Document 13664892

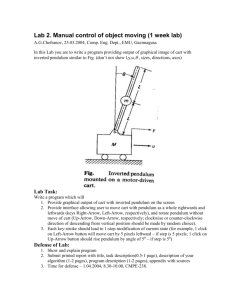

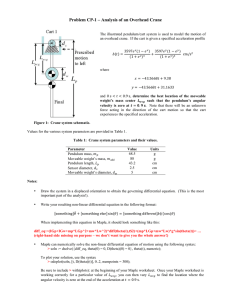

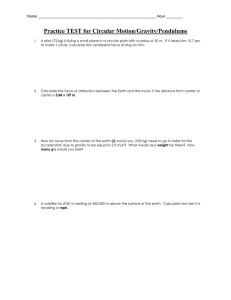

advertisement