Class 19: Course Wrap-up 1. Course Main Concepts and Simulation Debriefing

advertisement

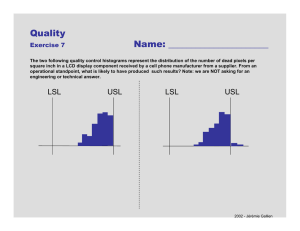

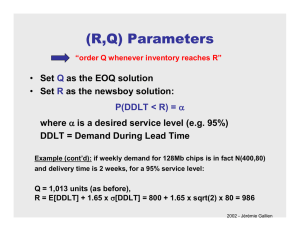

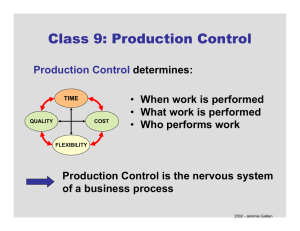

Class 19: Course Wrap-up 1. Course Main Concepts and Simulation Debriefing 2. Sloan Evaluation Forms 3. Final Feedback Survey after class 2002 - Jérémie Gallien Intro to Ops At-a-Glance # Day Date Contents Readings 1 Mon 2 Assignments Sim 29-Mar Course Introduction Course Syllabus Wed 31-Mar Case: Burger King + McDonald's Types of processes 3 Fri 2-Apr Lecture: Capacity Wait-in-line blues 1 Ex. Buildup, 1 Ex. Queueing 4 Mon 5-Apr Case: National Cranberry 5 Wed 7-Apr Case: Webvan 6 Fri 9-Apr Lecture: Inventory Automate or Die 1 Ex. EOQ, 1 Ex. Newsboy 7 Mon 12-Apr Case: Barilla Managing Supply-Chain Inventory 8 Wed 14-Apr Case: Sport Obermeyer Rocket Science Retailing Case Write-up 9 Fri 16-Apr Lecture: Production Control Growth in MRP, Control of JIT 1 Ex. Kanban, 1 Ex. Commonality 10 Wed 21-Apr Case: Hewlett-Packard 11 Fri 23-Apr Book: The Goal The Goal Book Review 12 Mon 26-Apr Lecture: Quality Hank Kolb case 1 Ex. SPC, 1 Ex. 6 Sigma 13 Wed 28-Apr Case: Toyota 14 Fri 30-Apr Lecture: Process Design 15 Mon 3-May Case: Global Financial Corporation 16 Wed 5-May Lecture: Supply Chain Design 17 Fri 7-May Lecture: Product Design 18 Mon 10-May Case: Sega Dreamcast 19 Wed 12-May Simulation & Course Wrap-up Reengineering Work, ERP Tech. Note Chapter 8 Clockspeed Simulation Write-up 2002 - Jérémie Gallien What is Operations Management? TIME OM = Strategy Execution! QUALITY FLEXIBILITY COST 2002 - Jérémie Gallien Benchmark Companies • Toyota • FedEx (Webvan) • Dell Lean Manufacturing Hub & Spoke Direct-to-Consumer ATO technology • Walmart (Barilla) Vendor-Managed Inventory • Sport Obermeyer Quick Response • Zara Assortment Optimization 2002 - Jérémie Gallien Operations Management History • 1920’s: Ford & Taylor Moving Production line and standardized work • 1930’s: Shewhart Statistical Control of Quality • 1960’s: Ohno Lean Production System • 1980’s: Goldratt Theory of Constraints • 1990’s: Hammer Reengineering & Process Focus • 2000’s: 15.760 Alumni Storytelling 2002 - Jérémie Gallien A Translation Challenge Corporate Structure Top Management speaks the language of MONEY Operations Management Mid-Mgt., Associates, Workers speak the language of THINGS OM merges physical and financial analyses, and requires great care to people issues! 2002 - Jérémie Gallien Operations Management Architecture Product Supply-Chain Integral Vs. Modular: Integral Vs. Modular: • Functions • Interface • Interchangeability • Geography • Organization • Culture • Communication Customization Process HR Project Functional Managers Job Shop General Manager Batch Flow Line Flow Continuous Volume Project Managers 2002 - Jérémie Gallien Operations Management Activities Set of responsibilities: 1. DESIGN Product, Process, Supply-Chain, HR 2. PLANNING Demand (forecast), Supply (Capacity) 3. CONTROL Inventory, Production Control, Suppliers Pricing, LT Quote, Quality, HR 4. IMPROVEMENT Time, Cost, Flexibility, Quality 2002 - Jérémie Gallien Operations Management Tools Product Design & Devlpt. Design Planning Control Improvement Process Supply Chain Product Architecture Development Process Reengineering Market Positioning Process Architecture Reengineering SC Architecture Strategic Sourcing CPM DSM Capacity Analysis ERP, CPM Quick Response Capacity CPM CPM Critical Chain Inventory TOC, CPM, ERP Production Control TQM Inventory Theory VMI (JITD) Production Control TQM TQM TPS TOC (The Goal) TQM, TPS & Lean Manufacturing TPS, Lean Manufacturing 2002 - Jérémie Gallien Factory Simulation Skills Product Design & Devlpt. Design Planning Control Improvement Process Supply Chain Process Architecture Process Flow Diagram Forecasting Capacity Analysis Cycle Time Analysis Inventory Control Team Organization TOC (The Goal) TPS 2002 - Jérémie Gallien 4,000,000 3,500,000 3,000,000 2,500,000 2,000,000 1,500,000 1,000,000 500,000 0 0 5 10 15 20 25 Max # of Machines 2002 - Jérémie Gallien Capacity Analysis Processing Time (hours): Step 1 2 3 4 Station 1 2 3 2 Set-up time (per lot) 0 0 1.5 0 Operation time (per unit) 0.062777 0.02 0.001666 0.021388 + FORECAST Capacity Utilization ρ=λ/Nxµ 2002 - Jérémie Gallien … and Queueing Theory Average Waiting Time W 0 1 2 ( S +1) C +C 1 ρ W= × λ 1− ρ 2 2 A Capacity Utilization ρ=λ/Mxµ 2 S 2002 - Jérémie Gallien An Example for Insight 1 job arrives every minute on average Server takes 45 sec. to process each job Queue initially empty λ=1 µ = 1.33 Queue Length 5 4 3 2 1 0 1 2 3 4 5 6 7 8 9 10 11 12 Time (min) 2002 - Jérémie Gallien Cycle Time Analysis Station 1 Station 2 Station 3 Station 2 60 kits/lot total cycle time 30 kits/lot total cycle time 2002 - Jérémie Gallien Customer and Process Timeline stage 1 LT1 stage 2 stage 4 stage 3 LT2 0 LT3 LT4 Target customer delivery LT customer t PULL stage 1 stage 2 stage 3 stage 4 customer PUSH 2002 - Jérémie Gallien Delayed Differentiation demand Customization Step Upstream Steps demand demand LT1 0 LT2 t Target customer delivery LT 2002 - Jérémie Gallien Delayed Differentiation Customization Step Upstream Steps demand demand demand LT1 0 LT2 t Target customer delivery LT 2002 - Jérémie Gallien Inventory Theory… Order Quantity Q EDDLT EDDLT EDDLT DDLT1 Reorder Level Order Quantity Q = Lead Time = Expected Demand During Lead Time = (Actual) Demand During Lead Time DDLT2 LT EDDLT DDLT Inventory Safety Stock LT 1 Order 1 placed LT 2 Time Order 1 received 2002 - Jérémie Gallien Slide courtesy of Prof. Thomas Roemer, MIT. … and Inventory Practice • EOQ Model • ROP/ROQ • Newsboy Model • Continuous Review/Periodic Review 2002 - Jérémie Gallien $4,000,000 $3,500,000 $3,000,000 $2,500,000 $2,000,000 $1,500,000 $1,000,000 $500,000 $0 4/30 5/1 5/2 5/3 5/4 Date 5/5 5/6 5/7 5/8 2002 - Jérémie Gallien Simulation Performance Drivers • Proactive Vs. Reactive Strategy: this is what models allow!!! • Extent of quantitative analysis does have an impact BUT describing qualitatively the correct trade-offs brings you a long way… • Understanding financial impact of operational data (lead time, utilization, queues, etc…) had a huge impact! 2002 - Jérémie Gallien Final Words Do Keep in Touch and… GOOD LUCK!!! 2002 - Jérémie Gallien