Tech Tips T Evaluating the Methods for Refurbishing Firefighter Cordura Items

advertisement

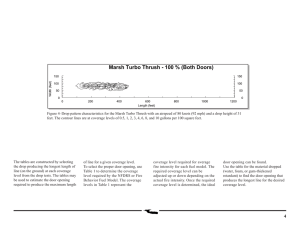

United States Department of Agriculture Forest Service Tech Tips National Technology & Development Program • Fire • November 2013 • 5100 • 1451–2306P–MTDC Evaluating the Methods for Refurbishing Firefighter Cordura Items Sean Wildhaber, Interagency Hotshot Squad Leader and Mary Ann Davies, Program Leader Highlights… • Avoid machine washing Cordura items if possible. Pay attention to equipment care labels and the National Wildfire Coordinating Group “Fire Equipment Storage and Refurbishing Standards” <http://www.nwcg.gov /pms/pubs/PMS448`/pms448.pdf>. • Take special care when machine washing Cordura items with polyurethane linings. Always machine wash on the gentle wash setting with cold water in a front-loading machine. • When faced with extremely soiled items, soak or spray with approved biodegradable degreasers before washing. T he Missoula Technology and Development Center (MTDC) was asked to determine the effects of washing Cordura items available for firefighters from the U.S. General Services Administration (GSA). Cordura is a collection of fabrics that are durable with resistance to abrasions, tears, and scuffs. The National Interagency Support Caches supply and distribute items made with Cordura, such as fireline packs, during the fire season. When the Cordura items are returned, the cache cleans them as well as all other items, this is known as refurbishing. Required refurbishing standards are published by the National Wildfire Coordinating Group (NWCG). The 2011 update of the NWCG publication “Fire Equipment Storage and Refurbishing Standards” allows for machine washing of most Cordura items handled by the caches. However, long-term effects of machine washing Cordura items and alternative drying techniques, other than hanging to dry, are not known (figure 1). Figure 1—The fuel bottle bag (left) and line gear (right) are Cordura items evaluated in the refurbishing equipment study. For additional information, contact: USDA Forest Service, MTDC; 5785 Hwy. 10 West; Missoula, MT 59808–9361. Phone: 406–329–3900; fax: 406–329–3719; email: wo_mtdc_pubs@fs.fed.us A 2010 MTDC questionnaire to the national cache community on textile cleaning methods with special emphasis on handling of Cordura items identified that 15 of the 18 caches do not perform any inhouse machine washing of Cordura items while 3 said they do. Of the three, two said that they are following the recommended machine washing method (cold water, gentle wash setting, and hang-to-dry) and were satisfied with the outcome. The third cache was soaking items in CitroSqueeze (a commercial citrus-based cleaning product), machine washing in warm water, and machine drying at 100 °F. MTDC tested five methods of washing Cordura items. The focus was to evaluate positive or negative effects of these methods. The main questions to answer were: • Do any of these methods reduce long-term durability of Cordura items? • How does Cordura hold up to the alternative washing and drying methods? • Which method or methods are the best? • Does the evaluation of these washing methods support the current NWCG cleaning practices? MTDC determined which methods are less than ideal for the serviceability of Cordura items and made recommendations on them. Fraying of unbound edge Loose or missing stitching Comparison of Refurbishing Methods Figures 2a and 2b—Some factory defects (fraying and incomplete stitching) of Cordura items that were evaluated in this study. MTDC inspected Cordura items for any visible factory defects, such as loose or missing stitching, abrasions, tears, fraying, flaking or missing polyurethane coatings, and delaminating silk screen placards (figures 2a and 2b). We took photos and measured the Cordura items (length, width, and height) to build a log of information. We set up a control group by referencing the refurbishing methods of NWCG and most regional caches. We also set up five additional test groups to evaluate alternative methods (table 1). After each cycle (soak, wash, and dry), if we observed defects, careful evaluation would determine textile serviceability. If we found serviceability to be deficient (based on NWCG standards), we removed Cordura items from the testing. We took photographs and measurements after the first and fifth cycles. 2 Results Table 1—Refurbishing methods used for the test groups. Cordura Refurbishing Methods Groups Soak for 10 to 12 hours in CitroSqueeze Wash settings Drying procedures Control Group Yes Rinse or pressure wash with a “Hotsy” machine Hang-to-dry Group 2 Yes Machine wash heavy Hang-to-dry Group 3 Yes Machine wash heavy Machine dry air Group 4 Yes Machine wash heavy Machine dry low Group 5 Yes Machine wash gentle Hang-to-dry Group 6 Yes Machine wash gentle Machine dry low Cordura Physical Characteristics and General Care Guidelines Cordura with polyurethane coating is designed to be longlasting and is generally resistant to all types of normal wear and tear. Over time, all synthetic laminated materials are prone to delaminating of the polyurethane coating. This can be hastened by exposure of the polyurethane coating to direct sunlight for long periods; use of harsh chemicals for cleaning; exposure to chlorine; or long periods of storage in damp areas, particularly on cement floors. When put in storage, Cordura items must be 100 percent dry and preferably stored hanging up with adequate air circulation. The Control Group showed the best results in maintaining durability and equipment lifespan. After 10 successive cycles of soaking, pressure washing, and hanging to dry, the Control Group had little to no observable damage. Although much more labor-intensive, manual washing potentially may be more cost effective. The Control Group will stay in service longer and will not need to be replaced as frequently due to refurbishing damage. These results support the current NWCG standards. Groups 5 and 6, washed on a gentle wash setting in cold water, also showed promising signs as an alternative method. Placards on the fuel bottle bags did not show any increase in wear or delamination compared to the Control Group. Polyurethane linings showed some breakdown after the fifth cycle was completed (figure 3). Polyurethane lining degradation Figure 3—Polyurethane lining showing some degradation after five cycles of soaking, washing on gentle cycle, and hanging to dry. 3 Washing Cordura items on a heavy wash setting had adverse effects on the lifespan and serviceability. After the first heavy wash setting, 100 percent of the items in Groups 2, 3, and 4 showed significant signs of wear, especially the fuel bottle bags; flammable liquid placards were delaminating. After initial delaminating occurred, a marked increase in the speed at which placards broke down occurred. The placards were so heavily damaged by the fifth cycle that all fuel bottle bags in Groups 2, 3, and 4 were deemed unserviceable and were eliminated from the evaluation (figures 4a and 4b). One cycle Figures 4a and 4b—On a heavy wash setting, flammable liquid placards show delamination after only a single cycle. Excessive delamination shows after the fifth cycle. Five cycles 4 Washing Cordura items on a heavy wash setting had serious damaging effects on line gear in test Groups 2 and 4. Serious damage and breakdown of the polyurethane lining and heavy fraying of unbound edges were identified after five cycles (figures 5a and 5b). Due to excessive damage and based on NWCG refurbishing standards, the packs were deemed unserviceable and removed from the evaluation. Fraying of unbound fabric edges was accelerated by the heavy wash setting. In contrast, the Control Group packs showed little to no damage to the polyurethane lining and unbound fabric edges. Separated polyurethane Excessive fraying Figures 5a and 5b—The heavy wash setting caused serious damaging effects to the polyurethane lining of fire packs after five successive wash cycles. Excessive fraying of edges with no binding was also observed. 5 Drying procedures showed some varied effects. We performed three drying procedures in order to look at drying time, volume (shrinkage) changes, and damage. The three drying procedures were hang-to-dry, dryer (air dry setting), and dryer (low heat setting). We took and recorded initial volume measurements for the Control Group (hang-to-dry) and Group 4 (low heat setting). After these initial measurements were recorded for each group, we evaluated them after each cycle (one through five). Based on the measurements, the Control Group and Group 4 showed signs of shrinkage. However, Group 4, dried on a low heat setting, showed more volume loss per cycle, except cycle 4 (figure 6). Total average volume loss after five cycles was more significant for Group 4 that was dried on a low heat setting (figure 7). It was observed that none of the drying procedures of Cordura items sped up the process of polyurethane or placard breakdown. Most observable damage came during washing practices. Volume Loss Per Cycle Due to Drying Procedures Average Volume (cubic inches) Control Group Group 4 Comparing the Control Group and Group 4—Five Cycles Figure 6—Cordura items in the Control Group that were air dried showed less volume loss due to shrinkage than items in Group 4 that were dried on a low heat setting, except cycle 4. 6 Volume Loss (cubic inches) Total Average Volume Loss After Five Cycles (Control Group vs. Group 4) Control Group Group 4 Figure 7—Total average volume loss of the Control Group and Group 4 after five successive cycles of soaking, washing, and drying. Recommendations loading washing machine. Top-loading machines with agitaAll the different washing and drying methods performed tors should not be used because this can amplify damaging showed measurable and physical differences in the effects on effects. Eco-friendly detergents show great results and do not the Cordura items. The results support the current NWCG contain harsh washing chemicals. When pressure washing washing and refurbishing standards and the wash and care Cordura, use a pressure wand that is not on a straight stream instructions on equipment labels. Based on this information, setting. Straight streaming can quickly damage Cordura texMTDC recommends washing Cordura items with extreme tiles. The best methods for drying Cordura are either the hangcare. Soaking in CitroSqueeze or other biodegradable degreas- to-dry or machine air dry procedure. Avoid hanging Cordura ers helps the cleaning process and does not damage Cordura items in the direct sunlight as this can further degrade polytextiles. Cordura should only be washed with a pressure urethane coatings. Ensure all Cordura items are completely washer or on a gentle wash setting with cold water in a front- dry before being stored and provide adequate air circulation. 7 About the Authors Library Card Sean Wildhaber is an interagency Hotshot squad leader at the San Juan National Forest. He has worked as an assistant project leader for two programs (fire and aviation and safety and health) while on a detail to Missoula Technology and Development Center during the winters of 2011 and 2012. Wildhaber started his Forest Service career in 2002 as a firefighter on a district crew in Heppner, OR. From 2003 to the present, he has held positions as a senior firefighter, squad leader, and assistant superintendent on Hotshot crews on the Lewis and Clark and Bitterroot National Forests. Wildhaber has a bachelor’s degree in human biological sciences from the University of Montana. Mary Ann Davies received a bachelor’s degree in mechanical engineering with a minor in industrial and management engineering from Montana State University. She worked in the Pacific Northwest Region as a facility engineer and as a tramway engineer. Davies has worked in fire management as a crewmember and as a crewboss. She worked for 5 years with the Rocky Mountain Research Station in the fire chemistry and fire behavior groups before coming to MTDC in 1999. In 2012, she served a detail as Fire and Aviation Program Manager at MTDC while this publication was underway. Wildhaber, Sean; Davies, Mary Ann. 2013. Evaluating the methods for refurbishing firefighter cordura items. Tech. Rep. 1451–2306P–MTDC. Missoula, MT: U.S. Department of Agriculture, Forest Service, Missoula Technology and Development Center. 8 p. Fire caches supply many items to firefighters made of Cordura because of its durability. After fire season, the items are returned and refurbished; machine washing and drying is one refurbishing method. Long-term effects of this method were not known. The Missoula Technology and Development Center conducted tests on Cordura items using different cleaning methods. This tech tip includes the results and recommendations. For additional technical information, contact MTDC: USDA Forest Service Missoula Technology and Development Center 5785 Hwy. 10 West Missoula, MT 59808-9361 Phone: 406–329–3900 Fax: 406–329–3719 Electronic copies of National Technology and Development documents are available on the Internet at: http://www.fs.fed.us/eng/pubs Keywords: Cordura, drying, fire fighting, firefighting, personal protective equipment, PPE, refurbishing, safety at work, washing Forest Service and Bureau of Land Management employees can search National Technology and Development documents, CDs, DVDs, and videos on their internal computer networks at: http://fsweb.mtdc.wo.fs.fed.us/search/ http://fsweb.sdtdc.wo.fs.fed.us/ The Forest Service, an agency of the U.S. Department of Agriculture (USDA), has developed this information for the guidance of its employees, its contractors, and its cooperating Federal and State agencies. The Forest Service assumes no responsibility for the interpretation or use of this information by anyone except its own employees. The use of trade, firm, or corporation names is for the information and convenience of the reader. Such use does not constitute an official endorsement or approval of any product or service to the exclusion of others that may be suitable. USDA Non-Discrimination Policy The U.S. Department of Agriculture (USDA) prohibits discrimination against its customers, employees, and applicants for employment on the bases of race, color, national origin, age, disability, sex, gender identity, religion, reprisal, and where applicable, political beliefs, marital status, familial or parental status, sexual orientation, or all or part of an individual’s income is derived from any public assistance program, or protected genetic information in employment or in any program or activity conducted or funded by the Department. (Not all prohibited bases will apply to all programs and/or employment activities.) To File an Employment Complaint If you wish to file an employment complaint, you must contact your agency’s EEO Counselor (http://www.ascr.usda.gov/doc/EEO_Counselor_List.pdf) within 45 days of the date of the alleged discriminatory act, event, or in the case of a personnel action. Additional information can be found online at http://www.ascr.usda.gov/complaint_filing_file.html. To File a Program Complaint If you wish to file a Civil Rights program complaint of discrimination, complete the USDA Program Discrimination Complaint Form, found online at http://www.ascr.usda.gov/complaint_filing_cust.html, or at any USDA office, or call (866) 632–9992 to request the form. You may also write a letter containing all of the information requested in the form. Send your completed complaint form or letter to us by mail at U.S. Department of Agriculture, Director, Office of Adjudication, 1400 Independence Avenue, S.W., Washington, D.C. 20250-9410, by fax (202) 690–7442 or email at program.intake@usda.gov. Persons with Disabilities Individuals who are deaf, hard of hearing or have speech disabilities and you wish to file either an EEO or program complaint please contact USDA through the Federal Relay Service at (800) 877–8339 or (800) 845–6136 (in Spanish). Persons with disabilities who wish to file a program complaint, please see information above on how to contact us by mail directly or by email. If you require alternative means of communication for program information (e.g., Braille, large print, audiotape, etc.) please contact USDA’s TARGET Center at (202) 720–2600 (voice and TDD). 8