A comparative study of baking effects produced by electric, gas... by Martha Johnson Haynes

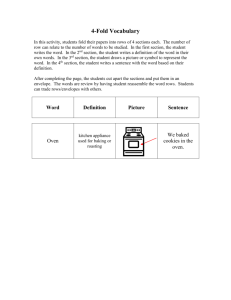

advertisement

A comparative study of baking effects produced by electric, gas and coal range ovens on yeast rolls

by Martha Johnson Haynes

A Thesis submitted to the Graduate Committee in partial fulfillment of the requirements for the Degree

of Master of Science in Home Economics

Montana State University

© Copyright by Martha Johnson Haynes (1932)

Abstract:

1. In this study a comparison was made of the baking qualities of three commonly used types of fuels;

electricity, gas and coal. The product used for these baking tests was a standard Parker House roll and

comparisons were made in each case with rolls baked In the electric oven.

2. Tests were made for loss in weight during the baking process in each of the ovens. The electric ones

showed a loss of 11.2%; the gas, 12.8%,; and the coal range 11.2%. These data agree with other studies

which dealt with meat shrinkage. In scoring the rolls, the opinions of the judges were that the bottom

crusts of the rolls coming from the gas oven were drier than those from the other two ovens.

2. Measurements of volume of rolls baked in the three ovens showed that the greatest increase was with

the rolls from the coal range, being 2.4% greater than the volume of rolls from the electric oven. The

rolls baked in the gas oven had a 4% smaller volume than the electric.

4. A definite correlation was found between color of crust and tenderness. The Munsell color system

was used to determine color and for the tenderness a mechanical device to measure breaking strength.

The crusts that were darkest in color were the least tender.

5. The rolls baked in the gas oven had lighter colored and more tender top crusts but darker colored and

less tender bottom crusts than the rolls baked in the electric oven. Rolls baked in the coal range oven

had a very light brown bottom crust but a darker brown top crust in spite of the fact that they were

baked on the bottom of the oven.

conclusions In comparing the three kinds of ovens studied it may be concluded that there is no

outstanding advantage of any one kind of fuel or energy source as far as the final product is concerned

if conditions are controlled to the same degree. However, the electric range seemed to give the most

uniform results as to desirable color and quality of both top and bottom crusts.

■

A CQIfP^KATIVE SSeUDY OF

I*. DJQ hi X; u I- ODUCl D 3Y

,C

IC ,

BY

r i.T.ih j . ILmms

A T h e s i s s u b m it t e d t o t h e G r a d u a te C o m m itte e

i n p a r t i a l f u l i i l l r e n t o f t h e r e q u ir e m e n t s

f o r tn e D egree o f

IfASTER QF SC IJlitCE

III

HOME ECONOMICS

M ontan a S t a t e C o lle g e

B oaem an , M on tan a

June, 19L2

Al-'i'ROVED!

(jjL iru J '

I n c h i.r j e o f R u jo r

airman Exm i

ork

oacwvti

MM.

UMLMZ.

C h u lm m i ( r u d u u te c o m m it te e

M 37?

H 53c_

TAiiLE OP CCXTKNTS

page

INTBODUCTIOR..........................................................................................I

HIiiTORT..........................................................

. . . . . ----- . . . .

-iWi IHKETTAl jTlOCtHXTRK..........................

.2

10

I l l u e t m t Ion I . —The !^inooll Color Apparatna

as i t wua s e t up fo r matci*Izx-: the c o lo r

o f r o lls . . . . . . .

.10

I ll u s t r a t io n 2 . —Devloo fo r te n tin g th e brookIng stre n g th o f the oruota o f Perker Iiouae

r o l l s .................. ...................................................... — 20

RSiiLTLTS............................

31

DlSCUiSIOH...............................

49

.55

SUMtMiT....................

CONCLUSIONS........................................................................................ SG

ACJQfOiSLBDCRJCDtTS...........................................................

BIBLIOGRAPHY......................................................................

4808«

.56

..

.57

IIiIiEX TO TABLES

pace

Table I . P rop ortion o f In c r e a io n ts used in J !iking

arker House r o l l s , Toasured by Volume and by

e i g h t .................. ............... ........................................ .............. . . 1 2

Table I I . The Lose in e ig h t o f Parker House I o i l s hen

Baked in an K le o tr lo Oven : .quip ed w ith an automa­

t i c I ca t C o n tro l......... ............................................. ..................22

Table I I I . The Loss in e ig h t o f Parker ouse B o lls When

Baled in a O&s Oven Equipped w ith an Automatic

Robert >huw Heat C ontrol.............. ................... ..................... .2 4

Table IV. The Logs in e ig h t o f Parker house h o lla aen

Baked in u Coal Kant e Uveru........................................25

T able V. TiIe Vol m o f . a r k e r Jiouae RoULti Baked i n an

l e o t r l o Uven Equipped w ith an A utom atic h e a t

C o n tr o l..................................................

.27

Table V I. The Volume o f Parker Houser R o lls Poked in a

Gas Oven Equipped w ith an Automatic Robert Uhaw

Heat C o n tr o l.............

20

Table VII* The Vol ,me o f Parker house P o lls Be :ed in a

Coal Range U v e n . . . . ...............

.............2 9

Table V III. Color u t i l i t i e s ooordin to ? u n s e ll , o te tlo n

and Breaking Utrength o f Top C rusts o f arker ouse

R o lls Baked in ane l e c t r i c Oven.... ........................................Bh

Table IX. C olor u t i l i t i e s Aoc or din*” to I u n s e ll R otation

and Breaking stre n g th o f Bottom C rusts o f j arker

House i o i l s Baked in an H e c tr ic O v e n .................... ..3 0

Table X. C olor u t i l i t i e s According to R unaell R otation

and Breaking str e n g th o f Top C ruets o f Parker House

P o lls Baked in a Cue O v en .* .* . .

............................. 41

Table X I. C olor u t i l i t i e s According to I u n s e ll R otation

and Breaking S tren gth o f Bottom C rusts o f Parker

House R o lls Baked in a Gas O v e n ................................. ..4 3

Table X II. Color u t i l i t i e s According t o i'u n so ll R otation

and Breaking S trength o f Top C rusts o f Pazker House

R o lls Baked in a Coal Range O v u n . . . . . . . . . . . . . . . . . . . 4 5

pape

Table X III. Color ^ u tilitie s tcoor&lng to X unoell

flo ta tio n UZidL Breaking str e n g th o f Bottors

C rusts o f lu rk er ^ouue R o lls Baked in a Coal

Kazit’e Oven........................ .................................................. 47

Table XIV. Average C olor q u a li t ie s and Breaking

str e n g th o f Cruata o f R o lls From the Three

. . . . .

...5 2

D iffe r e n t Ovens................ ..

Table XV. Data Showing the Jodal Color q u a litie s

and Breaking Utrent th o f C rusts o f R o lls from

th e Thrt e D iffe r e n t O vens....................... ............... .5 3

Table XVI. J r e fe r e n c e s o f Ten In d iv id u a ls fo r Color

o f Crust o f marker Houue R o l l s . . . . . ......... . . . . . 5 4

A COMPARATIVE STUDY OF YEAST ROLLS

BAKED IR ELECTRIC, OAS AIiD COAL RARJE OVEBS

IRTR ODUCTIOS

W ithin the p a st Yew y ears th ere has been developed, a wide

v a r ie t y o f cooking ranges fo r home use*

In most o a se s they em­

p lo y one o f the th ree p r in c ip a l k in d s o f f u e l or e n e r g y ,- e l e c ­

t r i c i t y , gas or co al*

The c o n str u c tio n o f d if f e r e n t k in d s o f ran ges has been im­

proved to a la r g e d eg re e, the m anufacturers aim ing to have them

g iv e equal performance in a l l cooking op eration s*

However, many

homemakers f e e l th a t in th e baking p ro cess they have not o b ta in ­

ed s im ila r r e s u lt s in th e c o a l range, gau and e l e c t r i c o v en s.

The homemaker w ish in g to purchase a new range h as very l i t t l e

d e f in i t e in form ation upon which to base her ch oice*

h i l e th ere

have been s tu d ie s made o f the com parative c o s t s and e f f ic ie n c y

o f o p era tin g th e se ra n g es, very l i t t l e data are a v a ila b le in

regard to t h e ir r e la t iv e perform ance, e s p e c ia lly in baking.

One reads many c o n f lic t in g statem en ts in a d v e r tis in g l i t e r ­

atu re about the good q u a lit ie s o f each kind o f range and ex tr a ­

vagant claim s are made fo r each by e n th u s ia s tic salesm en.

S in ce

so l i t t l e has been rep orted on t h e ir r e la t iv e perform ance, the

purchaser i s unduly in flu e n c ed by such fa c to r s as c o s t and

appearance.

The recen t in c r e a sin g in t e r e s t among Home S e rv ice w orkers,

d e a le r s and homemakers in regard to kinds o f f u e ls used fo r

—

2—

oooking h as le d to a demand fo r resea rch s t u d ie s comparing th e

performance o f th e v a rio u s ranges u sin g th ese d if f e r e n t f u e ls

or energy so u r c e s.

Ih t h i s co n n ectio n i t has seemed a d v isa b le

to make a stud y o f the com parative baking e f f e c t s produced in

c o a l ran, e , gas and e l e c t r i c o v en s, a s th ey u t i l i s e the th ree

so u rces o f energy a v a ila b le in t h i s community.

HISTOEy

Baking o f food may be d escrib ed a s an o p era tio n in which

c e r ta in p h y s ic a l and chem ical changes take p la ce in the food

under c o n tr o lle d c o n d itio n s .

P r im itiv e man baked h is food by

co v erin g I t w ith hot a sh es and a llo w in g i t to stand fo r a tim e.

Later food was baked by p la c in g hot sto n e s around i t .

Wood was

probably the f i r s t f u e l used and w ith c o a l was th e on ly f u e l

used fo r s e v e r a l c e n t u r ie s .

W ithin com p aratively recen t tim es

o th er f u e ls have been developed by modern s c i e n t i s t s ; l . e . o i l s ,

gas and e l e c t r i c i t y .

The f i r s t oven was probably a "Dutch oven", a covered con­

t a in e r o f heavy m a te ria l th a t cou ld be imbedded in c o a l s .

With

th e development o f the cooking sto v e or range, the oven eventu­

a l l y became a part o f t h i s equipment and has been p e r fe c te d

u n t i l we have the e f f i c i e n t ovens o f today.

An oven i s a cham­

b er in which m a te ria ls are a r t i f i c i a l l y heated in an a ir tedium .

The

I r occupying th e space between the h ea t source and the

m a te r ia l to be baked i s a medium through which th e h eat must

be tra n sm itted ( I p .2 8 6 ).

There are th ree met no tie hy whieii h eat oan be tra n sm itted

from one p o in t to a n oth er, whioh are termed r e s p e c t iv e ly ,

c o n v e c tio n , con d uction and r a d ia tio n ( 2 ) .

C onvection la a mode o f d is t r ib u t in g h eat throuf-h a mass

o f e it h e r liq u id or g a s by motion o f the f l u i d , the cu rren ts

b ein g u s u a lly produced by d iffe r e n c e s in d e n s ity due to e x j ansio n caused by the source o f h eat I t s e l f .

Conduction i s th a t method o f tr a n sm ittin g h ea t in which

the h eat p a sse s from the h o tte r p a r t ic le s o f a body to the c o ld ­

e r ones ly in g in co n ta ct w ith them, and so throughout the whole

body.

Some su b sta n ces conduct neat much more ra p id ly than

o th e r s.

n-udiation i s h eat p a ssin g from one body to th e oth er by

electro m a g n etic w v e s .

'ih is i s known as "radiation" o f h e a t,

and i s independent o f the tem perature o f th e medium through

which i t o c c u r s,

n u d lation ta k es p la c e in s t r a ig h t l i n e s ,

in a l l d ir e c t io n s from the body which i s e v o lv in g h ea t and f o l ­

low s the same (general laws o f r e f l e c t io n a s th o se which govern

lig h t.

At the earo temperature d if f e r e n t b od ies r a d ia te heat

a t d if f e r e n t r a t e s .

The ra te o f r a d ia tio n i s a f f e c t e d both by

th e nature o f the r a d ia tin g m a teria l ana a ls o tn e c o n d itio n o f

i t s s u r fa c e , whether rough or smooth.

I l l # Iy p o lish e d su r fa c e s

r a d ia te l e s s r a p id ly than th o se which are roughened.

Baking, t h e r e fo r e , i s the cooking by a p p lic a tio n o f h eat

to food in an oven by co n v ectio n o f h eated a i r , by r a d ia tio n o f

h ea t from the w a lls o f th e oven and by the conduction o f h eat

front th e pans In which the food i s being baked.

For baking i t i s very d e s ir a b le to have a tem perature th a t

i s con stan t and not f lu c t u a t in g .

T his i s now accom plished in

w e ll-in s u la t e d g a s and e l e c t r i c ranges equipped w ith autom atic

tem perature c o n tr o ls and a ls o in th e c o a l range by manually

r e g u la tin g the d r a fts and amount o f c o a l u sed .

At was form erly

estim a ted th a t a s much a s 90 per cen t o f the h ea t su p p lied fo r

baking in ovens was u s e le s s ly l o s t through th e s id e s o f the

oven I S ).

oven s.

T his i s not the e a se w ith th e modem w e ll-I n s u la ted

The p r in c ip a l advantage o f in s u la tio n i s th a t i t keeps

th e h eat w e ll w ith in the oven .

The oven th a t i s in su la te d w ith

th e id ea o f con servin g f u e l has the sp aces between i t s w a lls

lin e d w ith m ineral w o o l, a sb e sto s or some e q u a lly e f f e c t i v e

m a te r ia l.

Some ranges in corp orate two o f th e se m a te ria ls w ith

a d ea d -a ir space between them and thus r e a lly a ch ie v e a high

degree o f in s u la t io n .

So thoroughly in su la te d are some ovens

th a t th e g a s may be shut o f f a f t e r tw o -th ir d s o f a lo n g -tim e

cooking job has been done, u t i l i z i n g the r e ta in e d h eat to f i n i s h

the work.

T his type o f oven cannot h elp but save on f u e l c o s t s .

A modern e l e c t r i c oven i s so w e ll in su la te d t h a t , when once

h eated to the d e sir e d tem perature, most o f the baking i s done

on th e sto r e d h e a t.

The c o a l range oven i s h eated by cu rren ts o f hot a ir c i r ­

c u la tin g around the oven.

Most c o a l ra n g e s are made o f heavy

iro n w ith an in t e r lin in g o f a s b e s t o s , which h elp s to r e ta in

-

6-

h ea t and. makes p o s s ib le the maintenance o f a more co n sta n t

tem perature.

An exam ination o f the lit e r a t u r e a v a ila b le has shown th a t

co n sid er a b le work has been aone on the comparison o f c o s ts o f

baking w ith e l e c t r i c i t y and g a s , but very l i t t l e has been re­

ported con cern in g the com parative r e s u l t s .

In a p ie c e o f resea rch by K lo e ff le r (fc) a t Kansas b ta te

A g r ic u ltu r a l C o lle e in 1917 s e v e r a l typ es o f e l e c t r i c cooking

a p p lia n ces were stu d ie d m ainly from the stand p oint o f mechani­

c a l and economic e f f i c i e n c y .

A b r ie f p art o f the work in clu d ed

a comparison o f shrinkage o f meats in o o a l, ga s and e l e c t r i c

ovens.

As the author s t a t e s , the t e s t s we e not very e x te n siv e

and th e in d ic a tio n s were th a t "there i s an a c tu a l d iffe r e n c e

o f from 4 per cen t to 8 per cen t in favor o f the e l e c t r i c oven."

A more recen t study somewhat s im ila r to K lo e f f le r *e was made

in 1931 by the American Gas A sso c ia tio n ( 7 ) .

They co n sid e r t h e ir

work a " te n ta tiv e study fo r comments o f member companies" but

again i t d e a ls m ainly w ith c o s t and e f f ic ie n c y fr o m t he economic

and t in e sta n d p o in ts.

A b r ie f com parison o f meat shrinkage in

e l e c t r i c and gas ranges showed a 1 7 .8 per cent average s iirInkage in the former type o f oven and 1 9 .5 per cen t average shrink­

age in gas o v en s.

Iro n the stand p oint o f q u a lity l i t t l e d i f f e r ­

ence e x is te d between ga s ana e l e c t r i c ra n g es.

The American Gas A sso c ia tio n a ls o ca r rie d on an e x te n siv e

study o f the a p p lic a tio n o f h eat to bread baking IlU ) .

This

work was done in the la r g e commercial t y , e s o f bread ovens fo r

—ti­

the "purpose o f determ ining the b e st method o f bread baking and

the p art wnloh f u e l gas played In such a p p lic a tio n " .

Their

co n c lu sio n s were th a t h ea t a p p lic a tio n fo r bread baking could

be ach ieved through e it h e r low temperature r a d ia tio n or con­

v e c tio n or a com bination o f the two and th a t when one co n sid ers

th e econ om ica lly low r a te a t which ga s i s a v a ila b le i t would

be th e most s u it a b le f u e l fo r w h o lesa le bread baking.

This

stud y i s o f in t e r e s t because ga s and c o a l ovens h eat m ainly by

co n v ectio n w h ile e l e c t r i c ovens h eat n a in ly by r a d ia tio n (1 3 ).

a Inoe y e a st r o l l s , a form o f bread, were e hosen a s the

product to be used in stu d y in g the r e la t iv e baking e f f e c t s o f

th e se th ree kinus o f ov n s , i t seemed n ecessa ry to make a pre­

lim in a ry stud y o f the e s ta b lis h e d p r o c e sse s Involoved in bread

making.

The fo u r most Important in g r e d ie n ts used in the p rep aration

o f bread are f lo u r , y e a s t , f a t and liq u id .

The bread-making

value o f d if f e r e n t ty p es o f wheat f lo u r depends oh th e q u a n tity

and q u a lity o f the g lu te n th a t can be developed in them.

H ou rs

are c a lle d "strong" i f they Iiave a com p aratively la r g e q u a n tity

and good q u a lity o f g lu te n , qnd "weak" i f t h e ir g lu te n i s low

in q u a n tity or poor in baking q u a lit y .

The nature and amount

o f g lu te n in flo u r depends both on the kind o f wheat from which

i t i s made and on the m illin g ,

stro n g flo u r made from hard

wheat i s con sid ered b e s t fo r y e a s t bread because i t co n ta in s

more o f th e p r o te in c a lle d " gluten ".

Gluten i s a substance

th a t has the a b i l i t y o f s tr e tc h in g and expanding and

~7—

forn a the Xracework o f bre.-tL.

"Chemical a a a ly s ia has shown th a t

t h i s g lu te n c o n s is t o m ostly o f two p ro to in o , g lla u in and g lu te n in*

The dough i s a c o l lo id a l mass o f staroh and p r o te in p a r t i­

c l e s covered by th in film s o f w ater.

She su rfa ce te n sio n f o r c e s

in h eren t in th e se film s o f w ater bind the sta rch p a r t ic le s to ­

g eth er a s the p a r t ic le s o f c la y arc h e ld to g e th e r .

The assum ption

i s made th a t the p r o te in p a r t ic le s form ch ain s or stran d s tmioh

have a r u b b e r -lik e e l a s t i c i t y and th ese stran d s are m a te d to ­

g e th e r in a mass known as ’g lu ten ' •

The q u a lity o f dough i s de­

term ined by th e number o f pax t i d e s p resen t which fo ra the s tr a n d s ,

by t h e ir in h eren t str u c tu r e and a ls o by the environment o f the

p a r tic le s .

The number o f p a r t ic le s i s r e la te d to t,*e q u a n tity

o f p r o te in in th e f lo u r , uad t h e ir str u c tu r e to th e q u a lity ."

(4 p.2b9)

The form ation o f the g lu te n i s due to the s t ic k in e s s o f

the m oist g lla d ln bind in g to g eth e r the in so lu b le and e l a s t i c

p a r t i c l e s o f g lu t e n ln .

I t i s the te n a c ity o f the g lu te n in th e

dough th a t h o ld s the bubbles o f ga s Introduced b

the lea v en in g

p r o c e ss and g iv e s " lig h tn ess" to the bread.

There are two kind s o f y e a s t commonly used— compressed and

dry y e a s t .

fr y y e a s t i s a mass o f d ried y e a s t p la n t s .

.although a l i v e ,

th e se p la n ts a . e in a c tiv e and even a f t e r warmth, m o istu re, food

and a ir are su p p lied they req u ire some time to become a c tiv e

a g a in .

A compressed y e a s t cake i s a m s s o f a m illio n or so y ea st

p la n ts In which o n ly one o f the requirem entG fo r a c t i v i t y la f o r nlaJied; th a t I l , uiolnturu.

I s soon ue fo o u , warmth and. a ir are

su p p lie d to th e se y e a s t p la n ts th ey a re ready to g-row*

A l i t t l e auyar i s a^led. to cJive a d d itio n a l food to the

y e a s t ana a ls o fo r fl..-Vorx ig the bread.

The r a is in g

t.*e y e a s t p la a t e .

the dou^h I s caused by the growth In i t o f

The d ia s ta s e In the douu.., produced by a c tio n

o f the y e a st on p art o f the s o lu b le p r o te in o f th e f lo u r , con­

v e r ts some o f th e sta rc h In to su g a r s.

Then ta e y c a s t - o e l l s ,

feed in g on th ese su gars and th e sugar which has been added, pro­

duce a lc o h o lic ferm en ta tio n , c o n v er tin g thoa in to a lc o h o l and

Carbon u io x iu e .

T hese, in gaseous f o r a , being d is tr ib u te d a l l

ta r o U0H t..e dough, cau se i t to r a is e as L e g a s expands in thou­

sands o f l i t t l e p o c k e ts.

«hen the bread i s p la ced in the oven,

the h ea t k i l l s the y e a s t c e l l s and sto p s the ferm en tation but

a t tho same time ca u ses the gas a lrea d y formed to expand* thu s

the aough r a is e s s t i l l fu rth er*

L a ter, a s th e w a lls o f th ese

p o ck ets harden and cra ck , the gas esca p es and ta e r e s u lt pro­

p e r ly c o n tr o lle d i s a l i g h t , porous bread*

w ait i s used in th e making o f bread fo r two r e a so n s: — f i r s t ,

to g iv e the n ece ssa r y f la v o r , w ithou t wbicu bread would Le

t a s t e l e s s and in s ip id .

In the second p la c e , s a l t a c t iv e ly con­

t r o l s some o f the chem ical changes which proceed during ferm enta­

t i o n , e x e r tin g so lv e n t in flu e n c e on some o f the in so lu b le pro­

t e in s o f flo u r : but in th e q u a n titie s employed In bread-making

i t produces a d ecid ed ly binding e f f e c t on the g lu te n o f the

-

dough.

9-

I t fu r th e r checks d ln s t a t lc notion and. no re ta r d s th e

co n version o f the sta rch o f the f lo u r in to d e x tr in and m a lto se.

S a lt a ls o checks a le o n o lic ferm en tation and exten d s a reta rd in g

in flu e n c e to the o th er ferm en ts, thus tending to prevent in ju r ­

io u s f e m e n ta tio n goin g on in the dough ( 2 ) .

I t has been reco g n ized by nueh a u th o r it ie s a s th e American

I n s t it u t e o f Baking and o th er c e r e a l ch em ists (16) th a t rethods

o f m anipulation are a ls o s ig n if ic a n t in the p roduction o f stand­

ard bread#

M xln g and kneading th e dough g iv e oven d is t r ib u t io n

o f th e y ea st p la n ts and th e r e fo r e have a great d ea l to do w ith

the te x tu r e ana q u a lity o f the bread.

Kneading a ls o adds oxygen

from th e a ir to the dough and t h is in e s s e n t i a l to the p la n t

growth and d ev elo p s the g lu ten in f lo u r , making +he dough more

te n a c io u s .

O b v io u s ly i t i s e s s e n t i a l t o have the same p rop ortion o f

in g r e d ie n ts each time a product i s made and the o n ly way to be

sure o f t h is i s to weigh a l l in g r e d ie n ts and not to depend on

measuring a lo n e .

Although th e c o r r e c t in g r e d ie n ts may be su p p lie d in proper

p rop o rtio n s and the moat s a t is f a c t o r y methods o f m anipulation

used in bread making i t i s s t i l l very e s s e n t ia l th a t the dough

s h a l l be su b jec te d to c o n tr o lle d baking temperature fo r a g iv en

tim e in order th a t th e product s h a ll be o f standard q u a lity .

The q u e stio n o f nHow does heat act" has been pondered over by

a l l in q u irin g minds ana. we are s t i l l confronted w ith many un­

answered q u e stio n s such as nHow does food absorb heat * a t what

10-

r a te ; i s th a t r a te th e same fo r a l l k in s o f food, or does i t

d i f f e r fo r m asses o f w id ely d if f e r e n t ch a ra cter; and does the

pan have an e f f e c t on the r a te o f heat?"

problems fo r p h y s i c is t s .

These q u e stio n s are

In t h i s stu d y , however, an attempt

has been made to answer on ly the q u estio n as to th e com parative

e f f e c t s o f baking y e a st r o l l s w ith the th ree energy so u r c e s,

c o a l, gas and e l e c t r i c i t y under uniform c o n d itio n s o f temp­

e r a tu r e , time ana m anip u lation.

EXPEIi IMKNTAL PROCEDURE

I any d if f e r e n t r e c ip e s fo r p la in and sw eet r o l l s were c o l­

le c t e d and s tu d ie d .

S ev era l were t r ie d but fo r th e reason th a t

a Parker House r o l l nay be con sid ered a standard tys e i t was

chosen as the product to be used in th e se b ak ln : t e s t s .

A r ic h ­

er r o l l i s more l i k e cake and might be a ffe c te d by a lt it u d e and

la a ls o more e x p e n siv e , an item which had to be co n sid ered .

V arious methoas o f procedure were t e s t e d u sin g both s t r a ig h t

dough and sponge methods, and w h ile both gave good r e s u lt s i t

wus d ecided to use the sponge method in th ese experim ents be­

cause i t Wt s thought to be the one moot commonly u sed .

iiome o f the m anipulation f a c t o r s which were varied were:

p o s it io n in oven, baking tem perature and tim e, ferm en tation time

and tem perature, number o f b ea tin g and kneading s t r o k e s , and

k in d s o f pans and u t e n s i l s .

In a d d itio n to th e se fa c to r s v a riou s

p ro p o rtio n s a s recommended in the a i fe r e n t r e c ip e s were t r ie d .

—11—

purpose o f tJ i s p reliniuarp- vork b e ln j o n ly to a t t a in a

B a t ls j1OCtory method and p rop ortion s fo r n a k ln j Parker Poubo " o ils

th e se f a c t o r s were n ot stu d ied In d e t a i l .

Yhne no data are b ein g

rep orted on t h i s pitaoe o f the work a s th ey would not rep resen t

oonclur-lve ev id e n c e,

"'heme p relim in a ry b&klnpB were done In the

e l e c t r i c oven.

The e l e c t r i c oven used throughout the problem ms on a

new P o tr o ln t ran^;o, Model Ho. 210* ’ 74.

The oven measured 16

Inches w id e, 14 in ch es hic'h and 16^ in ch es d eep , was w e ll in ­

s u la te d and. lin e d w ith enam el.

I t was equipped w ith upper and

low er elem en ts, autom atic h ea t c o n tr o l and a v e n t, which was

kept open one notch a l l duriny th e se h a k iiics.

The ^as oven was on a new Tappan Cabinet ran ge. Model Ho.

K916riR.9.

Rie oven measured 16 ln olies w id e, 13 ln oh es high and

1G£ in ch es d eep , was in su lated, and the lin in g vrb o f chromium

p la t e .

I t was equipped w ith a Robert L5haw heat c o n tr o l and a

vent which le d Into the chimney o f the b u ild in g .

The c o a l oven was in a ItaJestlo range, h o d el Ho. 966, wiiich

had been in a food s la b o ra to ry o f Montana S ta te C o lle e se v e r a l

y ears.

The oven measured 22 in olies w id e, 15£ ln ohes high and 23

in ch es d eep .

I t had the u su a l d r a fts o f a c o a l range.

The temp­

era tu re was r e g is te r e d by a Taylor oven thermometer placed in s id e

th e oven a s c lo s e o s p o s s ib le to th e sp ot where the r o l l s were

baked.

The th ree ran e s were lo c a te d in the same la b o ra to ry and

a l l t e s t s were made in t h is room.

The f i r s t a e r ie s o f bakings

-1 2 -

was cond-uoted In the e l e c t r i c and g a s ranges and the second

s e r ie s in the e l e c t r i c and c o a l ra n g es.

The p rop ortion o f in ­

g r e d ie n ts used in making Jarker House r o l l s , measured both by

volume and w eight are found in Table I and th e m anipulation

f i n a l l y adopted i s d escrib ed in the fo llo w in g paragraphs.

TABLE I . - PROljORTIOn CF IRGEKDIEHTS USED IR HAKIBtt

PARKER HOUSE ROLLS, MEASURED BY VOLUME

ABD BY WEIGHT.

In g re d ie n ts

Volume

Wt.

gras.

Sweet whole m ilk

2 o.

488

Granulated sugar

4 T.

50

C rlsco

4 T.

50

I i t.

6

S a lt

Flelaohm an1S y e a s t

I cake

1 8 .2

Tap w ater

i o.

5 9 .2

o.

682.9

8-i T.

3 1 .2

Bread flo u r

B u tter

^

-------------------------------------------------------------------------------------------------------------------------------------

The f lo u r used fo r the e n t ir e experiment was Cer eta n a , a

hard wheat f lo u r made from the blend o f se v e r a l d if f e r e n t kinds

o f wheat and m ille d in Bozeman, Montana.

I t was sto r e d in the

la b o ra to ry where th e room tem perature va ried o n ly from 78-80° C*

C onsequently the flo u r always ranged between th e se tem peratures.

The m ilk , f a t ana y e a st were kept in an e l e c t r i c r e fr ig e r a to r .

She b o t t le o f m ilk w;j.b tip p ed over and back 10 tim es to mix i t

thoroughly#

Yhen the b o tt le cap was removed, ana the m ilk s t ir r e d

w ith a fo rk IU tim e s.

. i l k , 4b6 grams, was weighed and j oured

in to an aluminum pan.

^

a r , 6u grarae; Criseo,hU

S c ilt, U grans; were added to the milk*

inxis;

and

.he pan was then i la o ed

on the speed u n it o f the c l e e t r i o range ana the h eat turned on.

i/h ile t h is

n t e r i a l was h e a tin g , 69*2 grams o f water a t 26° C.

were weighed o u t , and in to i t was broken a f r e s h , e orJreesed

y e a s t cake 116*29 gram s)•

Yhe m ilk was heated to the sc a ld in g

p o in t (76° C*) to prevent a b a c t e r ia l type o f ferm en ta tio n , und

then cooled to 2 8 © C ., the optimum temperature fo r ferm entation

(5)*

While c o o lin g i t was s t ir r e d se v e r a l t i. c s to thoroughly

d is s o lv e the su g a r, s a l t and C riso o •

»«hen the temperature o f t h i s

m ixture was reduced to 28° C ,, i t was poured in to the w hite p orce­

la in m ixing bowl ana the d is s o lv e d y e a s t was adued.

Thea 27^ .5

grans o f flo u r which had been s if t e d once ana weI nod were n ixed

in to the llq u la

w e ll.

w ith u wire whisk u sin g IbO str o k e s to mix i t

The bowl co n ta in in g the bread-sponge was s e t in a d ish

pan o f warm w ater o f a tem perature ju st n ecessa ry to keep the

tem perature o f the sponge a t 28° C. and the bowl covered w ith

a to w e l.

A thermometer was kept in the sponge and the tempera­

ture was m aintained by c a r e fu l w atching.

The span e was allow ed

to i a lo e fo r 68 m inutes, a t the enu o f whici tim e vbb.2 grams of

s i f t e d flo u r were mixed in With a wooden spoon, u sin g 50 s t r o k e s .

From 8 4 .7 - uO grams o f flo u r had p r e v io u sly been

p laced on a bread board.

elg h ed out and

The dough was then tiirneu onto the

14-

flo u r e d bread board and kneaded fo r 65 str o k e s by pusM ng th e

dough down w ith the palm o f the hand and turning i t one-qu; r t e r

way round w ith euch push*

The dough was then returned to the n ix in g bowl which had

been s l i g h t l y o ile d w ith m elted butter*

The bowl was returned

to the pan o f w ater and the tem perature o f the dough was kept

a t 28° C*

The dough was a g a in allow ed to r a is e ob minutes*

At the

end o f th a t time i t was turned out onto the bread board and

kneaded fo r 65 s t r o k e s .

With 18 str o k e s i t was r o lle d out w ith

a r o l lin g p in t o approxim ately i inch th ic k n e ss and out w ith a

3 in ch aluminum b is c u it c u t t e r .

B u tte r , 60 grams, had p r e v io u sly been weighed out and

m elted .

A sm all amount o f i t was used to o i l the m ixing bowl

and baking s h e e t s , and th e remainder was used on th e r o l l s .

Kach r o l l was crea sed in the m iddle, rubbed w ith m elted b u tte r ,

fo ld e d over in poeket-book s t y l e and th e top brushed w ith

b u tte r .

Bix r o l l s were out and a c c u r a te ly weighed to 40 grams ea ch ,

to be used l a t e r f o r volume t e s t .

Three o f th e se were p la ced

a t the end row o f eaoh o f th e two baking s h e e t s .

The remainder

o f th e r o l l s were d iv id ed ev e n ly between the two baking s h e e ts

but were not weighed in d iv id u a lly .

Small in te r n a l maximum-

tem perature thermometers 2..a' in ch es in le n g th w ith temperature

s c a le range o f 200-260° F . were p laced in s id e o f two r o l l s and

one each o f th e se r o l l s p la ced in th e c e n te r o f each baking s h e e t.

15-

Ih cee a h eete w ith r o l l s on them were p laced a c r o ss a d ish pan o f

warm water and covered w ith c le a n w h ite paper.

The r o l l s were

allow ed to stand thus fo r 26 m in u tes, and thn put In the v a riou s

ovens which had been preheated to 390° F ,

The r o l l s were baked

fo r 14 m inutes on a rack a t approxim ately th e m iddle o f the oven

fo r the e l e c t r i c and gas ranges and on the bottom o f the c o a l

range oven.

D esp ite th e f a c t th a t so many d ir e c t io n s fo r making

i'arker House r o l l s g iv e 425° F, a s th e c o r r e c t temperature and

15-20 m inutes as the tim e fo r bakin g, th e author found t h is

tem perature too high fo r good r e s u lt s and the time too lo n g .

The baking s h e e ts p lu s the r o l l s were weighed ju s t before

goin g in to th e oven and im m ediately upon coming out o f the oven

ana the p ercen tage o f l o s s in w eight fig u r e d .

The thermometers

were removed from ln s la e the r o l l s and the In te r n a l tem peratures

record ed .

Iieohanieal t e s t s f o r ten d ern ess and volume were BkAe.

An attem pt was made to sco re the r o l l s according to the fo llo w ­

in g sco re card;

16-

SCOlS CAKD FOR KOLJS

P e r fe c t

Score

General appearance

S iz e

6

Shape 6

10

Crust

Top

H o lo r

C haracter

Depth

Texture

Tenderness

20

3

2

2

2

3

Bottom

Color

Character

Depth

Texture

Tenderness

2

I

2

I

2

C r it lo I sd

12

8

Crumb

L igh tn ess

10

C haracter

( e l a s t i c i t y ) 10

Texture and

10

g ra in

6

C olor

36

F lavor ana odor

36

T o ta ls

Your

Score

-

100

As the p erso n a l f a c to r In sc o rin g was so v a r ia b le and a

s u f f ic ie n t number o f Judges cou ld n ot be r e g u la r ly secured to

e lim in a te t h i s f a c t o r , on ly the m echanical t e s t s are co n sid ered

as s ig n ific a n t.

To compute the volume o f the baked r o l l s , a standard method

o f seed disp lacem ent was u sed .

Kape seed was a llow ed to f a l l

in to a ston e Jar w ith s t r a ig h t s id e s from a fu n n el which r e ste d

17-

upon an iro n rin £ fa ste n e d to a rin*? stand so th a t the eted l e f t

the fu n n el Juot above the mouth o f the sto n e J a r.

The bottom

o f the Jar was covered w ith se e d , one o f th e r o l l s th a t had been

weighed b efore baking was planed In the Jar and the seed was

allow ed to f a l l u n t il the r o l l was com p letely co v ered .

Then th e

seoona r o l l was put in and covered w ith seed and th e th ir d r o l l

was handled in the same manner.

hen th e Jar was f u l l o f seed

a str a ig h t-e d g e d sp a tu la was used to s t r ik e o f f th e e x c e ss se e d ,

th e s t r a ig h t edge r e s t in g sim u lta n eo u sly on the opposing edges

o f th e Jar.

The seed th a t surrounded the r o l l s was then weighed

and volume computed In the fo llo w in g manner.

The empty ja r was f i l l e d w ith rape seed and the co n ten ts

were found to weigh 1290 grama.

Then the ja r was f i l l e d w ith

tap w ater from a graduate to fin d the amount n ecessa ry to f i l l

i t , which was 1928 c . c .

Therefore 1290 grams o f seed ■ 1928

o .o . volume, and I gram o f seed * 1928 ■ 1.4 9 4 c . c . which i s

th e volume rep resen ted by I gram o f se e d .

The w eight o f seed

surrounding th ree r o l l s was su b tra cted from 1290 g ra n s, the

w eight o f the Jar f u l l o f se e d .

T his gave the number o f grams

o f seed d isp la c e d by th e th ree r o l l s .

M u ltip ly t h i s number by

1 .4 9 4 and the r e s u ltin g fig u r e i s the volume o f th e r o l l s in o . o .

A d ev ic e was a ls o s e t up fo r t e s t in g the breaking stre n g th

o f the upper c r u s ts and low er c r u e ts o f the r o l l s .

An agate­

b earing t r ip b alance was fa ste n e d near the top o f an iron t r i ­

pod support and on the l e f t hand s id e was a u ju sted a u n iv e r sa l

clump.

In to t h is clamp was fa ste n e d a t e s t tube clamp w ith i t s

18-

Jawa p o in tin g upward toward the t r ip b a la n c e.

From the low er

l e f t hand s id e o f the t r ip balance was suspended by a sto u t

cord another t e s t tube clomp w ith I t s Jaws banking; down toward

and p a r a lle l to the jaws o f the low er t e s t tube clam p.

jaws o f th e se two clamps were about S in ch es a p a r t.

r a tu s was then balanced to the zero mark.

The

The appa­

Boon a f t e r baking,

a s t r ip o f c r u st one inch wide was cu t through the c e n ter o f

th e top and bottom o f a r o l l .

One p ie c e was then fa ste n e d by

each end in the Jaws o f the two t e s t tube clamps t i g h t l y eno gh

30 th a t th e balance was kept on z e r o .

Two beakers which had

p r e v io u s ly been balanced were then p la ced on e it h e r sid e o f the

b a la n c e,

-e a sand was poured in to th e beaker on th e r ig h t hand

s id e o f the balance u n t il the c r u st sample broke Into two p a r ts .

The sea sand was then weighed and I t s w eight recorded a s the

breaking stre n g th o f th a t p a r tic u la r sample o f c r u s t .

Therefore

the g r e a te r the w eight o f sand the l e s s tender was the r o l l .

Three sam ples o f top c r u s t and th ree o f bottom c r u s t were thus

t e s t e d fo r each b king from each ran ge, b ein g taken from what

appeared to be good average r o l l s .

( I l l u s t r a t i o n 2 p.20)

These same samples were n ext matched fo r c o lo r w ith the

Jlu nsell C olor d is k s and apparatus d escrib ed on page <22.

For t h is work a p ie c e o f gray cardboard was s e t up, onto which

a aIn, Ie sample o f c r u st could be fa ste n e d , the su rfa ce o f the

c r u s t to be in th e s&me p lan e w ith th e d isk s used as sta n d a rd s,

a s w i l l be seen in i l l u s t r a t i o n I .

The person matching the

c o lo r s sto o d approxIn t e l y S f e e t away.

The use o f a reading

—

19-

le n s p u t th e c r u s t s u r fa c e s u f f i c i e n t l y o u t o f fo cu s so th a t

th e r e s u l t ap p eared a s one s o l i d c o lo r even though th e c r u s t

i t s e l f was i r r e g u l a r in c h a r a c te r o r s p o tte d in ap p e aran c e.

A djustm ents were made by changing th e a r e a s o f th e d is k s u n t i l

th e re was a p e r f e c t m atch betw een th e c o lo r o f th e c r u s t and

t h a t o f th e r o t a t i n g d is k when viewed th ro u g h th e e y e p ie c e .

The re a d in g s were re c o rd e d by n o tin g th e p e rc e n ta g e o f th e ex­

posed a r e a o f each c o l o r .

These p e rc e n ta g e a r e a s o f s ta n d a rd

c o lo r were c o n v e rte d in to h u e , b r i l l i a n c e and chroma by th e

M unsell system and form ulae re c o rd e d on page 34.

I l l u s t r a t i o n I . — The M unsell C olor A p p aratu s as i t was

s e t up f o r m atching th e c o lo r o f r o l l s .

-

20-

— se a sand

I f t|< \H ' ju j

i i >i .

J n i i » | t M * |f*\i

.------T rip b alan ce

c o rd —

t . t . clam p---c r u s t sam ple-----t . t . clam p---- -|

U n iv e rs a l C

clamp----

wood s t r i p s

I l l u s t r a t i o n 2 . —D evice u sed f o r t e s t i n g th e b re a k in g

s tr e n g th o f th e c r u s t s o f P a rk e r House r o l l s .

- 21-

EESULTii

In t h i s com parison o f y e a s t r o l l s , baked in th r e e k ln a s

o f e v e n s, nam ely , e l e c t r i c , ^ aa and c o a l, a l l o f th e v a rio u s

f a c t o r s were s tu d ie d f o r w hich m easuring d e v ic e s c o u ld be

s e t up.

Loas in w eig h t was computed by ; e o o ra in g th e Weifi te

o f th e r o l l s b e fo re and

f t e r b a k in g ; volume was m easured by

se e d d is p la c e m e n t, and i n t e r n a l te m p e ra tu re s were re c o rd e d

w ith maximum oven th erm o m eters.

> eterm in atio n s were made f o r

tn e te n d e rn e s s o f th e o u s t s and c r u s t c o lo r s were m atched by

use o f s ta n d a r d M uneell c o lo r d is k s *

show th e l o s s in

T a b le s I I , I I I , and IV

e ig h t o f y e a s t r o l l s baked in e l e c t r i c , gae

and c o a l ran g e o v en s.

TABLE I I . — TlIK LOSH IH HEIGHT OF PAKXEk HOUJK HOLL., HHEH BaKEB IH AH ELECTRIC

OVKH KkUIPBED SITH AM AUTOMa TIC HEAT CONTROL.

Date

Kind o f

oven

Feb. 9

Kleo t r io

Feb. 11

Temp, o f

oven

Wt. o f r o l l s

b efore baking

gras.

i‘ime o f

baking

min.

Wt. o f r o l l s

a f t e r baking

eras.

lo s s in

w t.

IiOsB in

.

T

S90° F.

62 7 .6

12

667.1

6 0.5

9 .6

n

390

69 3 .1

12

526.8

6 6 .3

11.2

Feb. 12

it

390

681.0

14

694.9

8 6 .1

12.6

Feb. 16

n

390

67 6 .3

14

60 6 .6

6 5 .8

1 0 .2

Feb. 18

it

400

64 1 .6

12

672.4

6 9 .2

1 0 .2

Feb. 19

n

400

646.9

12

676 .4

6 9 .6

10.8

Mar. a

n

390

661.9

14

680.4

71.6

11.0

Mar. 4

n

390

667 .4

14

69 7 .4

70.0

10.6

Mar. 5

n

390

667.4

14

597.4

70.0

1 0.6

Mar. 8

#

390

6 7 4 .0

14

596.0

78.0

11.6

Mar. 12

t»

390

667.4

14

692.4

75.0

11.3

Mar. Ib

M

390

644.1

14

663.4

6 0 .7

1 2.4

Mar. 26

It

390

611.6

14

536.6

76.0

12.3

Mar. 29

It

390

66 2 .6

14

593.5

6 9.0

10,4

Mar. SI

If

390

713.3

14

628.5

64.8

11.9

Mar. SI

H

390

676.7

14

606.6

6 8 .2

10,1

I

TABIK II (C ont1A)

Bate

Kind o f

oven

Apr. I

K le e tr io

Apr. 8

Temp, o f

oven

wt. o f r o l l s

b efore baking

Time o f « i . o f r o l l s

baking

a f te r baking

min. .......... g**"........

Loss in

w t.

. ena.

Loss in

w t.

#

890* F.

61 0 .2

14

68 8 .4

76.8

1 2.6

#

890

6 7 1 .4

14

601.6

69*8

1 0 .4

Apr. 7

Ii

890

67 6 .4

14

606.4

70.0

1 0 .4

Apr. 8

R

890

6 7 7 .6

14

6 0 7 .8

70.2

1 0 .4

Avg# $> Iuoe In wte s 1 1.2

Date

Feb. 9

IU: LOv. IU . IOKT CF I RB HOOSE

LI, m> I E >ED IH n CAS

OVEH E ,UIPPKD SITH Al* ,.UTOXAflO ROBERT LHAif ESAT COlTROL.

Kind o f

oven

Temp, o f

oven

JtT. o? rbTla * Tine o f ~ r r . o f r o l l s

b efore Vuklng baking

a f t e r baking

DiiU

^ ea.

-J S B t.........

O s la

Wt.

i'ffls.

t o s s In

T

390° F.

635.8

12

8 7 6 .6

5 7 .3

9 .0

Feb. U

Gae

n

690

6 4 3 .5

12

4 6 6 .1

77.4

14.2

Feb. 13

N

390

6 3 8 .6

14

645.4

9 3 .1

1 4 .6

Feb. 16

«

390

664*3

14

5 7 8 .1

8 1 .2

1 2 .4

Feb. Iti

n

400

684 .0

12

6 1 0 .6

73.6

1 0 .7

Feb. 19

M

40V

619.4

12

68 6 .6

83.9

1 3 .6

lia r . I

M

390

6 7 7 .0

14

8 6 1 .4

9 6 ,6

1 4.1

Mar. D

n

690

66 3 .4

14

5 7 6 .4

6 5 .0

1 2.8

Mar. 4

«

890

6 4 8 .4

14

6 7 0 .4

78.0

1 2 .0

Mar. 6

»

890

6 4 8 .4

14

67 0 .4

78.0

1 2 .0

890

681.4

14

672.4

79.0

1 2 .1

390

684.9

14

856.9

76.0

1 2 ,3

Mar* ti

Mar. 12

n

B

Avg. « Ia sa In rfc. e ig .b

i

.» 3

TABLE

TABJLE IV .— TillI LO,,S JM .JEIGHT OF PARKER HOUSE ROLLS WHEB BAKED IB A

COAL RAHOK OVEH.

Date

I^ar. I

KlM o f

oven

Coal

Temp, o f

oven

wt. o f r o i l s

b efo re baking

goB.

Time oi r

baking

min.

it* o i r o lls

a f t e r baking

tp s.

l o s s In

wt.

gma.

l o s s In

-

T

BOO0 F«

6 3 5 .2

14

664.4

71.8

1 1 .3

390

6 7 5 .3

14

6 0 8 .5

6 6 .6

1 0.0

390

639.9

14

5 6 7 .6

77.4

1 2 .1

Ub t , 15

n

Lar. 2ti

ft

Mar. 28

n

390

706.4

14

627.7

77.7

1 1 .0

Mar. BI

H

390

6 0 3 .4

14

5 3 8 .4

6 5 .0

10.6

Mar. BI

R

390

6 2 8 .4

14

565.6

62.9

1 0 .0

Apr. 5

ft

390

6 4 8 .6

14

57 6 .5

70.0

1 0 .6

Apr. 7

R

390

65 2 .6

14

5 7 6 .5

76.0

11 .7

Apr. 8

If

390

6 3 3 .4

14

568.4

76.0

1 1.8

Avg. ^ Ioae in w t. = 11*2

26

The r e a u l t e In T ab les I I , I I I , and IV in d ic a t e th a t th e r e

i s a s l i g h t v a r i a t i o n in lo s s in w eig h t o f r o l l s baked in th e

th r e e d i f f e r e n t o v en s; 11. 2; f o r th e e l e c t r i c oven; 11*256 f o r

th e c o a l ra n 0 oven and 1 2 . f o r th e g a s oven.

Tlie amount

o f d if f e r e n c e betw een th e g a s oven and th e two o th e r s i s p ro ­

b a b ly to o sm a ll to be s i g n i f i c a n t .

Volume i s g e n e r a lly used, in s ta n d a rd b read b ak in g t e s t s

a s an in d ic a t io n o f " f l o u r s t r e n g t h " .

However, in th e s e s tu d ie s

f l o u r from th e same sa ck was used and p o r tio n s o f th e same l o t

o f dough were baked in th e d i f f e r e n t o v en s.

T hus, e lim in a tin g

o th e r v a r i a b l e s , in th e s e t e s t s volume can s a f e l y be a t t r i ­

b u te d to d if f e r e n c e s in b a k in g .

Volume t e s t s were made by ra p e seed d isp la c e m e n t a s d es­

c r ib e d on page 17.

In T a b le s V, V I, and V II w i l l to found th e

r e s u l t s o b ta in e d in th e s e t e s t s .

tABLB V.— THE HOVM l Of PAHKKR HOC H ROLLS BaKKR 13 A3 ELECTRIC OVFS

QUIPPED wITH AS AUTOMATIC RSaT CCHIfEOLe

ia te

Kind o f

UVC.I

Mar# 3 E le o tr io

Kar. 4

K

Temp# o f

oven

m wV*'per r o ll' "

B efore Baking So# o f

SMN

ro lls

n t . o f "seed

”

T oT T T T " T or. o f

d la p ltio e d by

I gm#

S ro lls

S roJULo a f t e r

seed

a f t e r baking

LtO#

o .e ,

090* P.

40

3

190.0

1.494

283.66

290

40

Z

174.3

1.494

26 0 .4

liar. 6

n

390

40

3

174.3

1.494

26 0 ,4

iai*. 8

n

390

40

3

161.0

1.494

2 4 0 .6

Ear. 12

n

390

40

3

17 9 .4

1.494

268.0

Mar. 15

1»

390

40

3

192.7

1.494

887.9

Mar. 28

#

390

40

3

20 4 .3

1.494

8 0 6 ,2

Mar. 26

it

390

40

3

202.7

1.494

30 2 .8

Mar. 29

«

390

40

3

20 9 ,0

1.494

312.2

Mar# SI

ft

390

40

3

1 6 9 .3

1.494

282.8

Mar# SI

R

290

40

3

229.0

1.494

34 2 .1

Apr. I

M

390

40

3

194.2

1.494

29 0 ,1

-Apr. 6

If

390

40

2

191.3

1.494

2 6 6 .8

Apr. 7

«

390

40

3

197.0

1.494

294.8

>tpr. 6

n

390

40

3

206 .3

1.494

311.2

AVg. voluiio o f three

2 % :

• Ee * j^lt #4

SABIK V I.— SiK V O im a OF f AKKKR HOU EJ ROLJ-U BAKKD IH A OAS OTO

M I m s t ITH AB AUSmiATlC ROBKRS SHAW XSAf COJiSROLe

Kind o f

oven

Date

T em pe

o f

ovon

f t .

per r o l l

b efo re b a k i n g

g m se

Ho. Of

r o lls

I .

o f seeC

d isp lttoea by

3 r o l l s a f te r

b&kln#: *73«.

Of

seed

OeC.

V oi. o f "

2 r o lls

a f t e r baking

0 .0 .

V o le

I

gas.

40

8

190.0

1.494

291.83

8 9 0

40

3

163.0

1.494

273.40

8 9 0

40

8

1 7 0 .6

1.494

262.30

8 9 0

40

3

170.6

1.494

268.80

n

890

40

8

173.2

1.494

2 6 6 .6 0

n

890

40

8

210.0

1.494

318.70

G ttS

R a r e

I

M aJPe

a

«

M ttT e

4

M

WttTe

6

M ttT e

8

M ttT e

12

n

S 9 0 O

F e

Afg. voltme o f three r o l l s • 8 7 7 .0 c .c .

Pe w ±19«7 "

• •e * ±1. #2 n

i

vii.—u rn

tABK’

v o K ir.

of

:

m ,

ro lls baked

<t« per r o l l

Bate

Mar. I

K ln a o f

oven

Coal

T ea p . of

ovon

before baking

5%*#

fio . o f

r o lls

n

a coal il j io i : o v er .

j i t . o f seed

d isp la c e d by

3 r o lls

baking

a fte r

/gaa*

V o l. o f

I gm .

seed

e .c .

V1O l . o f

3 v o llti

a f t e r baking

0 .0 ,

3900 T m

40

8

1 7 0 .0

1 .4 9 4

2 6 4 .0

%&r. 1 6

"

390

40

3

2 1 0 .2

1 .4 9 4

8 1 4 .4

l a r . 28

"

390

40

3

2 1 3 .7

1 .4 9 4

3 1 9 .8

H up * 2 8

"

390

40

3

8 0 1 .7

1 .4 9 4

3 0 1 .3

J ar. 31

*»

890

40

3

1 8 9 ,3

1 .4 9 4

2 8 8 .6

M ar. 3 1

"

390

40

3

2 1 8 .0

1 .4 9 4

3 8 6 .7

Apr. I

n

390

40

3

1 9 0 .0

1 .4 9 4

2 8 3 .9

Apr. 6

"

390

40

3

1 7 7 .0

1 .4 9 4

£ 6 4 .4

Apr. 7

"

890

40

3

2 0 2 .0

1 .4 9 4

3 0 1 .8

Apr. 8

n

890

40

3

1 9 2 .0

1 .4 9 4

£ 8 6 .0

Avg# volurso a t th r e p o l l s - 296.6 c . c .

£ . D. • * 2 2 .2 " 1

P t E. s ± 1 6 .0 "

-8 0 -

From th e a u ta reoordea. in T ab le s V, V I, and V II i t i s

i n t e r e s t i n g t o n o te t h a t th e g r e a t e s t volume o f r o l l s (2 9 6 .6

Omti,) was o b ta in e d when th e y were baked, in th e o o a l ran g e oven,

fh e r o l l s from th e e l e c t r i c oven had a volume o f 2U8.5 c . o .

and th o se from Uie g a s o v en , 2 7 7 .0 c . o .

To f u r t h e r t e s t th e s e

d a ta to s e e i f th e f in d in g s wore s i g n i f i c a n t , th e s ta n d a rd

d e v ia tio n s were c a l c u l a t e d and from th e s e th e p ro b a b le e r r o r s

w ere d e r iv e d .

The r e s u l t s snowed in each I n s ta n c e t h a t ftO'g

o f th e c a s e s d id n o t f a l l w ith in one tim e s th e

b u t w ere w ith in two tim e s th e p ro b a b le e r r o r .

ro b a b le e r r o r

T h e r e f o re , a c c o rd ­

in g to s t a t i s t i c a l i n t e r p r e t a t i o n , th e chances a r e 4& to I

t h a t th e f in d in g s a r e s i g n i f i c a n t . I t was th o u g h t a d v is a b le to compare th e c o lo r q u a l i t i e s

and th e b re a k in g s tr e n g t h o f th e u p p e r and lo w er c r u s t s of r o l l s

*

f o r a j.;o a s lb lc c o r r e l a t i o n .

T h is was su g g e ste d in p r e lim in a r y

work wiien i t was n o tic e d t h a t th e or u s t s baked to a d a rk e r c o lo r

seemed to p o s s e s s a g r e a t e r d eg ree o f to u g h n e ss.

The fo llo w ­

in g p a ra g ra p lis e x p la in how th e c o lo r was m easured and T ables

V III to X III c o n ta in th e d a ta re c o rd e d on s ta n d a r d c o lo r s and

b re a k in g s tr e n g t h o f u p p er and lo w e r c r u s t s of y e a s t r o l l s

baked in th e th r e e o v en s.

—<w.L—

B a ile y (9) s t a t e s t h a t c o l o r , one o f th e s i g n i f i c a n t

c h a r a c t e r i s t i c s o f baked p ro d u c ts i s i n a l l lik e lih o o d th e

Boat d i f f i c u l t to m easure ana r e c o r d .

V arious e x p re s s io n s and

te rm s a r e used to d e s c r ib e c o l o r s , t h e i r l i n e ( h u e ) , i n t e n s i t y

( b r i l l i a n c e ) , and p u r i t y ( chrom a), and th e c o n c e p tio n conveyed

to one in d iv id u a l by th e s e term s may d i f f e r g r e a t l y from th a t

conveyed to a n o th e r .

F or exam ple, i n jud<-lnt: r o l l s th e term

Ng o lu e n brown" w hich I s an I d e a l c o lo r f o r r o l l s g iv e s no de­

f i n i t e m easure o f th e b r i l l i a n c e o f th e c o lo r and lu c k s d e f in ­

i t e n e s s so f a r a s the chroma o f th e c o lo r i s concerned#

In d e s c r ib in g any o b je c t d e f i n i t e t e r n s a r e d e s i r a b l e .

The use o f th e U u n se ll c o lo r sy ste m . In c lu d in g fo rm u lae and

a p p a r a tu s , f o r d e te rm in in g th e c o lo r o f a g r i c u l t u r a l p ro d u c ts

h a s been d ev elo p ed by D orothy N ick erso n ( 1 6 ) , c o lo r te c h n o lo ­

g i s t , B ureau o f

^ r i e u l t u r a i hoonom ics, and t h i s h a s been used

f o r m easu rin g th e c o lo r o f b re a d by Grewe (10 p .6 0 ) .

The I u n s e l l C o lo r System a s d e s c r ib e d by Grewe (10 p#60)

I e a s fo llo w s :

"T h is system i s b a se d upon th e p s y c h o lo g ic a l f a c t t h a t

c o lo r h as th r e e a t t r i b u t e s : h u e , b r i l l i a n c e and chroma.

"Hue i s th e t e r n w hich Ie u se d to in d ic a te th e name o f th e

c o l o r , su ch as r e d , b lu e , o r g re e n .

The 6 p r i n c i p a l h u es a re

r e d , y e llo w , g re e n , b lu e , and p u r p le ; and th e 6 in te rm e d ia te

hues a r e y e llo w -r e d , g re e n -y e llo w , b lu e - g r e e n , p u r p le - b lu e , and

r e d - p u r p le .

These 10 a re known a s s ta n d a rd h u e s .

The s ta n d a r d

hues a r e s u b d iv id e d in to 100 h u e s , and th e s e may be s t i l l f u r t n e r su b d iv id e d i f n e c e s s a r y .

yiB r llI la n u e I s th e v alu e o f c o lo r —l i g h t n e s s o r d a rk n e s s .

G ra d a tio n s from w h ite to H a c k th ro u g h a a e r i e s o f g r a y s , each

s te p d i f f e r i n g from th e n e x t by e ;u a l am ount.

A b so lu te b la c k ,

w hich i e u n a t t a i n a b l e , i s g iv e n & n o ta tio n o f 0/ and. p la c e d a t

th e end o f th e s c a le ; a b s o lu te w h ite i s g iv e n a n o ta tio n o f

1 0 / and p la c e d a t th e to p o f th e s c a l e .

A ll th e g ra y s f a l l

betw een b la c k and w h ite and ra n g e from l / to 9 / ; I / i s what

i s o r d i n a r i l y c a l l e d b la c k and i s a b o u t the c o l o r o f b la c k v e l­

v e t , w h ile 9 / i s th e w h ite o r d i n a r i l y se e n .

"Chroma l a i n t e n s i t y o f c o lo r — b r ig h tn e s s o r d u l l n e s s .

Chroma d e s c r ib e s th e d is ta n c e o f the c o lo r from g ra y o r n e u t r a l ­

ity .

I f th e chroma s c a le o f any c o l o r i s f i l l e d i n tow ard th e

c e n t r a l g ra y c o re a t th e sai e b r i l l i a n c e a t which i t was s t a r t e d

i t becomes l e s s and l e s s in te n s e u n t i l i t lo s e s a l l c o lo r and

becomes g r a y .

I f th e chroma i s ex ten d ed outw ard from the g r a y

c o re o f th e s o l i d th e c o lo r becomes s tr o n g e r u n t i l i t re a c h e s

a maximum.

K u n se ll lik e n s t h i s change in chroma to t h a t o f a

l e a f w hich, a s autumn cornea, g r a d u a lly lo s e s i t s chroma and

fa d e s to n e u t r a l , r a y . "

The Iiu n s e ll a p p a ra tu s i s p ro v id e d w ith d is c s made to r e ­

p r e s e n t th e p r i n c i p a l and In te rm e d ia te h u e s , a s r e d , r e d - y e llo w ,

y e llo w , e t c . , a t each s te p in b r i l l i a n c e and chroma f o r th e

h u es t h a t can be prod u ced i n perm anent p ig m e n ts.

i s marked a s to h u e , b r i l l i a n c e , and chrom a.

p ro v id e s d i s c s ra n g in g from b la c k to w h ite .

a te d w ith th e sym bols l / to 9 / in o lu a iv e .

aoh d is c

The in d ex a ls o

Theee a r e d e sig n ­

The c o l o r o f an o b je c t l a meBBuzedL by s p in n in g 2 o r more

B tandarh c o lo re d d i s c s and n e u t r a l c o lo r d is c s on a motor s h a f t

a t a speed h ig h enough tc r e s o lv e th e c o lo r s o f th e d is c in to

a s in g l e c o l o r ,

a s t r a i g h t - l i n e opening i s naae on th e d is c

from th e c irc u m fe re n c e to the c e n t e r .

When th e d is c s a re p la c e d

on th e s h a f t f o r s p in n in g , th e y a re o v e rla p p e d by means o f th e s e

o p en in g s so t h a t p a r t o f each d is c I s exposed a t th e s u r f a c e .

The p r o p o r tio n s o f th e d i f f e r e n t c o lo r s o f th e v i s i b l e s e c tio n s

can be a d ju s te d u n t i l th e re i s a p e r f e c t n a tc h betw een the

o b je c t u n d er t e s t and th e r o t a t i n g d i s c s .

C o n sta n t l i g h t i n g c o n d itio n s a r e e s s e n t i a l to a l l c a r e f u l

c o lo r w ork.

The o b j e c t s u n d er in v e s t i g a t i o n sh o u ld be p la c e d

on a c o n ta in e r o r ra c k a t d e f i n i t e d is t a n c e s from t. e o b s e rv e r.

The a p p a ra tu s sh o u ld be s e t up p r e f e r a b ly in a n o r th window o r

u n d er a n o r th s k y li g h t a t an .n g le c o m fo rta b le to view .

F or

m atching th e c o lo r o f tlie r o l l s i n th e s e e x p e rim e n ts th e a u th o r

found i t more c o n v e n ie n t to u se a so u th window.

However, c a re

was ta k e n to have th e l i g h t i n g alw ays th e sam e, w orking on g ra y

d ay s and n e v e r in s u n l i g h t .

The o b s e rv e r sh o u ld s ta n d o r s i t

f a r enough from th e d itto s th a t a d i r e c t l i n e from d is c to eye

w i l l be ab o u t f o u r o r f iv e f e e t .

A c a l i b r a t e d d is c g ra d u a te d a t i t s p e rim e te r in 100 d i v i ­

s io n s may be us d f o r

by ea ch d i s c ,

a s s u rin g th e amount o f sp ace o cc u p ied

^ f t e r th e c o lo r s a r e m atched th e d is c i s su p e r­

im posed upon th e c o lo r d ls o s and re a d in g s o f th e exposed a r e a s

a r e ta k e n .

The sum o f th e hue d is c an a Uie n e u t r a l d is c sh o u ld

e q u a l 100.

The fo llo w in g fo rm u lae have "been d ev elo p ed f o r

g e n e r a l u se In c a l c u l a t i n g h u e , b r i l l i a n c e , and chroma:

x e number o f f i r s t hue ( olookw lae on th e hue c i r c l e ) .

z M number o f second hue ( c lo c k w ise on th e hue o i l o l e ) .

A a a rea

P a power number ( b r i l l i a n c e x chrom a).

H s hue r e s u l t a n t .

B « b rillia n c e .

C a chrom a.

A3iP35;

“ * * ”

'

A 'a f- I = - x I

E V ‘b 21 . 2 . Z . . . )

100

I

c

I

.. ................)

100

In fo llo w in g th e above p la n th e f i r s t hue o r x was y ello w red. w ith & number o f 1 6 , and th e second hue o r z was y ello w w ith

a nameer o f 2 6 .

b ers.

The c o lo r o f r o l l s f e l l w ith in tn e s e two num­

The numbers re c o rd e d u au e r hue In tn e fo llo w in g ta b l e s

mean t h a t th e h ig h e r tn e

umber, th e c l o s e r i t i s to y ello w .

Tne b r i l l i a n c e h a s a s c a le o f 0 to 10.

The h ig h e r th e num­

b e r , th e n e a r e r i t i s to w h ite .

The chroma a ls o h as a ran g e o f 0 to 10.

The h ig h e r th e

num oer, th e more ln to n a e o r p u re i s tn e c o l o r .

S a b le s V IiI to X III p r e s e n t th e d a ta re c o rd e d on c o lo r

and b re King s t r e n g t h .

VAnm

vxxxc o m

m ifr a

a -cohdiho so t m s r x i

nor

tioh * ahd

s r j . ’x m

streboth

OF fOi> CkUaTb OF f ARXRk HOVul BQLLu BaiCLD ISi AS BLlCTRIC CV-CB•

"""""""

Difcte

R«roCniiCg* o f

e ta ru la ra u o l:;

J

J

3c O

JO.

vmMMMMHm

^

*.

'

il ;

urn '# " **

C o lo r n o t a t io n

m> Mi

BreaJcliHi

'«"«#»—■»■>mu,

Tub/b Y7/8 Y4/4 « 9 , 4 / l i t / Hg/

Ktte

I ir illla n e e Ctiroaa

'iX MMS2

gmiie

mm

16

YB 7 .6 4

6 .0 7

6,8

129.0

mm

rnm

15

YE 7.64

6 .0 7

6.8

206.8

11

26

mm

IG

YF 0 .1 6

5.61

5 ,5 6

279.6

47

16

20

mm

18

YH 8 .4

6 .6 5

6 ,7 6

257,0

6

44

11

26

mm

19

YK 8 .2 8

5,46

8 ,44

2 6 7 .4

28

lb

43

4*e»

30

mm

27

YB 6 .8 9

4 .6 2

4 .6 4

356.2

R

22

43

«#«*

30

mm

27

YIi 6.89

4 .6 2

4 .6 4

296.0

n

31

23

43

mm

27

YB 6.69

4 .6 2

4 .6 4

3 1 8 .4

it

m

24

43

*»*»

30

mm

27

YB 6 .8 9

4 .6 2

4 .6 4

213.9

R

«t

25

43

mum

30

mm

mm

27

Ys 6.89

4 .6 2

4 .6 4

144.0

«

28

44

19

•mm

15

mm

mm

06 Yc 7.09

3 .4 4

2 .1 2

416.0

n

it

45

19

15

mm

66

YB 7.09

3 .4 4

2 .1 2

344.5

M

a

46

10

15

66

YB 7.09

3 .4 4

2.12

514.4

6

71

33

mm

66

mm

Yii 8 .5 8

4 .6 7

4 .8 4

305.4

n

M

72

33

mm

65

12

YB 6.66

4 .8 7

4 .0 4

363.0

R

7

90

43

mm

66

2

YB 7.99

4 .9 8

5 .6 4

264.7

Mar. 31

M

n

I

65

HO

2

65

20

W

29

4

46

n

«

6

#

n

#

*

Apr#

30

mm

mm

mm

12

mm

"'.OLn T

L iate

Pi©

r?0 .

Apr# 7

n

n

»

I

24sr. 16

m

{ C o at'd )

Teroeniu^o o f H2-«o) fle d

ataaoard c a l uI ^kti U ifdL

------------- - 7 ------ ----------- ------ r ~ T

Tj b /B Y 7 /8 Y4/4 #9. 4/ H fi/ Hg/

91

43)

—

66

#*ee

92

46

13

41

#»**

2

” w’

Culor a # ta tIan

BreAltlzy

—■■ ■“'— --------- —' « Lrfir1^th

Hue

S r l l l i s a e e C hron#^

gras#

Yii 7*99

4 .9 6

8 ,0 4

£ 0 6 ,0

Yil 8*80

6 ,4 3

6 ,3 6

233.0

n o

46

61

mm

4

YR 7,74

6 .0 3

8 .6 4

27 4 .3

114

46

61

eee»

4

YIl 7 ,7 4

6 .0 3

5 .6 4

142.0

61

4

WW

WW t i l 7 .7 4

8 .2 6

6 ,64

3 0 7 ,4

61

4

WW

YL 7 ,7 4

6.20

6 .6 4

23 0 .2

"

6

116

48

w

n

U fi

46

m

n

117

42

mm

SI

7

YTi 7,66

6 .4 3

8.40

166.8

"

Ifi

UQ

42

4

47

7

WW YIi 6 ,3 6

5 ,6 6

6,66

217.6

*

m

119

41

7

41

11

WW Yn 9 .4 6

5 ,0 7

6 .46

275.0

ISO

41

7

41

U

WW

YL 9 .4 b

8 .0 7

6 .48

280.0

Apr* 8

mm

*»

w

121

48

10

36

10

WW WW Yit 9 .4 2

8 .9 6

6 .80

2 1 2 ,4

W

H

122

46

10

36

10

WW WW YH 9 .4 2

8 ,9 6

6.80

172,0

lia r , SQ

123

46

10

36

10

WW

WW YK 9 ,4 2

6 .9 6

6,60

117.0

Apr* I

124

42

12

SQ

6

WW

YH 9 , b 8

6 .6 4

6 ,64

174.6

#

128

42

12

36

6

WW YL 9 .6 0

6 .6 4

8 .84

261,4

12

Iu S

39

10

40

11

YR 9 ,9 1

6 .9 8

6.62

2 6 0 .0

H

WW

TABLE V I I I . — (C oat'd.)

l'eroenta,v;e of ap e o iiT cd

atazidard c o lo r dlsJce UHeA

......................... ....... ..............

YR6/8 YV/t Y4/4 3 9 .4 / R b/ HS/

"

C o lo r n o ta tio n

Brealzlng

........ ..... ..........—......... —

st r engt h

Hvie

B r lll la n o e Chroma

gaws.

B ate

Baisp ie

Ho.

i& r . 12

153

39

10

40

11

Tit 9 .9 1

6 .9 2

5 .5 2

279.2

n

H

154

53

16

41

10

YE 9 .9 5

5 .94

5 .56

1 6 3 .6

n

g

158

46

16

32

7

YE 8 .9 5

5 .9 6

6.16

146.0

Tl

M

139

46

16

32

7

YR 8 .9 5

6 .9 6

6.16

214,0

H

1«

140

45

16

32

7

YR 6 .9 6

5 .9 6

6 .16

1 6 7 .0

A pr. 6

145

45

16

82

7

YK 6 .9 6

6 .9 6

6 .16

304.6

I

147

62

YR 6*70

6 .3 3

6 .46

279.8

Mar. a

153

50

22

24

4

YB 9 .0 8

6.01

6 .72

263.9

H

88

n

31

154

60

22

24

4

YB 9 .0 8

6.01

6.7 2

105.6

R

8

160

38

22

24

16

Yli 9 .7 0

6 .5 1

5.76

129,0

it

M

161

38

22

24

16

T . 9 .7 0

6 .6 1

6.76

119.5

n

It

162

29

23

28

20

Y 0»B5

.

5 ,2 8

1 8 ;.6

* R efer to page (M ) fo r - untie 11 n o ta tio n .

TABLE U . --'JOLOR -UAJJTIKi ACCORDlBO TO MUB.: LL 30?ATIOB ABD BRB KIBO JTREBCfH

OP BOTTOM C UOTii OF PARKER HOUi-E ROLLS BAKED IN AN BLECimiC OVEB.

"

Date

YR 6 .9 5

5 .25

6 .3 2

212.0

a#

42

CO

Liar. 31

PercVntago1o f BpeoIfieA"r

3amstanaard o o lo r uieka used

Color n o ta tio n

Breaking

p ie ------------- -------- ------------------ ------ 7 — -------------------------------------- -a tr e n g th

No. YR6/8 Y7/8 Y4/4 3 9 .4 / HO/ HE/

Hue

B r ill la n o e Chroma

gne.

5 .3 3

5 .7 6

199.0

YR 8 .0 3

5 .2 5

5 .6 0

£67.6

9

YK 7.94

6.21

6 .6 0

149.0

10

YL 7.66

5 .2 7

5 .66

£47.0

27

YIi 6 .8 9

4 .6 2

4 .6 4

373,6

30

21

YIi 6 .7 0

4 .6 2

6.12

169.0

43

30

27

YlL

6.89

4 .6 2

4 .6 4

477.0

36

15

31

54

YR 9 .0 8

3 .5 4

2 .4 4

2 9 9 .6

n

37

15

31

04

Yli 9 .0 8

3 .0 4

2 .4 4

277.0

M

»

36

6

6

08

YK 7.50

2 .5 6

0 .7 3

227,0

it

til

3V

6

6

68

Yh 7,00

2.58

0 .7 2

49 8 ,0

M

n

40

9

6

80

YR 6 ,8 2

2.7b

0 .96

4 9 7 .0

n

it

41

9

6

86

YK 6 .6 2

2 .7 6

0 .9 6

497.0

A pr. 7

48

29

YL 9 .5 2

4 .7 2

5 .1 2

225.0

3

OS

29

7

45

8

30

9

Yh

ti

M

8

41

8

42

9

n

Il

9

46

4

42

n

28

16

48

4

38

n

n

17

43

30

H

3

31

49

n

it

32

n

28

n

n

I

ce

—

2

M L B I: . - I C o a t ja)

. u ru e n ta t'o o f up#o i'fio d

d is k s tUlbd

s ta a d u r d

C olor n o ta tio n

Iiuv

YX6/8 Y7/8 Y d/4 8 9 , 4 / ;:5 / a a /

6U

ES

57

17

W W

51

ES

57

17

W W

T

at)

27

66

7

W W

t»

Jb

16

«*«•

77

7

Y

Apr* I

it

ii

SO

8»

w #w

70

7

61

44

W W

Jti

21

Apr# 7

B

«

Mar# AL

Tl

irlllla n o e

I

SanylS

ao*

CI

C

H

C

*

Dato

B reaking

s t r o a .’t h

gs».

9 ,2 3

4 .7 8

4 ,3 6

t-lJ-U,0

9 .2 3

4 .7 8

4 .3 6

221.4

Yli y .49

4,69

4 .0 0

206,0

1 .1 6

4 .4 5

4 .3 6

240.7

Y 0 ,0 4

4 .6 1

4 ,u 4

371.4

W W

YB ‘7.lU

5 .1 7

4 .9 2

271.7

«

y

62

*>7

W W

42

21

W W

Yli 7 .7 6

5 .0 3

4 ,6 4

319*0

w

a

6*

80

e*W

57

li>

W W

T . t 08

4*81

4 .6 6

274,6

«

ft

SJ

E2

W W

27

51

YB 7 .o l

3 .7 8

2 .8 4

156.6

a

n

S^

22

W W

27

61

Yli 7, j l

3 .76

2 .8 4

044. 0

dti

JS

MttFm J l

M

Il

Sb

as

B

Q

ub

41

a

IE

9V

57

«

if

Iv l

45

W W

—

.

56

€»

YT c ,.10

4 ,9 1

5*28

212.4

66

6

Yfi 0 .3 0

4 .9 1

5 .2 6

160*4

67

2

YB 6 .1 7

4 .9 4

£>•56

220*6

as

5

YB 6 .8 2

5 .2 8

6 ,06

232.0

53

4

YH 7 .9 1

8.00

5 .5 6

.’,27.4

W W

T A L tii. U . . C o n t t Ai

-Dtite

Apr# 6

n

M

MiUP. in

»>tua»

I*

Ho.

L e ro e n ti^ e or Br OOUAett

s ta n tia r a, ooloi* CUakB tu r d

YRb/6 Y7/6 Y4/4 19. 4/ ..6/

•*ee

1C2

46

IOS

46

m

m

61

136

46

U

Sg

V

7

61

«*«*

W

16

148

46

16

62

(i

28

146

62

wee

38

M

e

157

50

22

24

6

M

W

166

60

It

24

10

H

!I

166

44

10

37

0

16

IL l

n«

W W

27

*

C o lo r n o ta tio n

2/

a re a l in #

a tr e n e th

Htta