STEREO IMAGING OF WELD POOLS Andrew Neill

advertisement

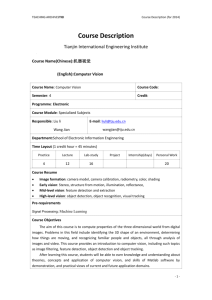

STEREO IMAGING OF WELD POOLS Andrew Neill Introduction ‣ In-Situ weld pool 3D vision ‣ Robotic welding systems – Deaf, dumb, and blind – Limited in control and adaptability ‣ Holy Grail of Robotic Welding: – Comprehensive sensing and feedback – Weld pool characterization – Adaptive real time control Introduction ‣ Problem domain – Camera Calibration – OpenCV stereo implementation – Refine matching by algorithms and adjusting matching criteria ‣ Assumptions – Stereo camera rig fixed in position on welding torch ‧ All regions of interest will be the same – Reading images from files rather than directly from process ‧ Better in terms of cost, time, and working outside of lab ‧ Allows analysis of speed Previous Work ‣ Off-line stereo – 3D over time – Visualization of weld pool motion – Effect of parameter variation on length, width, height, etc. [2] ‣ Other’s techniques: all postprocess – Structured light – Bi-prism stereo [1] [4] Approach ‣ Calibrate cameras ‣ Acquire stereo image sets ‣ Implement stereo matching – Stereo Block Matching – Semi-Global Block Matching ‣ Refine matching parameters Experiments ‣ Camera Calibration ‣ Choosing exposure for collecting weld images ‣ Block Matching parameter tuning BMTune Screenshot [3] Results: Test Scene Results: Stereo Matching Initial Results Original Image: Rectified Image: Results: BM vs. SGBM ‣ BM vs SGBM Results: Calibration Tuning ‣ Several controls to consider 1000 1000 1000 1000 1000 1000 1000 10000 100000 200 200 200 200 200 Inf 1.00E‐05 1.00E‐05 X 1.00E‐05 X 1.00E‐05 1.00E‐05 1.00E‐05 X 1.00E‐05 1.00E‐05 1.00E‐05 1.00E‐05 1.00E‐05 1.00E‐05 1.00E‐05 1.00E‐05 1.00E‐05 X X X X X X X X X X X X X X X X X X X X X X X FixK5 FixK4 FixK3 FixK2 FixK1 ZeroTangentDist SameFocalLength FixFocalLength FixAspectRatio FixPrincipalPoint UseIntrinsicGuess Avg Error 1 208.1 2 172.58 3 172.59 4 1007.43 5 275.83 6 172.59 7 1007.43 8 231.77 9 282.39 10 230.86 11 234.07 12 307.354 13 2111.75 14 662.4 15 172 FixIntrinsic Run MinError Calibration more or less automated Iterations ‣ OpenCV X X X X X X X X X X X X X X X X Discussion and Conclusions ‣ Calibration – Poor calibration limits matching ability – Matching requires epipolar geometry ‣ OpenCV Stereo – Very fast, 0.5 frames/second with high resolution images – Tunable for different scenes to improve speed Works Cited ‣ ‣ [1] Chen, S. B. (2005). Acquisition of Weld Seam Dimensional Position Information for Arc Welding Robot Based on Vision Computing. 43.1, 77-79. Hirshmuller, H. (2008). Stereo processing by semiglobal matching and mutual information. IEEE Transactions on pattern analysis and machine intelligence , 30 (2), 328-41. ‣ Hoff, W. (2012). Stereo Vision. EGGN 512, Computer Vision. Class Lecture . Colorado School of Mines. ‣ Liu, Y. K., Zhang, W. J., & Zhang, Y. M. (2013, November). Estimation of Weld Joining Penetration under Varying GTA Pools. Welding Journal , 313-321. ‣ [2] Mnich, C. A.-B. (2004 йил 19-21-July). In Situ Weld Pool Measurement using Stereovision. ASME Symposium on Flexible Automation . ‣ Mnich, C. M. (2004). Development of a Synchronized, High-Speed, Stereovision System for In Situ Weld Pool Measurement. Masters Thesis, Colorado School of Mines, Department of Engineering, Golden, Colorado. ‣ Peris, Martin. "OPENCV: STEREO CAMERA CALIBRATION." Web log post. OPENCV: STEREO CAMERA CALIBRATION | Martin Peris' Blog. N.p., n.d. Web. 04 Oct. 2013. ‣ [3] Peris, Martin. "OPENCV: STEREO MATCHING." Weblog post. OPENCV: STEREO MATCHING | Martin Peris’ Blog. N.p., n.d. Web. 04 Oct. 2013. ‣ Seyffarth, P. a. (n.d.). Image Processing for Automated Robotic Welding. Ingenieurtechnik Und Maschinenbau GmbH Rostock . ‣ Szeliski, R. (2011). Computer Vision: Algorithms and Applications. London: Springer. ‣ Zhang, W., & Zhang, Y. (2013). Dynamic Control of the GTAW Process Using a Human Welder Response Model. Welding Journal , 92. ‣ [4] Zhang, Y. D., Liang, Z. M., Wang, D. L., & Wang, J. (2012). 3D Rconstruction of Weld Pool Surface by a Biprism Stereo System. Applied Mechanics and MAterials , 469-473. ‣ Zhang, Y. M., Kovacevic, R., & Li, L. (1996). Characterization and Real-time Measurement of Geometrical Appearance of the Weld Pool. International Journal of Machine Tools and Manufacture , 36.7, 799-816.