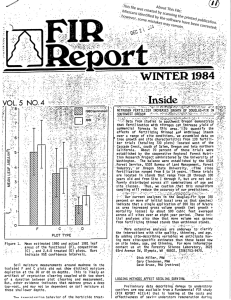

5th Forest Research Laboratory School of Forestry Oregon State University

advertisement