperature CO t r e a t m e n t h a s n o t o n l y i n c r e a s e d t h e s u r f a c e area, 2 b u t h a s a l s o peroduced a w e l l d e f i n e d p o r e s t r u c t u r e t h a t o p t i m i s e s a uniform gas d i f f u s i o n i n t o t h e e l e c t r o d e . It a l s o i n d i c a t e s a good platinum d i s p e r s i o n on t h e s u r f a c e , and any s u r f a c e modifica35 t i o n by t h e C 0 2 t r e a t m e n t would a p p e a r t o be b e n e f i c i a l . No PCT/GBS5/00400 WO 86101642 - 8 - d e t e c t a b l e H 0 w a s evolved, whereby t h e carbon w a s n o t d e s t r o y e d 2 2 from t h i s cause (improving t h e l i f e t i m e of t h e e l e c t r o d e ) and whereby e f f i c i e n c y w a s improved (none of t h e reduced oxygen b e i n g if w a s t e f u l l y converted t o r e a p p e a r as H202). 05 To p u t t h e f o r e g o i n g i n t o c o n t e x t , t h e long- range g o a l of 3 f u e l - c e l l r e s e a r c h is t h e development of f u e l - c e l l b a t t e r i e s t h a t o p e r a t e on inexpensive f u e l s and have a i r as t h e oxidant. These b a t t e r i e s must c o n v e r t chemical energy t o electric power w i t h h i g h e f f i c i e n c y a t practical c u r r e n t d e n s i t i e s ; 10 long o p e r a t i o n a l l i f e they must a l s o have - o r a low- cost replacement of ageing p a r t s - i f they are t o compete w i t h p r e s e n t forms of power g e n e r a t i o n from t h e same i n e x p e n s i v e f u e l s . A primary impediment t o t h e commercial r e a l i s a t i o n of f u e l - c e l l technology is f a i l u r e t o i d e n t i f y s u i t a b l y c a t a l y t i c e l e c t r o d e s 15 having a long o p e r a t i o n a l l i f e i n a c i d i c e l e c t r o l y t e s . Alkaline e l e c t r o l y t e s react w i t h carbon d i o x i d e t o form c a r b o n a t e s t h a t from t h e a i r can b e 2 slowed t o n e a r l y t o l e r a b l e rates f o r low- cost, exchangeable a l k a l i n e f o u l the electrodes. Although f o u l i n g by CO a i r e l e c t r o d e s in a p u r e hydrogen- air f u e l c e l l , a n a c i d i c e l e c t r o l y t e 20 h a s g r e a t advantages. High performance r e q u i r e s f a b r i c a t i o n of a porous e l e c t r o d e s u b s t r a t e of h i g h s u r f a c e area on which-a s u i t a b l e c a t a l y s t i s e f f e c t i v e l y disposed; moreover, t h e e f f e c t i v e s u r f a c e area must n o t be degraded by normal o p e r a t i o n a l c o n d i t i o n s . 25 Degradation may b e caused by: (1) chemical a t t a c k from the product of a n unwanted s i d e reaction, 30 (2) porosity, (3) mechanical c o l l a p s e , o r ( 4 ) s i n t e r i n g due t o h e a t from i n t e r n a l l o s s e s . T h e r e f o r e a t t e n t i o n must be d i r e c t e d t o the c h o i c e of s u b s t r a t e - c material and c a t a l y s t as w e l l as t o t h e method of e l e c t r o d e f a b r i c c a t i o n and c a t a l y s t d i s p e r s i o n . S e l e c t i o n of a s u i t a b l e s u b s t r a t e material is d i c t a t e d by a t 35 least six f a c t o r s : c o s t , i n e r t n e s s i n o p e r a t i n g medium, ease of WO 86101642 - 9 f a b r i c a t i o n i n c o l l o i d a l - s i z e p a r t i c l e s , high electrical conduct i v i t y , e f f e c t i v e n e s s as s u b s t a t e f o r a h i g h l y d i s p e r s e d c a t a l y s t , and i n e r t n e s s t o unwanted s i d e r e a c t i o n s . Various t y p e s of a c t i v e (high- surface- area) carbon have been examined as s u p p o r t s f o r 05 platinum- metal c a t a l y s t s i n e l e c t r o d e s used f o r both oxygen r e d u c t i o n and methanol o x i d a t i o n i n a c i d s o l u t i o n . a s h c o n t e n t prove t o be s u p e r i o r ; Carbons of low t h e s e appear t o be f r e e of t h e i m p u r i t i e s r e s p o n s i b l e f o r hydrogen- peroxide g e n e r a t i o n , a s i d e r e a c t i o n r e s p o n s i b l e f o r chemical a t t a c k of t h e s u b s t r a t e s . I0 Vulcan XC-72 carbon, made by Cabot Corp., which h a s a low a s h c o n t e n t , functions as a n excellent a i r - e l e c t r o d e s u b s t r a t e i n a c i d i f i t s s u r f a c e i s s u i t a b l y p r e - t r e a t e d and platinum is uniformly d i s p e r s e d onto it. Such a Teflon-bonded e l e c t r o d e as set f o r t h above a p p e a r s t o reduce dioxygen t o water i n 5M H SO w i t h no 4' d e t e c t a b l e formation of hydrogen peroxide and t o be a b l e t o 2 15 s u s t a i n l o a d c u r r e n t s of a b o u t 900 mA cm-2 w i t h o u t s e r i o u s degradation. 43u f o r long p e r i o d s W O 86101642 - 10 CLAIMS 1. An e l e c t r o d e f o r reducing oxygep, comprising a s u b s t r a t e which i s an e l e c t r o n i c conductor c a p a b l e of reducing elemental oxygen t o water y i e l d i n g n o t more t h a n 5%hydrogen peroxide, t o which s u b s t r a t e i s a t t a c h e d a c a t a l y s t which can reduce elemental 05 oxygen t o water y i e l d i n g n o t more t h a n 5%hydrogen p e r o x i d e when used a t c a t h o d i c p o t e n t i a l s of -300 mV a g a i n s t t h e Hg/HgO e l e c t r o d e i n a l k a l i n e o r non- alkaline s o l u t i o n . 2. An e l e c t r o d e according t o Claim 1, wherein t h e e l e c t r o n i c conductor i s capable of reducing elemental oxygen t o water y i e l d i n g 10 n o t more t h a n 1%hydrogen peroxide. An e l e c t r o d e a c c o r d i n g t o C l a i m 2, wherein the c a t a l y s t can reduce elemental oxygen t o water y i e l d i n g n o t more t h a n 1%hydrogen 3. peroxide 4. 15 An e l e c t r o d e according t o C l a i m 3 , wherein t h e e l e c t r o n , i c conductor is capable of reducing elemental oxygen t o water y i e l d i n g n o t more t h a n 0.1% hydrogen peroxide. An e l e c t r o d e a c c o r d i n g t o C l a i m 4 , wherein the c a t a l y s t can reduce elemental oxygen t o w a t e r y i e l d i n g not more t h a n 0.1% 5. hydrogen peroxide. 20 6. An e l e c t r o d e a c c o r d i n g t o any preceding claim, wherein t h e s u b s t r a t e is carbon of a n ash e o n t e n t less- t h a n 0.1%. 7. An e l e c t r o d e according t o C l a i m 6 , wherein t h e s a i d a s h c o n t e n t i s less t h a n 0.05%. 8. 25 A n e l e c t r o d e according t o C l a i m 7 , wherein t h e s a i d a s h c o n t e n t i s less t h a n 0.01%. 9. An e l e c t r o d e according t o any preceding claim, wherein t h e carbon i s 'coconut carbon'. 10. An e l e c t r o d e according t o C l a i m 9, wherein t h e carbon is d e r i v e d from coconut s h e l l s by c o n v e r t i n g t h e s e t o c h a r c o a l , 30 washing and comminuting t h e c h a r c o a l , and exposing t h e comminuted c h a r c o a l t o gas. 11. An e l e c t r o d e according t o C l a i m 10, wherein t h e gas is f i r s t carbon d i o x i d e and a f t e r w a r d s ammonia. PCT/GB85/00400 WO 86/01642 - 11 . 12. An e l e c t r o d e according t o any of Claims 1 t o 8, wherein t h e s u b s t r a t e is made by t r e a t i n g t h e carbon, which is of amorphous 2 t y p e and h a s a s u r f a c e area of a t least 200 m /g, a mean p a r t i c l e s i z e i n t h e range 5 nm t o 50 nm, and an a p p a r e n t d e n s i t y of 80 05 t o 110 kg/m 3 , by comminuting it and exposing i t t o gas a t e l e v a t e d temperature. 13. An e l e c t r o d e according t o C l a i m 12, wherein t h e carbon b e f o r e 2 the treatment h a s a s u r f a c e area of n o t more t h a n 300 m /g. 14. 10 An e l e c t r o d e according t o C l a i m 1 2 o r 13, wherein- t h e carbon b e f o r e t h e t r e a t m e n t h a s a pH below 7. 15. r An e l e c t r o d e according t o C l a i m 12, 1 3 o r 14, wherein t h e g a s t o which the carbon i s exposed i s carbon d i o x i d e . 16. An e l e c t r o d e according t o C l a i m 15, wherein t h e s a i d e l e v a t e d temperature i s from 800 C t o 1000 C. 15 17. An e l e c t r o d e according t o C l a i m 16, wherein t h e d u r a t i o n of t h e exposure a t s a i d e l e v a t e d t e m p e r a t u r e is from 40 t o 90 minutes. 18. An e l e c t r o d e according t o any of Claims 12 t o 17, when i n u s e t o reduce oxygen t o water i n an a c i d medium. 19. 20 An e l e c t r o d e according t o any of Claims 9 t o 11, when i n u s e t o reduce oxygen t o water i n a n a l k a l i n e medium. 20. An e l e c t r o d e according t o any preceding claim, wherein t h e c a t a l y s t i s a macrocyclic d e r i v a t i v e of t r a n s i t i o n metals o r of B- metals (i.e. 21. 25 Cu, Ag, Au, Zn, Cd, Hg, In, T1, Sn, Pb, Sb o r Bi).' An e l e c t r o d e according t o C l a i m 20, wherein t h e c a t a l y s t l o a d i n g i s 1 t o 15%by weight of t h e s u b s t r a t e . 22. An e l e c t r o d e according t o C l a i m 21, wherein s a i d c a t a l y s t l o a d i n g is 2 t o 12%. 23. An e l e c t r o d e according t o any of Claims 1 t o 19, wherein t h e c a t a l y s t is an oxide c o n t a i n i n g ruthenium. 30 24. An e l e c t r o d e according t o C l a i m 23, wherein t h e c a t a l y s t i s a n oxide c o n t a i n i n g ruthenium and one o r more o t h e r metals. r 25. An e l e c t r o d e according t o C l a i m 24, wherein t h e c a t a l y s t B i Ru 0 where x i s from 0 t o 2 and y is from 0 t o 1. is Pb2-x x 2 6+y 26. Amethod of making an e l e c t r o d e according t o Claim 24 o r 25, 35 comprising adsorbing i o n s of t h e o t h e r m e t a l ( s ) o n t o t h e s u b s t r a t e WO 86/01642 PCT/GB85/00400 - 12 and t r e a t i n g t h e s u b s t r a t e w i t h a s o l u t i o n of ruthenium 0x0-anion complex, whereby t h e d e s i r e d c a t a l y t i c oxide i s p r e c i p i t a t e d on, and i s a t t a c h e d t o , t h e s u b s t r a t e . 05 27. An e l e c t r o d e made by a method according t o C l a i m 2 6 . 28. A f u e l c e l l i n c l u d i n g an e l e c t r o d e according t o any of Claims 1 t o 25 o r 27. 29. A method of reducing oxygen, comprising c o n t a c t i n g elemental oxygen w i t h a s o u r c e of hydrogen a t a n e l e c t r o d e according t o any of Claims 1 t o 25 or 27, and a p p l y i n g t o t h e e l e c t r o d e a p o t e n t i a l 10 of from 0.1 t o -0.2 v o l t s w i t h r e s p e c t t o t h e Hg/HgO e l e c t r o d e . 30. Amethod according t o C l a i m 2 9 , wherein the c u r r e n t d e n s i t y exceeds 8000 A/m 43u 2 . $ % WO 86101642 c PCT/GB85/00400 WO 86/01642 * PCl"/GB85/004OO INTERNATIONAL SEARCH REPORT. Internatlonal ADDiicatlon NO PCT/GB 8 5 / 0 0 4 0 0 I. CLASSlFlCATlON OF SUBJECT MATTER (if several classificition symbols apply. indicate all) ' According to International Patent Classification (IPC) or to both Natlonat Clrrsification and IPC * IPC : H 0 1 *M 4 / 9 0 ; H 01 M 4/96 11. FIELDS SEARCHED Mlnlmum Documentation Searched Classification System 4 IPC I 1I 7 Classlficatlon Symbols H 0 1 M Oocumentation Searched other than Minlmum Documentation to the Extent that such Document8 are Included In the Flrldr Searched 8 111. D O C U M E N T S CONSIDERED TO BE RELEVANT' Citation of Document. with lndlcatlon. where appropilate. of the relevant passages :ategory 11 X Y (2 ?elevant to Claim No. 13 P a t e n t s A b s t r a c t s of J a p a n , vol. 8 , no. 1 9 0 , 31 August 1 9 8 4 ; ( E - 2 6 3 ) ( 1 6 2 7 ) & J P , A , 5 9 7 9 9 7 7 (PENTEL K . K . ) 9 May 1 9 8 4 , see t h e whole a b s t r a c t 1,9,10,19,2( 21 6,7,8,11 ,l5, 16,23,25,28 -- X P a t e n t s A b s t r a c t s of Japan, v o l . 4 , no. 56, 25 A p r i l 1 9 8 0 : (E-8) (538) & J P , A , 5 5 2 5 9 1 6 (TOSHIBA RAY-0-VAC KK) 2 5 February 1 9 8 0 , see t h e w h o l e >.a b s t r a c t 1 , 9 , 1 0 , 1 9 , 2 c -- Y J o u r n a l of P o w e r Sources, v o l . 1 0 , no. 4 , November 1 9 8 3 ( A m s t e r d a m , N L ) R. Manoharan e t a l . : "Oxygen r e d u c i n g porous carbon electrode for electrochemical p o w e r sources w i t h a l k a l i n e e l e c t r o l y t e " , pages 3 3 3 - 3 4 1 , see page 334, line 7 page 335, l i n e 1 2 ; f i g u r e s 7 , 8 ; page 3 3 9 , l i n e 1 1 page 3 4 0 , l i n e 5; page 3 4 0 , l i n e s 13- 21 - . * - -- * oat0 Of the Actual Completlon of th8 International Search 1 9 t h December 1 9 8 5 international Searching Authority E U K P E A N PATENT OFFICE Signature of Authorlred Omcar 28 International Application ill. DOCUMENTS CONSIDERED TO BE RELEVANT No-PCT/GB 8 5 / 0 0 4 0 0 -2- (CONTINUED FROM THE SECOND SHEET) Cttrtton of Document. witn indiutmn. where amrowrate. of ma rebvant mssams :ategor US, A, 4292197 (R.D. CHAMBERLIN) 2 9 September 1981 see c l a i m s 1 , 2 ; column 3 , l i n e 57 column 4 , l i n e 18; column 6 , l i n e s 4- 12; column 7, l i n e s 34-44, 57-61 A - Relevant to Claim No 1,9,19,27 -- Extended A b s t r a c t s , ~0.1. 8 7 , no. 2 , 1981 (Pennington , N e w .Jerssv,US) a b s t r a c t no. 1 1 4 : J . G i n e r e t a l . : "Gasdiffusion e l e c t r o d e f o r m e t a l a i r - b a t t e r i e s " , pages 289-291, see page 2 9 0 , p a r a g r a p h 3 Y 23-25 -- J o u r n a l of t h e E l e c t r o c h e m i c a l S o c i e t y , v o l . 130, no. 9 , September 1983 (Manchester, New Hampshire, U S ) H . S . Horowitz: "Oxygen e l e c t r o c a t a l y s i s on some o x i d e p y r o c h l o r e s " , pages 1853-1859, see a b s t r a c t ; f i g u r e 3; page 1858; l e f t - h a n d column; p a r a g r a p h s 4-5 Y 1,23-25 -- EP, A , 0068664 (AJINOMOTO CO.) 5 J a n u a r y 1983 see claims 1 , 2 , 6 , 7 ; example 1 ; page 2 , l i n e s 5-19; page 3 , l i n e s 26- 30 A 1-5 ,2 0 ,28 -- Extended A b s t r a c t s , v o l , 8 3 , no. 2 , 1983 (Washington DC, U S ) a b s t r a c t no.' 391: S.L. Eupta e t a l . : "The r o l e of t r a n s i t i o n metal i n t h e p y r o l y z e d m a c r o c y c l i c s t o w a r d s oxygen r e d u c t i o n i n concentrated photophoric acid" , pages 624-625, see page 6 2 4 , l e f t - h a n d column, p a r a g r a p h s 1-2; r i g h t - h a n d column, p a r a g r a p h 1 ; f i g u r e 1 A 1-5 ,18 ,28 4 -- Chemical A b s t r a c t s , v o l . 9 7 , no. 18, November 1982 (Columbus, Ohio, U S ) see page 570, column 1 , a b s t r a c t no. 153063a; & J P , A , 82107244 ( P e n t e l Co.) 3 J u l y 1 9 8 2 , see t h e whole a b s t r a c t A 1,9,29 -- J o u r n a l of Applied E l e c t r o c h e m i s t r y , v o l . 15, no. 5 , September 1985; Chapman and Hall; A.K. Shukia e t a l . : "High e f f i c i e n c y cathodes f o r a l k o l i n e a i r e l e c t r o d e s " , pages 7 7 4 - 7 7 6 , see page 774,- l e f t - h a n d r i g h t - h a n d column,. column, l i n e 1 l i n e 15; page 775, f i g u r e 1 - I Form PCT ISA!210 (extra 8hee~t)(January 1985) -- 1,6,7,8,9, 10,11,15,16 19,20,21 ,22 2 7 ,28 =I* intrrnationii Application No. 111. D O C U M E N T S CONSIDERED TO BE R E L E V A N T (CONTINUED PCT/GB 8 5/ 0 0 4 0 0 FROM T H E SECOND SHEET) Cititm of Doarment. wdh indication. vhrr aporopnite. of r a b m t prasagen Relevant t o Claim No E l ec t r o c h i m i c a A c t a , v o l . 30, no. 2 , February 1985, Pergamon Press ( G B ) R. Elanoharan e t a l . : "Oxides s u p p o r t e d carbon a i r e l e c t r o d e s f o r a l k o l i n e power d e v i c e s " , pages 205-209, see a b s t r a c t ; page 2 0 5 , r i g h t - h a n d colu.m, p a r a g r a p h s 1-3; f i g u r e 1 -- J o u r n a l of Power S o u r c e s , vol. 1 3 , no. 4, December 1984 (Lausanne, CH) R. Manoharan e t a l . : "High performance p l a t i n i z e d carbon e l e c t r o d e s f o r oxygen r e d u c t i o n i n power s o u r c e s w i t h a.lkalinc e l e c t r o l y t e s " , pages 273-285, see page 2 7 4 , l i n e s 26- 30; f i g u r e 3 GB, A , 2 0 0 9 1 3 0 (EXXON RESEARCH) 1 3 June 1971 FR, A , 2445031 (ETAT FRANCAIS REPRESENTE PAR LE DELEGUE GENERAL POUR L'ARMEMENT) 18 J u l y 1980 see c l a i m s 1 , 3 m PCT ISA:210 (extra rhea0 (January lS85) 1 - 3- This Annex lists the patent family members relating to the patent documents cited in the above-mentioned international search report. The members are as contained in the European Patent Office EDP file on 17/01/86 The European Patent Office is in no way liable for these particulars which are merely given for the purpose of information. Patent document ..Publication cited in search date report Patent family member( s) Publicatisgi date For more details about this annex : see Official Journal of the European Patent Office, No. 12/82