Document 13604456

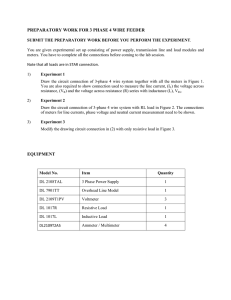

advertisement