UNIT STRESSES IN TIMBE R LIBRAR Y

advertisement

UNIT STRESSES IN TIMBE R

1927

:4

FOREST RESEARCH LABORATOR

Y

LIBRAR Y

UNITED STATES DEPARTMENT OF AGRICULTUR E

FOREST SERVIC E

FOREST PRODUCTS LABORATOR Y

Madison, Wisconsi n

In Cooperation with the University of Wisconsin

MOOR FO EST FORUM IPORATOR Y

LISRA Ry .

... .

1

.

UNIT STRESSES IN TIIVIBERBY

,,' :,!. -

J-. A .. 1EWLIN, Principal Enginee r

The fact that there are several hundred species of arbOrescevt plant s

in the U'll4t?“te.take-samd .a greater mAtiPlioit,ofsue4 u:eOpl iDiAhe traipUe.s

has led nlaRy.leRg4neexe .4.o consider the subject9fmot and. J*,piVi:es.,

too indRfIrritle-aWoP14sato4 t o 4pltafY PvPE-g w4ptieTfi4a7-'6t%d5;V MPch ,

less a close anaIyets .

The speaker t s .purp .

is to correct se.le 7 m1sconceutiO48' . PotfiWDe

wood . Under his supervisiem about 700P0OO ' seie4gth tests of iic.e%bltO

performed, many of which were on structural tubers . Many others wert'Ade

during the World War in contaction with aeroplaz,e ionstrvwtiph .

I

People see pieces of balsa wood, O r read abgi t .,>

0 alY . aye

sixth as heavy as water l, and.0out other speffq:bOkl$ Ivri-Ati% ;ishan w Vkol,

They hear that the Army and . pp.vy are using for 4-fatia 0*esS in extren

fiber in bending of , 9 x 400 W43?er . sq . "in &P , airi'CW0tA,itoplanes have._ , _

been examined and evi4ence's,' fOv.d that the tim*'iOlems: Abeen subje(OW

to a stress of 11,000- to 12;000 lb .'without fal,Waid:then) ,as

climax, they see a table of stresses'!recotmendeiPlioresil P pag45P :

Laboratory, in which a "Select" grade of spruce- it dated a=s 6:6 d

lb . per sq . in. Usually, engineers and contractors stop here and say, . "Well,

since the factor of safety for spruce is evidently about 12, the ?4ad- PaP

cated by a stress of 1,140 M .,- way be multiplied by 4 and 'frtil n bJeAtt'h:1. a good margin of safety ; and with this wide mOgin..alpoet any wdO ies can

be substituted for another in the same sizes, ."- ' TheedG0,hotl'ob* 40ed tiler=

; e - wa:FF1.1eW. - Onc

04

.oughly,rtewdncoivfthsmargn

does fail . Most of the failures occur in concrete forms seBI-clAll- wRot& I

The optimistic contractor thinks he has this, large factor of safety, h e

quadruples the load p and down goes the structure .

resented at the special meeting of the Structural Division, America n

Society of Civil Engineers, Oct . 2S, 1925 and published in Transaction s

of American Society of Civil Engineers, Vol . 91, p . 387 (December 1927) .

R1221

does io t ` ieed1 .te-bicame an ex •rt in the

s, or does he have to be familiar with the proper order to use wood intelligently . It ins: heto4sually

stinguish between species that are gori, t. e* . ike itt

under these conditions their strtgths would,

]

far as stren th is concerned, for instance, it '

. istinguish etween t ;. .- fifty-sev different }

e divided

lair *era

impossi in f ac

1 L -~ 4 044

e

lumb e

Pariou

classed as Sbuthern'e . If

eaf' pine

iec ?l 40

loblo l

has the growth and

perties o f

stance of't Id a

safi t

%3af ; or a

in weight

e 6f true 1gleaf Mir be soft and

al

of "Aipine than th e average of short-.

leaf pine

Arkansas oft pie" is selected .

,Af

The extremes of the species,

use for structural timbers ,

n'e

'when considered from a strength int, are Eastern hemlock and whit e

fir, the weakest, and southern yellow pine and Douglas fir, the strongest .

The latter have about one and one-half times the strength and stiffness o f

the•$e "ock-' and. white fir . Southern pine and Douglas fir furnish not onl y

'most o America's structural timbers, but also more than one-half of all it s

1140e r

11kh

A

A

The chi

ics of- the species, their inherent properties, th e

ce of certain defects and their relative likelihood to develop othe r

rvice, and the influence of duration of stress are all con, vg working stresses . Different limitations imposed o n

Mkared in ass =

factA;-g j,

~tnmon to all species explain the difference in recommende d

taking stresses for wood in aeroplanes and in house construction . Thes e

faetars will be illustrated in the inverse order of their importance, a s

follows : (1)

variability of the strength of the clear wood ; (2) th e

tress ; and (4) defects ,

rte.,

;

~- , ;r r

. .t!

r~;~

4

Str

th of clear ' Rio „• r ; ~r

~. r

~

1

;-,,';d

1

.14 17.41,

reen condition . Si

's tak e

able on this speci :

gracti c

y {~ ry . .r

ce in airs

4;

' .a .carv e

,►

God . It w-'

.

s (6

iit of 1,3010 giv

.•e -*ariation , lying . ` va

•orres Mthnito the hig a

.w the

age . it density curve f•

T

.anal .

ity

ve .

-

g

• . :•

ge, whi~f

e a

point on - he curv e

y given species i

_-fi t

properties of a specie s

tional but greater tha n

the type shown in Figure 1 .

ti

In assigning working stresses, primary consideration is given to th e

one-fourth of'• he pieces lowest in strength . For aeroplanes, a lower limi t

for specific, gravity is set which eliminates most of the lower one-tenth o f

the material but does not change the most probable value . In southern

yellow pine and Douglas fir it is possible to eliminate a little of thi s

low material (along with a little of the higher) by the "ring" rule or "i rat e

of growth" rule, A more satisfactory rule for selecting material of thes e

species is that known as the density rule, by which density is determine d

from an estimate of the proportion of summerwood ,

Variation of strength with moistur e

In Figure 2 is shown the influence of moisture on the strength o f

spruce wood, These are old curves . They represent work that was done quit e

a number of years ago on-relatively few pieces of small size . More recen t

data show the average strength,of the green material to be slightly highe r

than these early tests indicate . The horizontal line at the right of eac h

curve represents the strength of the green material ; when the fiber saturation point is reached, ,that is, when all the free water is out of the cell ,

the cell wall begins to lose its water and the strength of the material

goes up . quite rapidly . Since in any ordinary drying some of the cells wil l

contain free water while others are below the fiber saturation point, i n

practice the curve } instead of being straight to the fiber saturation point ,

and then having a sudden break upward, is a transition curve of varyin g

radius, depending on numerous conditions . As between this ."green" strengt h

and the strength at , 15% moisture, the most recent curve for modulus o f

rupture shows practically an increase .of 50 percent . The increase in th e

shear strength is not sufficient to be of much importance in structura l

material .

Duration of stres s

The diagram, Figure 3, shows the influence of duration of stress o n

the strength of timber . A logarithmic scale is used for the time co-ordinate because it illustrates the law better than a direct plotting . Th e

upper curve is for fiber stress at the elastic limit and the lower one fo r

modulus of rupture . In each curve the value from the Forest Product s

Laboratory's standard static-bending tests, which require on the averag e

about 5 min ., is taken as 100% (point marked a, Fig . 3)„ The point farthes t

to the right (b) represents the average strength of pieces which broke i n

from six months to a year under dead load . No rupture strength data ar e

available for periods of t,me much less than 1 sec . The point in the extreme left-hand corner (c) = represents an elastic limit stress in impact *

In developing the curves little weight was given this point (even thoug h

it represents thousands of tests), since there are several factors whic h

cannot be eliminated and tend to raise the point slightly .

2

From Bulletin 556, U .S . Dept . of Agriculture .

R1221

-3-

-

-r'jlf-76' •41-011.--di

ane flight i is impossible to maintain the condition s

wh

stress for more than a few seconds, in which case ther e

It'4actor

. almost V-wo as compared with the load that the same materia l

wi

long time--as in a library floor, for instance . This show s

y

L

r st

ures should be designed for static loads and the impac t

$&ve log ' neglec$ea unless the impact stress exceeds the stati c

I

Ole to the live ]oad .

a►'t?

.1

-t"

t'

leer impor t

ing the

i-lo-i

fects . O

- f the mos t erious de . :_ .- s decay ,

be allowed in any important structural member . Timber tha

air-dry and constantly kept in that condition will not de c

in contact with other material that is decaying . A mill f l

phi al Pa ., recently examined, revealed that wet pine had bee n

a sub -. floor, with paper and wet concrete below and a tight to p

thoroughly oiled, making the conditions ideal for decay . The sub-floo r

rotted out completely, and the fungi passed through the top floor and bas e

moulding into the longleaf pine columns, rotting them out in two years .

These columns in the ground, unprotected, ought to have stood for seven o r

eight years . Decay must be prevented in timber buildings .

r 4

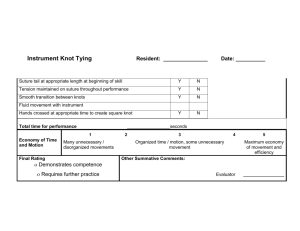

Figure L . shows a knot, another serious type of defect in timbe r

which often reduces the strength of a piece almost to zero . A knot is a

part of the limb which,, as the tree grew, became a part of the trunk . Th e

fibers run from the bottom out into the limb . On the top they produce a

kind of crinkle around the knot . Some of them seem to end there, but a

number run through into the limb, The strength of the wood along the grai n

ern& across the grain is tremendously different . The variation is fiftee n

to fortyfold, Therefore, it would be better to have a hole the size of th e

knot proper than to have the knot with its attendant cross-grain .

The influence that a knot on the tension face at the point of maximum

moment . exerts on the strength of a green beam is approximately measured b y

the ratio of the diameter of the knot to the width of the face . The diameter of the knot is measured between lines parallel to the edges of th e

face .- .That is, a knot one-fourth the width of the face g ill -reduce th e

Ift0elp4ilt,ettilti 25 percent . The same knot on the compression side would hav e

It ;lone-half this influence .' Large knots have a somewhat greate-r influewe on the strength than-is indicated by this rule, owing-to the rdlhtivel y

larger distortion of the grain around them . This effect is' 'taken care o f

in the grading rules- recommended by the T . S . Forest Products-Laborator y

tintvOmstu Select" grade will insure 75% of the s't'rength of the olear' good.,'

Large timbers never dry to . as low a moisture content as small stocky

ate$ they develop more checks, especially around knots . The result is that

although the average strength is, increased by dryingi_ about- 25'g of th e

~~~'f3.ii dhow no increase, and, therefore, no increase in working stress o n

R1221

account of seasoning

less in thickness-, a

plane stock the full

stress of 11. sec . may

is allowed . In the higher grades of joists, 4 in.. an d

slight increase in s-tr .eAgth- s Fecagn :zed . In aerostrength of clear weod:at 15` meisturt- and duration- off '

be developed .

How working stresses

are determir-ie d

.

In arriving at a safe stress for a ''Select" grade of spruce structura l

timber, the starting point would be 5,760 lb . . per sq . in ., which is th e

average modulus of rupture for small, clear stock tested green at standad . . ,

speed . Reduce this by one-fourth to take care of variability of the clea r

wood ; make another reduction of one-fourth to take care of the maximum defec t

permitted in=the grade ; then take off about seven-sixteenths for the-dea d

load effect over a, number of years, This give s

5,760 x - x - x i6 y,

or 1,•820 lb . per sq ._ in .

as the stress under long-time leading at which an-occasional timber- . ' possibly

1 in 25, would be expected to fail . Thus, the recommended s'tTess of . 1,10 0

lb . per sq . in . gives a factor of safety of 1-2/3 for-this bad timber an d

this worst condition of loading . The average timber has a fa-. or of safet y

of about 2. 1/4 for long-time loading, and for a few minutes will• skoW a ;e-or eEf

safety of 4 . With average timbers under impact there would be a factor o f

about 6 . When the influence of duration of stress on the Strength of timbe r

is considered, it is apparent why it is recommended that timber be designed '

for dead load and for a long period-of ' time negl:ectirg any impact stresse s

unless they exceed the stresses due to the ' live load which produces thos e

stresses . Wh:Wiever tests of structural timbers are available they ar e

found to check these factors quite closely .

For-make years the Forest Products Laboratory' refrained fro m . assign- ,

ing any stress to-timber and it always has refused to recommend ' s.tresse s

where the grading rule does not limit quite closely the weakest timber tha t

could be accepted . The stresses were finally recommended at the urgent re quest of engineers, and although the lumber interests were given attention :

they have had no vote in fixing these final values . '

-

1

y

MI= IN=

•

IEEE

ENE=

Kil,„,

NEI ME

°

'‘

AEI■■■ ummmin ■■■ =4

IIEEWI

•

111111111NM

UM*

o

t

SPRUC E

12 1 000_

11,00010,000

C)

\a

H

t,

,

o0

5

50

15

25

35 40 45

20

30

MOISTURE-PERCENT OF DRY +lE I GHT

Fig . 2 .-Comparison of the various strength values of spruce with variatio n

in moisture . (The two upper curves are from bending tests an d

the lowest one from compression at right angles to grain . )

81221

10

e

r

•

Figure 3 .--Relation between mechanical property o f

Sitka spruce and duration of stress .

81221

h

ti

(la

to

t

t..1

--amo

W

h

ti

O JW

h

o

R rry

W

SAd0 0/

o

dQ

2 t

.

0

ve; /

51100H 0/

Q

5,Y/70H 5

ao

0

-I

k

h

Z

w

Y

ti

o

V

'K

p~.

=

p O

g

is

-I Z.

h

o

p p p ti

Q

a

Q

p

h~u

Z Q

h

C}

O

.z

y

k,

p

4i

J

v

ti

h

¢ h

4s

Q

ti

W ?

W h

Z

o

°

2

h

tZ,

ca Q

h o W

4.)

vt

aFo2

y q

u h

¢

FIB o '2c k `"

L~

QOp

44

p h

k

o ip 44

W

o o4

av h

c 1 oq W :t

m

a -e

a•

0

=

(cC

Y00H /

N/A/ o f

N//4/ o r

1

-

-N/A/ S

'/v/A./ /

•

.735 O r

O

1

0

031 0 /

_T

035 S

•

o

a

_

••

J •

1

D5 /'0

1

1

1

1

+

+

J

f

0

i

o

v

v,

e

~v

•°

o

m

h

(1N3O i/3d) 31//N/W 2/1d 71AfrWl d0 HON/ 50/0 iv 9N/0N39

0/1GLS O61 VONd1S N/ 031031 /l/3d0Nd 2t/7/12//S 01 t1113d02'd 7d,7/NVH.73W 10 0/1VE/

x.

m

0

0

0

(la

Fig . 14 .--Knot showing characteristic differ ence in behavior of fibers on lower an d

upper sides .