Document 13562477

advertisement

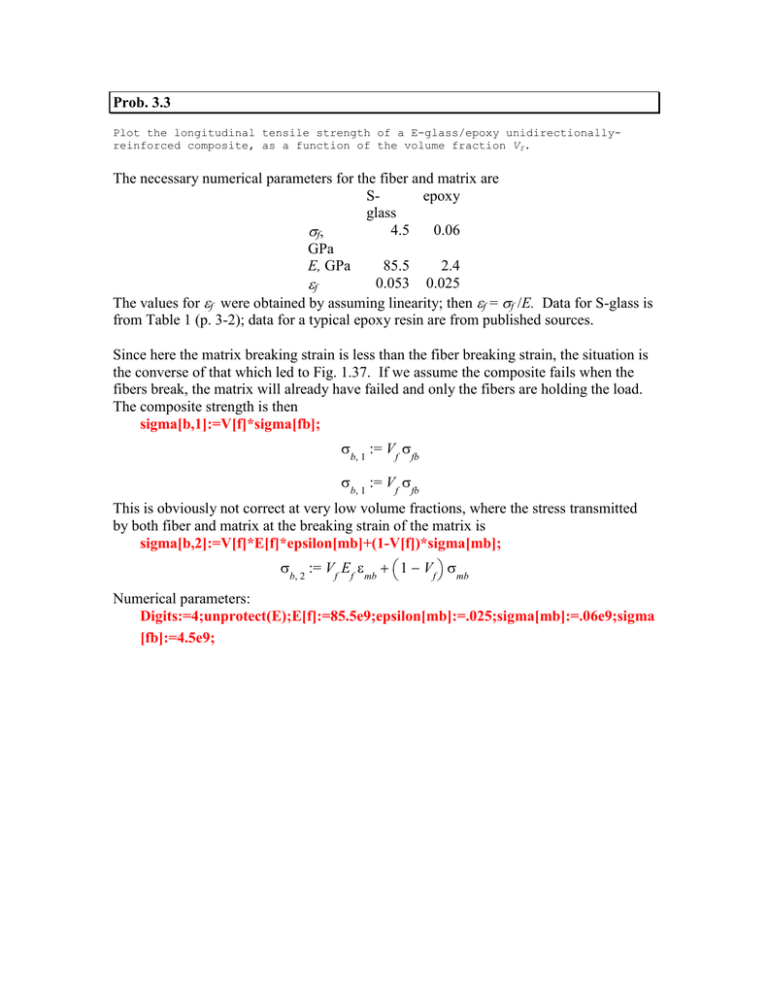

Prob. 3.3

Plot the longitudinal tensile strength of a E-glass/epoxy unidirectionally­

reinforced composite, as a function of the volume fraction Vf.

The necessary numerical parameters for the fiber and matrix are

Sepoxy

glass

4.5

0.06

σf,

GPa

E, GPa

85.5

2.4

0.053 0.025

εf

The values for εf were obtained by assuming linearity; then εf = σf /E. Data for S-glass is

from Table 1 (p. 3-2); data for a typical epoxy resin are from published sources.

Since here the matrix breaking strain is less than the fiber breaking strain, the situation is

the converse of that which led to Fig. 1.37. If we assume the composite fails when the

fibers break, the matrix will already have failed and only the fibers are holding the load.

The composite strength is then

sigma[b,1]:=V[f]*sigma[fb];

σb, 1 := Vf σfb

σb, 1 := Vf σfb

This is obviously not correct at very low volume fractions, where the stress transmitted

by both fiber and matrix at the breaking strain of the matrix is

sigma[b,2]:=V[f]*E[f]*epsilon[mb]+(1-V[f])*sigma[mb];

σb, 2 := Vf Ef εmb + 1 − Vf σmb

Numerical parameters:

Digits:=4;unprotect(E);E[f]:=85.5e9;epsilon[mb]:=.025;sigma[mb]:=.06e9;sigma

[fb]:=4.5e9;

Plotting these two relations, over full and reduced scales of Vf: :

plot({sigma[b,1],sigma[b,2]},V[f]=0..1);

4e+009

3e+009

2e+009

1e+009

00

0.2

0.4

0.6

0.8

1

0.04

0.05

V[f]

plot({sigma[b,1],sigma[b,2]},V[f]=0..0.05);

2e+008

1.5e+008

1e+008

5e+007

00

0.01

0.02

0.03

V[f]

Whichever curve is greater for a given Vf should predict the composite strength.