Predicting Injuries at Michael D Computer Company Tee Welton

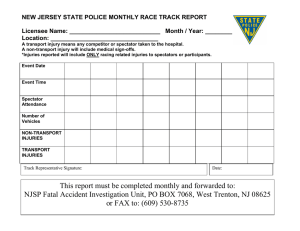

advertisement

Predicting Injuries at Michael D Computer Company Tee Welton 6.780 – Semiconductor Manufacturing Agenda Background Qualitative Data Analysis Poisson Regression Model Injury Model Results Sensitivity Analysis Summary Background Internship at Michael D Corp Task: To correlate Headcount and factors of Productivity Concern: Non-Productivity factors such as Injury Rates and Quality are important too Background (2) This Report: Determine how Headcount and Other factors impact the number of Injuries seen in the factory Given: Injuries are Poisson distributed with value of 0, 1,2, or 3 Qualitative Analysis Output seems to have an impact on Injury levels (not certain) Shift data shows Shift 2 appears to have more Injuries (0.96 vs. 0.67 average) 3 First Second 100 100 N=64 2.5 80 Percent 70 60 50 40 30 20 N=64 90 80 2 70 60 1.5 50 40 1 30 0.5 20 10 10 0 0 0 0 1 2 5000 3000 Total Factory Injuries7000 3 0 1 2 17000 15000 9000 11000 13000 Total Factory Injuries RTDB Output 3 Cum Percent Total Factory Injuries 90 Qualitative Analysis (2) Day of the Week (hard To determine trends) Saturday and Monday look significant, but it is hard to tell. Pareto Plot FRI THU WED TUE MON SAT 100 100 N=22 N=24 N=26 N=26 N=24 N=6 90 80 80 70 70 60 60 50 50 40 40 30 30 20 20 10 10 0 0 0 1 2 3 Total Injuries and Near Misses 0 1 2 3 Total Injuries and Near Misses 0 1 2 3 Total Injuries and Near Misses 0 1 2 3 Total Injuries and Near Misses 0 1 2 3 Total Injuries and Near Misses 0 1 2 3 Total Injuries and Near Misses Cum Percent Percent 90 Poisson Regression Model Poisson Distribution is described with the following equation: P(Y=k) = Exp(-µ)*µ n / n! µ can be value or linear equation The Poisson Loss Function guarantees No negative values No skewness No growing variability with mean growth Final Poisson Loss function (3) Ln(Y) = -(InjuriesAndNearMisses*model- Exp(model)) -Log(Γ(InjuriesAndNearMisses+1)) Poisson Regression Model (2) The model setup included these factors: Variable Injuries and Near Misses Description This variable is the target of the study. It is a count of the Injuries that occurred in the factory, as well as incidents recorded that could have resulted in an injury on the factory floor, but was avoided. This information is collected by shift. S hift This is the shift of the factory for which the injury data was collected. Total Headcount The total headcount of the TM C factory floor, collected by the shift. This is a measure of the total number of hours worked in each shift. This measures the total output, as the number of units Total Output shipped from the factory, for each shift. Percent Temporary Employees This measures the number of temporary employees used in the factory, as a percent of the total workforce. This would be used to measure the impact of using temporary employees on the number of injuries seen in the factory. This is the day of the week for the model. Day of the Week Hours in the S hifts Injury Model Results Output gives Estimate, Upper and Lower Limits Confidence Limits test effect significance Param eter Estim ate ApproxStdErr Low er CL Upper CL Monday -0.836 0.405 -1.681 -0.072 Tuesday -0.012 0.292 -0.584 0.566 Friday -0.032 0.341 -0.716 0.63 Saturday 1.102 0.459 0.152 1.967 Wednesday -0.422 0.321 -1.066 0.202 Second 1.048 0.385 0.299 1.812 Intercept -0.125 1.688 -3.36 3.277 rcentTempCo -7.711 3.65 -14.885 -0.542 rsWorkedCoe 0.068 0.181 -0.3 0.41 HeadcountCoe 0.879 0.439 0.025 1.75 OutputCoeff -0.008 0.097 -0.187 0.192 Injury Model Results (2) Analysis of Residuals shows no trends Concern: Unexplained low values Std Dev = MSE = 0.867 for the model 1.5 1 Residuals 0.5 0 -0.5 -1 -1.5 -2 -2.5 -3 07/02 703 07/2 07/25/2 07/23/20 07/20/200 07/18/2002 07/16/2002 07/13/2002 07/11/2002 07/09/2002 07/03/2002 07/01/2002 06/27/2002 06/25/2002 06/21/2002 06/19/2002 06/17/2002 06/13/2002 06/11/2002 06/08/2002 06/06/2002 06/04/2002 05/31/2002 05/29/2002 05/24/2002 05/22/2002 05/20/2002 05/16/2002 05/14/2002 05/10/2002 05/08/2002 05/06/2002 07 07/2 07/26/ 022 07/24/2 07/22/200 07/19/2002 07/17/2002 07/15/2002 07/12/2002 07/10/2002 07/08/2002 07/02/2002 06/28/2002 06/26/2002 06/24/2002 06/20/2002 06/18/2002 06/14/2002 06/12/2002 06/10/2002 06/07/2002 06/05/2002 06/03/2002 05/30/2002 05/28/2002 05/23/2002 05/21/2002 05/17/2002 05/15/2002 05/13/2002 05/09/2002 05/07/2002 Actual Date Sensitivity Analysis Manager want conservative estimate of Day and Shift effects. Assume: Model predicts three Injuries for Wednesday, Second shift. Use average Estimates for all other Factors Sensitivity shows Injury rate could vary between 1.973 and 4.027 Injuries per Shift. Factor Wednesday Second Shift Total Avg Case Best Case Worst Case Adjustment Adjustment -0.422 -0.642 0.642 1.048 -0.385 0.385 -1.027 1.027 Conclusion Poisson Regression used to predict Poisson Distributed output. No skew, negative numbers, or growing variance Allows for Confidence Intervals to test factor significance Prediction Equation can be used to estimate total Injuries. Sensitivity Analysis can be done to get best and worst case scenarios.