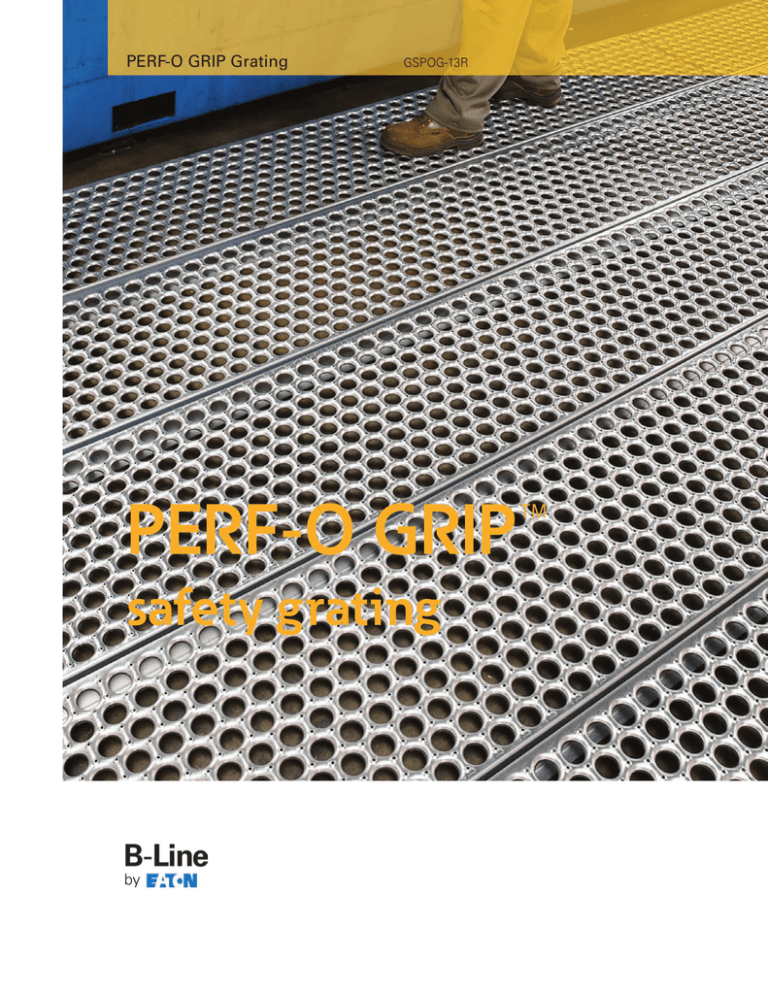

PERF-O GRIP Grating

GSPOG-13R

PERF-O GRIP™

safety grating

Table of Contents

General Information

Load Information

........................................................... 3

................................................................ 4

PERF-O GRIP™ Design Load Tables

2-Hole Planks - 5” Width

(Steel, Aluminum, Stainless Steel)

........................................... 5

3-Hole Planks - 7” Width

(Steel, Aluminum, Stainless Steel)

........................................... 6

PERF-O GRIP Pattern

5-Hole Planks - 10” Width

(Steel, Aluminum, Stainless Steel)

........................................... 7

6-Hole Planks - 12” Width

(Steel, Aluminum, Stainless Steel)

........................................... 8

10-Hole Planks - 18” Width

(Steel, Aluminum)

.............................................................. 9

13-Hole Planks - 24” Width

(Steel)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

16-Hole Planks - 30” Width

(Steel)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

PERF-O GRIP Grating

Walkways - 24” & 30” Width

(Steel)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

PERF-O GRIP Accessories

P-Bolt Seat

J-Clip

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Mid Clip

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Splice Plate Kits

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

PERF-O GRIP Stair Treads & Carrier Plates

PERF-O GRIP Specifications

How To Order

. . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 - 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

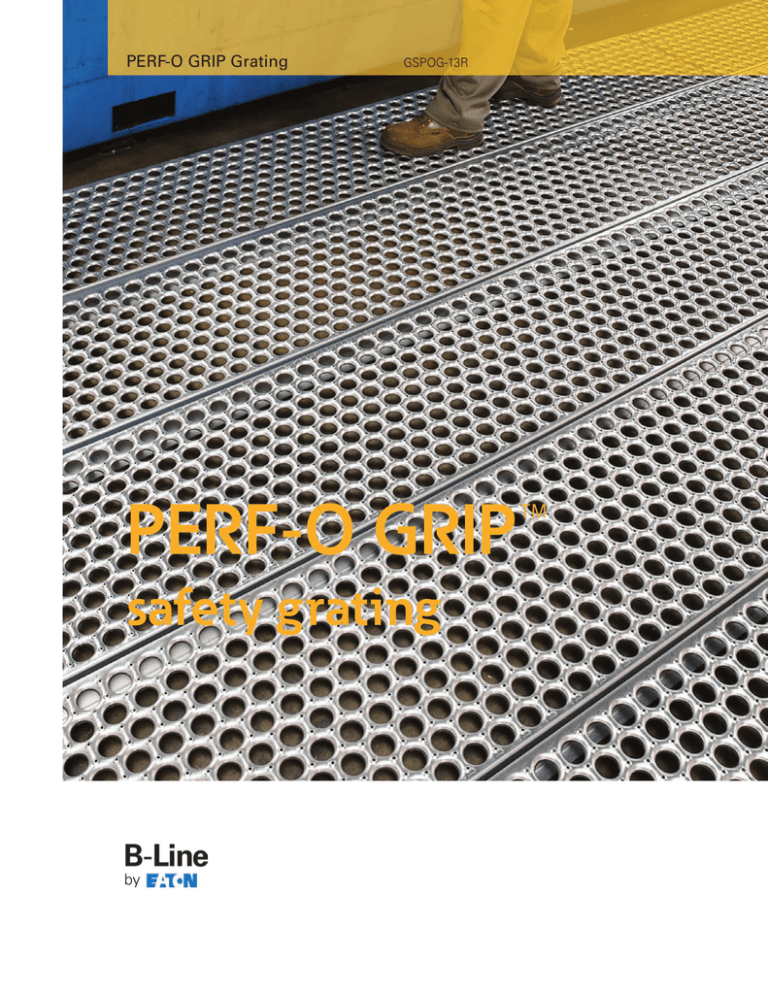

PERF-O GRIP Walkway

PERF-O GRIP Stair Tread

2

PERF-O-GRIP Grating

General Information

PERF-O GRIP™ Safety Grating

PERF-O GRIP safety grating’s unique surface of large

debossed holes and perforated buttons helps provide

maximum slip protection and performance under

practically all conditions and in every direction.

The large debossed holes allow fluids, mud, chips and

other debris to drain away. With 5 inch high side channels,

PERF-O GRIP Walkways meet OSHA requirements for

toeboards on elevated structures. Canadian OH & S

compliant designs are also available.

In addition to providing safety, the resilient surface of

PERF-O GRIP grating cushions the impact of footfalls

thereby lessening worker fatigue and increasing efficiency.

PERF-O GRIP safety grating is your best safety buy. It helps

cut cost and improve plant productivity.

Fast Installation

Light, easy-to-handle planks make installation simple and

quick. They can be handled by one person. Most sections

are rapidly bolted, clamped or welded into place, easily

field cut at virtually any angle, or fabricated to adapt to field

conditions.

Attachment devices permit fastening to most existing

surfaces, allowing for fast installation and disassembly.

Economical To Install and Use

In addition to offering a lowest total installed cost,

PERF-O GRIP safety grating also features long-lasting,

rust- resistant materials and finishes. Standard millgalvanized finish resists corrosion to provide lasting

surfaces. High-strength aluminum, Type 316-2B and

Type 304-2B stainless steels are available to provide

maximum corrosion resistance. Plain unpainted steel

(HRP&O) is available for those installations requiring paint.

Lightweight but brawny panels permit substantial reduction

in structural steel requirements.

PERF-O GRIP 2 Safety Grating

We offer a second style of PERF-O GRIP grating.

PERF-O GRIP 2 safety grating features 115/16” on center

hole spacing (compared to 2” on the original style). In

addition, PERF-O GRIP 2 safety grating can be produced

with safety end margins on its 2-hole (5” wide) through 6

hole (12” wide) plank and without end margins on its

10-hole (18” wide) through 16-hole (30” wide) plank. The

original PERF-O GRIP is still available in 2-hole (5” wide)

through 16-hole (30” wide).

Versatility

A variety of standard widths and channel heights are

available as well as numerous non-standard shapes and

sizes to meet almost any requirement of strength, size,

durability, weight, finish, appearance and application.

PERF-O GRIP safety grating combines safety and durability

with ease of fabrication and versatility. One-piece

construction — no welds or rivets to fail — minimizes need

for field fabrication. Special shapes and forming can be

accomplished to suit unusual requirements.

All surfaces are accessible to brush or spray, making it

simple and economical to apply finish coatings.

PERF-O GRIP safety grating may be hot dipped galvanized

after fabrication, anodized, plated, plastic-coated or

otherwise finished to suit job requirements. Standard

PERF-O GRIP plank is available in materials and sizes to

meet most load/span requirements. May be used as is, or

banded, cut, welded or notched to suit requirements.

PERF-O GRIP 2 plank with its safety end margins is stocked

in 5”, 7” 10” and 12” widths and in 10’-0” (1201/8”) and

12’-0” (144”) lengths. PERF-O GRIP plank is stocked in

18”, 24” and 30” widths, in 10’-0” (120”) and 12’-0” (144”)

lengths. Other lengths can be manufactured per order

requirements. Standard metals are 11 gauge and 13 gauge

carbon steel (mill-galvanized), 16 gauge stainless steel

(Type 316-2B to 12” wide), and .125” aluminum. PERF-O

GRIP can also be manufactured in HRPO steel and

stainless steel (Type 304-2B) on special order.

Safe Surface

Grips soles securely — in all directions. Non-slip

PERF-O GRIP safety grating surfaces are ideal for inside or

outside locations where mud, ice, snow, oil and detergents

can create hazardous walking conditions.

The circular openings (38% of surface area depending on

product size) are small enough to catch most falling tools

and other dangerous objects. But the self-cleaning open

design permits quick drainage of fluids, chips, grease and

mud while permitting ventilation and lighting flow. Ice

accumulation shears easily under normal foot pressure.

Open design allows convenient access for cleaning.

PERF-O GRIP is easily cleaned with brush, liquid or air

spray if desired.

Helps Extend Life

PERF-O GRIP safety grating offers a high load capacity,

long-life, and high strength-to-weight performance; which

is achieved through depth of section and structural design.

Formed struts with integral side channels form a plank

that can support loads with minimum transverse and

longitudinal deflection. There are no rivets or pressure

joints to break or loosen. This sturdy construction provides

the advantages of heavy load-carrying capacity with

minimal deflection; rugged durability with longer-lasting

performance.

PERF-O GRIP Grating

3

Load Information

produce, as shown in Example A. If desired, the load

which will produce a specific deflection can also be

determined if the load is in the elastic range as illustrated

in Example B.

How To Read Load Tables

™

To select the proper size of PERF-O GRIP grating,

determine load, clear span and deflection requirements

by first determining your loading requirements.

Example A

What deflection will a 300 lb. midspan concentrated load

produce on a plank spanning 5’-0” (part number P133011 page 11)?

Example — Clear span of 4’-0” with a concentrated load

requirement of 600 lbs. at 0.25” maximum deflection, for a

10’-0” wide plank; Refer to the 5-Hole Plank (10” Width),

then locate the Clear Span subheading for 4’-0” to find the

first occurrence of 600 lbs. (or greater) Concentrated Load

(C). In this example, the 13 gauge, 2” depth product (part

number P52013) carries a load of 648 lbs. with a 0.10”

deflection. While this is one product which meets the

minimum requirements, other options might be selected to

carry greater loads. For economical selection, choose the

greatest width that will support the load consistent with

job requirements and choose deeper channels rather than

heavier steel gauges.

C = 1517 lbs.

D = 0.09”

D @ 300 lbs. = 0.09” x (300 lbs. ÷ 1517 lbs.) = 0.02 inches

Example B

If a plank (part number P132011 - page 11) is spanning

7’-0”, what midspan concentrated load will produce a

.25” deflection?

C = 598 lbs.

D = 0.27”

C @ .25” = 598 lbs. x (0.25” ÷ 0.27”.) = 554 lbs.

How Load Tables Were Prepared

The values shown in the following tables are based on

actual load tests. The tables have been prepared in

accordance with the provisions of the AISI Specification

for the Design of Cold-Formed Steel Structural Members,

1986 edition.

Special Note On Planks

As width increases, grating surface performance

becomes more critical. Thus, for PERF-O GRIP product

widths greater than 12”, use of the grating surface splice

kit is recommended to mechanically join butt ends of plank

sections.

These load table values are based on consideration of

side channel flexure only and do not consider grating

surface performance. Side channel flexure occur when

the channels at midspan of the plank deflect relative to

support points. To verify the performance of the side

channels, samples were loaded with concentrated and

uniform loads at different spans (See Figures 1 and 2). To

approximate the most severe condition, there were no

attachments between the channels and the supports.

Load - C

Deflection values indicated in the tables are the midspan

side channel deflection produced when the allowable

uniform or allowable concentrated load is placed at

midspan. Load data is based on yield strength of 33,000 psi

for steel, 27,000 psi for aluminum, 35,000 psi for Type 304

stainless steel, and 30,000 psi for Type 316-2B stainless

steel.

D

Figure 1. Concentrated Load

(U) = Allowable Uniform Load (lbs./ft.2)

Load - U

(C) = Allowable Concentrated Load (lbs.) applied

by 2” round bar across full width of grating

(D) = Vertical Deflection (inches) of side channels

at mid span resulting from allowable load

Load/Deflection Conversion Formulas

In the elastic range, deflection is proportional to the

applied load for both uniform and concentrated loads.

This relationship can be used to determine the deflection

that any load which is less than the allowable load will

D

Figure 2. Uniform Load

4

PERF-O GRIP Grating

Grating Load Tables

PERF-O GRIP™ — 2-Hole Plank — 5” Width

415/16”

3

/32”

11/2” or 2”

90°

7

7

/8”

/8”

PERF-O GRIP

PERF-O GRIP 2

Plank Selection/Design Tables

Allowable Loads and Deflections: U=Uniform Load (lb./ft. ) C= Concentrated Load (lb.) D=Deflection (in.)

2

Material

Gauge

Channel Weight

Depth lb./lin.

in.

ft.

Catalog

(mm)

(kg/m) Number

11/2”

2.6

P21513*

(38.1)

(3.8)

A21513

2”

2.8

P22013*

(50.8)

(4.1)

A22013

Alum.

2”

1.3

P220125*

0.125”

(50.8)

(1.9)

A220125

Stainless

Steel

2”

2.1

P22016S*

(50.8)

(3.1)

A22016S

Steel

13 ga.

16 ga.

Span

2’-0”

2’-6”

3’-0”

3’-6”

4’-0”

4’-6”

5’-0”

5’-6” 6’-0”

6’-6”

7’-0”

7’-6” 8’-0”

9’-0” 10’-0” 11’-0” 12’-0”

U

D

2008

.05

1287

.08

895

.11

659

.15

505

.20

400

.25

325

.31

269

.38

227

.45

194

.53

168

.62

146

.71

130

.82

103

1.04

85

1.30

70

1.57

60

1.90

C

D

836

.04

670

.06

559

.09

481

.12

421

.16

375

.20

338

.25

308

.30

284

.35

263

.43

244

.49

229

.57

216

.65

194

.83

176

1.04

162

1.27

150

1.52

U

D

3035

.04

1944

.06

1352

.09

994

.12

762

.15

603

.19

490

.24

405

.29

341

.34

292

.41

253

.47

221

.54

194

.62

155

.79

126

.98

105

1.20

89

1.43

C

D

1228

.03

1003

.05

845

.07

725

.09

635

.12

566

.15

510

.19

465

.23

427

.28

395

.32

368

.38

344

.43

324

.50

290

.63

263

.79

240

.96

223

1.15

U

D

2910

.08

1863

.12

1294

.18

950

.24

728

.32

575

.40

466

.50

385

.60

323

.72

276

.84

237

.98

207

1.12

182

1.27

143

1.61

116

1.99

96

2.41

81

2.87

C

D

1213

.06

970

.10

809

.14

693

.20

606

.25

539

.32

485

.40

441

.48

404

.57

373

.67

346

.78

323

.90

303

1.02

270

1.29

243

1.60

221

1.93

202

2.29

U

D

2781

.05

2049

.08

1422

.12

1046

.16

800

.21

632

.26

512

.32

424

.39

355

.46

303

.54

262

.63

227

.72

200

.82

159

1.04

128

1.28

106

1.56

89

1.85

C

D

1334

.04

1066

.06

889

.09

761

.13

666

.16

593

.21

534

.26

485

.31

445

.37

410

.43

381

.50

355

.58

334

.66

296

.83

267

1.03

243

1.25

223

1.48

* PERF-O GRIP: To order standard PERF-O GRIP grating use part number “Pxxxxx”.

PERF-O GRIP 2: To order New PERF-O GRIP 2 grating use part number “Axxxxx”. End margins are standard on new PERF-O GRIP 2 grating

2-Hole through 6-Hole plank only ( 5” through 12” widths). Standard lengths are 10’-0” and 12’-0”.

PERF-O GRIP Grating

5

Grating Load Tables

PERF-O GRIP™ — 3-Hole Plank — 7” Width

615/16”

3

/32”

11/2”, 2” or 3”

90°

7

7

/8”

/8”

PERF-O GRIP

PERF-O GRIP 2

Plank Selection/Design Tables

Allowable Loads and Deflections: U=Uniform Load (lb./ft. ) C= Concentrated Load (lb.) D=Deflection (in.)

2

Channel Weight

Material Depth lb./lin.

Gauge

in.

ft.

Catalog

(mm)

(kg/m) Number

11/2”

3.0

(38.1)

(4.4)

P31513*

A31513

Steel

13 ga.

Steel

11 ga.

Alum.

0.125”

Stainless

Steel

16 ga.

2”

3.3

(50.8)

(4.9)

11/2”

4.2

(38.1)

(6.2)

2”

4.5

(50.8)

(6.7)

3”

4.8

(76.2)

(7.1)

2”

1.5

(50.8)

(2.2)

2”

2.4

(50.8)

(3.6)

P32013*

A32013

P31511*

A31511

P32011*

A32011

P33011*

A33011

P320125*

A320125

P32016S*

A32016S

Span

2’-0”

2’-6”

3’-0”

3’-6”

4’-0”

4’-6”

5’-0”

5’-6”

6’-0”

6’-6”

7’-0”

7’-6”

8’-0”

9’-0” 10’-0” 11’-0” 12’-0”

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

1536

.05

914

.04

1965

.03

1369

.03

1981

.05

1165

.04

2899

.03

1762

.03

5806

.03

3188

.02

2138

.07

1509

.07

984

.07

731

.06

1473

.06

1096

.05

1269

.07

932

.06

1978

.06

1410

.05

3716

.04

2550

.03

1491

.14

1207

.11

685

.11

609

.08

1024

.08

913

.07

883

.11

777

.09

1375

.08

1175

.07

2581

.06

2125

.04

1035

.20

1006

.16

504

.14

522

.12

754

.11

783

.09

650

.15

666

.12

1012

.11

1032

.09

1898

.08

1822

.06

761

.27

862

.21

387

.19

457

.15

578

.14

685

.12

498

.19

582

.15

776

.15

904

.12

1454

.11

1594

.07

582

.35

755

.28

306

.24

406

.19

458

.18

609

.15

394

.24

518

.19

614

.19

805

.15

1150

.13

1417

.10

460

.44

671

.35

249

.29

366

.24

371

.23

548

.18

320

.30

467

.24

498

.23

726

.19

932

.17

1275

.12

372

.54

604

.44

206

.36

332

.29

307

.27

498

.22

265

.36

426

.29

411

.28

661

.23

771

.20

1159

.15

308

.66

549

.53

174

.43

305

.34

259

.33

456

.26

224

.43

391

.34

347

.34

607

.27

649

.24

1132

.19

258

.78

503

.63

149

.50

283

.40

222

.38

421

.31

191

.51

362

.40

302

.40

573

.32

554

.28

1050

.22

221

.92

464

.74

129

.58

263

.47

192

.44

391

.35

165

.59

337

.47

261

.47

533

.37

479

.33

976

.26

190

1.07

431

.85

112

.67

246

.54

167

.51

366

.41

144

.68

316

.54

228

.54

499

.43

417

.37

913

.30

166

1.23

402

.98

100

.77

232

.61

147

.58

344

.47

128

.78

297

.62

201

.62

469

.49

367

.43

857

.34

146

1.39

377

1.12

79

.98

208

.78

118

.74

308

.59

101

.98

266

.79

160

.78

420

.63

291

.54

764

.43

115

1.76

335

1.41

65

1.22

190

.98

96

.92

279

.74

83

1.22

241

.98

130

.97

380

.78

236

.67

690

.54

93

2.18

302

1.74

55

1.51

174

1.20

80

1.13

257

.90

69

1.50

222

1.20

108

1.18

348

.95

196

.81

630

.65

77

2.64

274

2.11

46

1.81

162

1.44

68

1.36

237

1.08

59

1.81

205

1.44

92

1.42

321

1.14

166

.98

581

.78

65

3.14

252

2.51

U

D

C

D

1419

.03

1275

.03

1399

.07

1021

.05

971

.10

850

.08

714

.13

729

.11

546

.17

638

.14

432

.22

567

.18

350

.27

510

.22

289

.33

464

.26

243

.39

425

.31

207

.46

392

.37

178

.53

365

.43

155

.61

341

.49

137

.70

319

.56

107

.88

283

.70

88

1.09

255

.87

72

1.31

232

1.05

61

1.56

213

1.25

* PERF-O GRIP: To order standard PERF-O GRIP grating use part number “Pxxxxx”.

PERF-O GRIP 2: To order New PERF-O GRIP 2 grating use part number “Axxxxx”. End margins are standard on new PERF-O GRIP 2 grating

2-Hole through 6-Hole plank only ( 5” through 12” widths). Standard lengths are 10’-0” and 12’-0”.

6

PERF-O GRIP Grating

Grating Load Tables

PERF-O GRIP™ — 5-Hole Plank — 10” Width

915/16”

3

/32”

11/2”, 2” or 3”

90°

7

7

/8”

/8”

PERF-O GRIP

PERF-O GRIP 2

Plank Selection/Design Tables

Allowable Loads and Deflections: U=Uniform Load (lb./ft. ) C= Concentrated Load (lb.) D=Deflection (in.)

2

Material

Gauge

Channel Weight

Depth lb./lin.

in.

ft.

Catalog

(mm)

(kg/m) Number

11/2”

3.5

(38.1)

(5.2)

P51513*

A51513

Steel

13 ga.

Steel

11 ga.

Alum.

0.125”

Stainless

Steel

16 ga.

2”

3.9

(50.8)

(5.8)

11/2”

4.5

(38.1)

(6.7)

2”

5.1

(50.8)

(7.6)

3”

5.1

(76.2)

(7.6)

2”

1.8

(50.8)

(2.7)

2”

2.7

(50.8)

(4.0)

P52013*

A52013

P51511*

A51511

P52011*

A52011

P53011*

A53011

P520125*

A520125

P52016S*

A52016S

Span

2’-0”

2’-6”

3’-0”

3’-6”

4’-0”

4’-6” 5’-0”

5’-6”

6’-0”

6’-6”

7’-0”

7’-6”

8’-0”

9’-0” 10’-0” 11’-0” 12’-0”

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

963

.04

855

.03

1735

.04

1297

.02

1385

.05

1086

.03

2261

.04

1670

.02

4214

.03

3095

.02

1048

.05

1431

.06

745

.08

684

.05

1110

.06

1038

.04

888

.07

888

.05

1447

.06

1336

.04

2697

.04

2476

.03

1022

.12

1145

.09

517

.11

645

.09

771

.08

865

.05

618

.10

772

.08

1005

.08

1113

.06

1873

.06

2064

.04

710

.18

954

.13

380

.15

554

.12

568

.11

741

.08

455

.14

663

.11

739

.11

954

.08

1376

.08

1769

.05

522

.24

818

.19

291

.19

485

.15

435

.15

648

.10

349

.18

582

.15

567

.15

888

.11

1053

.10

1548

.07

400

.31

715

.25

230 187

.24

.30

431 388

.19

.24

344 281

.18

.23

645 584

.15

.18

276 225

.23

.29

518 467

.18

.23

449 364

.19

.23

823 758

.14

.18

832 674

.13

.16

1376 1238

.08

.11

316 256

.40

.49

636 572

.32

.39

154

.36

353

.29

232

.28

532

.22

186

.35

426

.28

300

.28

689

.22

557

.19

1126

.14

212

.59

520

.47

129

.43

323

.35

196

.33.

489

.26

157

.41

392

.33

253

.33

631

.27

468

.23

1032

.16

178

.71

477

.57

110

.51

298

.41

167

.39

453

.31

134

.49

363

.39

216

.39

583

.31

399

.27

952

.19

153

.83

440

.66

95

.59

277

.47

144

.45

422

.36

117

.57

338

.45

186

.45

541

.36

344

.31

927

.24

131

.96

409

.77

83

.67

259

.54

126

.52

392

.41

101

.65

318

.52

162

.52

505

.42

300

.35

902

.28

115

1.10

382

.88

73

.77

242

.61

110

.59

368

.47

90

.75

299

.60

142

.59

473

.47

263

.41

878

.33

101

1.26

358

1.00

58

.98

216

.78

88

.75

327

.60

71

.95

268

.76

112

.75

421

.60

208

.52

781

.41

80

1.59

318

1.27

46

1.20

191

.95

70

.91

297

.79

59

1.20

244

.96

91

.92

378

.74

168

.64

702

.51

65

1.96

286

1.57

38

1.44

176

1.16

60

1.14

267

.89

48

1.45

225

1.17

75

1.12

344

.89

139

.77

638

.62

54

2.37

260

1.90

32

1.71

162

1.39

50

1.34

245

1.06

41

1.74

205

1.39

63

1.32

316

1.06

117

.92

585

.74

46

2.83

238

2.26

U

D

C

D

1418

.04

1148

.03

907

.07

918

.05

630

.10

765

.07

463

.13

656

.10

354

.17

574

.13

280

.21

510

.17

187

.32

430

.26

158

.38

393

.30

134

.44

363

.36

115

.52

337

.41

101

.59

315

.48

88

.67

295

.54

70

.85

263

.69

57

1.06

237

.85

47

1.28

215

1.02

39

1.50

197

1.22

226

.26

459

.21

* PERF-O GRIP: To order standard PERF-O GRIP grating use part number “Pxxxxx”.

PERF-O GRIP 2: To order New PERF-O GRIP 2 grating use part number “Axxxxx”. End margins are standard on new PERF-O GRIP 2 grating

2-Hole through 6-Hole plank only ( 5” through 12” widths). Standard lengths are 10’-0” and 12’-0”.

PERF-O GRIP Grating

7

Grating Load Tables

PERF-O GRIP™ — 6-Hole Plank — 12” Width

1115/16”

3

/32”

11/2”, 2” or 3”

90°

7

7

/8”

/8”

PERF-O GRIP

PERF-O GRIP 2

Plank Selection/Design Tables

Allowable Loads and Deflections: U=Uniform Load (lb./ft. ) C= Concentrated Load (lb.) D=Deflection (in.)

2

Material

Gauge

Channel Weight

Depth lb./lin.

in.

ft.

Catalog

(mm)

(kg/m) Number

11/2”

4.3

(38.1)

(6.4)

P61513*

A61513

Steel

13 ga.

Steel

11 ga.

Alum.

0.125”

Stainless

Steel

16 ga.

2”

4.6

(50.8)

(6.8)

11/2”

5.3

(38.1)

(7.9)

2”

5.5

(50.8)

(8.2)

3”

6.2

(76.2)

(9.2)

2”

2.1

(50.8)

(3.1)

2”

3.2

(50.8)

(4.7)

P62013*

A62013

P61511*

A61511

P62011*

A62011

P63011*

A63011

P620125*

A620125

P62016S*

A62016S

Span

2’-0” 2’-6”

3’-0” 3’-6”

4’-0”

4’-6”

5’-0”

5’-6”

6’-0”

6’-6”

7’-0”

7’-6”

8’-0”

9’-0” 10’-0” 11’-0” 12’-0”

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

669

.03

960

.03

1510

.03

1442

.02

986

.03

1231

.03

1937

.03

1881

.02

3828

.02

3448

.02

1463

.08

1612

.06

655

.07

819

.05

966

.05

1154

.04

739

.06

985

.05

1240

.05

1505

.04

2450

.04

2759

.02

936

.12

1290

.09

456

.10

684

.08

671

.07

961

.06

515

.09

821

.07

861

.07

1292

.06

1701

.05

2299

.04

650

.17

1075

.14

336

.13

588

.11

493

.10

862

.08

378

.12

703

.10

633

.10

1109

.08

1250

.07

1971

.05

478

.23

921

.18

258

.17

516

.14

378

.13

756

.10

291

.16

615

.13

486

.13

971

.10

957

.10

1724

.07

366

.30

806

.24

204

.22

460

.18

299

.16

673

.13

230

.21

547

.16

385

.16

865

.13

757

.12

1533

.09

290

.38

716

.30

166

.27

416

.22

243

.20

608

.16

188

.25

492

.20

312

.20

781

.16

614

.15

1405

.11

235

.47

645

.38

138

.33

380

.26

201

.25

555

.20

156

.31

448

.25

259

.24

712

.20

507

.18

1396

.14

194

.57

586

.45

117

.40

349

.32

170

.29

509

.23

131

.37

410

.29

218

.29

654

.23

427

.22

1282

.17

163

.68

537

.54

100

.47

325

.37

145

.35

472

.28

112

.43

379

.34

186

.34

604

.27

365

.25

1185

.20

140

.79

496

.63

87

.55

303

.44

126

.40

440

.32

97

.50

352

.40

161

.40

563

.32

315

.29

1102

.24

120

.92

461

.74

76

.63

285

.50

110

.46

413

.37

85

.57

328

.46

140

.46

527

.37

274

.34

1030

.27

104

1.05

430

.84

67

.72

268

.58

97

.53

388

.42

75

.65

308

.52

124

.52

496

.42

242

.39

968

.31

93

1.20

403

.96

54

.92

241

.74

77

.68

349

.54

60

.82

274

.66

99

.67

444

.54

192

.49

864

.39

73

1.52

358

1.22

44

1.16

218

.91

63

.85

317

.67

50

1.02

246

.81

80

.83

403

.67

156

.61

781

.49

60

1.88

322

1.50

37

1.43

198

1.11

53

1.03

291

.82

41

1.25

227

1.00

67

1.01

389

.81

130

.74

714

.59

49

2.27

293

1.82

31

1.68

182

1.32

45

1.25

270

.99

35

1.50

210

1.20

57

1.22

341

.98

108

.87

652

.70

41

2.70

269

2.16

U

D

C

D

1289

.04

1252

.03

825

.07

1002

.05

573

.10

835

.07

421

.13

715

.10

322

.17

626

.13

255

.22

556

.17

206

.27

501

.21

170

.33

469

.26

143

.39

430

.31

122

.46

397

.37

105

.53

368

.42

91

.61

343

.49

80

.69

322

.55

64

.88

286

.70

51

1.08

257

.86

42

1.30

234

1.05

35

1.54

215

1.25

* PERF-O GRIP: To order standard PERF-O GRIP grating use part number “Pxxxxx”.

PERF-O GRIP 2: To order New PERF-O GRIP 2 grating use part number “Axxxxx”. End margins are standard on new PERF-O GRIP 2 grating

2-Hole through 6-Hole plank only ( 5” through 12” widths). Standard lengths are 10’-0” and 12’-0”.

8

PERF-O GRIP Grating

Grating Load Tables

PERF-O GRIP™ — 10-Hole Plank — 18” Width

1715/16”

3

/32”

11/2”, 2” or 3”

90°

7

7

/8”

/8”

PERF-O GRIP

Plank Selection/Design Tables

Allowable Loads and Deflections: U=Uniform Load (lb./ft. ) C= Concentrated Load (lb.) D=Deflection (in.)

2

Material

Gauge

Channel Weight

Depth lb./lin.

in.

ft.

Catalog

(mm)

(kg/m) Number

11/2”

5.7

(38.1)

(8.5)

P101513

Steel

13 ga.

Steel

11 ga.

Alum.

0.125”

2”

6.0

(50.8)

(8.9)

11/2”

6.8

(38.1)

(10.1)

2”

7.1

(50.8)

(10.5)

3”

7.9

(76.2)

(11.7)

2”

2.8

(50.8)

(4.1)

P102013

P101511

P102011

P103011

P1020125

Span

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

U

D

C

D

2’-0”

2’-6”

3’-0”

3’-6”

4’-0”

4’-6”

5’-0”

5’-6”

6’-0”

6’-6”

7’-0”

7’-6”

8’-0”

9’-0” 10’-0” 11’-0” 12’-0”

714

.04

964

.03

1072

.03

1452

.02

781

.04

1257

.03

1250

.03

1924

.02

2675

.02

3531

.01

992

.07

1652

.05

457

.07

771

.04

686

.05

1162

.03

500

.06

1006

.05

800

.05

1539

.04

1712

.04

2825

.02

635

.10

1322

.08

317

.10

642

.07

476

.07

968

.05

347

.09

838

.07

555

.07

1283

.05

1189

.05

2354

.03

441

.16

1102

.13

233

.13

551

.09

350

.10

830

.06

255

.12

718

.09

408

.09

1099

.07

873

.07

2018

.04

324

.21

944

.17

179

.17

495

.12

268

.13

726

.09

196

.15

629

.12

314

.12

962

.09

669

.09

1766

.06

248

.28

826

.22

142

.21

481

.17

212

.16

645

.12

156

.19

559

.15

249

.15

855

.12

528

.11

1569

.08

196

.35

734

.28

116

.26

434

.21

173

.20

581

.14

127

.24

503

.19

201

.18

770

.14

428

.14

1412

.10

158

.44

661

.35

96

.32

397

.26

143

.24

528

.17

105

.29

457

.23

167

.22

700

.17

354

.17

1284

.12

131

.53

601

.42

82

.39

366

.31

121

.29

509

.22

89

.34

419

.27

141

.26

641

.21

297

.20

1177

.14

110

.63

551

.50

69

.45

337

.36

103

.34

489

.27

76

.40

387

.32

121

.31

592

.24

254

.24

1141

.20

94

.74

508

.59

60

.52

314

.42

90

.40

470

.32

66

.47

359

.37

104

.35

550

.28

219

.28

1106

.23

81

.86

472

.69

52

.60

293

.48

78

.46

439

.37

58

.53

335

.43

91

.41

514

.33

190

.31

1070

.25

70

.98

441

.79

45

.68

274

.55

69

.53

411

.42

52

.61

314

.49

80

.46

484

.37

167

.36

1003

.29

62

1.12

413

.89

36

.86

243

.69

55

.67

366

.53

41

.77

279

.62

64

.59

434

.48

132

.45

892

.36

49

1.42

367

1.13

PERF-O GRIP: To order standard PERF-O GRIP grating use part number “Pxxxxx”.

Standard lengths are 10’-0” and 12’-0”.

PERF-O GRIP Grating

9

29

1.05

220

.85

44

.82

329

.65

34

.96

253

.76

53

.74

395

.59

107

.56

802

.45

40

1.75

330

1.40

24

1.27

199

1.03

36

.98

299

.79

29

1.20

234

.94

44

.91

363

.73

89

.68

730

.54

33

2.11

300

1.69

21

1.56

183

1.23

31

1.19

274

.94

25

1.45

219

1.14

37

1.08

337

.87

74

.81

669

.65

27

2.52

275

2.01

Grating Load Tables

PERF-O GRIP™ — 13-Hole Plank — 24” Width

2315/16”

3

/32”

2” or 3”

90°

7

7

/8”

/8”

PERF-O GRIP

Plank Selection/Design Tables

Allowable Loads and Deflections: U=Uniform Load (lb./ft. ) C= Concentrated Load (lb.) D=Deflection (in.)

2

Material

Gauge

Channel Weight

Depth lb./lin.

in.

ft.

Catalog

(mm)

(kg/m) Number

2”

8.9

(50.8)

(13.2)

P132011

Steel

11 ga.

3”

9.8

(76.2)

(14.5)

P133011

Span

2’-0”

U

D

C

D

U

D

C

D

2’-6”

3’-0”

3’-6”

4’-0”

4’-6”

5’-0”

5’-6”

6’-0”

6’-6”

7’-0”

7’-6”

8’-0” 9’-0” 10’-0” 11’-0” 12’-0”

1094 700

.03

.05

2092 1674

.02

.03

1971 1261

.02

.03

3792 3033

.01

.02

486

.06

1395

.05

876

.04

2528

.03

357

.09

1196

.06

644

.06

2167

.04

273

.12

1046

.09

493

.08

1896

.05

216

.15

930

.11

389

.10

1685

.07

175

.18

837

.14

315

.12

1517

.09

145

.22

761

.17

261

.15

1379

.10

123

.26

697

.20

219

.18

1264

.12

105

.31

644

.23

187

.21

1167

.15

91

.36

598

.27

161

.24

1083

.17

79

.41

558

.31

141

.28

1011

.19

70

.47

540

.37

124

.32

948

.22

56

.60

504

.49

99

.40

843

.30

45

.75

459

.61

80

.50

758

.38

38

.92

423

.74

67

.61

689

.46

33

1.13

393

.90

57

.73

632

.54

PERF-O GRIP: To order standard PERF-O GRIP grating use part number “Pxxxxx”.

Standard lengths are 10’-0” and 12’-0”.

10

PERF-O GRIP Grating

Grating Load Tables

PERF-O GRIP™ — 16-Hole Plank — 30” Width

2915/16”

3

/32”

2”, 3” or 4”

90°

7

7

/8”

/8”

PERF-O GRIP

Plank Selection/Design Tables

Allowable Loads and Deflections: U=Uniform Load (lb./ft. ) C= Concentrated Load (lb.) D=Deflection (in.)

2

Material

Gauge

Steel

11 ga.

Channel Weight

Depth lb./lin.

in.

ft.

Catalog

(mm)

(kg/m) Number

2”

11.8

(50.8)

(17.5)

3”

12.7

(76.2)

(18.9)

4”

13.5

(101.6)

(20.1)

P162011

P163011

P164011

Span

U

D

C

D

U

D

C

D

U

D

C

D

2’-0”

2’-6”

3’-0”

3’-6”

4’-0”

4’-6”

5’-0’

5’-6”

6’-0’

6’-6”

7’-0’

7’-6” 8’-0”

9’-0” 10’-0” 11’-0” 12’-0”

956

.02

2564

.01

1413

.02

3802

.01

2240

.01

5838

.01

612

.03

2051

.02

904

.03

3041

.02

1434

.02

4670

.02

425

.04

1709

.03

628

.04

2534

.03

996

.03

3892

.02

312

.05

1465

.04

461

.06

2172

.04

731

.04

3336

.03

239

.07

1282

.06

353

.08

1901

.05

560

.06

2919

.04

189

.09

1140

.07

279

.10

1690

.07

443

.07

2595

.05

153

.11

1026

.09

226

.12

1521

.09

358

.09

2335

.07

126

.13

932

.10

187

.14

1382

.10

296

.11

2123

.08

106

.16

855

.12

157

.17

1267

.12

249

.13

1946

.09

91

.18

789

.15

134

.20

1170

.14

212

.15

1796

.11

77

.21

733

.17

116

.23

1086

.17

183

.17

1668

.13

68

60

.24

.28

684 641

.20

.22

100

89

.26

.30

1014 950

.19

.22

159 140

.20

.23

1557 1459

.15

.17

47

.35

570

,28

70

.38

845

.28

111

.29

1297

.21

PERF-O GRIP: To order standard PERF-O GRIP grating use part number “Pxxxxx”.

Standard lengths are 10’-0” and 12’-0”.

PERF-O GRIP Grating

11

38

.43

513

.35

57

.47

760

.34

91

.36

1168

.26

32

.52

466

.42

46

.57

691

.41

75

.44

1061

.32

27

.62

427

.50

39

.67

634

.53

64

.52

973

.38

Grating Load Tables

PERF-O GRIP™ — Walkway — 24”, 30” & 36” Widths

26”

32”

38”

1”

1”

24”

30”

36”

5”

3

90°

7

/32”

/16”

PERF-O-GRIP

Walkway Selection/Design Tables (Note: Consult factory for data on 36” width)

Allowable Loads and Deflections: U=Uniform Load (lb./ft. ) C= Concentrated Load (lb.) D=Deflection (in.)

2

Material

Gauge

Steel

11 ga.

24” wide

Channel Weight

Depth lb./lin.

in.

ft.

(mm)

(kg/m)

5”

11.8

(127.0)

(17.5)

(609.6)

Steel

11 ga.

30” wide

(762.0)

5”

13.6

(127.0)

(20.2)

Span

Catalog

Number

U

D

P135011W

C

D

U

D

P165011W

C

D

2’-0” 2’-6”

3’-0”

3’-6”

4’-0”

4’-6”

5’-0”

5’-6”

6’-0”

6’-6” 7’-0”

7’-6”

8’-0”

9’-0” 10’-0” 11’-0” 12’-0”

5751

.02

9504

.01

3868

.01

9534

.00

2556

.04

6336

.02

1719

.03

6356

.02

1878

.05

5431

.03

1263

.04

5448

.03

1438

.06

4752

.04

967

.05

4767

.04

1136

.08

4224

.05

764

.06

4237

.05

920

.10

3802

.06

619

.08

3813

.06

760

.12

3456

.07

511

.10

3467

.07

639

.14

3168

.08

430

.12

3178

.08

544

.16

2924

.10

366

.13

2933

.10

409

.22

2534

.13

275

.18

2542

.13

359

.25

2376

.15

242

.20

2383

.15

284

.31

2112

.19

191

.26

2119

.19

3681

.02

7603

.01

2475

.02

7627

.01

469

.19

2715

.11

316

.16

2724

.11

230

.39

1901

.23

155

.32

1907

.23

190 160

.47 .56

1728 1584

.28 .34

128 107

.39 .46

1733 1589

.28 .33

PERF-O GRIP: To order standard PERF-O GRIP grating use part number “Pxxxxx”.

Standard lengths are 10’-0” and 12’-0”. Longer lengths of 20’-0” and 24’-0” are available. Consult factory.

12

PERF-O GRIP Grating

Accessories

PERF-O GRIP™ Bolt Washer Seat

Carriage

Bolt **

Part Number Includes

(1) Bolt Washer Seat (PBOLTSEAT)

P Bolt

Seat

Flat

Washer

Order Separately

(1) 3/8”-16 Carriage Bolt **

(1) 3/8” Flat Washer

(1) 3/8”-16 Hex Nut

Hex Nut

Field drilling is required.

** Plank carriage bolt lengths = Side Channel Height + 1”

Walkway carriage bolt = 5/16”-18 x 2”

PERF-O GRIP Bolt Seats help provide a secure anchor

of the grating to structural supports. The standard bolt

seat features oblong holes specifically designed to help

ensure a vertical anchor (with a 3/8” bolt) even if the

hole is off concentrically by as much as 1/4”.

Hardware is not provided.

Bolt Washer Seat (P Bolt Seat)

UPC Number

Catalog Number

Wt./Ea.

66251626616

PBOLTSEAT

0.10

Assembly

1. Align PERF-O GRIP planks on I-Beam or other

anchoring cross-member.

2. Mark the I-Beam for drilling purposes under the

PERF-O GRIP hole nearest the end. Drill a pilot hole.

3. Remove PERF-O GRIP plank and drill a finish hole.

4. Replace PERF-O GRIP plank to its original position.

Place bolt seat in the PERF-O-GRIP hole which is

now lined up with the drilled hole.

5. Run the carriage bolt through the bolt seat,

PERF-O GRIP and I-Beam, and tighten with washer

and nut until secure.

6. Test for movement or slippage. If PERF-O GRIP

planks are not secure, check fastening system for

loose or missing parts. Repeat steps 1 thru 5.

Note: Do not walk on PERF-O GRIP planks if

they are not secure. Serious injury could result.

Welding

A common method of fastening safety grating is

welding. It is recommended that all B-Line Safety

Grating products be fillet welded per AWS D1.3.

For more information, consult Technical Services.

PERF-O GRIP Grating

13

Accessories

PERF-O GRIP™ J-Clip

Carriage

Bolt **

Part Number Includes

P Bolt

Seat

(1) J-Clip & (1) P Bolt Seat

Order Separately

(1) 3/8”-16 Carriage Bolt **

(1) 3/8” Flat Washer

(1) 3/8”-16 Hex Nut

J Clip

Flat

Washer

Hex Nut

** Plank carriage bolt lengths = Side Channel Height + 1”

Walkway carriage bolt = 5/16”-18 x 2”

PERF-O-GRIP J-Clips fasten the grating securely to the

supporting steel without drilling holes.

Standard finish is galvanized.

Hardware is not provided.

Seated J Clip

UPC Number

Catalog Number

Wt./Ea.

78205153667

JCLIP

0.30

Assembly

1. Align PERF-O GRIP planks on I-Beam or other

anchoring cross-member.

2. Place bolt seat on center hole of PERF-O-GRIP

nearest the overhanging end.

3. Align J-Clip below PERF-O-GRIP plank so that the

carriage bolt can slide through. Make sure the

lower lip of the J-Clip reaches well into the I-Beam.

4. Run the carriage bolt through the bolt seat to the

J-Clip and tighten securely with the washer and nut.

5. Test for movement or slippage. If PERF-O GRIP

planks are not secure, check fastening system for

loose or missing parts. Repeat steps 1 thru 4.

Note: Do not walk on PERF-O GRIP planks if

they are not secure. Serious injury could result.

Welding

A common method of fastening safety grating is

welding. It is recommended that all B-Line Safety

Grating products be fillet welded per AWS D1.3.

For more information, consult Technical Services.

14

PERF-O GRIP Grating

Accessories

PERF-O GRIP™ Mid Support Clip with Hardware

Part Number Includes

(1) Clip & (2) Set Screws

Mid Support Clip (with hardware)

UPC Number

Catalog Number

Wt./Ea.

66251639386

MSCLIP

0.50

PERF-O-GRIP mid support clips can be used at midspan

to increase load carrying capacities of individual

channels by fastening several planks together to form

an integral section. Mid support clip is manufactured

from galvanized steel and includes two set screws.

Assembly

1. Align PERF-O GRIP planks on I-Beam or other

anchoring cross-member.

2. Place clip around the bottom flanges of the

PERF-O GRIPS planks.

3. Slide to the required location.

4. Tighten the set screws.

5. Test for movement or slippage. If PERF-O GRIP

planks are not secure, check fastening system for

loose or missing parts. Repeat steps 1 thru 4 as

required.

Note: Do not walk on PERF-O GRIP planks if

they are not secure. Serious injury could result.

Welding

A common method of fastening safety grating is

welding. It is recommended that all B-Line Safety

Grating products be fillet welded per AWS D1.3.

For more information, consult Technical Services.

PERF-O GRIP Grating

15

Accessories

PERF-O GRIP™ Splice Plate Kits

Surface Splice Plate Kits

As width increases, grating surface performance

becomes more critical. Thus, for PERF-O GRIP product

widths greater than 12”, use of the grating surface

splice kit is recommended to mechanically join butt

ends of plank sections.

• POG-ES-10 (for 18” wide plank) & POG-ES-13 (for

24” wide plank) includes six (6) each of hardware

shown below.

• POG-ES-16 (for 30” wide plank) & POG-ES-20 (for

36” wide plank) includes eight (8) each of hardware

shown below.

• Hardware included: 3/8” x 1” carriage bolts, 3/8” flat

washers and bolt seats.

POG-ES-10

POG-ES-10 shown

POG-ES-13

POG-ES-16

POG-ES-20

Walkway Splice Plate Kits

Walkway Splice Plates provide continuity when multiple

lengths of PERF-O GRIP are desired. Connections are

reinforced with the addition of splice plates attached to

side channels.

• POG-WS-30 for 24”, 30” and 36” wide walkway.

• Each Kit includes: Two (2) splice plates and

thirty-two (32) each of the following hardware: 1/2” x

11/4” hex bolts, 1/2”-13 hex nuts and 1/2” flat washers.

POG-WS-30

30”

17/8”

33/4” C to C

5

/8”

41/2”

17/8”

3

/4”

POG-WS-30

11 Ga.

16

PERF-O GRIP Grating

Stair Treads & Carrier Plates

PERF-O GRIP™ Stair Treads

Specify original PERF-O GRIP or PERF-O GRIP 2 stair

treads. All treads have welded ends for attachment to

stringers.

• Mill-galvanized steel: 11 ga and 13 ga.

• Hot rolled, pickled and oiled carbon steel:

11 ga. and 13 ga.

• 24”, 30”, 36” and 48” lengths.

• 5”, 7” 10” and 12” (nominal) widths.

• 11/2” and 2” channel heights.

• For stair treads, intermediate stringer is

recommended for spans over 4 feet.

PERF-O GRIP Carrier Plates

Carrier plates allow you to create your own custom

stair treads. They are sold by the pair.

(2 plates = one pair).

“A”

“D”

“C”

“B”

7

/16” x 13/4” Slot

7

/16” Dia. Hole

PERF-O-GRIP Carrier Plate

Product

Nominal

Width

“A”

“B”

15

2-Hole Tread

3-Hole Tread

5-Hole Tread

6-Hole Tread

PERF-O GRIP Grating

5” (127mm)

7” (178mm)

615/16” (176mm)

615/16” (176mm)

10” (254mm)

915/16” (254mm)

915/16” (254mm)

12” (305mm)

“C”

“D”

1 /2” (38mm)

3

/4” (19mm)

2” (51mm)

2” (51mm)

11/2” (38mm)

1” (25mm)

3

/4” (19mm)

4” (102mm)

1

4 /16” (125mm)

415/16” (125mm)

2” (51mm)

1115/16” (303mm)

1115/16” (303mm)

17

2” (51mm)

1” (25mm)

/4” (19mm)

4” (102mm)

11/2” (38mm)

3

7” (178mm)

2” (51mm)

11/2” (38mm)

1” (25mm)

3

/4” (19mm)

7” (178mm)

2” (51mm)

1” (25mm)

9” (227mm)

9” (227mm)

Specifications - PERF-O-GRIP™

Notes to architect

1. PERF-O GRIP and PERF-O GRIP 2 gratings are intended for general purpose use in plants and process facilities by

industry, commerce, and public utilities, and on air, water, and surface, for both mobile and stationary equipment.

2. PERF-O GRIP and PERF-O GRIP 2 stair treads are intended for utility stairs and fire escapes in commercial, public and

private buildings where local code permits. They are not intended for staircases used regularly by the general public

where flat closed surfaces are desired. For this type of application, see TRACTION-TREAD™ stair treads and sheets.

3. These specifications are presented as a general guide to the architect or structural engineer in preparing project

specifications. Allowable loads, spans and other limiting conditions presented in this catalog offer product data for use

in design and construction.

4. All supports should provide a smooth, level, 11/2” minimum bearing surface, free of burrs, bridging, welds or other

irregularities.

5. Random cut ends and diagonal or circular cut exposed edges should be banded with a bar at least 1/8” thick and equal

to the overall side channel depth of grating welded at contact points at the discretion of the design engineer.

6. Bolted connections, except stair or ladder tread attachment to stringer channels, may be replaced by welded

connections that develop the same strength.

Part 1: General

1.1 Scope

The contractor shall furnish and install PERF-O-GRIP and PERF-O-GRIP 2 Gratings and Stair Treads, as specified and

shown on the drawings.

1.2 Qualifications

PERF-O-GRIP and PERF-O-GRIP 2 Gratings, Stair Tread and accessories, unless otherwise indicated, shall be

manufactured by Eaton’s B-Line Business, and shall be installed in accordance with its current printed directions.

Safety surface shall be slip-resistant in all directions.

1.3 Submittals

The contractor shall furnish shop drawings of grating layout, framing and supports, unit dimensions and sections, type

and location of fasteners and welds.

1.4 Storage and Handling

All materials shall be stored and handled to avoid damage. Damaged materials shall be removed from the premises.

Part 2: Products

2.1 Grating Materials

a. Type: (PERF-O-GRIP and PERF-O-GRIP 2 Gratings) (PERF-O-GRIP Walkways)

b. Metal and Finish: Standard (mill-galvanized steel, ASTM A924) (stainless steel, alloy Types 304-2B/D) (aluminum, alloy

5052 H32); Special order (carbon steel — hot rolled, pickled and oiled, ASTM-A569) (stainless steel, alloy Type 316-2B/D)

c. Metal gauge: (13-ga. steel) (11-ga. steel) (16-ga. stainless steel) ( .125” aluminum)

d. Section width: (5”) (7”) (10”) (12”) (18”) (24”) (30”) plank; (24”) (30”) (36”) walkway

e. Channel height: Safety Grating (11/2”) (2”) (3”) (4”) plank; (5”) Walkway Grating - OSHA compliant; Canadian OH & S Compliant

f. Standard lengths: (10’-0”) (12’-0”)

2.2 Stair Tread Materials

a. Type: (PERF-O-GRIP and PERF-O-GRIP 2 Stair Tread)

b. Metal and Finish: Standard (mill-galvanized steel, ASTM A924) (stainless steel, alloy Types 304-2B/D) (aluminum, alloy

5052 H32); Special order (carbon steel — hot rolled, pickled and oiled, ASTM-A1011) (stainless steel, alloy Type 316-2B/D)

c. Metal gauge: (13-ga. steel) (11-ga. steel) (16-ga. stainless steel) ( .125” aluminum)

d. Tread Depth: Standard (10”); Special Order (5”) (7”) (12”)

e. Channel height: Standard (11/2”); Special Order (2”)

f. Span or Width of Staircase: (24”) (30”) (36”)

2.3 Accessories

a. Bolt Seats: Standard (mill-galvanized steel, ASTM A924); Special order (carbon steel — hot rolled, pickled and oiled,

ASTM A569) (aluminum, alloy 5052-H32); (stainless steel, alloy Types 304-2B/D) (stainless steel, alloy Type 316-2B/D)

b. “J” Clip Attachment: Standard (mill-galvanized steel, ASTM A924); Special order (carbon steel — hot rolled, pickled and

oiled, ASTM A569) (aluminum, alloy 5052-H32); (stainless steel, alloy Types 304-2B/D) (stainless steel, alloy Type 316-2B/D)

18

PERF-O GRIP Grating

Specifications - PERF-O-GRIP™

c. Midsupport Clip: Standard (mill-galvanized steel, ASTM A924); Special order (carbon steel — hot rolled, pickled and

oiled, ASTM A1011) (aluminum, alloy 5052-H32); (stainless steel, alloy Types 304-2B/D) (stainless steel, alloy Type 316-2B/D)

d. Surface Splice Kit: Standard (mill-galvanized steel, ASTM A924); Special order (carbon steel — hot rolled, pickled and

oiled, ASTM A1011) (aluminum, alloy 5052-H32); (stainless steel, alloy Types 304-2B/D) (stainless steel, alloy Type 316-2B/D)

e. Walkway Splice Kit: Standard (mill-galvanized steel, ASTM A924); Special order (carbon steel — hot rolled, pickled and

oiled, ASTM A1011) (aluminum, alloy 5052-H32); (stainless steel, alloy Types 304-2B/D) (stainless steel, alloy Type 316-2B/D)

f. Universal Handrail Bracket for Walkways: Eliminates unnecessary substructure for supporting handrail posts.

Part 3: Execution

3.1 Condition of surfaces

Prior to grating installation, contractor shall inspect supports for correct size, layout and alignment and verify that

surfaces to receive grating are free of debris. The contractor shall report to the design or consulting engineer or

owner’s agent in writing any defects considered detrimental to proper application of grating so defects can be

remedied before grating is applied.

3.2 Grating installation

Install grating in accordance with manufacturer’s recommendations and shop drawings. Position grating sections

flat and square with ends bearing min. 11/2” on supporting structure. Keep grating sections at least 1/4” away from

vertical steel sections and 1/2” from concrete walls. Installation clearances are built into this product. Allow

clearance at joints between sections of max. 1/4” at side channels and max. 3/8” at ends. When specified, band

random cut ends and diagonal or circular cut exposed edges with a min. 1/8” thick bar welded at contact points.

3.3 Grating attachment

Attach grating to supports without warp or deflection as follows:

a. Single plank application: Secure plank ends to supporting members at every point of contact. Use(2) PERF-O GRIP

Bolt Seats or “J” Clip Assemblies at each end or secure both side channels at each end to supports by fusion

welding with 1/8” fillet welds, 1” long.

b. Multiple plank application: Secure perimeter plank to supporting members at every point of contact and

intermediate grating sections with at least (1) attachment each end of plank, on alternate sides. For added rigidity

when span exceeds (6’-0”) (8’-0”), attach side channels of adjacent plank together (at mid-point of span) using mid

support clip.

c. Welded attachment: Secure side channels to supports by fusion welding with 1/8” fillet welds, 1” long. Weld

adjacent planks together with 1/8” fillet welds, 1” long, 24” o.c. staggered top and bottom.

d. Clip attachment: Secure intermediate planks to supports using Bolt Seat and “J” Clip Assembly. Use Bolt Seat

with 3/8” carriage bolts and nuts for securing perimeter planks. Fasten adjacent side rails together with mid

support clip or 3/8” machine bolts and nuts through locally drilled holes.

3.4 Stair Tread Installation

Install PERF-O GRIP and PERF-O GRIP 2 stair treads as shown on the drawings. Fasten treads to stair stringers with

3

/8” x 1” machine bolts and nuts.

a. For stair treads, intermediate stringer is recommended for spans over 4 feet.

How To Order

Technical Assistance

For technical assistance not found in this catalog, contact your local PERF-O-GRIP and PERF-O-GRIP 2™ Gratings

Distributor, or contact our Technical Service Department at 1-800-582-3643 (phone) or 1-770-268-7213 (fax).

PERF-O GRIP and PERF-O GRIP 2 grating are stocked in all major markets. For the finest in slip-resistant grating and stair

treads, contact us or go to www.bline.com to locate your local distributor. You will receive skilled consulting service on

your specific requirements.

Fabrication Service

On large jobs, we estimate, quote, detail and fabricate to your requirement. After receipt of order, layout drawings

are prepared for easy installation.

Notice: We shall not be liable for incidental and consequential damages, directly or indirectly sustained, nor for any loss

caused by application of these goods not in accordance with current printed instructions or for other than the intended

use. Our liability is expressly limited to replacement of defective goods. Any claims shall be deemed waived unless made

in writing to us within thirty (30) days from date it was or reasonably should have been discovered.

See terms and conditions at www.cooperbline.com/legal.

PERF-O GRIP Grating

19

U.S. Customer Service Center is staffed Monday through Friday

from 7 a.m. to 5:00 p.m. Central Standard Time.

For more information visit, www.cooperbline.com/grating.

Eaton’s B-Line Business

United States

509 West Monroe Street

Highland, IL 62249

United States

Phone: (800) 582-3643

www.cooperbline.com/contactus

Eaton

1000 Eaton Boulevard

Cleveland, OH 44122

United States

Eaton.com

B-Line Business

509 West Monroe Street

Highland, IL 62249

Phone: 800-851-7415

Fax: 618-654-1917

www.cooperbline.com

© 2014 Eaton

All Rights Reserved

Printed in USA

Publication No. GSPOG-13R

August 2014

Eaton is a registered trademark

All other trademarks are property

of their respective owners.